MPa (megapascal) and psi (pound-force per square inch) are both measures of pressure or stress; MPa is the SI metric unit (1 MPa = 1,000,000 Pa = 1 N/mm²) and psi is the imperial/US customary unit (1 psi ≈ 6,894.757 Pa). For engineering and materials data you will usually see strength given in MPa (or N/mm²) internationally and in psi (or ksi) in older U.S. sources — you can convert exactly using 1 MPa = 145.03773773 psi (≈145.0377) or 1 psi = 6,894.7572931783 Pa.

Definitions — what are the MPa and psi means

MPa (megapascal). The pascal (Pa) is the SI derived unit of pressure and stress, defined as one newton per square metre (1 Pa = 1 N/m²). A megapascal (MPa) is 10⁶ pascals and is widely used in engineering because the pascal itself is very small; in mechanical properties and structural work MPa is the conventional unit.

psi (pound-force per square inch). The common abbreviation “psi” stands for pound-force per square inch (lbf/in²). It is the pressure produced by one pound-force acting on an area of one square inch and is prevalent in the United States and in historical specifications for pressure equipment and materials.

(From a dimensional viewpoint both are pressure or stress units: force divided by area. The difference is only the unit system and scale.)

Quick conversion rules and exact factors

These are the conversions you will use most often:

-

1 MPa = 1 N/mm² (this equivalence is exact because 1 MPa = 1,000,000 N/m² and there are 1,000,000 mm² in 1 m²).

-

1 MPa = 145.03773773 psi (≈ 145.0377).

-

1 psi = 6,894.7572931783 Pa (≈ 6,894.7573 Pa).

-

1 ksi = 1,000 psi = 6.894757 MPa (useful for tensile strength expressed as ksi in U.S. literature).

Notes on precision: For most engineering work round to 3–6 significant figures depending on tolerances (e.g., 1 MPa = 145.038 psi for three decimal digits). For instrument calibration or legal documents follow the standard rounding rules in the applicable test method (ASTM/ISO).

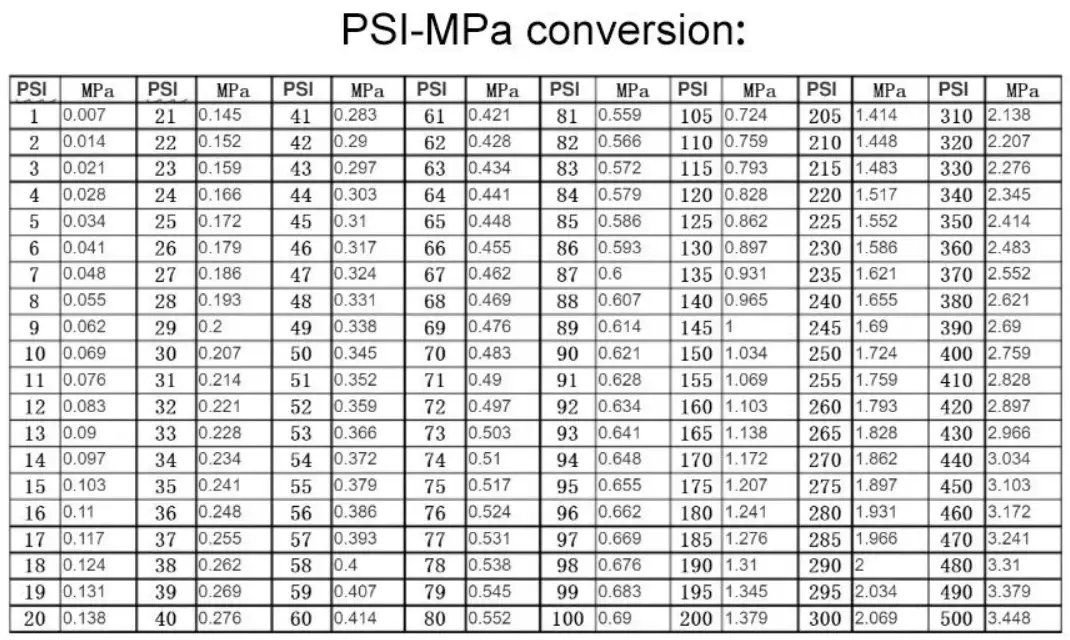

Quick-reference conversion table (handy)

| MPa | psi (≈) | ksi (≈) |

|---|---|---|

| 0.1 | 14.5038 | 0.01450 |

| 1 | 145.0377 | 0.14504 |

| 5 | 725.1887 | 0.72519 |

| 10 | 1,450.377 | 1.45038 |

| 20 | 2,900.755 | 2.90075 |

| 50 | 7,251.887 | 7.25189 |

| 100 | 14,503.774 | 14.50377 |

| 250 | 36,259.434 | 36.25943 |

| 500 | 72,518.869 | 72.51887 |

(Table values based on 1 MPa = 145.03773773 psi.)

Formulas and worked examples

Basic conversion formulas

From MPa to psi:

psi=MPa×145.03773773

From psi to MPa:

MPa=psi÷145.03773773

From psi to Pa:

Pa=psi×6894.7572931783

From Pa to MPa:

MPa=Pa÷1000000

Example 1 — converting tensile strength: A steel grade lists yield strength 250 MPa. In psi:

250 MPa×145.03773773≈36,259.43 psi

So this is commonly presented as 36.26 ksi.

Example 2 — converting pressure: A hydraulic system rated at 2,500 psi:

2,500÷145.03773773≈17.236 MPa

So a 2,500 psi system is about 17.24 MPa.

Use the exact factors (above) when you need traceable conversions; round only for presentation consistent with drawing or specification precision.

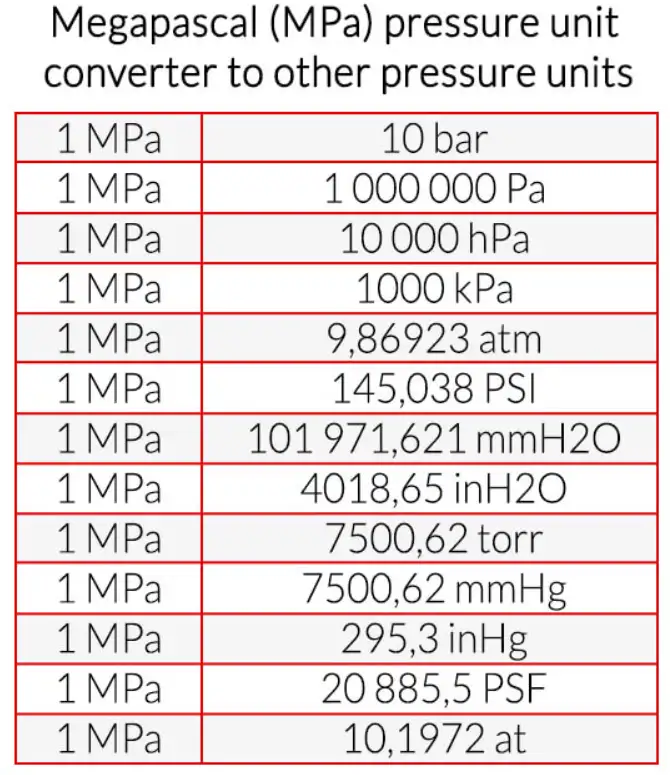

Relation to other units (bar, kPa, atm, ksi, N/mm²)

| Unit | Relationship |

|---|---|

| 1 Pa | 1 N/m² |

| 1 kPa | 1,000 Pa |

| 1 MPa | 1,000 kPa = 1,000,000 Pa = 1 N/mm² |

| 1 bar | 100,000 Pa = 0.1 MPa |

| 1 atm (standard) | 101,325 Pa ≈ 0.101325 MPa |

| 1 psi | 6,894.757293 Pa ≈ 0.006894757 MPa |

| 1 ksi | 1,000 psi ≈ 6.894757 MPa |

These equivalences let you move between pressure units used in hydraulics, standards, geotechnical fields and metallurgical property sheets without semantic mistakes.

Why engineers commonly use MPa — and why psi still exists

MPa advantages

-

MPa (and the broader SI family) are consistent with SI base units used across physics and materials science; calculations that mix stress, modulus, and energy density are simpler when everything uses newtons and metres. For tensile and yield strengths, MPa is directly equivalent to N/mm² which makes cross-sectional stress arithmetic neat.

Why psi persists

-

Many U.S. codes, older machine and hydraulic literature, and equipment specifications still use inches and pounds; maintenance manuals, pressure gauge faces, and some API/ASME documents are in psi. In industries where legacy documentation dominates (oil & gas, field hydraulics), psi and ksi remain in daily use.

Practical tip: Always record the unit in drawings, test reports and procurement specs. When sending material properties to an international purchaser, include both MPa and psi to avoid misinterpretation.

MPa, psi and material test standards (ASTM, ISO)

In tensile testing and material certifications the unit choice is standardized:

-

ASTM E8 / E8M (tension testing of metals) accepts values in both systems; ASTM E8 historically uses inch-pound units (psi) while E8M uses SI units (MPa). Readout rounding rules and specimen geometry are part of the standard.

-

ISO 6892-1 (metallic materials — tensile testing at room temperature) specifies reporting in MPa (N/mm²) and gives procedures for strain rates and test methods used internationally. For global procurement and certification ISO wording and units are often decisive.

Practical example: A test report from a lab following ISO 6892-1 will give yield and ultimate tensile strength in MPa (N/mm²). A U.S. customer may request equivalence in psi or ksi: the conversion above is exact and commonly used in certificates of conformity.

Measurement devices, transducers and calibration notes

Pressure transducers commonly provide outputs in multiple units; most configurable transducers allow selecting kPa, MPa, psi, bar or mbar. When specifying sensors for a system choose the unit that simplifies operator interpretation (e.g., psi for a field operator used to imperial units; MPa for lab test rigs).

Calibration and traceability

-

For legal metrology and laboratory calibration, follow a national metrology institute (NMI) traceability chain (e.g., NIST in the U.S.). Conversion between units is mathematical, but instrument calibration must be traceable to primary standards to ensure accuracy.

Transducer selection tip: Match the sensor accuracy class and the expected operating range; avoid using a transducer with a full scale much higher than the operating point because resolution and accuracy can suffer.

Common pitfalls, rounding and specification mistakes

-

Missing unit labels — drawings that list “yield = 250” are ambiguous: 250 what? Always state MPa or psi.

-

Mismatched rounding — converting a rounded MPa value to psi and re-rounding can introduce small errors; where possible convert from the raw measurement not the rounded label.

-

Confusing pressure vs. force — don’t mix Newtons (force) with pascals (force per unit area). Typical error in field calculations.

-

Assuming equivalence of “bar” and “MPa” without conversion — 1 bar = 0.1 MPa, not 1 MPa.

-

Using inconsistent test standards — ISO and ASTM may specify different specimen geometry and reporting conventions; check the contract’s referenced standard before performing tensile tests.

Useful engineering tables: material properties in MPa and psi

Below are representative numbers — use only for quick orientation; always refer to material certificates for exact, certified values.

Table A — Representative strength ranges

| Material / condition | Typical UTS (MPa) | Typical UTS (psi) |

|---|---|---|

| Low-carbon steel (structural) | 350–550 MPa | 50,763–79,768 psi |

| Mild steel (hot-rolled) | ~400 MPa | ~58,015 psi |

| High-strength structural steel | 500–700 MPa | 72,518–101,526 psi |

| 304 stainless (annealed) | 515–720 MPa | 74,669–104,427 psi |

| 6061-T6 aluminum | ~310 MPa | ~44,963 psi |

| Concrete (compressive, typical structural) | 20–40 MPa | 2,901–5,801 psi |

| Cast iron (gray, compressive) | 100–300 MPa | 14,504–43,511 psi |

(Conversions: MPa × 145.0377 ≈ psi). These are ballpark engineering ranges; material certificates and standards must be used for design.

Table B — Common pressure system ranges (for selection)

| Application | Typical pressure in MPa | Typical pressure in psi |

|---|---|---|

| Automotive brake systems | 10–20 MPa | 1,450–2,900 psi |

| Hydraulic systems (industrial) | 7–35 MPa | 1,015–5,076 psi |

| High-pressure hydraulic press | 100–350 MPa | 14,504–50,760 psi |

| Gas pipelines (distribution) | 0.1–5 MPa | 14.5–725 psi |

Use these ranges to match seals, fittings and pressure transducers.

Practical workflow: what unit to pick, when

-

Designing in metric environments (international, lab, research): use MPa / N/mm² throughout. Saves unit conversions and reduces risk of mismatch with material data sheets.

-

Working with U.S. legacy equipment or field teams: present both values but use psi on control panels and gauge faces if the crew is accustomed to imperial units.

-

Procurement and certificates: include both units on purchase orders and certificates of conformity (e.g., “Yield strength: 250 MPa (36.26 ksi)”), and explicitly reference the test standard (ASTM E8 / ISO 6892-1) the certificate follows.

FAQs

-

Q: Is MPa the same as N/mm²?

A: Yes, 1 MPa = 1 N/mm² exactly. This is a standard equivalence used in materials testing. -

Q: How many psi are in 1 MPa?

A: 1 MPa = 145.03773773 psi (use 145.038 for three decimal places). -

Q: How many MPa are in 1,000 psi?

A: 1,000 psi ≈ 6.894757 MPa (1,000 ÷ 145.03773773). -

Q: Should material certificates use MPa or psi?

A: Use the unit required by the governing contract or standard. ISO/European contracts favor MPa; some U.S. customers still request psi/ksi. Include both if in doubt. -

Q: Which unit is used for Young’s modulus?

A: Young’s modulus in most literature is reported in GPa (gigapascals) or MPa (when values are low). For steel E ≈ 210 GPa (not psi). -

Q: If a drawing lists 250 yield, how do I verify units?

A: Confirm by document header or the specification note; if unspecified, query the author — never assume. If the drawing references ISO/ASTM, use the units those standards prescribe. -

Q: Are conversions exact or approximate?

A: The mathematical conversion factors are exact to the defined numerical constants (1 inch = 0.0254 m exactly). Practical values are usually presented with limited significant digits. For traceable work use the exact factors. -

Q: How to convert a gauge reading in psi to MPa for an automated control loop?

A: Use the exact conversion factor in the PLC: MPa = psi ÷ 145.03773773. Implement scaling in the analog/digital input mapping and verify calibration after configuration. -

Q: Is bar or kPa better for pneumatics?

A: Both are common; kPa/bar are convenient because air system pressures are moderate. 1 bar = 100 kPa = 0.1 MPa. Choose whichever matches operator conventions and instrument scales. -

Q: How do ASTM and ISO rounding rules affect conversions?

A: Standards like ASTM E8 specify rounding conventions (e.g., nearest 1 MPa or 100 psi depending on range). When converting test data for certificates, follow the standard’s rounding and reporting rules.

Worked conversion examples for metallurgists

Example: Converting a steel spec

Spec shows: Minimum yield 355 MPa. The buyer wants psi.

-

Multiply: 355 × 145.03773773 = 51,441.38 psi.

-

Apply certificate rounding per ASTM/ISO (e.g., round to nearest 100 psi or as the standard says): present as 51,400 psi (if rounding to 100 psi) or 51.44 ksi depending on expected precision.

Example: Field pressure

Pressure gauge shows 3000 psi. For engineering calculation you need MPa:

3000 ÷ 145.03773773 ≈ 20.68 MPa.

Tips to avoid mistakes in procurement and testing

-

Insist that material test reports (MTRs) include the test standard reference (ASTM E8, ISO 6892-1 etc.) and unit label.

-

For international trade place both units on purchase orders and certificates of conformity. Example line: “Yield strength: 355 MPa (min) / 51,441 psi (min).”

-

In spreadsheets keep one canonical unit column (e.g., MPa) and auto-compute conversions; do not manually retype converted numbers.

Closing summary

-

Memorize the two key factors: 1 MPa ≈ 145.0377 psi and 1 MPa = 1 N/mm².

-

Always label units on drawings and certificates.

-

Reference the test standard (ASTM E8 / ISO 6892-1) when giving material strengths or ordering mechanical testing.

-

For traceability and calibration rely on national metrology references (NIST or equivalent) when precision matters.

Authoritative references

- NIST — Pressure and gas flow unit conversions (NIST Physical Measurement Laboratory)

- ISO 6892-1:2019 — Metallic materials — Tensile testing at room temperature (ISO)

- ASTM E8 / E8M — Standard Test Methods for Tension Testing of Metallic Materials (ASTM International)

- Wikipedia — Pound per square inch (psi) (background, conversions and context)