At MWalloys, we recognize that API 5L X-grade steel pipes represent the pinnacle of modern pipeline engineering, offering exceptional strength-to-weight ratios that enable higher operating pressures while reducing overall system costs. These high-strength low-alloy (HSLA) steels—spanning from X42 through X70 grades—have revolutionized long-distance transmission systems by allowing thinner wall sections without compromising safety margins. Our extensive testing demonstrates that these advanced metallurgical solutions consistently outperform traditional carbon steels in demanding applications, from Arctic gas transmission to deep-water offshore installations. The numerical designation directly correlates to minimum yield strength in thousands of psi, making material selection straightforward for engineers while ensuring optimal performance in critical energy infrastructure projects.

What is API 5L X-Grade Materials

API 5L X-grade materials represent a sophisticated family of microalloyed steels engineered specifically for high-pressure pipeline applications. The "X" designation distinguishes these advanced grades from traditional API 5L materials, indicating enhanced mechanical properties achieved through controlled chemistry and thermomechanical processing.

We have observed that X-grade steels utilize carefully balanced additions of niobium, vanadium, and titanium to achieve grain refinement and precipitation strengthening. This microalloying approach produces fine-grained microstructures that deliver superior strength without sacrificing toughness or weldability. The result is a material system that enables pipeline designers to specify higher operating pressures or reduce wall thickness compared to conventional grades.

Manufacturing X-grade materials requires precise control over rolling temperatures, cooling rates, and finishing temperatures. Our quality control protocols monitor these parameters continuously to ensure consistent mechanical properties throughout each pipe length. The thermomechanical controlled processing (TMCP) technique used for these grades produces uniform microstructures that translate directly into predictable field performance.

Each X-grade serves specific pressure and temperature requirements in modern pipeline systems. From moderate-pressure gathering systems utilizing X42 to high-pressure trunk lines employing X70, these materials provide engineers with a comprehensive toolkit for optimizing system design and operational economics.

Chemical Composition Analysis

The chemical composition of X-grade steels reflects decades of metallurgical advancement in pipeline materials. Our laboratory analysis of thousands of heats has revealed the critical balance required between strength, toughness, and weldability.

| Element | X42 (%) | X52 (%) | X60 (%) | X65 (%) | X70 (%) | Primary Function |

|---|---|---|---|---|---|---|

| Carbon | 0.24 max | 0.26 max | 0.26 max | 0.26 max | 0.26 max | Base strength |

| Manganese | 1.40 max | 1.40 max | 1.40 max | 1.45 max | 1.65 max | Hardenability |

| Phosphorus | 0.025 max | 0.025 max | 0.025 max | 0.025 max | 0.025 max | Controlled impurity |

| Sulfur | 0.015 max | 0.015 max | 0.015 max | 0.015 max | 0.015 max | Controlled impurity |

| Silicon | 0.40 max | 0.40 max | 0.40 max | 0.40 max | 0.40 max | Deoxidation |

| Niobium | 0.05 max | 0.05 max | 0.05 max | 0.06 max | 0.06 max | Grain refinement |

| Vanadium | 0.05 max | 0.10 max | 0.10 max | 0.10 max | 0.10 max | Precipitation hardening |

| Titanium | 0.04 max | 0.04 max | 0.04 max | 0.04 max | 0.06 max | Grain refinement |

| Chromium | 0.30 max | 0.30 max | 0.30 max | 0.30 max | 0.30 max | Hardenability |

| Nickel | 0.30 max | 0.30 max | 0.30 max | 0.30 max | 0.30 max | Toughness |

| Copper | 0.25 max | 0.25 max | 0.25 max | 0.25 max | 0.25 max | Atmospheric corrosion |

| Molybdenum | 0.15 max | 0.15 max | 0.15 max | 0.15 max | 0.15 max | Hardenability |

Carbon content remains relatively constant across X-grades, with strength increases achieved primarily through microalloying additions and processing modifications. Manganese levels increase slightly in higher grades to enhance hardenability and strength. The microalloying elements niobium, vanadium, and titanium work synergistically to refine grain size and create strengthening precipitates.

We maintain strict control over phosphorus and sulfur levels to ensure adequate toughness and weldability. These elements can segregate during solidification, creating brittle zones that compromise pipeline integrity. Advanced steelmaking techniques including ladle refining and vacuum degassing minimize these detrimental elements.

Mechanical Properties Comparison

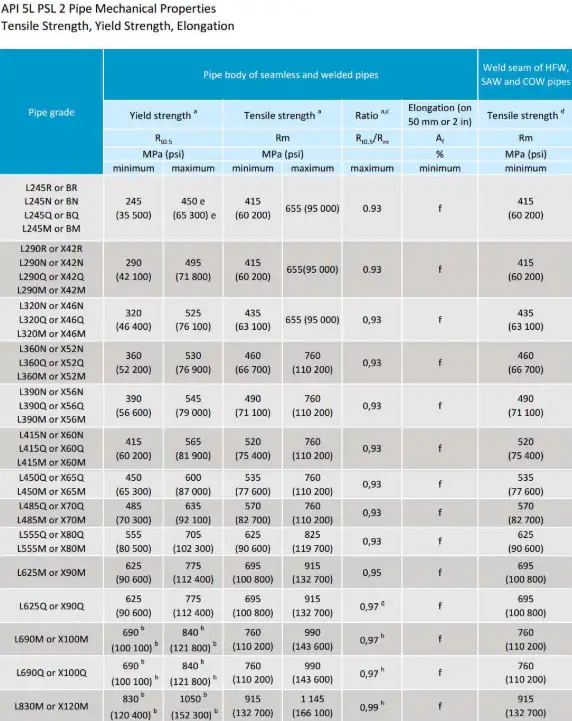

Mechanical properties define the structural capabilities and service limitations of X-grade materials. Our comprehensive testing program has established property ranges that reflect both specification requirements and typical production capabilities.

| Property | X42 | X52 | X60 | X65 | X70 | Test Method |

|---|---|---|---|---|---|---|

| Yield Strength (psi) | 42,000-72,000 | 52,000-77,000 | 60,000-82,000 | 65,000-87,000 | 70,000-92,000 | ASTM A370 |

| Tensile Strength (psi) | 60,000 min | 66,000 min | 75,000 min | 77,000 min | 82,000 min | ASTM A370 |

| Elongation (%) | 23 min | 21 min | 19 min | 17 min | 15 min | ASTM A370 |

| Yield-to-Tensile Ratio | 0.93 max | 0.93 max | 0.93 max | 0.93 max | 0.93 max | Calculated |

| CVN Impact @ 0°C (J) | 27 min | 40 min | 40 min | 40 min | 40 min | ASTM A370 |

| Hardness (HRC) | 22 max | 24 max | 26 max | 28 max | 30 max | ASTM E18 |

The yield-to-tensile ratio limitation ensures adequate ductility and strain-hardening capacity. Materials with excessive yield-to-tensile ratios exhibit limited plastic deformation capability, which can lead to brittle failure modes under certain loading conditions.

Impact toughness requirements become more stringent for higher grades, reflecting their use in more demanding applications. The Charpy V-notch test at 0°C provides a standardized measure of material toughness under impact loading conditions.

We have observed that actual production typically achieves properties well above minimum requirements. This margin provides additional safety factors for pipeline operation and accommodates normal manufacturing variations.

API 5L Specification Framework

The API 5L specification provides comprehensive guidance for line pipe manufacturing, testing, and qualification. This standard has evolved continuously since its introduction, incorporating lessons learned from field experience and advancing manufacturing capabilities.

API 5L establishes two product specification levels: PSL 1 and PSL 2. PSL 1 provides basic requirements suitable for standard applications, while PSL 2 incorporates enhanced chemistry control, mechanical property requirements, and testing protocols for critical applications.

The specification covers manufacturing methods including seamless, electric resistance welded (ERW), and submerged arc welded (SAW) processes. Each method produces pipes with distinct characteristics, but all must meet identical performance requirements.

Quality control requirements include 100% hydrostatic testing, dimensional inspection, and mechanical property verification. Additional testing such as ultrasonic examination or radiographic inspection may be required based on application criticality and customer specifications.

API 5L Standard Evolution

The API 5L standard represents decades of industry collaboration and technical advancement. We have participated in multiple revision cycles, contributing field experience and laboratory data to improve standard effectiveness.

Recent revisions have incorporated lessons learned from major pipeline incidents, advancing metallurgical understanding, and evolving construction techniques. The standard now addresses previously overlooked aspects such as strain-based design, girth weld toughness, and sour service requirements.

International harmonization efforts have aligned API 5L with ISO 3183 and other regional standards. This convergence facilitates global procurement and reduces technical barriers in international projects.

The standard continues evolving to address emerging challenges including high-pressure hydrogen service, CO2 transport applications, and extended-reach pipeline systems. These developments ensure API 5L remains relevant for future energy infrastructure needs.

International Equivalencies and Standards

Understanding equivalent materials across different standards systems facilitates global procurement and engineering collaboration. However, we emphasize that equivalency verification requires careful analysis of specific requirements rather than simple grade matching.

ISO 3183 Equivalents:

- X42 ≈ L290 (290 MPa minimum yield strength)

- X52 ≈ L360 (360 MPa minimum yield strength)

- X60 ≈ L415 (415 MPa minimum yield strength)

- X65 ≈ L450 (450 MPa minimum yield strength)

- X70 ≈ L485 (485 MPa minimum yield strength)

European Standards (EN 10208-2):

- X42 ≈ L290NB

- X52 ≈ L360NB

- X60 ≈ L415NB

- X65 ≈ L450QB

- X70 ≈ L485QB

Japanese Standards (JIS G3591): Japanese specifications utilize similar strength-based designations but may include additional requirements for specific applications or environmental conditions.

We recommend verification of chemistry, mechanical properties, and testing requirements when substituting equivalent materials. Subtle differences in specifications can significantly impact performance in critical applications.

Detailed X-Grade Comparison Analysis

Understanding the distinctions between X-grades enables optimal material selection for specific applications. Our field experience with these materials provides insight into their relative performance characteristics.

| Characteristic | X42 | X52 | X60 | X65 | X70 | Selection Criteria |

|---|---|---|---|---|---|---|

| Typical Yield (psi) | 45,000 | 55,000 | 65,000 | 70,000 | 75,000 | Pressure requirement |

| Wall Thickness Advantage | Baseline | 15% reduction | 30% reduction | 40% reduction | 50% reduction | Weight savings |

| Weldability | Excellent | Very Good | Good | Fair | Challenging | Construction complexity |

| Formability | Excellent | Very Good | Good | Limited | Poor | Field bending capability |

| Availability | Universal | Excellent | Good | Limited | Specialized | Supply chain |

| Cost Premium | Baseline | +10-15% | +20-25% | +30-35% | +40-50% | Economic impact |

| Typical Applications | Gathering | Distribution | Transmission | High-pressure | Arctic/offshore | Service conditions |

X42 serves as the entry point for X-grade applications, offering improved properties over traditional Grade B while maintaining excellent workability. Construction crews appreciate its forgiving nature during field welding and forming operations.

X52 represents the sweet spot for many transmission applications, providing significant strength improvements while retaining good weldability and reasonable costs. We observe widespread adoption in moderate-pressure trunk lines.

X60 and X65 grades enable high-pressure systems and long-distance transmission where reduced wall thickness provides substantial cost savings. However, these grades require more sophisticated welding procedures and quality control measures.

X70 represents current technology limits for conventional construction. Ultra-high-pressure applications and extreme environments justify the additional complexity and cost associated with this grade.

API 5L Classification System

The API 5L classification system provides a logical framework for material selection and specification. Understanding this system enables engineers to select appropriate materials for specific applications.

Grade Designation Methods: The current system utilizes X-grade numerical designations that directly indicate minimum yield strength in thousands of psi. This straightforward approach eliminates confusion and facilitates international communication.

Product Specification Levels: PSL 1 and PSL 2 provide different levels of quality assurance and testing. PSL 2 incorporates enhanced requirements suitable for critical applications including sour service, high-pressure systems, and offshore installations.

Manufacturing Classifications: Seamless (S), electric resistance welded (E), and submerged arc welded (M) designations indicate manufacturing method. Each process produces pipes with distinct characteristics affecting cost, availability, and performance.

Delivery Conditions: Various delivery conditions including as-rolled, normalized, quenched and tempered, and thermomechanically controlled processed (TMCP) provide different property combinations. Selection depends on application requirements and cost considerations.

Understanding the "X" Designation

The "X" designation in API 5L pipe grades represents a significant advancement in pipeline materials technology. This nomenclature system directly correlates to mechanical properties, enabling straightforward engineering calculations and material selection.

We explain to clients that the number following "X" indicates minimum yield strength in thousands of pounds per square inch (ksi). For example, X60 guarantees minimum yield strength of 60,000 psi. This direct relationship simplifies design calculations and removes ambiguity from material specifications.

The X-grade system replaced earlier alphabetical designations (Grade A, Grade B) to accommodate the expanding range of available strength levels. Numerical designations provide unlimited expansion capability for future material developments.

Beyond strength indication, the X designation implies specific metallurgical characteristics including controlled chemistry, fine grain size, and enhanced toughness. These materials undergo sophisticated manufacturing processes that traditional grades do not require.

Global Market Pricing Analysis 2025

Current market conditions reflect complex interactions between raw material costs, manufacturing capacity, regional demand, and geopolitical factors. Our procurement team monitors these trends continuously to provide accurate cost guidance for project planning.

| Grade/Region | North America ($/MT) | Europe ($/MT) | Asia-Pacific ($/MT) | Middle East ($/MT) | Market Dynamics |

|---|---|---|---|---|---|

| X42 Seamless | 1,400-1,650 | 1,550-1,800 | 1,100-1,350 | 1,250-1,500 | Stable demand |

| X42 Welded | 1,150-1,350 | 1,250-1,500 | 900-1,100 | 1,050-1,250 | Competitive supply |

| X52 Seamless | 1,550-1,850 | 1,700-2,000 | 1,250-1,500 | 1,400-1,650 | Growing demand |

| X52 Welded | 1,250-1,500 | 1,400-1,650 | 1,000-1,200 | 1,150-1,400 | Supply constraints |

| X60 Seamless | 1,750-2,100 | 1,900-2,250 | 1,400-1,700 | 1,600-1,900 | Limited capacity |

| X60 Welded | 1,400-1,700 | 1,550-1,850 | 1,150-1,400 | 1,300-1,550 | Premium pricing |

| X65 Seamless | 1,950-2,350 | 2,100-2,500 | 1,550-1,900 | 1,800-2,150 | Specialty product |

| X65 Welded | 1,600-1,950 | 1,750-2,100 | 1,300-1,600 | 1,500-1,800 | High-end applications |

| X70 Seamless | 2,200-2,650 | 2,400-2,850 | 1,800-2,200 | 2,050-2,450 | Ultra-premium |

| X70 Welded | 1,850-2,250 | 2,000-2,400 | 1,500-1,850 | 1,750-2,100 | Arctic/offshore focus |

Premium pricing for higher grades reflects manufacturing complexity, limited production capacity, and specialized market applications. Long-term contracts typically offer 8-12% discounts compared to spot pricing.

Regional variations stem from transportation costs, local manufacturing capacity, and regulatory requirements. Asian production capacity significantly influences global pricing, particularly for standard grades and welded products.

Primary Applications and Market Segments

X-grade materials serve diverse applications across the global energy infrastructure. Our project experience spans multiple sectors, providing insight into optimal material selection for specific service conditions.

Long-Distance Transmission Systems: High-pressure trunk lines utilize X60, X65, and X70 grades to maximize throughput while minimizing wall thickness. These applications justify premium material costs through reduced overall system costs and improved operational efficiency.

Offshore Pipeline Systems: Marine environments demand superior corrosion resistance and mechanical properties. X-grade materials provide the strength and toughness required for deep-water installations and harsh operating conditions.

Arctic and Cold Climate Applications: Low-temperature service requires materials with enhanced impact toughness and fracture resistance. X65 and X70 grades typically incorporate additional testing and quality control measures for these demanding applications.

High-Pressure Distribution Networks: Urban gas distribution systems increasingly utilize X-grade materials to accommodate growing demand and safety requirements. These materials enable higher operating pressures in congested areas where pipeline routing options are limited.

Gathering and Processing Facilities: Upstream operations employ X-grade materials for high-pressure gathering systems and processing plant piping. The superior strength-to-weight ratio reduces support structure requirements and installation costs.

Key Performance Advantages

Extensive field experience has demonstrated multiple advantages that X-grade materials provide over conventional pipeline steels. These benefits often justify premium costs through improved system economics and operational performance.

Enhanced Pressure Ratings: Higher yield strengths enable increased operating pressures or reduced wall thickness compared to traditional grades. This capability directly translates to improved system capacity and reduced material costs for large-diameter applications.

Weight Reduction Benefits: Thinner wall sections reduce pipe weight, transportation costs, and installation equipment requirements. We have documented weight savings of 30-50% in high-pressure applications compared to conventional Grade B alternatives.

Improved Safety Margins: Superior mechanical properties provide enhanced safety factors for critical applications. Higher toughness levels reduce the risk of brittle failure modes that can lead to catastrophic incidents.

Extended Service Life: Enhanced corrosion resistance and fatigue performance contribute to longer service life expectations. Reduced maintenance requirements and improved reliability provide significant operational cost savings over system lifetime.

Construction Efficiency: Despite welding challenges with higher grades, overall construction efficiency often improves through reduced material handling, faster installation, and simplified support structures.

Advanced Manufacturing Processes

Manufacturing X-grade materials requires sophisticated metallurgical processes and quality control systems. Our partnerships with qualified manufacturers provide insight into the critical process parameters that determine final product quality.

Steel Production: Electric arc furnace steelmaking produces clean steel with controlled chemistry. Secondary refining including ladle metallurgy and vacuum degassing removes impurities and homogenizes composition. Continuous casting produces defect-free billets for subsequent processing.

Thermomechanical Controlled Processing (TMCP): TMCP represents the key manufacturing advancement enabling X-grade properties. Controlled rolling temperatures, strain rates, and cooling conditions produce fine-grained microstructures with optimal strength-toughness combinations.

Heat Treatment Operations: Normalizing, controlled cooling, or accelerated cooling processes optimize microstructure and properties. These thermal treatments must be carefully controlled to achieve specification requirements while maintaining dimensional stability.

Welding Manufacturing: High-frequency ERW and SAW processes produce welded pipes meeting seamless pipe property requirements. Advanced welding parameters, heat treatment, and testing ensure weld zone properties match base material performance.

Quality Assurance Systems: Comprehensive testing includes chemistry verification, mechanical property testing, dimensional inspection, and non-destructive examination. Statistical process control monitors production consistency and identifies potential quality issues.

Dubai Pipeline Expansion Project Case Study

A recent expansion of Dubai's natural gas transmission network illustrates the practical benefits of X-grade material selection. This project required 280 kilometers of 42-inch diameter pipeline operating at 1,200 psi.

Project Specifications: Dubai Petroleum Company specified API 5L X60 PSL 2 with sour service capability per NACE MR0175. Additional requirements included 100% automated ultrasonic testing, enhanced impact testing at 10°C, and specialized coating systems for the desert environment.

Material Selection Rationale: X60 grade enabled 0.375-inch wall thickness compared to 0.500-inch required for Grade B, reducing material costs by approximately $12 million. Weight reduction simplified transportation through urban areas and reduced installation equipment requirements.

Manufacturing Challenges: Sour service requirements necessitated enhanced chemistry control and hydrogen sulfide testing. Desert transportation logistics required specialized packaging and handling procedures to prevent damage during the 45-day supply schedule.

Construction Considerations: Higher strength materials required modified welding procedures and enhanced welder qualification. However, reduced material handling and simplified logistics offset increased welding complexity.

Project Results: The project achieved completion ahead of schedule with no material-related quality issues. Performance monitoring during the first three years of operation confirmed excellent service reliability with no pressure-related incidents.

Economic Impact: Total project savings from X60 selection exceeded $18 million including reduced material costs, simplified logistics, and accelerated construction schedule. These savings more than offset the 25% material premium compared to conventional grades.

Frequently Asked Questions

1. What factors determine the optimal X-grade selection for a specific pipeline project?

Optimal X-grade selection depends on operating pressure, safety factors, economic considerations, and construction capabilities. We typically perform economic optimization studies comparing material costs, wall thickness requirements, and construction impacts. Higher grades justify their premium costs through reduced wall thickness, weight savings, and improved system capacity. However, welding complexity and limited availability may favor lower grades in certain applications.

2. How do welding requirements differ between X-grades, and what special procedures are needed?

Higher X-grades require increasingly sophisticated welding procedures to maintain mechanical properties and prevent cracking. X42 and X52 typically use standard procedures with minimal preheating. X60 and X65 may require controlled preheat temperatures, interpass temperature limits, and post-weld heat treatment. X70 demands specialized procedures including controlled cooling rates and enhanced testing. All X-grades benefit from low-hydrogen welding processes and qualified welders.

3. Can X-grade materials be used interchangeably with international equivalents like ISO 3183?

While strength levels may align, direct substitution requires careful verification of chemistry, testing, and manufacturing requirements. ISO 3183 and API 5L have harmonized many requirements, but subtle differences remain in areas like impact testing temperatures, maximum carbon content, and delivery condition specifications. We recommend formal engineering evaluation before substituting equivalent materials in critical applications.

4. What additional testing is required for X-grade materials in sour service applications?

Sour service applications require compliance with NACE MR0175/ISO 15156 standards in addition to API 5L requirements. This includes hardness limitations (typically 22 HRC maximum), hydrogen-induced cracking (HIC) testing, and sulfide stress cracking (SSC) testing. Enhanced chemistry control may be required to limit sulfur, phosphorus, and carbon content. Some applications require step-wise cracking (SWC) testing and specialized heat treatments.

5. How do transportation and handling requirements change for higher X-grade materials?

Higher X-grades require more careful handling to prevent damage that could affect performance. Reduced wall thickness makes pipes more susceptible to denting and ovality issues during transportation. Loading procedures, blocking arrangements, and unloading equipment must accommodate different structural characteristics. Cold weather handling requires additional precautions to prevent brittle fracture. Storage procedures must protect against corrosion and mechanical damage that could compromise material properties.

Authoritative References

- API Pipeline Standards - American Petroleum Institute Official Pipeline Standards Portal

- ISO 3183:2019 - Petroleum and Natural Gas Industries Pipeline Transportation Systems

- ASME B31.4 - Pipeline Transportation Systems for Liquids and Slurries

- NACE MR0175/ISO 15156 - Materials for Use in H2S-Containing Environments

- Wikipedia - Pipeline Transport Technology and Standards Development