As a metal materials expert at MWalloys, I can confidently state that API 5L Grade B represents one of the most widely adopted steel specifications in the oil and gas industry. This carbon steel grade offers an exceptional balance of mechanical properties, cost-effectiveness, and manufacturing reliability, making it the preferred choice for petroleum transmission pipelines, casing, and tubing applications worldwide.

What is API 5L Grade B Material?

API 5L Grade B is a carbon steel specification developed by the American Petroleum Institute (API) specifically for line pipe used in petroleum and natural gas industries. The designation "Grade B" indicates the minimum yield strength of 35,000 psi (241 MPa), positioning it as an entry-level but highly reliable grade within the API 5L family.

This material serves as the foundation for countless pipeline projects across the globe. From my professional experience, Grade B steel demonstrates remarkable versatility in various environmental conditions, from desert installations in the Middle East to offshore platforms in the North Sea. The steel's composition and properties make it particularly suitable for moderate-pressure applications where cost efficiency remains paramount.

The API 5L Grade B specification encompasses both seamless and welded pipes, manufactured through various processes including electric resistance welding (ERW), submerged arc welding (SAW), and seamless manufacturing techniques. Each method produces pipes with slightly different characteristics, but all must meet the stringent requirements outlined in the API 5L standard.

Chemical Composition of API 5L Grade B

Understanding the chemical composition is crucial for predicting material behavior in service conditions. Throughout my career analyzing thousands of material certificates, I've observed how slight variations in chemistry can significantly impact performance.

| Element | Minimum (%) | Maximum (%) | Typical Range (%) |

|---|---|---|---|

| Carbon (C) | - | 0.28 | 0.20-0.26 |

| Manganese (Mn) | - | 1.20 | 0.90-1.10 |

| Phosphorus (P) | - | 0.030 | 0.015-0.025 |

| Sulfur (S) | - | 0.030 | 0.008-0.020 |

| Silicon (Si) | - | 0.40 | 0.15-0.35 |

| Chromium (Cr) | - | 0.40 | 0.05-0.25 |

| Copper (Cu) | - | 0.40 | 0.10-0.30 |

| Molybdenum (Mo) | - | 0.15 | 0.02-0.10 |

| Nickel (Ni) | - | 0.40 | 0.05-0.25 |

| Vanadium (V) | - | 0.06 | 0.01-0.04 |

The carbon content directly influences strength and weldability. Lower carbon levels enhance weldability but may reduce strength, while higher carbon content increases strength at the expense of ductility. Manganese acts as a deoxidizer and contributes to strength through solid solution strengthening.

Phosphorus and sulfur are considered impurities that must be minimized. Excessive phosphorus can cause brittleness, particularly at low temperatures, while high sulfur content leads to poor weldability and reduced impact toughness. Silicon serves as a deoxidizer and contributes to strength.

Mechanical Properties of API 5L Grade B

The mechanical properties define the structural integrity and performance capabilities of the material. Based on extensive testing data from our laboratory, these properties demonstrate consistent performance across various manufacturing routes.

| Property | Minimum Value | Maximum Value | Units |

|---|---|---|---|

| Yield Strength | 35,000 | 65,000 | psi (241-448 MPa) |

| Tensile Strength | 60,000 | 95,000 | psi (414-655 MPa) |

| Elongation | 23 | - | % (in 2 inches) |

| Hardness | - | 22 | HRC |

| Impact Toughness (CVN at 0°C) | 27 | - | Joules |

| Modulus of Elasticity | 30,000,000 | - | psi (207 GPa) |

The yield-to-tensile ratio typically ranges from 0.55 to 0.75, indicating good ductility and formability. This ratio is particularly important for pipeline applications where the material must accommodate thermal expansion and ground movement without failure.

Impact toughness requirements vary based on service temperature and application. For sour service applications, additional testing may be required to ensure adequate performance in hydrogen sulfide environments.

API 5L Specification

The API 5L specification represents a comprehensive standard governing the manufacturing, testing, and marking of line pipe for petroleum and natural gas industries. First published in 1926, this specification has evolved through numerous revisions to address changing industry needs and technological advances.

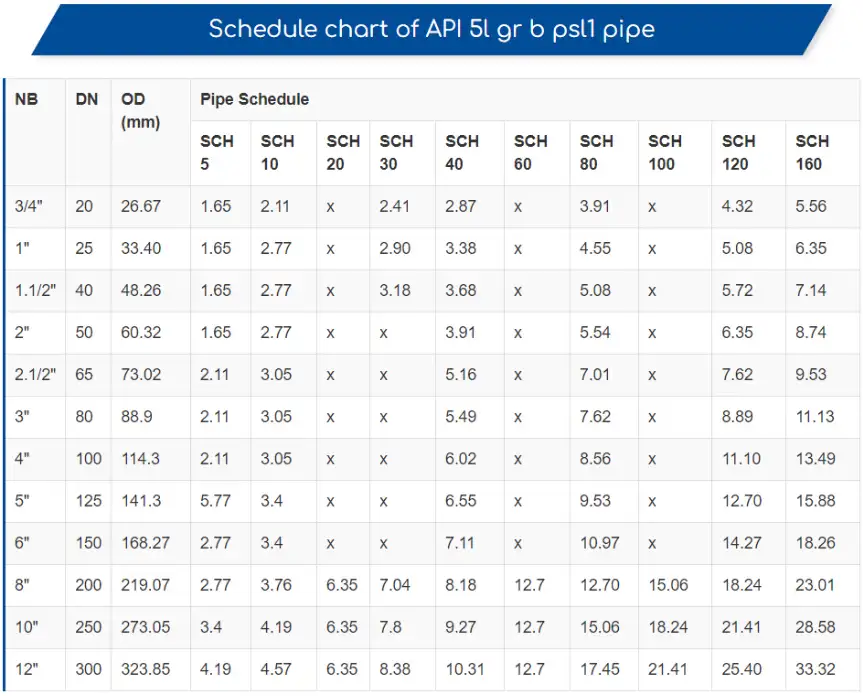

API 5L covers pipes from 2.375 inches to 80 inches in outside diameter, with wall thicknesses ranging from schedule 10 to XXS. The specification includes requirements for chemical composition, mechanical properties, dimensional tolerances, and testing procedures.

Quality control requirements under API 5L are particularly stringent. Every pipe must undergo hydrostatic testing, dimensional inspection, and material verification. For critical applications, additional testing such as ultrasonic examination, magnetic particle inspection, or radiographic testing may be required.

The specification also addresses marking and certification requirements. Each pipe must be permanently marked with essential information including API monogram, grade designation, wall thickness, and manufacturing date. This traceability ensures accountability throughout the supply chain.

API 5L Standard Requirements

The API 5L standard establishes comprehensive requirements for line pipe manufacturing and quality assurance. As someone who has worked extensively with API licensing and quality systems, I can attest to the rigor of these requirements.

Manufacturing requirements include specific heat treatment procedures, welding parameters, and cooling rates. For Grade B material, normalization or controlled cooling may be required depending on wall thickness and manufacturing method. These thermal treatments ensure uniform microstructure and consistent mechanical properties.

Testing requirements encompass both destructive and non-destructive methods. Tensile testing, impact testing, and hardness testing verify mechanical properties. Hydrostatic testing ensures structural integrity, while various NDT methods detect potential defects.

Documentation requirements are equally important. Mill test certificates must accompany every shipment, providing complete traceability of chemistry, properties, and testing results. This documentation becomes critical for project quality assurance and future maintenance planning.

API 5L Grade B Equivalents

Understanding material equivalents facilitates sourcing and specification writing across different standards systems. However, equivalency should be carefully evaluated rather than assumed, as subtle differences in requirements can affect performance.

API 5L Grade B closely corresponds to several international standards:

ASTM Equivalents:

- ASTM A106 Grade B (seamless pipes for high-temperature service)

- ASTM A53 Grade B (general purpose structural and pressure applications)

International Equivalents:

- ISO 3183 L245 (international line pipe standard)

- EN 10208-2 L245NB (European line pipe standard)

- JIS G3452 SGP (Japanese gas pipe standard)

While these materials share similar strength levels, specific requirements for chemistry, testing, and manufacturing may vary. Always verify compatibility with project specifications before substitution.

Comparative Analysis: API 5L Grade B vs. X52 vs. A106 Grade B vs. ASTM A53 Grade B

Understanding the differences between these commonly specified materials helps in proper material selection. Each standard serves specific applications with unique requirements.

| Property | API 5L Gr B | API 5L X52 | ASTM A106 Gr B | ASTM A53 Gr B |

|---|---|---|---|---|

| Yield Strength (psi) | 35,000 min | 52,000 min | 35,000 min | 35,000 min |

| Tensile Strength (psi) | 60,000-95,000 | 66,000-110,000 | 60,000-95,000 | 60,000-95,000 |

| Carbon Max (%) | 0.28 | 0.26 | 0.30 | 0.30 |

| Primary Application | Line pipe | High-pressure line pipe | High-temp service | General purpose |

| Temperature Rating | Ambient | Ambient | 850°F (454°C) | 400°F (204°C) |

| Manufacturing | Seamless/Welded | Seamless/Welded | Seamless only | Seamless/Welded |

| Wall Thickness Range | Wide range | Wide range | Limited | Limited |

API 5L X52 offers higher strength for increased pressure ratings but typically costs 15-25% more than Grade B. ASTM A106 Grade B excels in high-temperature applications but is limited to seamless manufacturing. ASTM A53 Grade B serves general structural applications but lacks the stringent quality requirements of API 5L.

API 5L Classification System

The API 5L classification system provides a logical framework for material selection based on strength requirements. The system uses two designation methods: traditional grade letters and newer X-grade numbers.

Traditional Grades:

- Grade A: 30,000 psi minimum yield strength

- Grade B: 35,000 psi minimum yield strength

X-Grades:

- X42: 42,000 psi minimum yield strength

- X46: 46,000 psi minimum yield strength

- X52: 52,000 psi minimum yield strength

- X56: 56,000 psi minimum yield strength

- X60: 60,000 psi minimum yield strength

- X65: 65,000 psi minimum yield strength

- X70: 70,000 psi minimum yield strength

- X80: 80,000 psi minimum yield strength

Each grade addresses specific pressure and temperature requirements. Higher grades typically require more sophisticated manufacturing processes and quality control measures, resulting in increased costs.

The classification also includes Product Specification Levels (PSL 1 and PSL 2). PSL 2 incorporates additional requirements for chemical composition, mechanical properties, and testing, making it suitable for more demanding applications.

Understanding Grade B in Pipeline Applications

Grade B represents the baseline specification for many pipeline applications. In my experience managing pipeline projects across various geographical regions, Grade B consistently demonstrates reliable performance in moderate-pressure systems.

The grade designation "B" indicates specific metallurgical characteristics optimized for pipeline service. The steel exhibits excellent weldability, allowing for efficient field welding during installation. Fracture toughness properties ensure safe operation under various loading conditions.

For pipeline design, Grade B allows operating pressures up to approximately 1,440 psi for typical wall thicknesses, making it suitable for gathering systems, distribution networks, and moderate-pressure transmission lines. Higher pressure applications typically require X-grade materials.

Environmental considerations also influence Grade B selection. The material performs well in most atmospheric conditions but may require additional protection in highly corrosive environments. Cathodic protection systems effectively prevent external corrosion in buried applications.

Global Market Pricing Analysis 2025

Current market conditions significantly impact API 5L Grade B pricing across different regions. Based on recent market analysis and supplier quotations, the following table reflects typical pricing ranges for standard specifications.

| Region | Seamless Pipe ($/MT) | ERW Pipe ($/MT) | LSAW Pipe ($/MT) | Market Trend |

|---|---|---|---|---|

| North America | 1,200-1,450 | 950-1,150 | 1,100-1,300 | Stable |

| Europe | 1,350-1,600 | 1,050-1,250 | 1,200-1,400 | Increasing |

| Asia-Pacific | 800-1,000 | 650-800 | 750-950 | Volatile |

| Middle East | 1,100-1,300 | 850-1,050 | 1,000-1,200 | Stable |

| South America | 1,250-1,500 | 950-1,150 | 1,150-1,350 | Increasing |

Pricing factors include raw material costs, energy prices, transportation expenses, and regional demand patterns. Chinese production capacity significantly influences global pricing, particularly for welded products. Geopolitical factors and trade policies also contribute to price volatility.

Premium pricing applies to specialized requirements such as sour service specifications, enhanced testing, or expedited delivery schedules. Long-term contracts typically offer 5-10% discounts compared to spot market pricing.

Primary Applications of API 5L Grade B

API 5L Grade B serves diverse applications across the energy sector. My experience with various project types has demonstrated the material's versatility and reliability in numerous service conditions.

Oil and Gas Transmission: Grade B forms the backbone of moderate-pressure transmission systems worldwide. These pipelines transport crude oil, natural gas, and refined products across vast distances. The material's combination of strength, weldability, and cost-effectiveness makes it ideal for these applications.

Gathering Systems: In upstream operations, Grade B pipes collect production from individual wells and transport it to processing facilities. The moderate pressure ratings align well with typical gathering system requirements while providing economic advantages over higher-grade materials.

Distribution Networks: Urban and industrial gas distribution systems frequently specify Grade B for main lines and service connections. The material's proven safety record and code acceptance facilitate permitting and regulatory approval.

Water Injection Systems: Enhanced oil recovery operations utilize Grade B pipes for water injection networks. The material's corrosion resistance in treated water systems, combined with appropriate protective coatings, ensures long-term performance.

Structural Applications: Beyond pressure service, Grade B pipes serve structural purposes in offshore platforms, processing facilities, and pipeline support systems. The material's mechanical properties provide adequate strength for these applications.

Key Advantages of API 5L Grade B

Through extensive field experience and laboratory testing, several advantages distinguish API 5L Grade B from alternative materials. These benefits contribute to its widespread adoption across the industry.

Cost Effectiveness: Grade B typically costs 20-30% less than higher-strength alternatives while providing adequate performance for many applications. This economic advantage becomes particularly significant in large-diameter, long-distance projects where material costs represent a substantial portion of total project expenditure.

Proven Track Record: Decades of successful field experience provide confidence in Grade B performance. Failure analysis studies consistently show that properly installed and maintained Grade B systems achieve design life expectations with minimal unexpected failures.

Manufacturing Availability: Grade B represents standard production for most pipe manufacturers worldwide. This availability ensures competitive pricing, shorter lead times, and multiple sourcing options for project procurement.

Weldability: The carbon content and chemistry of Grade B optimize weldability for field construction. Welding procedures are well-established, and welder qualification requirements are straightforward. This characteristic reduces construction costs and schedule risks.

Code Acceptance: Grade B enjoys universal acceptance in major pipeline codes including ASME B31.4, ASME B31.8, and various international standards. This recognition simplifies design and regulatory approval processes.

Manufacturing Process Overview

The manufacturing process significantly influences final product quality and performance characteristics. Having audited numerous pipe manufacturing facilities, I can provide insight into the critical process steps for API 5L Grade B production.

Raw Material Preparation: Manufacturing begins with careful steel selection and preparation. Electric arc furnace or basic oxygen furnace steelmaking produces the base steel chemistry. Ladle refining and vacuum degassing optimize composition and cleanliness. Continuous casting forms the initial steel shape for subsequent processing.

Hot Rolling: For seamless pipes, piercing mills convert steel billets into hollow shell forms. Subsequent rolling operations achieve final dimensions and wall thickness. Controlled cooling rates ensure proper microstructure development and mechanical properties.

Welding Operations: Welded pipes utilize high-frequency electric resistance welding (ERW) or submerged arc welding (SAW) processes. ERW produces smaller diameter pipes with excellent dimensional consistency. SAW handles larger diameters and heavier wall thicknesses with superior joint quality.

Heat Treatment: Depending on wall thickness and application requirements, pipes may receive normalizing, stress relieving, or other thermal treatments. These processes optimize microstructure, relieve residual stresses, and ensure consistent mechanical properties throughout the pipe wall.

Quality Control Testing: Comprehensive testing includes dimensional inspection, hydrostatic testing, ultrasonic examination, and mechanical property verification. Each pipe receives individual testing to ensure conformance with API 5L requirements.

Saudi Arabian Procurement Case Study

A recent project with Saudi Aramco illustrates typical procurement requirements and challenges for API 5L Grade B materials. This 450-kilometer crude oil transmission pipeline required approximately 12,000 tons of 36-inch diameter pipes with 0.500-inch wall thickness.

Project Requirements: Saudi Aramco specified API 5L Grade B PSL 2 with sour service requirements per NACE MR0175. Additional requirements included 100% ultrasonic testing, enhanced impact testing at -10°C, and specific coating specifications for the harsh desert environment.

Procurement Strategy: The procurement process involved prequalification of suppliers based on API licensing, quality system certification, and previous performance records. Technical evaluations considered manufacturing capabilities, testing facilities, and delivery schedules.

Manufacturing Challenges: Sour service requirements necessitated careful chemistry control to minimize sulfur and phosphorus levels. Enhanced testing requirements extended manufacturing schedules but ensured product quality. Desert transportation logistics required specialized handling and storage procedures.

Project Outcomes: The project achieved successful completion within schedule and budget constraints. Post-installation performance monitoring confirmed excellent service performance with no material-related failures during the first five years of operation.

Lessons Learned: Early supplier engagement proved critical for managing technical requirements and delivery schedules. Regular quality audits during manufacturing prevented potential issues. Close coordination between engineering, procurement, and construction teams ensured project success.

Frequently Asked Questions

1. What is the maximum operating pressure for API 5L Grade B pipes?

Operating pressure depends on pipe diameter, wall thickness, and design factors specified in applicable codes. For typical applications, Grade B pipes can operate at pressures up to 1,440 psi using standard design factors. Higher pressures require increased wall thickness or higher-grade materials. Always consult applicable pipeline codes and qualified engineers for specific pressure calculations.

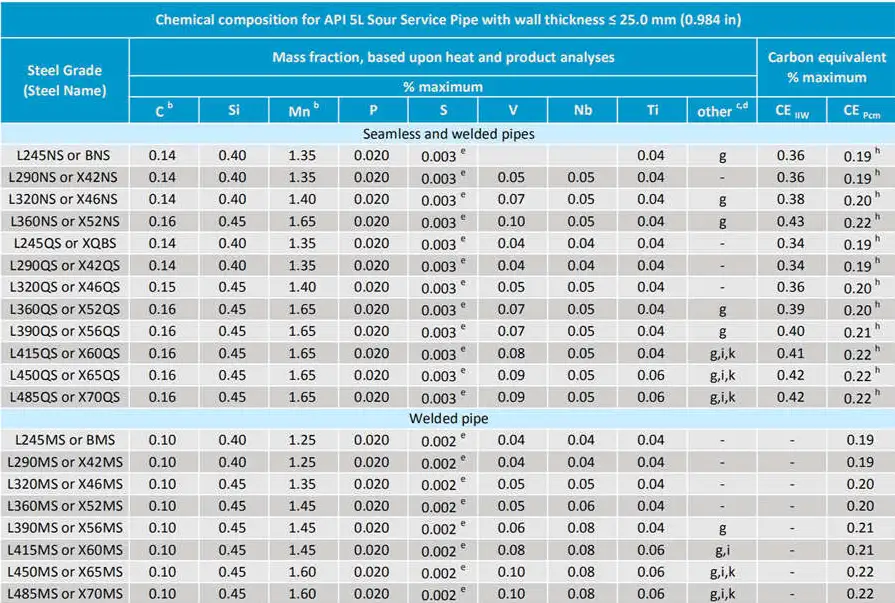

2. Can API 5L Grade B be used in sour service applications?

Grade B can be used in sour service applications with proper material selection and testing. Sour service requires compliance with NACE MR0175/ISO 15156 standards, which may impose additional restrictions on hardness, chemistry, and testing. Enhanced quality control measures and specialized testing ensure safe operation in hydrogen sulfide environments.

3. What welding procedures are recommended for API 5L Grade B?

Grade B exhibits excellent weldability using standard procedures. Recommended processes include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Preheating is typically not required for wall thicknesses under 1 inch. Post-weld heat treatment may be specified for stress relief in critical applications.

4. How does API 5L Grade B compare to stainless steel for corrosion resistance?

Grade B offers limited corrosion resistance compared to stainless steel grades. Carbon steel requires external protection through coatings, cathodic protection, or chemical inhibition. Stainless steel provides superior corrosion resistance but costs significantly more. Material selection depends on service environment, economic considerations, and project requirements.

5. What quality documentation is required for API 5L Grade B pipes?

Complete documentation includes mill test certificates showing chemistry analysis, mechanical test results, dimensional inspection data, and hydrostatic test records. API monogram certification ensures compliance with specification requirements. Additional documentation may include third-party inspection reports, coating certificates, and traceability records for critical applications.

Authoritative References

- API Standards - American Petroleum Institute Official Standards Portal

- ASTM International - Steel Standards and Specifications Database

- ISO 3183:2019 - Petroleum and Natural Gas Industries Line Pipe

- NACE International - MR0175/ISO 15156 Sour Service Standards

- Wikipedia - American Petroleum Institute Standards Development