Hastelloy alloys are a family of nickel-based, corrosion-resistant superalloys engineered for the harshest chemical and high-temperature environments. For most chemical-processing and high-chloride applications, Hastelloy C-276 and C-22 remain the default choices because they combine broad resistance to both oxidizing and reducing media with reliable weldability; Hastelloy B-2 is preferred in strongly reducing acid environments (for example concentrated hydrochloric acid); and Hastelloy X and N are chosen where high-temperature strength and oxidation resistance matter. When specifying a Hastelloy grade, match the alloy chemistry and form (plate, bar, tube, weld filler) to the fluid, temperature, and mechanical load — that single decision usually determines long-term performance and total life-cycle cost.

How Hastelloys are named and grouped (quick primer)

-

“Hastelloy” is a tradename originally associated with Haynes-developed nickel alloys; the family includes dozens of grades identified by letters and numbers (C-276, C-22, B-2, X, N, G-30, G-35, etc.). Haynes and other manufacturers provide the standard UNS designations (for example C-276 = UNS N10276, C-22 = UNS N06022, B-2 = UNS N10665).

-

Two practical groupings used in engineering selection:

-

High corrosion resistance (aqueous) — e.g., C-276, C-22, G-30/G-35.

-

Resistance to strongly reducing acids (low or no Cr) — e.g., B-2.

-

High-temperature alloys — e.g., X, N (designed for oxidation and creep resistance).

-

What are the grades of hastelloy?

| Grade | UNS | Typical application envelope | Fabrication / welding notes |

|---|---|---|---|

| Hastelloy C-276 | N10276 | Broad chemical resistance: oxidizing & reducing media, chlorides, organic acids; chemical process equipment, exchangers, valves. | Weldable in as-welded condition; low C minimizes precipitation. |

| Hastelloy C-22 | N06022 | Superior resistance to localized corrosion (pitting/crevice) and stress-corrosion cracking in oxidizing media (wet chlorine, ferric/chloride environments). | Excellent weldability; preferred where oxidizing contaminants possible. |

| Hastelloy B-2 | N10665 | Exceptional resistance to hydrochloric and other strong reducing acids. Not suitable for oxidizing environments. | Usually used in as-welded condition; avoid where oxidizers or ferric salts are present. |

| Hastelloy X | N06002 | High-temperature oxidation and creep resistance — gas turbines, furnace components, structural parts at >>600°C. | Good strength at elevated T; forged/annealed processing required. |

| Hastelloy N | N10003 | Molten fluoride salts / molten salt reactors and high-T fluoride salt compatibility; also good high-T oxidation resistance. | Developed for molten salts; consult nuclear/ORNL heritage data. |

| Hastelloy G-30 / G-35 | N06030 / N06035 | Designed for “wet-process” phosphoric acid and other oxidizing acid conditions (G-35 has very high Cr). | G-35 improves on G-30 for phosphoric acid evaporators and caustic de-alloying resistance. |

(This table is a condensed selection; many other Hastelloy variants exist for niche uses.)

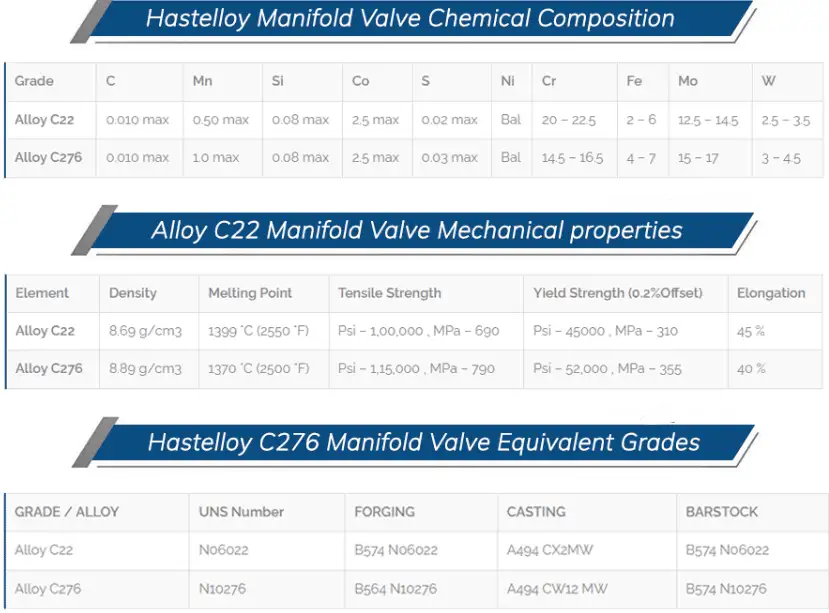

Representative chemical compositions (nominal)

Below are nominal compositions for the most commonly specified Hastelloy grades. Use manufacturer datasheets for final procurement specifications and tolerance bands.

Hastelloy C-276 (UNS N10276) — nominal (wt.%)

| Element | Typical (%) |

|---|---|

| Ni | Balance (~57) |

| Cr | 14.5 – 16.5 |

| Mo | 15.0 – 17.0 |

| W | 3.0 – 4.5 |

| Fe | 4.0 – 7.0 |

| Co | ≤2.5 |

| Mn | ≤1.0 |

| Si | ≤0.08 |

| C | ≤0.01 |

| (Sources: Haynes / manufacturer datasheets, AZoM, MatWeb.) |

Hastelloy C-22 (UNS N06022) — nominal (wt.%)

| Element | Typical (%) |

|---|---|

| Ni | Balance |

| Cr | ~22 |

| Mo | ~13 |

| W | ~4 |

| Fe | ~3 – 5 |

| Co | ≤2 |

| C | 0.01 max |

| (Source: Haynes / ASM digest.) |

Hastelloy B-2 (UNS N10665) — nominal (wt.%)

| Element | Typical (%) |

|---|---|

| Ni | ~68 |

| Mo | ~28 |

| Fe | ≤2 |

| Cr | ~1 |

| C | ≤0.02 |

| (B-type alloys have very low chromium by design to avoid oxidizing susceptibility.) |

Hastelloy X (UNS N06002) — nominal highlights

| Element | Typical (%) |

|---|---|

| Ni | Balance |

| Cr | ~22 |

| Fe | ~18 |

| Mo | ~9 |

| Co | ~1 |

| (High-temperature solid-solution alloy; check Haynes technical sheet for mechanical properties vs temperature).) |

Hastelloy N (UNS N10003) and G-35 (UNS N06035)

Nominal chemistries for N and G-35 are available from Haynes; G-35 is high-Cr (~33%) with Mo ~8%; N is Ni-Mo-Cr tailored for molten salt service.

Note: Nominal values above are for quick specification. Final acceptance must reference the supplier certificate (mill test report / MTR) and ASTM/EN purchase specifications (for example ASTM B-575/B-622 for C-276 pipes/plates).

What is the difference between hastelloy B and C?

-

Hastelloy B (e.g., B-2) is a nickel-molybdenum alloy with very low chromium. It’s engineered for strongly reducing acids (most notably hydrochloric acid) and resists chloride attack in non-oxidizing environments.

-

Hastelloy C (e.g., C-276, C-22) are nickel-chromium-molybdenum (±tungsten) alloys with substantial chromium. They’re designed for broad-spectrum resistance, including oxidizing and reducing media, and they have much better resistance to pitting, crevice corrosion and stress-corrosion cracking in chloride/oxidizing environments.

comparison table

| Aspect | Hastelloy B (B-2) | Hastelloy C (C-276 / C-22) |

|---|---|---|

| Main chemistry | Ni + high Mo, very low Cr | Ni + Cr + Mo (often W too) |

| Typical UNS | N10665 | N10276 (C-276), N06022 (C-22) |

| Best for | Strongly reducing acids (e.g., concentrated HCl) | Mixed/oxidizing media, chlorides, organics — broad resistance |

| Pitting/crevice resistance | Poor (vulnerable if oxidizers present) | Good — especially C-22 with higher Cr |

| Oxidizing acids (e.g., nitric) | Not suitable | Generally suitable (choose C-22/C-276 depending on chemistry) |

| Weldability & fabrication | Weldable but must avoid oxidizing contamination | Good weldability; C-276 often used as-welded; follow supplier guidance |

| Typical applications | Pickling lines, HCl service, reducing acid tanks | Chemical process equipment, exchangers, valves, seawater/chloride service |

Practical selection rules

-

If the service includes oxidizers (ferric salts, nitric acid, chlorine, or oxygenated chlorides) choose a C grade (C-22 or C-276).

-

If the service is strongly reducing (concentrated HCl, certain chloride-free reducing chemistries) then B-2 is often the correct choice.

-

For uncertain or mixed environments, C-276 (broad resistance) or C-22 (high pitting resistance) are usually safer choices.

Typical mechanical & physical properties (practical numbers)

Below are representative property ranges in the annealed or solution-treated condition. Always confirm for the exact product form.

-

Density: ~8.9 g/cm³ for many Ni-Mo-Cr Hastelloys (varies slightly by grade).

-

Tensile strength (annealed): generally ~650–900 MPa depending on grade and heat treatment (Hastelloy X at elevated temperature is stronger).

-

Yield (0.2% offset): typically 200–500 MPa in annealed condition (grade and temp dependent).

-

Maximum continuous service temperature: for corrosion grades (C-276/C-22/B-2) typically up to ~800–900°F (430–480°C) for short periods; high-temperature alloys (X) hold strength well above 1000°F (538°C).

(Because mechanical data vary with product form, thickness and heat treatment, quote manufacturer tables for design.)

Fabrication and welding notes — what an engineer must know

-

Weldability: Most Hastelloys (C-276, C-22, B-2, G-30/G-35) are readily welded using appropriate nickel-based filler metals; C-276 was chosen historically for its as-welded performance (low C, low Si) which reduces intermetallic precipitation. Refer to Haynes welding guidelines for preheat and post-weld heat treatment requirements.

-

Machinability: Hastelloys are tougher to machine than stainless steels because of high nickel and molybdenum; use rigid tooling, reduced speeds, and adequate coolant.

-

Forming: Cold and hot forming are possible but annealing/solution heat treatments are typically required to restore ductility and corrosion resistance after heavy working.

2025 price snapshot — global comparison (practical ranges)

Prices for Hastelloy are volatile and depend on alloy, product form (bar, plate, pipe), quantity, and delivery terms (EXW/FOB/DEL). Below is a sourced 2025 snapshot compiled from regional market indexes and supplier price lists (ranges are indicative and intended for budgeting only).

| Region | Representative 2025 price (Hastelloy C-276, indicative) | Source / notes |

|---|---|---|

| North America | ~USD 50–90 / kg (Q1 2025 index ~USD 51,940/MT ≈ USD 51.9/kg; some fabricated forms higher). | Chemanalyst Q1 2025 price index; supplier quotes vary. |

| Europe | ~USD 45–100 / kg (marketed EX-works / distributor premiums). | European price indices & distributor lists (varies with form). |

| China / APAC | ~USD 8–40 / kg (raw plate/bar offers on B2B marketplaces; lower FOB Shanghai quotes reported) — broad variance due to spot / small-lot listings. | Made-in-China / Alibaba / local suppliers show low unit prices for small lots; exercise caution. |

| India / S. Asia | ~USD 40–90 / kg (stockist quotes; often intermediate between China and Western distributors). | Regional stockist lists and pricing portals. |

Important caveats:

-

The Chemanalyst index gives a reliable market indicator (Q1 2025 C-276 North America ~USD 51,940/MT). Supplier web listings on B2B marketplaces frequently show promotional or small-lot prices that exclude certification, testing, machining, export controls and freight — expect delivered, certified material to cost more.

-

Prices differ by product form: plate vs round bar vs seamless pipe vs welded tube; seamless pipe and certified forgings command a premium.

Selecting the correct Hastelloy — practical decision flow

-

Define the service environment: oxidizing or reducing? presence of chlorides? fluoride salts? temperature?

-

Map to chemistry: If oxidizing + chlorides → C-22 (higher Cr). If mixed/uncertain media or broad resistance required → C-276. If strong reducing acids (HCl) → B-2. If molten fluoride salts or reactor environment → N. If high-temperature structural duty → X.

-

Decide fabrication needs: required welding, post-weld heat treatment, and availability of certified forms.

-

Procure with MTR and traceability: always request a mill test report and conformity to ASTM/EN standards (for example ASTM B-575/B-622 for plates/pipes).

Environmental and regulatory considerations

-

For pressure-retaining components, follow applicable codes (ASME, PED) and include qualified welding procedures and NDT. Material substitution must be validated via corrosion testing or referencing manufacturer iso-corrosion diagrams when service is aggressive.

-

Some Hastelloy types (e.g., those with high cobalt) may have traceability/REACH considerations in Europe — check regulatory compliance for the target market.

Frequently asked questions

-

Which Hastelloy is best for chloride-rich seawater service?

For chloride-bearing aqueous service, C-22 and C-276 are top candidates; C-22 typically has superior resistance to pitting and crevice corrosion due to higher chromium content. Always validate with specific water chemistry tests. -

Can Hastelloy B-2 be used in nitric acid?

No. B-2 is excellent for reducing acids like HCl but is not intended for oxidizing acids (nitric). Use high-Cr Hastelloys (G-35/C-22) for nitric environments. -

Is Hastelloy C-276 weldable without post-weld heat treatment?

In most standard chemical processing applications, C-276 can be used in the as-welded condition because of its low carbon content; follow supplier welding guidance for critical service. -

How much more expensive is Hastelloy than 316L stainless?

Depending on form and region, Hastelloy C-276 in 2025 is commonly an order of magnitude or more costly per kg than 316L because of high nickel/molybdenum content and lower global supply; exact multiples depend on market conditions and product form. -

Are Hastelloys immune to corrosion?

No metal is universally immune. Hastelloys offer exceptionally wide resistance, but specific media and temperatures (for example oxidizers with particular impurities) can attack even these alloys. Use iso-corrosion data and field testing for critical services. -

Which standards cover Hastelloy products?

Common standards include ASTM specifications (plates, sheets, bars, pipes) such as ASTM B-575, B-622 (C-276), and various UNS/EN designations. Always specify exact UNS and ASTM/EN standards on purchase orders. -

Is there a cheap “equivalent” to Hastelloy?

For specific environments, alternatives exist (e.g., duplex/super-austenitic stainless steels, other Ni-alloys), but they often trade off in one performance axis. For severe chemistries, Hastelloy performance and life-cycle cost usually justify the premium. -

How should I budget for Hastelloy in 2025?

Use market indexes (e.g., Chemanalyst) as a benchmark; expect regional spreads and premiums for certified, machined or welded components. For C-276 in Q1 2025, budget roughly USD 50–90/kg in North America and higher for finished parts. Always request formal quotes.

Practical procurement checklist

-

Specify exact UNS (e.g., N10276) and ASTM/EN standard.

-

Request MTR, heat treatment record, and mill tolerances.

-

Clarify product form (plate, bar, seamless pipe) and dimensions.

-

Require welding/filler metal spec and welding procedure if delivery includes welds.

-

Budget for lead time — Hastelloy grades frequently have longer lead times than stainless steel because of limited mill capacity.

Closing notes (practical engineer’s takeaway)

Hastelloy alloys are premium nickel-base solutions for corrosive and/or high-temperature problems. The right grade choice is a function of chemistry, temperature and mechanical duty. Use manufacturer iso-corrosion data, validated lab testing when in doubt, and secure MTRs and certified supply chains to avoid costly failures. Market prices in 2025 show regional spread and form-dependent premiums — treat price estimates as preliminary until you receive a formal mill/distributor quote.