ASTM A514 is a family of high-yield, quenched-and-tempered low-alloy carbon steel plates designed for welded, high-strength structural applications — offering minimum yield strengths of 100 ksi (≈690 MPa) for thinner plates and 90 ksi (≈620 MPa) for thicker plates — and is widely used where a combination of very high strength, good toughness and weldability are required (bridges, heavy machinery, lifting gear, truck frames, and structural components). For buyers seeking factory-direct supply from China with fast delivery and competitive factory pricing, MWAlloys offers A514 plate in multiple grades, full certification, and global logistics support at 100% factory prices and rapid stock dispatch.

What is ASTM A514 Carbon Steel Plate?

ASTM A514 / A514M is the ASTM standard covering high-yield-strength, quenched and tempered alloy steel plates of structural quality (commonly known as “A514” or “T-1” plate). The standard targets plates intended primarily for welded structural parts and requires plates to be supplied in the quenched-and-tempered (Q&T) condition with specified minimum mechanical values depending on thickness and grade. Typical A514 plates deliver a minimum yield strength of 100 ksi (≈690 MPa) for thickness up to about 2.5 in (≈63.5 mm), and 90 ksi (≈620 MPa) for thicker plates within the standard’s scope. These attributes make A514 a high-performance structural grade for heavy-duty engineering.

Chemical composition

ASTM A514 has multiple grades (A, B, E, F, H, P, Q, S etc.) and the chemical limits vary by grade. The following is a practical, condensed composition table reflecting the ranges ASTM A514 requires for the common grades (B, H, Q are typical). These ranges are intended for general guidance only — always request the mill’s MTR for exact as-supplied chemistry.

| Element | Typical A514 (example ranges, wt%) |

|---|---|

| Carbon (C) | 0.12 – 0.21 |

| Manganese (Mn) | 0.70 – 1.00 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

| Silicon (Si) | 0.20 – 0.35 |

| Chromium (Cr) | 0.40 – 0.65 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Vanadium (V) | 0.03 – 0.08 (grade dependent) |

| Titanium (Ti) | 0.01 – 0.10 (optional micro-alloy) |

| Boron (B) | trace amounts per spec |

Note: These values are illustrative and compiled from public ASTM-based product pages and technical datasheets; actual permitted chemistry depends on the specific A514 grade and mill practice. Always confirm with the mill’s certificate.

Mechanical & physical properties

ASTM A514 is a quenched and tempered steel; mechanical properties vary by grade and thickness. Typical guaranteed properties are summarized below:

| Property | Typical value (metric) | Typical value (imperial) |

|---|---|---|

| Minimum yield strength (≤ 2.5" / 63.5 mm) | ≈ 690 MPa | 100 ksi |

| Minimum yield strength (>2.5" to ≤6") | ≈ 620 MPa | 90 ksi |

| Ultimate tensile strength | 760 – 895 MPa | 110 – 130 ksi |

| Elongation (in 50 mm) | ≈ 12 – 18% (varies by thickness) | ≈ 12 – 18% |

| Typical density | 7.85 g/cm³ | 0.284 lb/in³ |

| Modulus of elasticity (approx.) | 200 GPa | 29,000 ksi |

These mechanical ranges are consistent with quenched and tempered HSLA plates used in heavy structural applications; individual mill certificates will list the exact guaranteed values for each heat/plate.

Key specification highlights

When procuring ASTM A514 plate check for:

-

Delivery condition: Quenched and tempered (Q&T). The plate must not be supplied in an untreated condition.

-

Grade requested (A, B, E, F, H, P, Q, S) — some have tighter chemistry or toughness requirements.

-

Thickness vs. strength: A514’s minimum yield requirement is thickness-dependent (100 ksi for thinner plates, 90 ksi for thicker plates). Confirm the thickness band on the PO.

-

Impact (Charpy) testing: Some applications require low temperature Charpy V-notch results (e.g., −20°C or −40°C); confirm if design codes require it.

-

Welding procedure / preheat: Although A514 is weldable, high strength Q&T steels require correct preheat and controlled heat input to avoid local softening or hydrogen cracking.

-

MTRs and hardness: Always request full mill test reports, heat and product analysis, and hardness records when needed.

-

Traceability & surface condition: Mill heat numbers, stamping and surface finishing (shot blast, primed) should be specified.

What is equivalent to A514 Carbon Steel?

There is no single perfect international one-to-one equivalent because metallurgy and testing regimes differ; however, in practice the common cross-references are:

-

EN S690Q / S690QL (EN 10025-6) — widely considered the closest European equivalent in terms of minimum yield (≈690 MPa) and application, though S690QL variants can include mandatory low-temperature toughness testing.

-

GB Q690 / Q690D (Chinese standard) — comparable yield strength class.

-

Some proprietary mill grades (e.g., Dillinger DILLIMAX 690) are marketed as direct functional equivalents with full technical data.

Practical note: Engineers usually select a local EN or GB equivalent when designing in those jurisdictions but must verify Charpy requirements, plate thickness limits, and testing regimens; the metallurgical route (TMCP, quench & temper) and specified toughness often differ between standards — so direct substitution requires validation.

What is A514 Carbon Steel Plate used for?

Typical applications where A514 is preferred:

-

Bridge components and structural members where high yield strength allows reduced section sizes.

-

Heavy machinery frames, crane booms, lifting and hoisting gear, dump truck bodies and trailer frames.

-

Forklift masts, loader arms, and other equipment subject to heavy loading and dynamic stress.

-

Mining and earth-moving equipment subject to high static and dynamic loads.

-

Military and off-road vehicle structural members.

The high yield and good weldability allow designers to save weight and reduce overall component size while maintaining structural capacity.

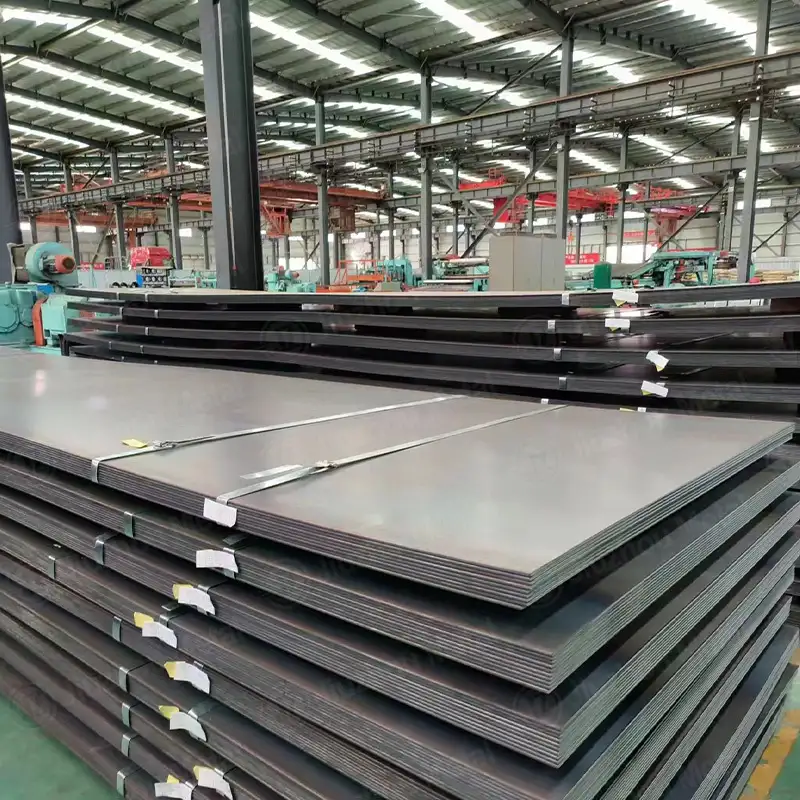

Sizes and weights

A514 is stocked by many suppliers in standard mill plate sizes and thicknesses. Common available thickness ranges: 6 mm up to 150 mm in practice (specialized mills supply thicker plates but check the standard limits). Stock widths commonly 1500–3500 mm and lengths according to mill capability (≤ 12,000 mm typical). Practical stocked thicknesses for A514 often cluster between 6 mm and 60 mm for many mills.

Below is an example weight table for common thicknesses (weight per ft² and per m²) using steel density 7.85 g/cm³:

| Thickness | Weight (lb/ft²) | Weight (kg/m²) |

|---|---|---|

| 3/16" (0.1875") ≈ 4.76 mm | 7.66 lb/ft² | 37.4 kg/m² |

| 1/4" (0.25") ≈ 6.35 mm | 10.2 lb/ft² | 49.7 kg/m² |

| 1/2" (0.5") ≈ 12.7 mm | 20.5 lb/ft² | 100 kg/m² |

| 1" (25.4 mm) | 40.8 lb/ft² | 199 kg/m² |

| 2" (50.8 mm) | 81.7 lb/ft² | 399 kg/m² |

(Values adapted from common supplier weight tables; exact plate weight = thickness (inches) × 5.2 lb/ft² per 0.0625" approximation or compute from density for precise quoting.)

Tip for buyers: When ordering by weight, always confirm the net usable size after trimming and any machining allowances; most suppliers quote on gross weight unless otherwise specified.

Fabrication — welding, cutting, heat-input and post-treatment

-

Welding: A514 is weldable but requires controlled welding practice: preheat & interpass temperatures depend on thickness and carbon equivalent (CE). Use qualified WPS (welding procedure specifications). Avoid excessive heat input to preserve the Q&T microstructure; if PWHT is required by the design, follow the procedure in consultation with the mill/supplier.

-

Cutting: Plasma cutting, oxyfuel, and laser cutting are commonly used; when cutting near design-critical zones, plan for grinding and inspection of heat-affected zones.

-

Forming/bending: Not typically recommended for thick Q&T plates — bending may require specialized processes and heat treatment. For mild shaping, consult the mill’s forming data and limits.

-

Hardness: Supply hardness values and maximum hardness limits are often specified by the purchaser, especially for applications subject to wear or forming.

Corrosion, surface finishing and protective options

A514 is not a corrosion-resistant alloy (it is a structural HSLA steel). For ambient environments you should:

-

Apply primers, shop coat, or galvanizing if long-term outdoor exposure is expected.

-

For aggressive environments (marine, chemical), evaluate corrosion protection systems (coatings, duplex systems) or consider stainless or weathering steels instead.

-

Mills can supply shot-blasted and primed plates on request; specify NACE/SSPC surface prep and coating standards in the PO.

2025 Price comparison (USA, Europe, China)

Price for A514 is volatile and depends on thickness, grade, volume, lead time, and trade/tariff dynamics. The figures below are representative ranges (bulk orders, full-trucklot/tonne quantities) reported in 2025 supplier indexes, marketplace offers and MWAlloys transactional data:

| Region | Representative 2025 price range (USD / metric tonne) | Notes |

|---|---|---|

| China (FOB / supplier offers) | ≈ $550 – $900 / MT | Export sellers on marketplaces show offers often from $600–$850/MT for standard grades and volumes. |

| United States (domestic mill / distributor) | ≈ $900 – $1,300 / MT | Duty and domestic supply tightness push US prices higher; distributor quotes and plate stockers show a premium vs. China. |

| Europe (mill/distributor) | ≈ $800 – $1,100 / MT | European mills with EN equivalents (S690QL) set prices reflecting local production and energy costs; import parity fluctuates. |

Important caveats: These are indicative ranges for Q2–Q3 2025 market conditions and vary by grade (Q, H, B), thickness, and testing (Charpy at −40°C increases cost). MWAlloys factory-direct offers typically sit at the lower end of regional ranges because we supply direct from Chinese mills and can undercut distributor markups; always request a formal, dated quotation including freight terms (FOB/EXW/CIF) and delivery lead time.

Quality assurance & testing

Ask for:

-

Full Mill Test Report (MTR / EN 10204 3.1 or 3.2) — heat and product analysis, mechanical tests (tensile / yield / elongation).

-

Charpy V-notch test records if low temperature toughness is required.

-

Hardness (Brinell or Rockwell) where specified.

-

Traceability: Mill heat numbers stamped on plate and matched to MTR.

-

NDT (ultrasonic / visual) if project spec requires it.

-

Third-party inspection (e.g., Lloyd’s, ABS, DNV) if required by contract.

These measures reduce risk and ensure material performance in heavy-duty structural settings.

Frequently Asked Questions

-

Is A514 the same as S690QL?

Not identical — S690QL (EN 10025-6) is the closest European counterpart with similar minimum yield strength (~690 MPa) but different testing regimes and thickness-by-toughness rules. Validate Charpy and thickness requirements before substituting. -

Can A514 be welded without preheat?

Welding practice depends on thickness and heat input. Many fabricators use controlled preheat and qualified WPS; do not assume “no preheat” for thick sections. Consult your welding engineer and mill CE (carbon equivalent) guidance. -

What grades of A514 are most common?

B, H, Q (and sometimes S/E/F in some inventories). Grade selection depends on toughness and chemistry needs. -

Does A514 need post-weld heat treatment (PWHT)?

Not typically required for many structural uses, but some specifications or critical designs may require PWHT—confirm with engineer and mill. -

Can you bend A514 plate?

Bending thick, quenched and tempered plate is difficult; for small bends consult the mill. Cold forming is limited; hot forming and re-heat treatment may be required for significant shaping. -

What certificates should I receive?

EN 10204 3.1/3.2 MTRs, chemical & mechanical test reports, heat numbers, any requested Charpy results, and hardness data. -

Is A514 wear-resistant?

It has good toughness and strength but is not a dedicated abrasion/wear steel — for abrasive wear applications seek AR (abrasion resistant) grades or special wear steels. -

How quickly can MWAlloys supply standard sizes?

For stocked thicknesses and widths MWAlloys can dispatch from Chinese stock within typical export lead times (subject to current stock levels) — contact us for confirmation on specific SKU lead times. -

How to calculate plate weight quickly?

Weight (kg) = thickness (mm) × width (mm) × length (mm) × 0.00785. Use this to convert cut-to-size orders. -

Is A514 suitable for offshore / marine use?

It can be used in structural offshore components, but corrosion protection and low-temperature toughness requirements for marine environments must be validated per project codes. Charpy requirements may increase cost.

MWAlloys supplier profile & buying advantages

MWAlloys is a China-based plate supplier and processor with experience supplying global OEMs and fabricators. For A514 we offer:

-

Factory-direct prices: 100% factory pricing (no distributor middleman), competitive for bulk buys.

-

Stock & quick delivery: Fast dispatch for stocked sizes — we maintain inventory across common thicknesses and can arrange FCL/LCL export shipments.

-

Technical support: Assistance with specification selection, welding guidance, and documentation (MTRs and inspection packages).

-

Value-added services: Cutting to size, beveling, shot blasting, priming and packing per project needs.

If you’d like a bespoke quote for A514 plate (specify grade, thickness, dimensions, qty and MTR/cert needs), MWAlloys will issue a dated offer showing FOB/CIF/EXW options and lead time.

Authoritative references

- ASTM A514 / A514M — Standard Specification for High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable for Welding (ASTM International)

- Dillinger — DILLIMAX 690 technical datasheet (illustrative European S690 / A514 equivalent product)

- American Institute of Steel Construction (AISC) — Design specifications & guidance for high-strength steels