AISI/SAE 4130 chromoly square tube is a medium-carbon, chromium-molybdenum alloy steel that offers an excellent compromise among strength, toughness, weldability and cost — making it a first-choice material for structural, automotive, aerospace-grade framing, motorcycle frames, roll cages and high-fatigue components where strength-to-weight and predictable heat-treatment response matter. For buyers requiring reliable supply, MWAlloys stocks 4130 chromoly square tube and 4130 steel sheet with competitive factory pricing, rapid fulfillment from China, and full traceability for engineering approvals.

What is 4130 Chromoly?

4130 is a chromium-molybdenum low-alloy steel identified by SAE/AISI designation 4130 (UNS G41300). Its chemistry and heat-treatability make it a through-hardening alloy that can be used in normalized, annealed, quenched and tempered conditions. The “chromoly” name comes from the principal alloying elements — chromium (Cr) and molybdenum (Mo) — which improve hardenability, strength and toughness relative to plain carbon steels.

Why choose a square tube form?

Square tubing provides predictable bending stiffness, convenient mount surfaces and higher torsional rigidity for a given cross-section compared with round tubing of similar weight. When the alloy is 4130, you gain a beneficial strength-to-weight ratio plus the ability to tailor properties with heat treatment and weld procedures. This combination explains why aircraft-quality frames, motorsport chassis and specialty structures often specify 4130 square tube.

Chemical composition (typical SAE/AISI 4130 ranges)

Below is a practical composition table—useful for engineering specifications and certificates of analysis. Ranges reflect common SAE/AISI (and equivalent EN/DIN) specifications; manufacturers may quote slightly different min/max tolerances on mill certificates.

| Element | Typical range (wt.%) |

|---|---|

| Carbon (C) | 0.28 – 0.33 |

| Silicon (Si) | 0.15 – 0.35 |

| Manganese (Mn) | 0.40 – 0.60 |

| Phosphorus (P) | ≤ 0.035 (max) |

| Sulfur (S) | ≤ 0.035 – 0.08 (max) (varies by spec) |

| Chromium (Cr) | 0.80 – 1.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

| Nickel (Ni) | ≤ 0.25 (max) |

| Copper (Cu) | ≤ 0.35 (max) |

| Iron (Fe) | Balance |

(Source references for composition ranges and typical mill limits.)

Common 4130 chromoly square tube specifications

Manufacturers and stock-holders sell 4130 square tube in a wide range of wall thicknesses and outside sizes. The table below lists representative sizes used commonly in motorsport, bicycle frames and structural applications.

| Outside size (inch) | Wall thickness (inch) | Weight (lbs/ft) — typical | Common use |

|---|---|---|---|

| 0.500 × 0.500 | 0.049 | 0.12 | Light frames, prototypes. |

| 0.750 × 0.750 | 0.065 | 0.30 | Medium-duty frames, supports. |

| 1.000 × 1.000 | 0.065 | 0.63 | Motorsport frames, sub-frames. |

| 1.500 × 1.500 | 0.120 | 1.8 | Heavy chassis members. |

| 2.000 × 2.000 | 0.120 | 2.8 | Structural applications, fabricated assemblies. |

Note: exact weight depends on wall tolerance and surface finish. For critical designs always request certified weight table and mill test report (MTR).

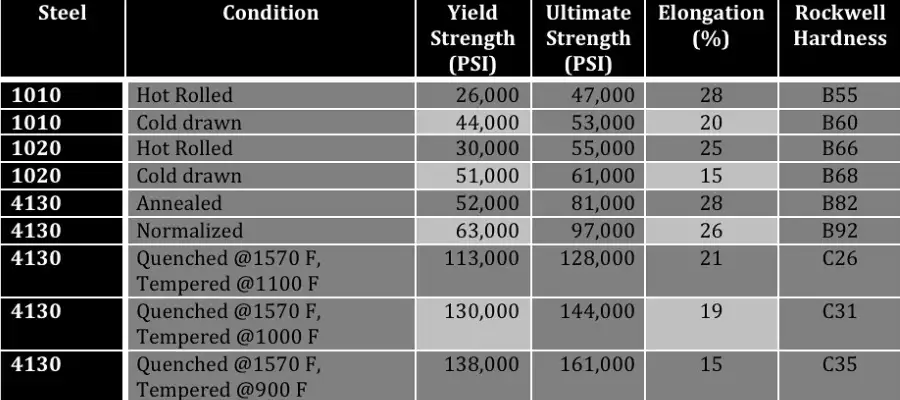

Mechanical properties

4130 properties vary widely with heat treatment. The following table summarizes commonly accepted, engineering-use values for normalized and typical quenched & tempered conditions. Use supplier MTRs for final design numbers.

| Condition | Tensile strength (MPa / ksi) | Yield strength (MPa / ksi) | Elongation (%) | Hardness (HB / HRC) |

|---|---|---|---|---|

| Annealed / normalized | 560 MPa (≈81 ksi) | 435–460 MPa (≈63–67 ksi) | 18–25% | HB ~180–220 |

| Quenched & tempered (moderate) | 700–950 MPa (≈102–138 ksi) | 450–850 MPa (≈65–123 ksi) | 8–18% | HB 200–380 (varies with temper) |

| Aircraft-quality normalized | 560–670 MPa (81–97 ksi) tensile typical; yield around 435–460 MPa. |

Engineering note: room-temperature impact toughness and fatigue strength depend on heat treatment, microstructure, and welding. For critical dynamic components, require supplier fatigue data or test coupons.

What is 4130 chromoly equivalent to?

SAE/AISI 4130 corresponds to several international equivalents frequently cited in procurement documents:

-

EN / DIN: 25CrMo4 (1.7218)

-

JIS (Japan): SCM430

-

GB (China): often referenced as 40CrMo or similar depending on exact spec; verify local designation on the MTR.

When writing purchase orders, specify the standard (e.g., “SAE 4130 per AMS 6345 / ASTM A29 / EN 25CrMo4” as required for your certs) and request an MTR showing the UNS or EN equivalence line so the mill certificate matches buyer expectations.

Differences: 4130 vs 4340

4130 and 4340 are both low-alloy steels but with different chemistry and intended uses:

-

4130 — chromium-molybdenum steel with lower carbon and no intentional nickel, optimized for good weldability, toughness and moderate hardenability. Common where a balance of machinability, weldability and strength is required.

-

4340 — a nickel-chromium-molybdenum steel with higher hardenability and higher strength capability; often used for highly stressed forgings, gears, shafts requiring very high toughness after heat treatment. 4340 typically attains higher tensile and yield strengths after appropriate heat treatment than 4130.

Practical implication: choose 4130 for welded frames and structural members where post-weld heat treatment is limited and ductility matters; choose 4340 for heavy forgings and components where maximum hardened strength and fatigue endurance are primary.

Fabrication, welding and heat-treatment notes

Weldability: 4130 is weldable using standard procedures (TIG, MIG, SAW) but requires attention to preheat, interpass, filler selection and — for high-strength service — post-weld heat treatment to avoid hydrogen cracking and to recover toughness in the HAZ. For thin-wall tubes used in bicycle or motorcycle frames, many fabricators use 4130 in a normalized or stress-relieved condition with matched filler (ER80S-D2/ER70S-2 depending on application).

Heat treatment guidance:

-

Anneal: heat to 760–780°C (1400–1435°F), furnace cool to soften for forming or machining.

-

Normalize: 870–900°C (1600–1650°F) air cool — used to refine grain and make mechanical properties more uniform.

-

Quench & temper: austenitize at ~830–870°C then oil/quench, temper to achieve desired hardness/strength balance. Always use controlled quench and temper cycles for predictable result. Typical practices and AMS/ASTM procedures should be referenced on purchase orders.

Recommendation for buyers: require full heat-treatment records on the MTR (temper temperature, quench medium, final hardness).

Corrosion, fatigue, and long-term performance

4130 is not stainless — alloying levels of chromium are insufficient for corrosion resistance comparable to stainless steels. For outdoor or corrosive environments, provide surface treatment (zinc plating, paint, powder coat) or use corrosion mitigation strategies. Fatigue resistance is reasonable for normalized or tempered conditions but is highly dependent on weld quality, surface finish and residual stress — all of which need specification in design and procurement documents.

2025 global price comparison

Prices for specialty alloy tubing like 4130 vary by quality (raw seamless vs finished mechanical tubing), quantity, finish, heat treatment and regional market factors (tariffs, energy cost, scrap price). The table below shows representative 2025 ranges aggregated from trade listings and wholesale channels; treat these as indicative and request quotes for firm pricing.

| Region / channel | Representative price (USD per tonne) — 2025 range | Notes / source |

|---|---|---|

| China — wholesale / factory (mill listings) | ~US$1,100 – US$1,400 / t | Chinese factory listings for AISI 4130 tubing show offers in this band for basic seamless tube volumes. Variance depends on QC and finishing. |

| India — domestic wholesale (round bar / rod listings) | ~US$1,200 – US$1,500 / t (≈ ₹110/kg listing ≈ US$1,250/t at Aug-2025 FX) | Local retail/wholesale listings indicate ₹110/kg as sample retail for bars (convert with market FX ~₹87.6/USD). Volume and finishing change final pricing. |

| USA — retail / small-quantity supply | US$4,000 – US$18,000 / t (retail, small orders & finished tubing) | U.S. retail cutters/metal service centers show significantly higher per-piece pricing for small quantities; manufacturer channel and industrial contracts are much lower per ton. |

| Europe — stock & service centers | US$2,500 – US$6,000 / t (typical distributor/stock prices) | Distributor pricing reflects certification, test reports, and logistic costs. Market outlooks and HRC baselines influence this band. |

Market context (2025): global steel benchmarks (HRC, CRC) and trade policy influence specialty alloy costs. Country-level import/export duty changes, freight and energy are material drivers. For finished, small-batch mechanical tubing (tight tolerances, small OD, polished finish, tested), expect retail premiums — sometimes multiple times the raw alloy mill price.

Buying tip: obtain FOB or EXW quotes from mills for bulk orders, and compare to local distributor landed prices for small orders; ask suppliers to show MTR, heat-treatment confirmation, and dimensional tolerance sheet.

Sourcing 4130 chromoly square tube — why choose MWAlloys

MWAlloys is a specialized supplier with direct factory relationships in China and a focus on alloy structural tubing. For buyers seeking repeatable quality and fast lead times, MWAlloys offers:

-

100% factory price advantage: direct-supply pricing model (no middleman markups) for most standard sizes.

-

Stock availability: common sizes of 4130 square tube held in inventory for rapid shipment to international buyers.

-

Documentation: full mill test reports (chemical & mechanical), NDT records where requested, and traceable heat-treatment data.

-

Export experience: regular shipments with proper export packing, customs paperwork and logistic partners experienced in alloy tubing.

If you require samples, MWAlloys can provide test coupons, short cut lengths and inspection photos prior to shipment. (Contact MWAlloys commercial team for an MOQ-tailored quote and delivery commitment.)

Purchase specification checklist

When issuing an RFQ / PO for 4130 chromoly square tube, include:

-

Exact grade and standard: SAE/AISI 4130 (or EN 25CrMo4)

-

Shape & size tolerance: outside dims, wall thickness tolerance, squareness tolerance

-

Heat treatment: normalized / quenched & tempered / as-drawn — specify temper temp and target hardness if required

-

Surface finish: black / bright / polished / OD tolerance / straightness

-

Required testing: MTR (EN 10204 3.1 or 3.2), PMI, hardness, tensile, NDT (if needed)

-

Quantity & packing: weight, pallets, wooden crates, export packaging

-

Delivery term: EXW / FOB / CIF and port of shipment

-

Special instructions: marking, traceability, certifications (e.g., ISO 9001 supplier, AMS, specific aerospace specs)

Including this information reduces ambiguity and shortens lead time for firm quotes.

FAQs

1. Is 4130 chromoly the same as “chromoly” used in bicycle frames?

Yes — “chromoly” broadly refers to the 41xx family; bicycle frames typically use 4130 in normalized or heat-treated conditions with thin walls.

2. Can 4130 be welded without preheat?

Thin-wall tube welding is often performed with minimal preheat, but thicker sections or high-hydrogen environments usually require preheat and controlled welding procedures. Use qualified weld procedure specifications for safety-critical parts.

3. What filler material should be used for 4130?

Common fillers are matching low-alloy weld wires such as ER80S series; choice depends on desired post-weld strength and toughness. Specification of filler metal should be in the welding procedure.

4. Is 4130 suitable for high-temperature service?

4130 performs acceptably up to ~315°C (600°F) in many cases, but prolonged high-temperature exposure reduces mechanical properties and may require a different alloy class.

5. How does 4130 compare cost-wise with 4140/4340?

4130 is usually less expensive than 4340 (which contains nickel and is more expensive to make) but specific pricing is volume and market dependent. See the 2025 price bands for context.

6. Are there standard dimension tables for 4130 square tube?

Yes — stock lists from distributors list common OD × wall thickness sets; however, always confirm wall tolerance and draw method (seamless vs ERW).

7. Does 4130 require post-weld heat treatment (PWHT)?

For highly stressed, fatigue-sensitive or safety-critical assemblies, PWHT is recommended to restore toughness and reduce residual stresses. For many light structural frames, designers rely on normalized condition and good welding practice.

8. Are there aerospace specifications for 4130?

Yes — certain 4130 variants are produced to aircraft-quality specifications (e.g., AMS or ASTM references). Specify the exact standard (AMS, ASTM) in POs for aerospace use.

9. How should I inspect incoming 4130 tubing?

Request MTRs, perform dimensional checks, confirm hardness and perform sample tensile tests or NDT per contract. Inspect weld seams (if ERW) and surface defects before acceptance.

10. What environmental finish should I request for outdoor use?

Ask for galvanizing, painting or powder coating. For long service life in corrosive atmospheres, consider corrosion-preventive coatings and design drains/venting to avoid trapped moisture.

Summary

4130 chromoly square tube remains a practical, cost-effective structural alloy for many engineering uses where good strength, toughness and weldability are required. Material choice should always be coupled with careful specification of heat-treatment, testing and welding procedures — and with supplier documentation (MTRs) required at the time of purchase. For buyers prioritizing rapid fulfillment, certified documentation and factory prices, MWAlloys can provide inventory, documentation packages and export logistics tailored to project timelines.