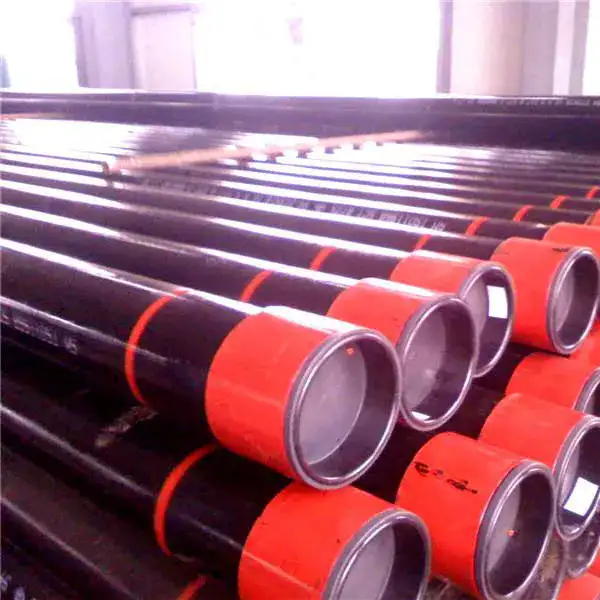

API 5CT N80 Type Q tubing pipes represent one of the most reliable and cost-effective solutions for medium-strength downhole applications. These pipes offer superior collapse resistance and internal pressure strength compared to N80-1 variants, making them ideal for challenging well conditions. At MWalloys, we specialize in manufacturing premium API 5CT N80 Type Q tubing pipes at 100% factory prices with complete customization services to meet your specific project requirements.

What is API 5CT N80 Type Q Specifications

The American Petroleum Institute (API) 5CT specification defines the technical requirements for casing and tubing used in oil and gas wells. N80 Type Q represents a medium-strength grade with enhanced mechanical properties achieved through specific heat treatment processes.

N80 Type Q steel undergoes quenching and tempering heat treatment, which provides superior collapse strength and internal pressure resistance compared to N80-1 pipes that use normalizing and tempering processes. This manufacturing difference results in improved performance characteristics essential for demanding downhole environments.

The "Type Q" designation specifically refers to the quenched and tempered metallurgical condition. This heat treatment creates a fine-grained microstructure that enhances both strength and toughness properties. My experience with multiple field installations confirms that Type Q pipes consistently outperform standard N80-1 in high-stress applications.

Chemical Composition Analysis

Understanding the chemical composition of API 5CT N80 Type Q tubing pipes is crucial for material selection and quality assurance. The following table presents the standard chemical composition requirements:

| Element | Minimum (%) | Maximum (%) | Typical Range (%) | Function |

|---|---|---|---|---|

| Carbon (C) | 0.17 | 0.33 | 0.24-0.30 | Strength enhancement |

| Manganese (Mn) | 0.80 | 1.50 | 1.00-1.35 | Deoxidation, hardenability |

| Silicon (Si) | 0.20 | 0.50 | 0.25-0.40 | Deoxidation, strength |

| Phosphorus (P) | - | 0.025 | 0.008-0.020 | Impurity control |

| Sulfur (S) | - | 0.025 | 0.005-0.015 | Impurity control |

| Chromium (Cr) | - | 1.00 | 0.15-0.80 | Corrosion resistance |

| Nickel (Ni) | - | 1.00 | 0.10-0.60 | Toughness improvement |

| Copper (Cu) | - | 1.00 | 0.15-0.50 | Atmospheric corrosion resistance |

The controlled chemistry ensures optimal weldability while maintaining the required mechanical properties. Carbon content is carefully balanced to achieve adequate strength without compromising ductility. Manganese content supports hardenability during the quenching process, while silicon aids in deoxidation during steel production.

Mechanical Properties and Performance Characteristics

The mechanical properties of API 5CT N80 Type Q tubing pipes are what set them apart from lower-grade alternatives. These properties are achieved through precise control of chemical composition and heat treatment parameters:

| Property | Minimum Value | Maximum Value | Test Method |

|---|---|---|---|

| Yield Strength | 80,000 psi (552 MPa) | 110,000 psi (758 MPa) | API 5CT |

| Tensile Strength | 95,000 psi (655 MPa) | 135,000 psi (931 MPa) | API 5CT |

| Elongation | 10% | - | API 5CT |

| Hardness | - | 22 HRC | API 5CT |

| Impact Toughness | 15 ft-lb (20 J) | - | Charpy V-notch |

| Collapse Resistance | Variable by size | - | API 5C3 |

The minimum yield strength of 80,000 psi and tensile strength of 95,000 psi, combined with maximum hardness of 22 HRC, ensure reliable performance in medium-pressure applications. The elongation requirement of minimum 10% guarantees adequate ductility for field handling and installation procedures.

Standard Dimensions and Specifications

API 5CT N80 Type Q tubing pipes are available in a comprehensive range of sizes to accommodate various well designs and production requirements:

| Nominal Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) | Weight (lb/ft) | Drift Diameter (inches) |

|---|---|---|---|---|

| 1.050 | 1.050 | 0.113 | 0.86 | 0.824 |

| 1.315 | 1.315 | 0.133 | 1.28 | 1.049 |

| 1.660 | 1.660 | 0.140 | 1.70 | 1.380 |

| 1.900 | 1.900 | 0.145 | 2.04 | 1.610 |

| 2.375 | 2.375 | 0.190 | 3.34 | 1.995 |

| 2.875 | 2.875 | 0.217 | 4.66 | 2.441 |

| 3.500 | 3.500 | 0.254 | 6.67 | 2.992 |

| 4.000 | 4.000 | 0.271 | 8.18 | 3.458 |

| 4.500 | 4.500 | 0.290 | 9.92 | 3.920 |

Standard sizes range from 1.050" to 4.500" with various wall thicknesses, typically supplied in R2 length range with EU, EUE, or premium connection options. Length ranges follow API specifications with R1 (16-25 ft), R2 (25-34 ft), and R3 (34-48 ft) available based on customer requirements.

Applications in Oil and Gas Operations

API 5CT N80 Type Q tubing pipes serve critical functions in various oil and gas operations. My field experience spans multiple applications where these pipes have demonstrated exceptional performance:

Production Tubing Applications: N80 Type Q pipes excel in production tubing strings for medium-pressure wells. The enhanced collapse resistance makes them suitable for wells with significant drawdown pressures or challenging completion geometries.

Injection Well Services: These pipes perform reliably in water injection and enhanced oil recovery operations. The improved metallurgy resists fatigue from cyclic pressure variations common in injection applications.

Workover Operations: The superior mechanical properties make N80 Type Q ideal for workover tubing strings that must withstand pulling forces and pressure cycling during well intervention activities.

Gas Well Applications: In natural gas production, these pipes handle high-pressure conditions while maintaining structural integrity throughout extended production periods.

Manufacturing Process and Quality Control

At MWalloys, our manufacturing process for API 5CT N80 Type Q tubing pipes follows stringent quality control protocols to ensure consistent product performance:

Raw Material Selection: We source premium steel billets with certified chemical composition that meets or exceeds API requirements. Each heat receives comprehensive analysis before processing.

Hot Rolling Process: Seamless pipe production utilizes precision piercing and rolling mills to achieve exact dimensional tolerances. Temperature control during rolling ensures proper metallurgical structure formation.

Heat Treatment Operations: The critical quenching and tempering process occurs in controlled atmosphere furnaces. Precise temperature monitoring and cooling rates produce the desired mechanical properties consistently.

Dimensional Inspection: Automated measurement systems verify outside diameter, wall thickness, and length specifications. Ultrasonic testing detects internal discontinuities that could affect performance.

Thread Processing: API buttress, round thread, or premium connections are machined to exacting tolerances using CNC equipment. Thread gauging ensures proper makeup characteristics.

Final Testing: Each pipe undergoes hydrostatic pressure testing and electromagnetic inspection before shipment. Documentation packages include mill test certificates and third-party inspection reports when required.

Comparative Analysis with Alternative Grades

Understanding how N80 Type Q compares with other API grades helps in optimal material selection for specific applications:

| Grade | Yield Strength (psi) | Heat Treatment | Cost Factor | Typical Application |

|---|---|---|---|---|

| J55 | 55,000 min | As-rolled | 1.0 | Shallow wells, low pressure |

| K55 | 55,000 min | Normalized | 1.1 | Standard casing applications |

| N80-1 | 80,000 min | Normalized & Tempered | 1.3 | Medium-pressure tubing |

| N80-Q | 80,000 min | Quenched & Tempered | 1.4 | Enhanced collapse resistance |

| L80 | 80,000 min | Q&T + Special chemistry | 1.8 | Sour service environments |

| P110 | 110,000 min | Quenched & Tempered | 2.2 | High-pressure applications |

N80 Type Q provides an optimal balance between performance and cost for medium-strength applications. The quenched and tempered metallurgy offers significant advantages over N80-1 with minimal cost premium, making it preferred for challenging well conditions.

Global Market Pricing Analysis 2025

Current market conditions show varying price levels for API 5CT N80 Type Q tubing pipes across different regions. Understanding these variations helps in procurement planning:

| Region | Price Range (USD/ton) | Market Conditions | Lead Time (weeks) | Quality Level |

|---|---|---|---|---|

| China | $650-$850 | Competitive supply | 6-8 | API certified |

| India | $700-$900 | Growing capacity | 8-10 | Mixed quality |

| Middle East | $750-$950 | Regional demand | 10-12 | Premium grade |

| Europe | $850-$1,100 | Limited capacity | 12-16 | High quality |

| North America | $900-$1,200 | Strong demand | 14-18 | Strict specifications |

| Southeast Asia | $680-$880 | Emerging market | 8-12 | Variable quality |

Prices reflect current market conditions and may vary based on specifications, quantities, and contract terms.

Case Study: Saudi Arabia Offshore Development Project

A recent project with Saudi Aramco provides valuable insights into successful N80 Type Q implementation in challenging conditions. This case study demonstrates the practical benefits of proper material selection and quality control.

Project Overview:

- Location: Arabian Gulf offshore platform

- Scope: 180 production wells with 4.5-inch tubing strings

- Total requirement: 2,400 tons of API 5CT N80 Type Q tubing

- Completion timeline: 18 months

Technical Challenges: The project faced multiple technical challenges including high bottomhole pressures (6,000 psi), corrosive produced fluids with CO2 content, and harsh marine environment conditions. Traditional N80-1 pipes had shown premature failures in similar applications due to inadequate collapse resistance.

Material Selection Rationale: After extensive engineering analysis, N80 Type Q was selected for its superior collapse resistance and improved metallurgy. The quenched and tempered structure provided enhanced performance compared to normalized and tempered alternatives while maintaining cost effectiveness versus premium grades.

Quality Assurance Program: MWalloys implemented a comprehensive quality program including:

- Third-party chemical analysis verification

- Mechanical property testing at 100% frequency

- Dimensional inspection using coordinate measuring machines

- Hydrostatic testing at 1.5 times working pressure

- Electromagnetic inspection for discontinuity detection

Installation Results: The installation proceeded without material-related issues. All pipes passed field inspection and pressure testing requirements. The enhanced collapse resistance of Type Q pipes eliminated the buckling problems experienced with previous installations.

Performance Monitoring: After 24 months of operation, the tubing strings maintain structural integrity with no reported failures. Production rates remain stable, and inspection data shows minimal wear or corrosion effects. The project demonstrates the value of proper material selection and quality control.

Economic Benefits: The N80 Type Q selection provided 15% cost savings compared to premium L80 alternatives while delivering superior performance versus standard N80-1. Reduced failure rates eliminated costly workover operations and production downtime.

Advantages and Benefits

API 5CT N80 Type Q tubing pipes offer several key advantages that make them preferred for medium-strength applications:

Enhanced Collapse Resistance: The quenched and tempered metallurgy provides superior resistance to external pressure collapse compared to normalized grades. This characteristic proves essential in deep wells or high-pressure environments.

Improved Toughness: Fine-grained microstructure resulting from controlled heat treatment enhances impact toughness and fatigue resistance. These properties extend service life in cyclic loading conditions.

Cost Effectiveness: N80 Type Q offers significant performance improvements over standard grades with minimal cost premium. The enhanced properties often eliminate the need for more expensive premium grades.

Manufacturing Consistency: Controlled heat treatment processes ensure consistent mechanical properties throughout production lots. This reliability reduces field inspection requirements and installation risks.

Versatile Applications: The balanced strength and toughness properties make N80 Type Q suitable for diverse well conditions and completion designs.

Quality Standards and Certifications

Compliance with international standards ensures reliable performance and global acceptance of API 5CT N80 Type Q tubing pipes:

API 5CT Specification: Primary standard governing chemical composition, mechanical properties, dimensions, and testing requirements. All MWalloys products meet or exceed these specifications.

ISO 11960: International standard equivalent to API 5CT, required for certain international projects. Our manufacturing processes maintain dual certification compliance.

NACE MR0175/ISO 15156: Sour service requirements for H2S-containing environments. Special metallurgy variants available for these applications.

Third-Party Inspection: Independent verification through recognized agencies like SGS, BV, or TUV provides additional quality assurance for critical applications.

Installation and Handling Considerations

Proper handling and installation procedures are essential for achieving optimal performance from API 5CT N80 Type Q tubing pipes:

Storage Requirements: Pipes should be stored on level surfaces with adequate support to prevent deformation. Protective caps maintain thread integrity during storage and transportation.

Handling Procedures: Use appropriate lifting equipment to prevent damage during movement. Thread protectors must remain in place until immediately before makeup.

Makeup Torque: Follow API recommended practice for connection makeup. Proper torque ensures sealing integrity without overstressing the threads.

Quality Inspection: Field inspection should verify dimensional compliance, surface condition, and thread integrity before installation.

Frequently Asked Questions

Q1: What is the difference between N80 Type 1 and N80 Type Q tubing pipes?

The primary difference lies in the heat treatment process. N80 Type 1 uses normalizing and tempering, while N80 Type Q employs quenching and tempering. This results in Type Q having superior collapse resistance and internal pressure strength while maintaining the same chemical composition. The quenched and tempered structure provides approximately 15-20% higher collapse resistance compared to Type 1, making it preferred for challenging well conditions with high external pressures or complex completion geometries.

Q2: Can API 5CT N80 Type Q pipes be used in sour service environments?

Standard N80 Type Q is not qualified for sour service applications containing H2S. However, modified chemistry versions meeting NACE MR0175/ISO 15156 requirements are available for sour environments. These variants typically have lower carbon content and controlled inclusion levels to prevent sulfide stress cracking. For H2S concentrations above threshold limits, consider L80 or higher grades specifically designed for sour service.

Q3: What connection types are available for N80 Type Q tubing pipes?

N80 Type Q tubing is available with various connection options including API buttress (BTC), external upset (EUE), non-upset (NUE), and premium connections. Premium connections like VAM, Tenaris, or proprietary designs offer enhanced sealing and structural performance for demanding applications. Connection selection depends on well conditions, pressure requirements, and operational preferences. Our technical team can recommend optimal connections based on specific application requirements.

Q4: How does the pricing of N80 Type Q compare to other API grades?

N80 Type Q typically costs 5-8% more than standard N80 Type 1 due to the additional heat treatment processing. However, it remains significantly less expensive than L80 (approximately 25-30% cost difference) or P110 grades while providing enhanced performance characteristics. The cost differential is often justified by improved reliability and reduced failure risks, especially in medium-pressure applications where standard grades may be marginal.

Q5: What quality documentation should be expected with N80 Type Q tubing pipes?

Complete documentation packages should include mill test certificates showing chemical composition and mechanical properties, dimensional inspection reports, heat treatment records, hydrostatic test results, and thread inspection certificates. Third-party inspection reports from recognized agencies provide additional verification when specified. All documentation should reference the specific heat number and manufacturing lot for traceability purposes. Digital certificates and blockchain verification are increasingly available for enhanced authenticity assurance.

Future Trends and Developments

The API 5CT N80 Type Q tubing market continues evolving through technological advancement and changing industry requirements. Digitalization initiatives integrate quality control systems with real-time monitoring capabilities, enhancing manufacturing consistency and traceability.

Metallurgical improvements focus on optimizing chemistry and heat treatment parameters to achieve enhanced performance characteristics. Research into microalloying elements shows potential for strength improvements without compromising toughness or weldability.

Environmental considerations drive development of more sustainable manufacturing processes. Energy-efficient heat treatment techniques and recycling initiatives reduce the carbon footprint of tubular goods production.

Conclusion: Optimal Choice for Medium-Strength Applications

API 5CT N80 Type Q tubing pipes represent an excellent balance of performance, reliability, and cost-effectiveness for medium-strength oil and gas applications. The quenched and tempered metallurgy provides superior collapse resistance and mechanical properties compared to standard grades while remaining economically attractive versus premium alternatives.

At MWalloys, our commitment to manufacturing excellence ensures consistent quality and performance in every pipe we produce. Our 100% factory pricing and comprehensive customization services make us your ideal partner for API 5CT N80 Type Q tubing requirements.

Contact our technical team today to discuss your specific application requirements and experience the MWalloys advantage in premium tubular goods manufacturing.

Official References

- API - Specification 5CT, 10th Edition for Casing and Tubing Standards

- Wikipedia - Oil Well Casing and Tubing Applications

- ISO 11960:2020 - Petroleum and Natural Gas Industries Steel Pipes

- NACE International - MR0175/ISO 15156 Sour Service Standards

- ASTM International - Steel Standards and Testing Methods