AISI/SAE 1018 cold-rolled steel coil is a low-carbon, easily machinable and highly weldable mild steel with nominal carbon ~0.15–0.20% that performs well for parts requiring good dimensional finish, case hardening by carburizing, and cost-effective volume supply. For stamping, cold forming, carburized components (pins, gears), and general fabrication where surface finish and tight tolerances matter, 1018 CRC is a reliable, economical choice. MWAlloys supplies factory-priced 1018 cold-rolled coils with ready stock, fast delivery, and quality inspection to support industrial and OEM procurement.

What is 1018 cold-rolled steel?

AISI/SAE 1018 is in the 10xx series of plain carbon steels and is one of the most widely produced low-carbon grades for cold-finished and cold-rolled product forms. The grade is prized for its combination of ductility, consistent mechanical behaviour, and amenability to surface hardening by carburizing. When supplied as cold-rolled coil (CRC), 1018 offers improved surface finish, tighter gauge tolerances, and better formability for parts that are later stamped, formed, or machined.

What “1018” indicates

The AISI/SAE four-digit numbering convention: the first digit (1) denotes carbon steel, the second digit (0) indicates plain carbon (no special alloying), and the last two digits (18) approximate the nominal hundredths of percent carbon content (≈0.18%). In practice 1018 is a medium low-carbon steel with tightly controlled Mn, P and S limits for consistent forming and machining. The grade is typically specified in coil, bar, plate and cold-finished forms and referenced in several ASTM/SAE and national standards.

Chemical composition

Below is a standard composition table used by most mill datasheets for AISI/SAE 1018 (cold-rolled / cold-drawn forms):

| Element | Typical range (wt.%) |

|---|---|

| Carbon (C) | 0.14 – 0.20 |

| Manganese (Mn) | 0.60 – 0.90 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.050 |

| Iron (Fe) | Balance (≈ 98.8 – 99.3) |

| Others (max traces) | Si, Cu, Ni, Cr typically ≤ 0.2 each (mill dependent) |

Notes: Mill certificates will show the exact chemical at the time of manufacture and trace interstitials (Cu, Cr, Ni) may be present at low ppm levels depending on feedstock and melt practice. Always request a mill Chemical Analysis certificate (EN 10204/3.1 or equivalent).

Material properties

The following are commonly published mechanical and physical properties for cold-rolled / cold-drawn 1018 data sheets. When high precision matters, use the mill test report or independent lab testing.

| Property | Typical value (metric) | Typical value (imperial) |

|---|---|---|

| Tensile strength, ultimate (UTS) | ~400–450 MPa | ~58–65 ksi |

| Yield strength (0.2% offset) | ~310–370 MPa (varies with finish) | ~45–54 ksi |

| Elongation (in 50 mm) | ~12–20% (depends on cold work) | ~12–20% |

| Hardness (Brinell) | ~110–130 HB (annealed/normalized baseline) | — |

| Modulus of elasticity | 200–210 GPa | 29–30 ×10^3 ksi |

| Density | ~7.85 g/cm³ | ~0.284 lb/in³ |

Interpretation notes: Cold rolling increases strength and reduces elongation compared with hot-rolled/annealed material. The ranges above reflect typical mill specifications for cold-finished 1018; always confirm with the supplier’s certificate for the precise lot.

Specifications, coil sizes and tolerances

Common reference standards and product forms relevant to buyers of 1018 cold-rolled coils:

-

Standards & specs: ASTM (A29 general reference for bars; A108 for bar products; mill sheet/coil standards like ASTM A568/A653 for coated sheet forms if coating required), SAE/AISI grade definitions, national standards for coil manufacture and testing. See ASTM catalog for steel standards.

-

Coil formats: CRC supplied in coils with thickness typically from 0.2 mm up to ~3.0 mm (standard thin gauges for CRC commonly 0.3–2.0 mm), widths 600–1,500 mm (custom widths available), coil weights commonly 3–8 tonnes depending on mill. Edge: mill edge (ME) or slit edge (SE).

-

Surface finish: cold-rolled bright finish, skin-passed, oiled or descaled per buyer preference. For high-finish needs specify surface roughness (Ra) or visual grade.

-

Tolerances: thickness tolerance per mill standard; for precision parts ask for tolerances to ±0.01–0.05 mm depending on thickness and finish.

-

Supply documents: Mill Test Certificate (MTC) EN 10204 3.1 or 3.2 where required, chemical report, mechanical test report, surface inspection report.

Equivalent grades and cross-references

Common equivalents used internationally for procurement, engineering substitution or comparative specs:

| AISI/SAE | UNS | EN / DIN / JIS | Common equivalents |

|---|---|---|---|

| SAE/AISI 1018 | G10180 | EN: approx. C15 / 1.0401 (note: check exact spec) | GB: Q235 variants sometimes used for structural low-carbon applications (not direct match) |

| — | — | DIN/EN historical equivalents: C15/Ck15 (check heat and tolerance) | JIS: suitable low carbon steels (consult supplier) |

Guidance: Grade equivalency charts vary by application (bar vs coil) and by the manufacturing route. Always verify chemical and mechanical ranges for a specific application — mechanical properties can differ between hot-rolled, cold-rolled and cold-drawn product forms.

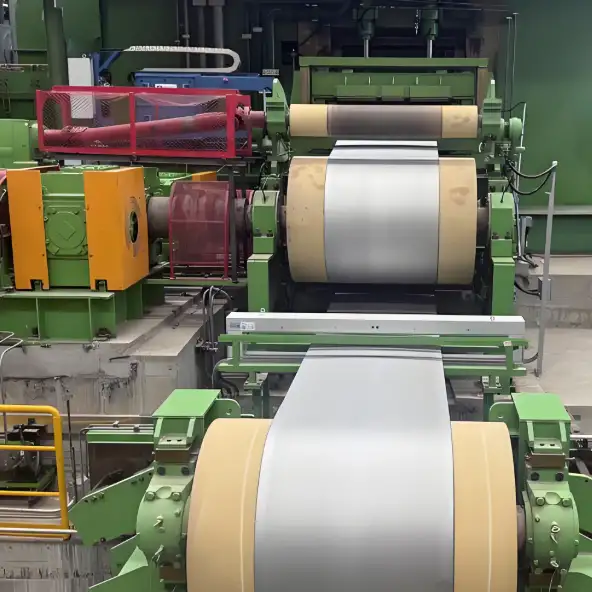

Cold rolling, surface finish and coil processing

Cold rolling reduces thickness, improves surface finish, and raises yield/tensile strength through strain hardening. Typical mill steps for 1018 CRC:

-

Pickling (if starting from hot-rolled coil) to remove scale.

-

Cold rolling through mills to target gauge.

-

Skin passing to control surface texture and yield point elongation.

-

Annealing stage (bright anneal or full anneal) — optional depending on desired mechanical properties and formability.

-

Oiling and coil packaging for corrosion protection in transit.

Surface finish options: bright (no anneal scale), skin-passed (slightly textured), polished (for specialty strips). For carburizing applications the coil surface condition affects pack/carburizing behaviour and should be discussed with heat-treaters.

Fabrication behaviour: machining, welding, heat treatment

Machining: 1018 is favored for general machining because of its balanced ductility and strength; tool life and feeds should be selected based on whether the coil has been cold-worked (higher hardness) or annealed. Chips are ductile; use adequate chip evacuation.

Welding: Excellent weldability using common methods (MIG, TIG, stick). Because carbon is low, pre-heat is rarely required for moderate thicknesses, and post-weld treatments are typically not needed for ordinary fabrication. For critical welded assemblies consult applicable welding standards.

Carburizing / case hardening: 1018 is widely used for carburized parts because the low bulk carbon allows a carbon-rich surface layer to be produced by pack, gas or vacuum carburizing to achieve a hard case and a tough core. Typical application: shafts, pins, small gears where a hard wear surface and ductile core are needed. The steel responds predictably to case depth control due to low base carbon.

Typical applications

-

Small gears, pins, shafts and carburized fasteners

-

Cold-formed components, stamped parts and deep-drawn parts from coil

-

Precision machined parts where finish and tight gauges are required

-

Automotive interior and non-safety structural components

-

Machine parts that require surface hardening while retaining a ductile core

Design note: avoid using 1018 for highly stressed, quenched hardened structural components — it is optimized for case hardening and general fabrication, not for high alloy strength in the through-hardened condition.

Quality control & inspection

When purchasing 1018 cold-rolled coil for industrial assemblies, include in procurement documents:

-

Mill Test Certificate (EN 10204 3.1 or 3.2) with chemical and mechanical values.

-

Surface inspection (visual + measured Ra if required).

-

Dimensional tolerances and coil IDs for traceability.

-

Non-destructive tests where needed (UT for critical thickness, eddy current for surface defects).

-

Sampling & acceptance criteria for delivered coils (internal inspection plan).

-

Packaging requirements to prevent transit corrosion (oiled paper, shrink wrap, wooden cradles).

2025 market pricing snapshot

Important: steel prices fluctuate by week. The figures below summarize public market indices and reports for cold-rolled coil (CRC) in mid-2025; use them as baseline indicators and confirm live quotes with MWAlloys sales. Sources: IMARC (China/Germany mid-2025), IndustrialTube/market briefs (US mid-2025), and MEPS export price summaries.

| Region | Representative CRC price (USD / metric tonne) — mid-2025 (indicative) |

|---|---|

| United States (spot CRC mid-2025) | ~1,100 – 1,140 USD/MT (mill/regional spot ranges reported). |

| Europe (Germany benchmark, mid-2025) | ~840 USD/MT (June 2025 IMARC Germany CRC benchmark). |

| China (domestic CRC mid-2025) | ~516 USD/MT (June 2025 reported average) — domestic Chinese CRC prices were materially lower versus western markets in mid-2025. |

Buyer’s note: Coil grade (cold-rolled vs skin-passed), coating, slitting, packaging, and freight (FOB vs CIF) materially change landed cost. For example, FOB China coil priced at ~$520/MT plus ocean freight, insurance, duties and inland delivery will approach the buyer’s landed cost in importing markets. When comparing quotes, specify full INCOTERMS and finishing. Market indices move — for procurement use a live quote from MWAlloys to lock price.

MWAlloys commercial offer

MWAlloys is a factory-direct supplier with mill relationships across China and global logistics experience. Our typical commercial proposition for AISI/SAE 1018 cold-rolled coil:

-

Factory price advantage: 100% factory-sourced pricing; we pass mill pricing and reduce intermediaries.

-

Stock & speed: maintained ready stock for common gauges and widths — typical lead time 7–21 days for stocked items; custom slitting or special finish lead times depend on mill schedules.

-

MOQ: variable — standard coils (3–5 MT per coil) with flexible MOQs for bulk procurement.

-

Testing & documentation: provide EN 10204 3.1 mill test certificates, chemical/physical reports, and traceable coil IDs.

-

Packaging & export: standard seaworthy packaging, skids and protective oiling; options for desiccant packing for long transit.

-

After sales: incoming inspection photos, third-party inspection on request, batch sampling.

If you need an immediate, verifiable quote for FCA/FOB Shanghai or CIF to your preferred port, provide: thickness, width, coil weight, surface finish, required certificate level, and estimated annual volume — MWAlloys will deliver a mill-backed offer with clear terms and lead times.

FAQs

-

Q: Is 1018 suitable for through-hardening?

A: No. 1018 is low-carbon and not appropriate for deep through-hardening to high core hardness. It is ideal for surface hardening (carburizing) to produce a hard case and ductile core. -

Q: Can 1018 CRC be welded without pre-heat?

A: Yes for common thicknesses — low carbon content provides good weldability and typically doesn’t require pre-heat for non-critical assemblies. Always follow welding procedure specifications for thicker sections. -

Q: What finish should I request for deep-draw stamping?

A: Request full-annealed bright finish or skin-passed coil with low yield point elongation and tight thickness tolerance. Specify Ra and visual grade in the PO. -

Q: How thick are standard CRC coils?

A: Common CRC thicknesses range from 0.3 mm to ~2.0 mm for general sheet; thicker cold-rolled sections exist but check with the mill for capability and tolerance. -

Q: How does cold-rolled 1018 compare to hot-rolled 1018?

A: Cold-rolled has superior surface finish, tighter thickness tolerances and higher strength (due to strain hardening) versus hot-rolled which is more ductile and cheaper. Choose according to finish and dimensional needs. -

Q: What certificates accompany MWAlloys shipments?

A: EN 10204 3.1 mill test certificate (chemical + mechanical), packing list, commercial invoice, and any requested inspection certificates; 3.2 or third-party inspection available on request. -

Q: Are there environmental or REACH concerns?

A: 1018 is plain carbon steel; confirm any specific regulatory compliance (REACH, RoHS) for coatings, processing aids, or lubricants used in finishing. -

Q: What is the expected hardness after carburizing?

A: Surface case hardness can reach HRC 55–62 locally depending on cycle and post-processing; core hardness remains low and ductile. Work with your heat-treat provider to specify case depth and hardness profile. -

Q: How should coils be stored on arrival?

A: Keep indoors if possible, store on wooden skids, avoid standing water, and leave protective oiling in place until further processing. -

Q: How do I request a sample coil or a test piece?

A: Contact MWAlloys with required gauge, width and sample size. We can arrange coil samples or sheared test coupons with chemical and mechanical test certificates.

Practical procurement checklist

-

Grade: AISI/SAE 1018 cold-rolled coil

-

Thickness/w Width/Coil weight range and edge type

-

Surface finish (bright / skin-passed / oiled)

-

Certificates required (EN 10204 3.1 / 3.2)

-

Incoterms and delivery port

-

Inspection (third party if needed)

-

Packaging & corrosion protection requirements

-

Payment, lead time and penalty/acceptance criteria for non-conforming deliveries

Closing summary

AISI/SAE 1018 cold-rolled coil is a workhorse material for manufacturers needing affordable, well-behaved mild steel with good surface finish and predictable response to carburizing and machining. For buyers seeking volume supply with clear paperwork and fast turnaround, MWAlloys offers factory pricing, stock options and full documentation to reduce procurement friction. For an exact price and delivery schedule to your plant, send your specification (gauge, width, finish, cert level, and quantity) and we will return a mill-backed quote.