For extreme chemical environments dominated by mixed acids, oxidizing and reducing media, and chloride-bearing crevice conditions, Hastelloy C-276 typically gives broader corrosion protection and longer life. For applications demanding elevated-temperature strength, superior tensile and creep properties, or where tight budgets require compromise, Inconel 625 often represents the better balance between mechanical performance and cost. Choose C-276 when maximum chemical resistance matters most; choose 625 when high strength at temperature, fabrication ease, or lower expenditure govern selection.

Key differences at a glance

-

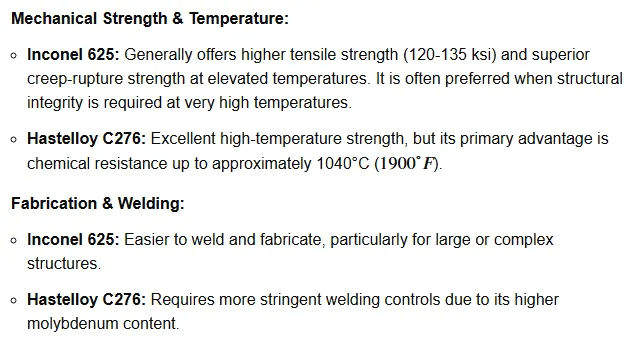

Primary design intent: Hastelloy C-276 is optimized for the widest range of aggressive chemical attack, including oxidizing and reducing solutions. Inconel 625 was developed for high strength across a broad temperature band while retaining strong resistance to pitting, crevice corrosion, and chloride stress-corrosion cracking.

-

Composition drivers: C-276 uses high molybdenum and tungsten with chromium to give corrosion breadth. 625 relies on a nickel-chromium base strengthened by molybdenum and niobium for mechanical properties at elevated temperatures.

-

Typical procurement tradeoffs: C-276 usually carries a higher unit cost because of alloying levels and market positioning; 625 often delivers lower cost per component for structural loading at temperature. Market surcharges fluctuate month to month and can change vendor selection.

The Metallurgical DNA: Chemical Composition Analysis

To understand why these alloys behave differently on the shop floor and in the field, we must analyze their elemental makeup. The primary differentiator is the Molybdenum (Mo) content and the presence of Tungsten (W) versus Niobium (Nb).

If your project requires Hastelloy C276 and Inconel 625, contact MWalloys for a free quote.

The Role of Molybdenum and Tungsten in C276

Hastelloy C276 is engineered as a shield against corrosion. Its defining characteristic is a massive Molybdenum addition (15-17%) combined with Tungsten (3-4.5%). Molybdenum is the key element that provides resistance to pitting and crevice corrosion, specifically in reducing environments. The addition of Tungsten further stabilizes the passive film, ensuring the material survives in environments containing ferric and cupric chlorides.

The Niobium Factor in Inconel 625

Inconel 625 takes a different approach. While it contains significant Molybdenum (8-10%), it substitutes Tungsten with Niobium (plus Tantalum) at levels of 3.15-4.15%. This is a critical distinction. Niobium acts as a stiffener for the alloy matrix. It provides Inconel 625 with immense tensile strength and creep-rupture strength without the need for precipitation hardening heat treatments. This makes 625 an easier material to specify for pressure vessels that require high strength in the as-welded condition.

Table 1: Comparative Chemical Composition (Nominal Weight %)

| Element | Hastelloy C276 (UNS N10276) | Inconel 625 (UNS N06625) | Impact on Performance |

| Nickel (Ni) | Balance (~57%) | Balance (~58%) | Base for ductility and stress corrosion resistance. |

| Chromium (Cr) | 14.5 - 16.5% | 20.0 - 23.0% | 625 has higher Cr, offering better oxidation resistance. |

| Molybdenum (Mo) | 15.0 - 17.0% | 8.0 - 10.0% | C276's higher Mo grants superior pitting resistance. |

| Iron (Fe) | 4.0 - 7.0% | 5.0% max | Controls cost and thermal expansion. |

| Tungsten (W) | 3.0 - 4.5% | - | Unique to C276; boosts localized corrosion defense. |

| Niobium (Nb) | - | 3.15 - 4.15% | Unique to 625; provides high structural strength. |

| Cobalt (Co) | 2.5% max | 1.0% max | Trace element from mining. |

Corrosion Resistance Profiles: Wet Chlorine vs. Oxidation

This is the section where procurement mistakes are most costly. Selecting the wrong alloy here results in catastrophic failure or unnecessary expense.

Performance in Reducing Acids (Hydrochloric & Sulfuric)

Hastelloy C276 is the gold standard for Hydrochloric Acid (HCl). Few metals can survive HCl at varying concentrations and temperatures; C276 is one of them. The high Molybdenum content prevents the acid from eating through the grain boundaries.

-

MWalloys Field Note: If your process involves "sour gas" (H2S) or aggressive acid streams, C276 is often the mandatory specification. Inconel 625 will perform adequately in mild acid scenarios but lacks the longevity of C276 in concentrated, hot, reducing acids.

Pitting Resistance Equivalent Number (PREN)

The PREN value is a theoretical calculation used to rank alloys based on their resistance to pitting corrosion.

-

Formula: PREN = %Cr + 3.3(%Mo) + 16(%N) + 1.5(%W)

-

Inconel 625 PREN: Approximately 45-50.

-

Hastelloy C276 PREN: Approximately 65-70.

The gap in PREN scores highlights why C276 is chosen for the most severe pharmaceutical and petrochemical scrubbers. A score difference of 20 points represents a completely different tier of reliability in chloride-rich environments.

Oxidation and High-Temperature Gas

Here, Inconel 625 takes the lead. The higher Chromium content (20-23%) allows 625 to form a robust oxide layer that protects the metal from scaling at temperatures up to 982°C (1800°F). While C276 has good high-temperature capabilities, it is prone to forming intermetallic phases (like Mu-phase) upon prolonged exposure to temperatures between 650°C and 1100°C, which can reduce ductility. Inconel 625 is far more stable in jet engine exhausts and flare stack linings.

Corrosion resistance: where real performance splits appear

Broad guidelines

Hastelloy C-276 ranks higher for mixed-acid environments and conditions that present both oxidizing and reducing chemistry, such as chemical processing streams with oxidizers plus chlorides, concentrated sulfuric-nitric blends, and many waste streams. Inconel 625 provides excellent resistance in many chloride-bearing waters, marine conditions, and oxidizing environments while offering better mechanical strength at elevated temperatures. The two alloys often perform well in the same tests that quickly attack stainless steels.

Laboratory and field tests worth noting

-

Boiling 45 percent magnesium chloride (ASTM G36) is a severe screen for chloride-induced stress-corrosion cracking. Both C-276 and 625 resisted cracking for long test durations in industry data, while many stainless grades failed quickly. This is a useful indicator for chloride SCC vulnerability in design reviews.

-

Crevice and pitting tests in seawater or simulated environments demonstrate C-276's superior resistance in some crevice setups, particularly where mixed chemistries or oxidizing agents are present. 625 performs very well in many seawater use cases and has been used extensively for marine hardware.

Practical interpretation

-

Choose C-276 for process lines, reactors, or waste systems that experience oxidizer-rich attack combined with chlorides, or where mixed-acid resistance is mission critical.

-

Choose 625 for marine components, heat exchangers, high-strength piping at temperature, or wherever thermal creep strength is necessary but the chemistry is less aggressive than the worst chemical plant waste.

Key experimental reference for mixed-acid and chloride resistance: manufacturer corrosion tables and independent studies.

Mechanical Properties and Structural Integrity

Engineers must calculate the load-bearing capacity of the material. Inconel 625 is generally the stronger material physically, which allows for thinner wall thicknesses in piping and vessel design, potentially offsetting its price per pound.

Table 2: Mechanical Properties (Room Temperature, Solution Annealed)

| Property | Hastelloy C276 | Inconel 625 | Implication |

| Tensile Strength (min) | 100 ksi (690 MPa) | 120 ksi (827 MPa) | 625 handles higher pressure loads. |

| Yield Strength (0.2% Offset) | 41 ksi (283 MPa) | 60 ksi (414 MPa) | 625 resists deformation better. |

| Elongation | 40% | 30% | C276 is slightly more ductile. |

| Hardness (Rockwell B) | ~87 HRB | ~92 HRB | Both work-harden rapidly. |

| Density | 8.89 g/cm³ | 8.44 g/cm³ | C276 is heavier; affects shipping/volume cost. |

The Niobium Stiffening Effect

The presence of Niobium in 625 creates a matrix stiffening effect. This is vital for applications like subsea piping or nuclear reactor components where the material must maintain dimensional stability under extreme pressure. C276 is strong, but its primary function is chemical inertness, not structural might.

Fabrication, Welding, and Machinability Insights

At MWalloys, we process both alloys frequently. Processing these superalloys requires distinct strategies to avoid scrapping expensive material.

Machinability Challenges

Both alloys are classified as difficult to machine. They have high shear strength and work-harden rapidly. If the cutter dwells or scrapes, the surface hardens immediately, potentially destroying the tool on the next pass.

-

Best Practice: Use rigid, overpowered machinery. Carbide tooling is essential. Maintain a positive feed rate to ensure the tool enters below the work-hardened layer of the previous cut.

-

Difference: Inconel 625 is slightly "gummier" due to the Niobium, leading to long, stringy chips that can wrap around tooling. C276 chips are tough but tend to break slightly cleaner.

Welding Characteristics

Welding C276 requires extreme cleanliness. The presence of sulfur, phosphorus, or lead (even from marking crayons) can cause immediate weld cracking.

-

Post-Weld Heat Treatment (PWHT): One of the massive advantages of C276 is that it is designed to be used in the "as-welded" condition for most chemical applications. Its low carbon content (0.01% max) minimizes carbide precipitation during welding.

-

Inconel 625 Welding: 625 has excellent weldability and is often used as a filler metal for welding dissimilar metals (e.g., joining steel to stainless). It is highly resistant to weld solidification cracking.

MWalloys Market Analysis: Price and Availability

Understanding the commercial landscape is vital for procurement.

The Cost Driver: Molybdenum

Molybdenum is a volatile commodity. Because C276 contains nearly double the Molybdenum of 625, its price is far more sensitive to fluctuations in the mining sector. Historically, Hastelloy C276 is 15% to 25% more expensive than Inconel 625. This premium pays for the Tungsten and extra Molybdenum.

Availability Profiles

-

Hastelloy C276: Readily available in plate, sheet, and pipe schedules tailored for the chemical process industry (CPI). Large flanges and fittings are standard stock items.

-

Inconel 625: Readily available but often stocked in forms suited for aerospace (round bar, billet) and oil & gas (heavy wall tube). Finding thin-gauge sheet 625 can sometimes be harder than C276, depending on market cycles.

Industry Applications: Where to Use Which?

Where Hastelloy C276 Reigns Supreme

-

Flue Gas Desulfurization (FGD): The scrubbers in power plants that remove sulfur use C276 to withstand the acidic slurry.

-

Pharmaceutical Manufacturing: Reactors requiring absolute purity and zero corrosion contamination.

-

Paper and Pulp: Bleaching stages involving chlorine dioxide.

-

Sour Gas Wells: Downhole tubing in environments with high H2S and CO2 pressure.

Where Inconel 625 Reigns Supreme

-

Aerospace Ducting: Exhaust systems and turbine shroud rings where heat resistance is key.

-

Marine Propulsion: Propeller blades and submarine propulsion motors (high corrosion fatigue strength).

-

Nuclear Industry: Reactor core and control rod components.

-

Waste-to-Energy: Boiler overlays to prevent corrosion/erosion in superheaters.

Comparative Data Table for Quick Selection

| Feature | Hastelloy C276 | Inconel 625 | Winner |

| Acid Resistance (HCl, H2SO4) | Excellent | Good | C276 |

| Oxidation Resistance (High Temp) | Good | Excellent | 625 |

| Yield Strength | Moderate | High | 625 |

| Pitting Resistance (PREN) | ~68 | ~48 | C276 |

| Machinability | Poor | Poor | Tie |

| Cost Efficiency | High Premium | Premium | 625 |

| Crevice Corrosion | Outstanding | Very Good | C276 |

Selection decision matrix for engineers and procurement

Table: gives a compact decision grid to help select between the alloys based on dominant design drivers.

| Primary driver | Choose C-276 when | Choose 625 when |

|---|---|---|

| Maximum corrosion breadth | Mixed oxidizers plus chlorides present | Chloride exposure but limited mixed-acid severity |

| High-temperature strength | Temperature moderate; chemistry dominates | High temperature mechanical strength required |

| Fabrication ease | Accept extra welding care for corrosion gain | Need easier welding and structural strength |

| Cost control | Budget allows premium for longevity | Budget constraints; need strength for thin sections |

| Marine service | When crevice conditions include deposits and mixed chemistries | Typical seawater, high fatigue applications |

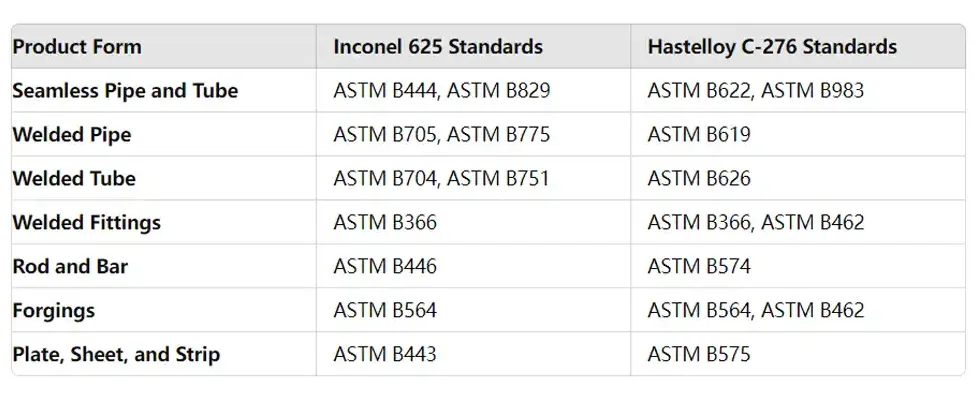

Multiple tables for specification checks

Table: Chemical composition quick reference (repeat for convenience)

| Alloy | Ni | Cr | Mo | Nb+Ta | W | Fe |

|---|---|---|---|---|---|---|

| Hastelloy C-276 | Bal. | 14.5-16.5 | 15.0-17.0 | trace | 3.0-4.5 | 4.0-7.0 |

| Inconel 625 | ≥58.0 | 20.0-23.0 | 8.0-10.0 | 3.15-4.15 | trace | ≤5.0 |

Sources: primary alloy datasheets.

Table: Corrosion test highlights

| Test or environment | Hastelloy C-276 performance | Inconel 625 performance |

|---|---|---|

| Boiling 45% MgCl2 (ASTM G36) | No cracking in long-term screening | No cracking in long-term screening |

| Seawater crevice testing | Very good resistance in mixed setups | Very good; excellent for many marine uses |

| Mixed acid (HNO3+H2SO4) | Superior life | Good; may require caution in strongly oxidizing mixtures |

Data from industry test summaries and manufacturer corrosion tables.

Case notes and micro-level fabrication advice

-

For C-276 piping that will see high chloride and deposit-prone fluids, avoid lap joints and prefer full-penetration welds with back purge where possible. Maintain welding cleanliness and avoid flux residues.

-

For 625 components intended for cyclic thermal loads, incorporate fatigue calculations and consider shot-peening or surface finishing to reduce stress concentrators.

-

For both alloys, specify mill certification and traceability in procurement documents. Require heat number traceability and, where relevant, PMI or chemical analysis certificates.

Hastelloy C276 vs. Inconel 625: Technical Comparison FAQ

1. Can I weld Inconel 625 directly to Hastelloy C276?

2. Why is C276 more expensive than 625?

The cost is driven by rare element density.

625: ~9% Molybdenum (No Tungsten)

Tungsten and high-purity Molybdenum are significantly costlier than Nickel or Iron, making C276 the premium choice for extreme chemistry.

3. Is Hastelloy C276 magnetic?

4. Which alloy is better for seawater applications?

5. What represents the biggest risk when machining these alloys?

6. Can Inconel 625 replace C276 in a bleach plant?

7. What is the maximum operating temperature for these alloys?

8. Does MWalloys supply C276 bolts and fasteners?

9. How do I distinguish C276 from 625 without a material test report?

10. What is the UNS designation difference?

Always use UNS numbers on purchase orders to ensure accuracy:

- Hastelloy C276: UNS N10276

- Inconel 625: UNS N06625

MWalloys: Your Strategic Partner in Superalloys

Choosing between Hastelloy C276 and Inconel 625 requires balancing the budget against the cost of failure. If the environment is chemically reducing and highly aggressive, C276 is the insurance policy you need. If the environment demands high heat strength and general oxidation resistance, 625 is the engineering champion.

For specific inventory inquiries, heat treatment capabilities, or machining advice regarding UNS N10276 and UNS N06625, contact the MWalloys engineering team today. We provide certified materials with full traceability for your most critical projects.