High-performance nickel-based alloys such as Inconel®, Hastelloy®, and Monel® are essential for critical applications in oil & gas, chemical processing, aerospace, and power generation. MWAlloys offers a comprehensive global sourcing solution, leveraging China-based manufacturing, 100% factory-direct pricing, rapid delivery of stocked items, and full customization support to meet stringent industry requirements.

Alloy Families and Characteristics

Inconel® Alloys

Inconel grades (e.g., 600, 625, 718) exhibit exceptional oxidation and corrosion resistance at temperatures up to 1,200 °C. Key traits include:

-

Nickel-chromium base.

-

High tensile strength.

-

Resistance to chloride-induced stress corrosion cracking.

Hastelloy® Alloys

Hastelloy variants (C-276, B-2, X) excel in highly corrosive chemical environments:

-

Nickel-molybdenum-chromium matrix.

-

Outstanding pitting and crevice corrosion resistance.

-

Stability in oxidizing and reducing conditions.

Monel® Alloys

Monel grades (400, K-500) combine moderate strength with superior resistance to seawater and salt environments:

-

Nickel-copper base.

-

Work hardening capacity.

-

Good mechanical properties down to cryogenic temperatures.

Core Applications

-

Oil & Gas Production: Wellhead components, downhole tools (Inconel 718, Monel K-500).

-

Chemical Processing: Reactors, piping, heat exchangers (Hastelloy C-276).

-

Aerospace: Turbine disks, combustor liners (Inconel 718).

-

Power Generation: Gas turbines, nuclear steam generator tubing (Alloy 600).

-

Marine Engineering: Propeller shafts, valves (Monel 400).

Market Drivers and Trends

-

Stringent Regulations: Emission control and petrochemical safety standards demand corrosion-resistant alloys.

-

Energy Transition: Growth in hydrogen, CO₂ capture, and LNG sectors expands superalloy usage.

-

Supply Constraints: Limited nickel and molybdenum availability pressures prices.

-

Regional Manufacturing Shifts: Asia-Pacific capacity expansion vs. Western supply chain resilience.

Supply Chain Considerations

-

Raw-Material Sourcing: Nickel cathodes, ferrochrome, molybdenum.

-

Mill Processing: Vacuum induction melting, forging, rolling, age hardening.

-

Testing & Certification: ASTM, ASME, AMS standards; mechanical testing; NDT (ultrasonic, eddy current).

-

Logistics Management: Inventory hubs in Asia, Europe, North America.

-

Risk Mitigation: Dual-sourcing, long-term agreements, stock buffer strategies.

Supplier Selection Criteria

-

Quality Systems: ISO 9001, PED, NACE MR0175 / ISO 15156 compliance.

-

Traceability: Mill certificates, lot trace reports, material test reports (MTRs).

-

Customization Capability: Special alloys, tight tolerances, complex geometries.

-

Service Levels: Standard vs. expedited production, stocked items availability, JIT delivery.

-

Cost & Total Value: Factory-direct pricing, inventory carrying costs, tariff considerations.

MWAlloys: Your Strategic Partner

MWAlloys stands out by combining:

-

Factory-Direct Advantage: Eliminates distributor markups, ensuring 100% direct pricing.

-

Custom Services: Tailored alloy development, machining, machining, surface treatments.

-

Inventory Network: Stocked lengths and bars for rapid dispatch—standard Inconel, Hastelloy, Monel grades.

-

Quality Assurance: Rigorous in-house testing; full adherence to ASTM, AMS, EN, and JIS standards.

-

Global Reach: Export experience spanning North America, Europe, Middle East, and Asia-Pacific.

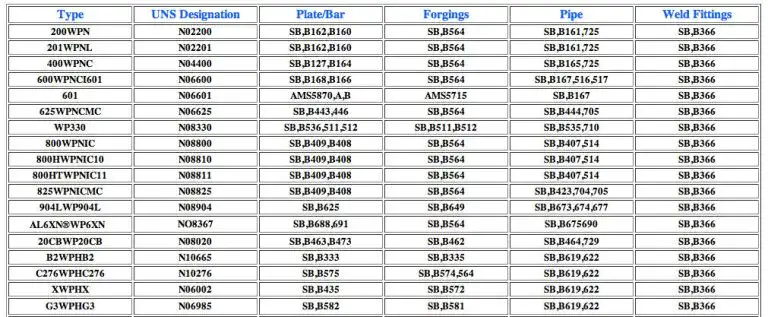

Alloy Grades Reference Table

| Alloy Family | Grade | UNS Number | Composition Highlights | Typical Use Temperature |

|---|---|---|---|---|

| Inconel | 600 | N06600 | Ni-16Cr-8Fe | up to 600 °C |

| Inconel | 625 | N06625 | Ni-22Cr-9Mo-3Nb | up to 650 °C |

| Inconel | 718 | N07718 | Ni-19Cr-3Mo-5Nb-Ti-Al | up to 700 °C |

| Hastelloy | C-276 | N10276 | Ni-16Cr-16Mo-4W | wide chemical range |

| Hastelloy | B-2 | N10665 | Ni-28Mo | reducing environments |

| Monel | 400 | N04400 | Ni-67Cu | cryogenic – marine |

| Monel | K-500 | N05500 | Ni-63Cu-2.5Al-2.5Ti | high strength marine |

Common Alloy Products Table

| Product Form | Alloy Grades | Standard Sizes | End Markets |

|---|---|---|---|

| Bar/Round | Inconel 625, 718; Monel 400 | Ø6 mm–Ø500 mm; lengths 1–6 m | Aerospace, Oil & Gas |

| Sheet/Plate | Inconel 600; Hastelloy C-276 | 1–50 mm thick; up to 2 m wide | Heat exchangers |

| Pipe/Tubing | Inconel 600; Monel K-500 | 1/2″–24″ OD; Schedule 10–160 | Chemical Processing |

| Fittings/Flanges | Hastelloy B-2; Monel 400 | ANSI B16.5; ASME B16.47 | Marine, Power |

| Wire/Welding Rod | Inconel 718; Hastelloy C-276 | Ø0.5 mm–Ø6 mm | Joining applications |

2025 Global Price Comparison

| Alloy Grade | North America (USD/kg) | Europe (EUR/kg) | Asia-Pacific (USD/kg) | China (USD/kg) – MWAlloys |

|---|---|---|---|---|

| Inconel 625 | 55–60 | 50–55 | 48–52 | 45–50 |

| Inconel 718 | 58–63 | 53–58 | 50–55 | 47–52 |

| Hastelloy C-276 | 85–92 | 80–88 | 78–85 | 75–82 |

| Monel 400 | 40–44 | 38–42 | 35–40 | 33–38 |

Prices reflect spot market averages as of Q2 2025, excluding VAT/duties.

Case Examples

-

Offshore Platform Valves: A North Sea operator reduced procurement costs by 18% using MWAlloys’ stocked Inconel 625 fittings with expedited shipment.

-

Chemical Reactor Piping: European chemical plant transitioned to Hastelloy C-276 pipes sourced from MWAlloys, achieving zero pitting incidents over two years.

-

Aerospace Component Blanks: Tier-1 engine manufacturer adopted MWAlloys’ custom Inconel 718 forgings, cutting lead time by 25%.

Frequently Asked Questions

-

What distinguishes Inconel from Hastelloy?

Inconel prioritizes high-temperature oxidation resistance, while Hastelloy focuses on superior corrosion resistance in aggressive chemical media. -

How does MWAlloys guarantee alloy traceability?

Every batch includes full Mill Test Reports (MTRs), heat numbers, and third-party inspection upon request. -

Can MWAlloys supply custom alloy formulations?

Yes. R&D capabilities allow modified chemistries for specific project challenges, pending feasibility and minimum order quantities. -

What lead times apply to standard stocked items?

In-stock bars, plates, and fittings ship within 5–7 business days; custom orders vary with order size (typically 4–8 weeks). -

Which certifications does MWAlloys maintain?

ISO 9001, PED Module H, NACE MR0175, and customer-specific approvals (e.g., API, ASME). -

Are small-volume orders accepted?

Yes. MOQ for stocked grades can be as low as 10 kg; custom alloy batches may require 500 kg. -

How are prices affected by raw-material fluctuations?

Pricing is reviewed monthly; long-term agreements can lock in rates or include floor/ceiling clauses. -

Is MWAlloys able to supply finished components?

Beyond mill products, we partner with CNC and fabricators to deliver ready-to-install parts. -

What packaging standards are used?

Standard export crating with moisture-proof paper, fumigation compliance, and protective end caps for tubes. -

How to request a quotation?

Provide alloy grade, form, dimensions, quantity, and any certification requirements via our online RFQ portal or direct email.