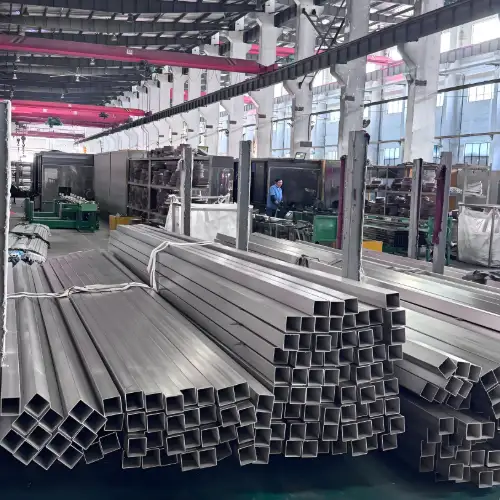

MWalloys delivers premium 304 stainless steel pipe, engineered to meet stringent global demands. Our pipes serve diverse sectors—from food processing and pharmaceuticals to petrochemical and construction—thanks to their exceptional corrosion resistance and mechanical strength.

Key Properties

| Property | Value | Standard/Notes |

|---|---|---|

| Material Type | Austenitic Stainless Steel | UNS S30400, EN 1.4301 |

| Manufacturing | Seamless (SMLS) / Welded (ERW, EFW) | ASTM A312, ASME B36.19 |

| Density | 7.93 g/cm³ (0.286 lb/in³) | At 20°C |

| Max Service Temp | 870°C (1600°F) continuous | Intermittent: 925°C (1700°F) |

| Corrosion Resistance | Excellent (oxidizing environments) | Poor in chlorides >50 ppm; use 316L |

Complete Chemical Composition (wt% - ASTM A312)

| Element | Min % | Max % | Typical % | Role |

|---|---|---|---|---|

| Chromium (Cr) | 18.00 | 20.00 | 18.20 | Forms passive oxide layer, corrosion resistance |

| Nickel (Ni) | 8.00 | 11.00 | 8.10 | Austenite stability, ductility |

| Carbon (C) | - | 0.08 | 0.05 | Strength; ≤0.03% for welding (use 304L) |

| Manganese (Mn) | - | 2.00 | 1.50 | Deoxidation, hot workability |

| Silicon (Si) | - | 1.00 | 0.50 | Deoxidation, scale resistance |

| Phosphorus (P) | - | 0.045 | 0.035 | - |

| Sulfur (S) | - | 0.030 | 0.015 | Machinability (reduced in pipes) |

| Nitrogen (N) | - | 0.10 | 0.05 | Strength enhancement |

| Iron (Fe) | Balance | - | ~71.00 | Base metal |

Notes:

-

304L variant: C ≤ 0.03% for welded applications to prevent carbide precipitation.

-

304H variant: Higher carbon (C ≥ 0.04%) for improved high-temperature strength.

Mechanical Properties (Annealed Condition - ASTM A312)

| Property | Seamless Pipe | Welded Pipe | Test Standard |

|---|---|---|---|

| Tensile Strength | ≥515 MPa (75 ksi) | ≥485 MPa (70 ksi) | ASTM E8 |

| 0.2% Yield Strength | ≥205 MPa (30 ksi) | ≥170 MPa (25 ksi) | ASTM E8 |

| Elongation (50mm) | ≥35% | ≥35% | ASTM E8 |

| Hardness (Max) | 90 HRB | 90 HRB | ASTM E18 |

| Pressure Rating | Sch 40: 180 bar@38°C | Sch 10: 120 bar@38°C | ASME B16.34 |

Standard Sizes & Weights (ASME B36.19 / ASTM A312)

| NPS (in) | DN (mm) | OD (mm) | Schedule | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|---|---|

| 1/8" | 6 | 10.29 | 40S | 1.24 | 0.28 |

| 1/4" | 8 | 13.72 | 40S | 1.65 | 0.49 |

| 1/2" | 15 | 21.34 | 40S | 2.11 | 1.00 |

| 3/4" | 20 | 26.67 | 40S | 2.11 | 1.26 |

| 1" | 25 | 33.40 | 40S | 3.38 | 2.50 |

| 2" | 50 | 60.33 | 40S | 3.91 | 5.44 |

| 3" | 80 | 88.90 | 40S | 5.49 | 11.10 |

| 4" | 100 | 114.30 | 40S | 6.02 | 15.97 |

| 6" | 150 | 168.28 | 40S | 7.11 | 28.15 |

| 8" | 200 | 219.08 | 40S | 8.18 | 42.55 |

Weight Calculation Formula

Metric (kg/m) = 0.02466 × Wall Thickness (mm) × [OD (mm) - Wall Thickness (mm)] Imperial (lb/ft) = 10.69 × Wall Thickness (in) × [OD (in) - Wall Thickness (in)]

Example (1" Sch 40S):0.02466 × 3.38 × (33.40 - 3.38) = 2.50 kg/m

Manufacturing Processes & Applications

Production Methods

| Type | Standard | Key Features |

|---|---|---|

| Seamless | ASTM A312 | Cold/hot rolled, no weld seam, high pressure |

| Welded | ASTM A312 | TIG/EFW, cost-effective for large diameters |

| Heavy Cold Worked | ASTM A312 | Enhanced strength via cold deformation |

Key Industries & Uses

| Industry | Application Examples | Preferred Pipe Type |

|---|---|---|

| Oil & Gas | Process piping, wellhead components | Seamless (Sch 80) |

| Chemical | Acid/alkali transport, reactors | Seamless/Welded |

| Food & Pharma | Sanitary lines, bioreactors (electropolished) | Welded (BA finish) |

| Power Generation | Boiler tubes, heat exchangers | Seamless (Sch 160) |

Technical Notes

-

Surface Finishes:

-

Annealed/Pickled: Mill finish (standard).

-

Polished: #180–#600 grit (sanitary applications).

-

Electropolished: Ra ≤0.3μm (ultra-clean for pharma).

-

-

Tolerances (ASTM A999):

-

OD: ±0.1mm (NPS ≤1½") to ±0.8% (NPS >18").

-

Wall Thickness: +20%/-12.5%.

-

-

Global Equivalents:

Region Standard Grade EU EN 10216-5 1.4301 Japan JIS G3459 SUS304TP China GB/T 14976 0Cr18Ni9

Summary for Engineers:

ASTM A312 TP304 stainless steel pipes offer optimal corrosion resistance and formability for industrial systems. Available in seamless/welded types per ASTM A312-22, sizes 1/8"–24" (DN6–DN600). Key specs: 18–20% Cr, 8–11% Ni, density 7.93 g/cm³. Weight = 0.02466 × Wall × (OD - Wall) kg/m. Use 304L for welded assemblies in corrosive environments.

Standards Compliance: ASTM A312/A312M-22, ASME B36.19, ISO 1127.

Disclaimer: Properties vary with processing. Always request Mill Test Reports (MTR) per EN 10204 3.1 for critical projects.

Manufacturing Processes

We employ:

-

Hot Rolling – achieves uniform wall thickness.

-

Cold Drawing – refines dimensions, improves surface finish.

-

Annealing – stress-relieving at 1 015 °C in a controlled furnace.

-

Pickling & Passivation – removes scale and creates a protective oxide layer.

This sequence yields pipes free of residual stress and with a scale-free surface.

Industry Standards & Certifications

Our 304 pipe complies with:

-

ASTM A312/A213 (USA)

-

EN 10217-7 (Europe)

-

JIS G3459 (Japan)

-

GB/T 14976 (China)

We hold ISO 9001:2015 and PED 2014/68/EU certification.

Dimensional Specifications

We offer sizes from ½" (21.3 mm OD) to 24" (609.6 mm OD) with schedules 5S–160.

| Nominal Size | OD (mm) | Schedule 40 WT (mm) | Schedule 80 WT (mm) | Weight (kg/m) |

|---|---|---|---|---|

| 1″ | 33.4 | 2.77 | 3.91 | 2.72 |

| 2″ | 60.3 | 2.77 | 3.91 | 4.70 |

| 4″ | 114.3 | 3.56 | 6.02 | 9.27 |

| 8″ | 219.1 | 6.35 | 9.27 | 32.20 |

Comparative Analysis

We compare 304 to 316 and Carbon Steel:

| Property | 304 SS | 316 SS | A106 GR B Carbon Steel |

|---|---|---|---|

| Cr–Ni Ratio | 18–20% / 8–10.5% | 16–18% / 10–14% | – |

| Mo Content | 0% | 2–3% | – |

| Corrosion Resistance | Good | Excellent (chlorides) | Poor |

| Cost Factor (Index) | 100 | 140 | 60 |

| Typical Uses | Water, air lines | Seawater, acids | Steam, oil |

Applications

We serve multiple sectors:

-

Food & Beverage: sanitary lines.

-

Pharmaceutical: ultra-pure utility piping.

-

Oil & Gas: flowlines outside sour environments.

-

Construction: architectural rails and supports.

-

Automotive: exhaust systems.

ASTM A312 TP304 stainless steel pipe prices for 2025

| 🌍 Market | Type | Price Range (USD/ton) | Notes |

|---|---|---|---|

| China | ERW/Seamless | $1,200–2,000 | Lower-end seamless and ERW pipes |

| China | High-end seamless/coated | $2,400–3,500 | Sch 10s/Dataset variations |

| China | Premium sealed/coated pipes | $2,900–3,800 | Industrial-grade seamless |

| Europe | Estimated | $3,380–4,835 | Includes welded & seamless styles |

| U.S. | Seamless (TP‑304) | $3,625–4,835 | Premium-quality market |

| U.S. | Welded/ERW (TP‑304) | $3,383–4,230 | Cost-effective welded options |

📌 Market Insights

-

China offers the most competitive pricing:

-

Lower-end seamless/ERW at $1,200–2,000/ton.

-

Premium seamless pipes fetch $2,400–3,800/ton.

-

-

Europe aligns with U.S. levels, with consistent pricing around $3,380–4,835/ton for both welded and seamless types.

-

U.S. market pricing:

-

Seamless TP‑304: $3,625–4,835/ton.

-

Welded/ERW TP‑304: $3,383–4,230/ton.

-

MWalloys Advantages

We invest heavily in R&D. We guarantee:

-

Traceability: full heat-number tracking.

-

Fast Delivery: global warehouses in US, EU, CN.

-

Custom Solutions: cut-to-length, beveling, testing.

Our client retention exceeds 95%.

Installation & Maintenance

We recommend:

-

Weld Inspection: 100% RT or UT.

-

Cleaning Regime: periodic passivation.

-

Leak Testing: hydrostatic at 1.5× working pressure.

Simple. Then complex: although stainless resists fouling, periodic inspections preserve longevity.

Environmental Considerations

We reduce our carbon footprint by recycling > 90% of process scrap. Our electric furnaces run on renewable energy. Overall, stainless steel piping is 100% recyclable at end of life, aligning with circular-economy goals.

FAQS

-

How does 304 SS pipe differ from other stainless‑steel grades?

We choose 304 for its 18–20% chromium and 8–10.5% nickel composition, which delivers excellent ductility and weldability. In contrast to 316, it doesn’t contain molybdenum, so its resistance to chlorides is somewhat lower—but it comes at a more competitive price and still excels in food, beverage, and general‑purpose piping. -

What pressure and temperature limits apply to 304 SS pipe?

At ambient temperature, our 304 SS pipe can safely handle up to 20 MPa (200 bar), depending on schedule. However, as temperature increases, allowable pressure drops. For instance, a 2″ Schedule 80 pipe retains about 8 MPa at 200 °C. Always refer to the ASTM A312 pressure–temperature charts for precise values. -

Is 304 SS pipe suitable for outdoor or marine use?

Yes—but with caveats. Proper passivation and occasional cleaning help sustain the chromium‑oxide film against salt spray. In highly corrosive marine zones, 316 may offer superior longevity. That said, 304 is widely employed for handrails, architectural elements, and freshwater docks, delivering reliable performance when maintained. -

Which welding techniques produce the best 304 SS pipe joints?

We favor TIG (GTAW) and MIG (GMAW) welding for their precision and low contamination risk. Pre‑ and post‑weld annealing around 1 000 °C helps relieve residual stresses. Using ER308L filler wire ensures the joint’s chemistry matches the base metal, preserving corrosion resistance in the heat‑affected zone. -

How should 304 SS pipe be stored and handled to prevent damage?

Always keep pipe indoors or under cover to avoid dust and moisture. Use soft slings or padded supports during lifting—chains or bare cables can scratch the surface. Even small nicks can become corrosion initiation points if left unpassivated, so handle with care and immediately address any surface damage. -

What documentation accompanies each 304 SS pipe shipment?

Every batch ships with a Mill Test Report (MTR) detailing chemical composition and mechanical test results (tensile strength, yield strength, elongation). We also include non‑destructive testing certificates (UT/RT) and full heat‑number traceability. Upon request, we can add PMI analysis or surface‑roughness data for extra assurance.