API 5CT L80 is a medium-high strength, restricted-yield grade of casing/tubing used widely in oil & gas wells — especially where a balance of strength, toughness and sour-service resistance is required. L80 exists in three main families (L80-1, L80-9Cr and L80-13Cr), meets minimum yield and tensile requirements that sit between API 5CT N80 and P110, and is available in standard API sizes and connections manufactured under API 5CT requirements. For buyers seeking dependable supply, MWAlloys supplies API 5CT L80 casing and tubing from China with factory direct pricing, fast stock dispatch, and full QC to API standards.

What is L80 tubing?

L80 is an API 5CT product grade for oilfield casing and tubing that provides a restricted yield strength and minimum tensile strength designed for many production and intermediate applications. It is a “workhorse” tubular grade when operators need stronger than J55/K55 but do not need the deep-well strength of P110. L80’s combination of yield, tensile and toughness makes it suitable for many corrosive and sour environments when the appropriate chromium variant (9Cr or 13Cr) is selected.

What does API 5CT mean?

API 5CT is the American Petroleum Institute specification for casing and tubing. The standard defines dimensional tolerances, mechanical property minima, manufacture methods, chemical reporting, heat treatment, marking, testing and acceptance criteria for OCTG (Oil Country Tubular Goods). API updates the specification periodically (the API webstore shows the current edition information). When a pipe is specified to “API 5CT L80”, it must meet the API 5CT requirements applicable to L80 grade products.

What are mechanical properties and performance of L80 Tubing?

Below are the commonly referenced minimum mechanical property ranges for API 5CT L80 (practical values used by mills and purchasers). Different L80 types (1, 9Cr, 13Cr) will have slightly different properties and test requirements (hardness, impact) per API. Use the mill certificate and API monogram where required.

-

Minimum yield strength (YS): ~552 MPa (80 ksi class, “L80” naming historically tied to yield class).

-

Minimum tensile strength (TS): ≥655 MPa (≈95 ksi).

-

Minimum elongation: typically ≥15% (depends on diameter/grade/type and heat treatment).

-

Hardness & impact: L80 may be subject to hardness limits and mandatory impact testing in some applications or sizes (refer to API 5CT).

Authoritative note: always confirm exact mechanical data on the mill’s test certificate (MTC) and in the order specification — API tables and mill practices (normalized/quenched & tempered) control the final values.

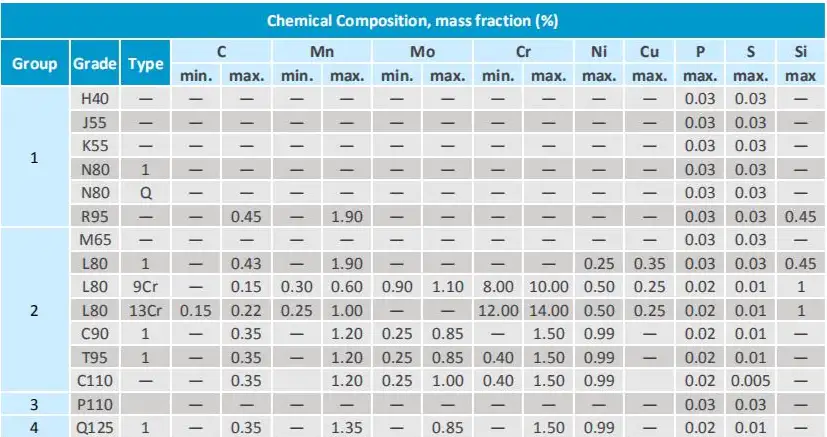

What is chemical composition of L80 Tubing?

The L80 family can be plain carbon/low-alloy (L80-1) or chromium-bearing corrosion-resistant variants (L80-9Cr and L80-13Cr). API 5CT gives composition ranges for some elements and allows other elements within declared limits. The table below shows typical mill practice ranges (representative, used for buyer guidance). Always verify with the mill.

| Element | Typical L80-1 (mass %) | Typical L80-9Cr (mass %) | Typical L80-13Cr (mass %) | Notes |

|---|---|---|---|---|

| C (Carbon) | 0.20 – 0.30 | 0.18 – 0.30 | 0.12 – 0.30 | Lower C improves toughness; verify for weldability |

| Mn (Manganese) | 0.40 – 1.00 | 0.40 – 1.00 | 0.40 – 1.00 | Common deoxidizer and strength contributor |

| Cr (Chromium) | ≤0.30 | 8.0 – 10.0 | 12.0 – 14.0 | Higher Cr for corrosion resistance |

| Mo (Molybdenum) | ≤0.40 | 0.10 – 0.50 | 0.10 – 0.50 | Used for strength and sulfide stress resistance |

| Ni (Nickel) | ≤0.30 | ≤0.30 | ≤0.30 | May be present in small amounts |

| Cu (Copper) | ≤0.30 | ≤0.30 | ≤0.30 | Small additions possible |

| P (Phosphorus) | ≤0.03 | ≤0.03 | ≤0.03 | Order limits for toughness |

| S (Sulfur) | ≤0.03 | ≤0.03 | ≤0.03 | Low S for improved properties |

Source: common mill practice summaries and L80 datasheets; use mill MTC for contract values.

What is API 5CT L80 equivalent to?

-

L80-1 (sometimes just “L80”) — the base restricted-yield grade (carbon/low alloy). Used where strength and reasonable corrosion resistance are adequate.

-

L80-9Cr (9% Cr) — chromium alloyed for improved corrosion resistance and better performance in some sour/wetted environments. Manufacturing and heat treatment are more demanding.

-

L80-13Cr (13% Cr) — higher chromium for aggressive corrosion environments (closer to stainless-like corrosion resistance while keeping the cost and strength characteristics of a carbon alloy).

Equivalent naming: API grades are product grades, not direct equivalents to general steel grades. In many mill catalogs you will see cross-references (for example L80 might be compared to certain EN or proprietary grades) — always request the chemical and mechanical MTC for equivalence confirmation.

What is the difference between L80 and P110?

-

Strength: P110 is a higher strength grade (higher YS and TS) intended for deep/high-pressure wells. L80 is lower than P110 but stronger than J55/K55.

-

Use case: choose L80 for intermediate depths and where toughness/corrosion balance is needed; choose P110 when collapse/axial loads and high burst/collapse margins in deeper wells are the priority.

-

Hardness and toughness: P110 often carries different hardness limits and additional testing for very high strength; if HB/WB hardness is exceeded it can affect downhole performance.

-

Cost and machinability: P110 generally costs more and is harder to machine/weld than L80. For completion/tubing operations where heavy tool running is expected, P110 may be selected despite higher cost.

For a direct technical comparison, consult API 5CT mechanical tables and the mill MTC for the exact grade values before final selection.

Typical specifications, connections & testing

When ordering API 5CT L80 casing/tubing, the purchase specification should reference API 5CT edition, include:

-

Product grade & sub-type (e.g., API 5CT L80-9Cr, or L80-1)

-

Size, wall, nominal weight (lb/ft or kg/m) and thread type (e.g., BTC, LTC, STC, etc.)

-

Heat treatment (normalized, quenched & tempered where applicable)

-

Required NDT (UT, RT, MPI, PT per product and API table)

-

Mechanical tests: yield, tensile, elongation, hardness limits, impact (Charpy V-notch) where required

-

Traceability: Mill heat number, MTC (EN 10204 3.1 or equivalent), chemical analysis & mechanical test reports — and API Monogram when applicable.

-

Coating / finish: bare, oil-coated, FBE, 3PE or other anticorrosion options.

-

Marking & color codes: API color coding on body/coupling to identify grade.

Sizes & weight (Representative table)

Below is a short sample of common casing/tubing sizes taken from API casing/tubing tables. These are representative — always consult the exact API chart and mill dimensions for the production batch.

| Nominal Size (in) | OD (in) | Nominal Weight (lb/ft) | Typical Use |

|---|---|---|---|

| 4 1/2″ | 4.5 | 8.0 – 9.5 lb/ft (example) | Tubing & small casing runs |

| 5″ | 5.0 | 9 – 10.7 lb/ft | Intermediate tubing |

| 7″ | 7.0 | 17 – 22 lb/ft | Production casing |

| 7 5/8″ | 7.625 | 24.0 lb/ft | Surface/intermediate casing (example from API charts) |

| 9 5/8″ | 9.625 | 40–47 lb/ft | Common production casing |

| 13 3/8″ | 13.375 | 68–82 lb/ft | Large diameter surface casing |

How to read the chart: API tables list OD, nominal weight, internal diameter, drift, and capacities per 100 ft. For joint properties (joint yield strength, collapse), consult the API tubing/casing tables and the mill’s joint specs.

Global price snapshot (2025) — comparative ranges and buyer notes

Important: OCTG prices fluctuate with scrap/steel mill cycles, commodity markets, finishing, end-use threads and coatings, order size, and freight. The table shows ballpark ranges (per metric ton) in 2025 as observed from multiple supplier listings and marketplaces; use it only for budgeting, not as a firm offer. Contact MWAlloys for a precise quotation including coupling, threading, coatings, inspection and freight.

| Region / source | Typical 2025 reported range (USD / ton) | Notes / common variation |

|---|---|---|

| China (factory sellers, marketplace listings) | $600 – $1,100 / ton (many L80 listings cluster US$700–900/ton) | Variation by alloy (9Cr/13Cr higher), MOQ, mill & finishing |

| India (domestic mills & traders) | $700 – $1,300 / ton (spot quotes show wide spread) | Local demand and import duties affect pricing |

| USA / Europe (distributors & surplus stocks) | $1,000 – $1,600+ / ton (higher due to logistics, certification, lower volumes) | Domestic stock, API Monogram, and short lead are premium factors |

| Used / surplus (marketplaces) | Varied — <$500/ton (surplus) to near mill cost | Salvage/surplus items require full inspection. |

Buyer tips: request a full Price, Quality & Delivery quote (PQD) that lists: base pipe price, threading & coupling cost, inspection fees (RT/UT), coating cost, packing, and EXW/FOB/CIF terms. Prices for chromium variants (9Cr/13Cr) are higher due to alloy content and special heat treatment.

Manufacturing & quality control (what to inspect)

When receiving L80 casing/tubing, insist on the following documents and checks:

-

Mill Test Certificate (MTC) with heat number, chemistry and mechanical tests (EN 10204 3.1 or equivalent).

-

API 5CT compliance statement (edition referenced in PO). If API Monogram is required, confirm license and API certificate.

-

NDT reports: UT/RT for wall integrity and RT for girth joints where specified.

-

Hardness & impact reports (if required by grade/size).

-

Dimension & thread inspection: verify OD, wall, joint length, and coupling thread profile (BTC/LTC/STC etc.).

-

Traceability & packing: heat number marking on each joint and painted grade code; bundled and properly packed for ocean export.

Quality requirements (normalization, heat treatment schedule, decarburization limits) should be spelled out in the purchase order. API’s addenda and Technical Reports (e.g., 5C3) provide calculation and acceptance guidance.

Applications & limitations

Common applications: production tubing, intermediate casing strings, some injection wells, and environments where corrosive fluids may be present (select chromium variant accordingly). L80’s balance of strength and toughness makes it widely used for general oil & gas well construction.

Limitations: for ultra-deep, ultra-high pressure or where collapse/burst margins are critical, higher strength grades such as P110 or Q125 may be necessary. Similarly, for very high corrosion or erosion service, consider specialized corrosion-resistant alloys beyond L80-13Cr. Always evaluate downhole chemistry (CO₂/H₂S/chlorides), temperature, and mechanical load cases before selecting grade.

Ten practical procurement & field tips

-

Specify exact API edition in PO (API 5CT edition affects acceptance criteria).

-

Request full MTC and confirm traceability to heat number.

-

Insist on required NDT for the application — UT is routine; RT may be added per design.

-

Confirm thread type (BTC/LTC/STC) and up-set/finish if required.

-

For sour service choose L80-9Cr / L80-13Cr and ask for sulfide stress cracking (SSC) test controls.

-

Compare landed cost (price + threading + inspection + freight) rather than just base pipe price.

-

Audit supplier QC — ask for API Monogram or mill audit reports if critical.

-

Use sample inspection prior to full shipment for large orders.

-

Plan logistics — OCTG shipments are heavy and require port handling arrangements.

-

Keep replacement stock if project downtime is costly — fast dispatch from factory stock is a competitive advantage.

FAQs

1. What is L80 tubing used for?

L80 is used for production tubing and intermediate casing where a balance of strength, toughness and corrosion resistance is required. Choose chromium variants for sour/wetted service.

2. Is L80 suitable for sour service?

Yes, L80-9Cr and L80-13Cr variants are designed for enhanced corrosion resistance and are commonly used in sour environments. Verify SSC controls with the supplier.

3. How does L80 compare with N80?

L80 generally has higher minimum yield than N80 in some classifications and different testing/heat treatment requirements; check exact mill MTC and API tables for direct numeric comparison.

4. Can L80 be welded?

Yes, but welding procedure specification (WPS) should account for carbon equivalent, pre-heat and post-weld treatment as appropriate to avoid HAZ toughness issues. Ask the mill for CE numbers.

5. What documentation should accompany a shipment?

MTC, NDT reports, thread inspection, heat treatment record, packing list and API compliance statement (and API Monogram certificate if required).

6. Does L80 need impact testing?

Impact testing is required for certain sizes, heat treatments and applications per API 5CT; it should be specified in the PO and reflected on the MTC.

7. What is a typical lead time?

Factory stock lead times can be short (days-weeks) while new mill production may take several weeks; chromium variants and special testing add time. MWAlloys maintains stock options for rapid dispatch.

8. Why do prices vary so much by region?

Scrap/steel cycles, alloy content, production costs, certification, logistics and local demand create region-to-region price differences. Always request landed cost.

9. How to ensure compatibility with downhole tools?

Verify drift OD, coupling ID, and threading; ensure the drift and ID allow passage of tools and completions. Use API drift & capacity tables.

10. Are chromium variants magnetic?

Yes, L80-9Cr and L80-13Cr are ferritic/martensitic alloys (not austenitic stainless) and will generally be magnetic; their metallurgy is different from stainless alloys. (Check the supplier’s metallurgical data for specifics.)

MWAlloys product & supply statement

MWAlloys is an established OCTG supplier and technical partner. For API 5CT L80 casing and tubing we offer:

-

Factory direct pricing — 100% factory EXW/FOB pricing for bulk orders (competitive China mill relationships).

-

Fast dispatch from stock — selected sizes and weights kept in inventory for urgent projects.

-

Full QC & traceability — complete MTCs, NDT reports and API-grade documentation; we can work with your inspector or third-party verifier.

-

Customization — threading, couplings, heat treatment and coatings per PO.

-

Competitive global shipping — experience exporting to India, Europe, North America and the Middle East; we provide landed cost breakdowns and packing for OCTG sea shipments.

If you want a formal quotation for specific sizes, alloys and quantities, MWAlloys can produce a PQD (Price-Quality-Delivery) within one working day for stocked lines — contact our sales team with size, grade (e.g., L80-9Cr), quantity, and destination port.