In the world of high-performance materials, NM400 and Hardox 400 are two of the most recognized wear-resistant steel grades used across various industries. Both steels are renowned for their hardness, strength, and durability, making them ideal choices for applications such as mining, construction, and agriculture. However, when it comes to selecting the right material for a specific project, it's essential to understand the differences between these two steel grades.

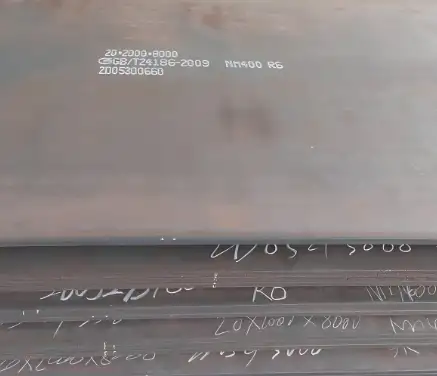

What is NM400 Steel?

NM400 is a high-strength, wear-resistant steel plate with a nominal hardness of 400 HBW. It is primarily used in applications where wear and tear resistance is crucial, such as in the mining and construction sectors. The steel is engineered to withstand high levels of abrasion, making it ideal for use in environments with frequent contact with abrasive materials.

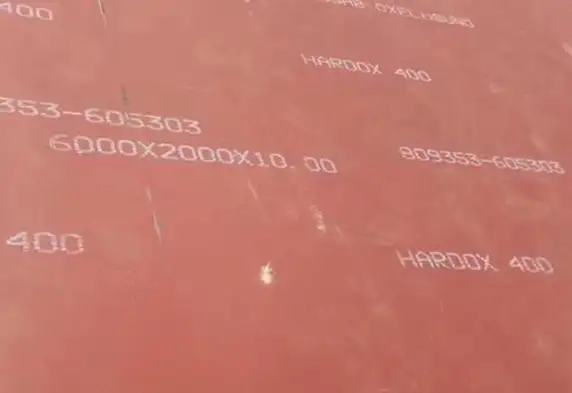

What is Hardox 400 Steel?

Hardox 400 is another premium wear-resistant steel designed for similar applications. Manufactured by SSAB, Hardox 400 features high hardness and toughness, making it highly effective in demanding applications. This steel is also used in the construction, mining, and agriculture industries, providing excellent resistance to impact, bending, and abrasion.

Chemical Composition Comparison

The chemical composition of NM400 and Hardox 400 plays a crucial role in determining their mechanical properties and performance in different environments. Here’s a detailed comparison:

| Element | NM400 | Hardox 400 |

|---|---|---|

| Carbon (C) | 0.24% | 0.22% |

| Silicon (Si) | 0.50% | 0.40% |

| Manganese (Mn) | 1.20% | 1.00% |

| Phosphorus (P) | 0.025% | 0.020% |

| Sulfur (S) | 0.015% | 0.010% |

| Chromium (Cr) | 0.90% | 0.90% |

| Nickel (Ni) | 0.40% | 0.50% |

| Copper (Cu) | 0.30% | 0.20% |

| Molybdenum (Mo) | 0.10% | 0.15% |

Mechanical Properties Comparison

Both NM400 and Hardox 400 are designed to deliver exceptional hardness and durability under extreme conditions. Below is a comparison of their mechanical properties:

| Property | NM400 | Hardox 400 |

|---|---|---|

| Hardness (HBW) | 400 HBW | 400 HBW |

| Tensile Strength | 900 MPa | 1000 MPa |

| Yield Strength | 700 MPa | 900 MPa |

| Elongation | 14% | 12% |

| Impact Toughness | -40°C | -40°C |

NM400 vs Hardox 400 Steel Specifications

While both steels have similar hardness levels, their specifications differ in terms of tensile and yield strength, which can affect performance in high-stress applications.

NM400:

-

Thickness: 3 mm – 100 mm

-

Width: Up to 3 meters

-

Length: Up to 12 meters

Hardox 400:

-

Thickness: 4 mm – 100 mm

-

Width: Up to 3 meters

-

Length: Up to 12 meters

NM400 Steel Equivalent Materials

Several materials offer similar properties to NM400. These include:

-

JFE EH400 (Japan)

-

Hardox 400 (Sweden)

-

Bisalloy 400 (Australia)

Hardox 400 Equivalent Materials

The equivalent materials to Hardox 400 include:

-

NM400 (China)

-

Bisalloy 400 (Australia)

-

JFE EH400 (Japan)

NM400 vs Hardox 400: Size and Weight Comparison

Both NM400 and Hardox 400 are available in a variety of sizes. The weight of these plates depends on the thickness and dimensions of the steel.

| Steel Grade | Thickness Range | Weight (per m²) |

|---|---|---|

| NM400 | 3 mm – 100 mm | 7.85 – 785 kg/m² |

| Hardox 400 | 4 mm – 100 mm | 7.85 – 785 kg/m² |

Global Prices for 2025: NM400 vs Hardox 400

In 2025, the pricing for NM400 and Hardox 400 is subject to fluctuations based on market conditions, but here is a rough estimate for global pricing:

| Steel Grade | Price (USD per ton) |

|---|---|

| NM400 | $900 – $1,100 |

| Hardox 400 | $1,200 – $1,500 |

Frequently Asked Questions (FAQs)

1. What are the main differences between NM400 and Hardox 400?

The primary differences between NM400 and Hardox 400 lie in their tensile strength, impact toughness, and cost. Hardox 400 offers slightly better tensile strength and impact toughness, making it a more premium option.

2. Is NM400 a good choice for heavy-duty applications?

Yes, NM400 is an excellent choice for heavy-duty applications due to its hardness and abrasion resistance.

3. Can NM400 be welded?

Yes, NM400 can be welded with appropriate techniques and equipment, though pre-heating and post-weld heat treatment may be necessary.

4. Is Hardox 400 more expensive than NM400?

Yes, Hardox 400 is generally more expensive than NM400 due to its premium quality and better performance in some applications.

5. How does NM400 compare to AR400 steel?

NM400 and AR400 are similar in terms of hardness, but NM400 typically offers better toughness and wear resistance.

6. Which steel is better for mining applications, NM400 or Hardox 400?

Both steels are suitable for mining, but Hardox 400 offers superior impact toughness, making it a better choice for applications involving frequent impacts.

7. What industries use NM400 and Hardox 400?

NM400 and Hardox 400 are used in industries such as construction, mining, agriculture, and material handling, where wear resistance is critical.

8. Can NM400 be used in marine environments?

NM400 is not typically recommended for marine environments due to its susceptibility to corrosion. Stainless steel or other corrosion-resistant materials are better choices.

9. Are NM400 and Hardox 400 corrosion-resistant?

Both steels have limited corrosion resistance. For corrosive environments, consider using materials like stainless steel.

10. How does the tensile strength of NM400 compare to other wear-resistant steels?

NM400 offers excellent tensile strength, but Hardox 400 and other high-performance wear-resistant steels may offer slightly superior tensile strength.

Conclusion:

Choosing between NM400 and Hardox 400 depends on the specific needs of your application. NM400 is a great choice for cost-effective wear-resistant solutions, while Hardox 400 offers superior performance in high-impact and high-stress applications. Both materials are highly durable, but understanding the nuances of their mechanical properties, equivalent materials, and price points is crucial for making the right decision for your business.

For high-quality NM400 and Hardox 400 steel plates, MWalloys is a trusted supplier offering competitive factory direct prices and custom steel solutions tailored to your needs.