Schedule 80 pipe has thicker walls, a smaller internal bore and greater weight than Schedule 40 for the same nominal pipe size, which yields higher allowable working pressure and greater mechanical robustness; choose SCH 40 for general-purpose, lower-pressure piping and lighter structural use, and choose SCH 80 when you need higher pressure rating, improved mechanical margin, or more wall thickness for corrosion/wear allowance.

Pipe schedule is a shorthand that controls wall thickness without changing outside diameter (for standard pipe sizes), so the same fitting geometry and OD are preserved while internal flow area and mechanical capacity vary. That single change affects flow rate, pressure capacity, weight, handling and cost — all critical to procurement, fabrication and plant safety.

What is “pipe schedule”?

“Pipe schedule” is a number that indicates nominal wall thickness for pipe produced to ASME/ANSI dimension standards; higher schedule numbers mean thicker walls for the same nominal pipe size. Nominal Pipe Size (NPS) and Outside Diameter (OD) are the geometry anchors; schedule changes the wall thickness (WT), and therefore the inside diameter (ID) and weight. This convention permits standard fittings and unions to keep OD constant while allowing different strength/flow characteristics.

Dimensional differences

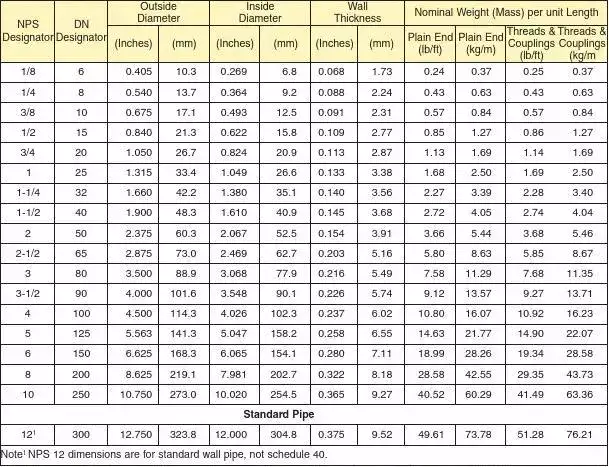

Below is a concise comparative snapshot for common NPS values. Numbers are taken from ASME/ANSI dimension tables (ASME B36.10M / common schedule charts) and represent typical nominal values used in engineering tables.

| NPS (inch) | Outside Diameter (OD) | SCH 40 wall thk (in) | SCH 40 ID (in) | SCH 80 wall thk (in) | SCH 80 ID (in) | Notes / Typical weight |

|---|---|---|---|---|---|---|

| ½ | 0.840 | 0.109 | 0.622 | 0.147 | 0.546 | common water/steam pipe |

| 1 | 1.315 | 0.133 | 1.049 | 0.179 | 0.957 | widely used in process piping |

| 2 | 2.375 | 0.154 | 2.067 | 0.218 | 1.939 | common utility and structural uses |

| 4 | 4.500 | 0.237 | 4.026 | 0.337 | 3.826 | significant difference in pressure capacity and weight |

Source notes: OD values follow ASME B36.10M; wall thickness values for SCH 40 and SCH 80 are the standard schedule table entries used by material suppliers and piping codes. For a full table up to large NPS sizes consult ASME B36.10M or an ANSI schedule chart.

How schedules are standardized

-

ASME B36.10M / B36.19M define dimensions/weights for welded and seamless steel pipe (covers NPS to DN), which are the primary references used by mills and fabricators.

-

ASTM specifications (for material quality and manufacturing types) — common examples include ASTM A53/A53M (black/galvanized welded & seamless steel pipe), ASTM A106 (seamless carbon steel for high-temperature service), ASTM A312 (stainless steel pipe). These standards specify chemical, mechanical and testing requirements but not the schedule tables (which are dimensional standards).

-

For water-distribution steel pipe the AWWA family (e.g., C200) provides additional requirements and acceptance criteria where applicable.

Pressure rating, temperature and design implications

Wall thickness directly affects the pipe’s calculated allowable working pressure using thin-wall or thick-wall hoop stress formulas (per ASME B31.1/B31.3 piping codes and other design rules). For a given material and temperature, thicker walls (SCH 80) will result in a higher allowable internal pressure before yielding or reaching the design stress limit. Real allowable pressures depend on material yield/tensile strength, temperature derating, corrosion allowance and the chosen code stress intensification factors. Engineering tables and manufacturer pressure charts translate schedule & size to a practical pressure rating for a specific material and temperature.

Materials and where each schedule is used

-

Carbon steel (ASTM A53, A106, API 5L): the most frequent pairing for SCH 40/SCH 80. SCH 40 is typical for low-pressure service; SCH 80 for higher pressure process lines, hydraulic lines, or when corrosion allowance is required.

-

Stainless steel (ASTM A312): schedules apply similarly; many fabricators order stainless to schedule numbers for compatibility with existing bolting/fitting geometry.

-

PVC/CPVC: these materials also use “schedule” nomenclature (e.g., Schedule 40 PVC vs Schedule 80 PVC) but the numeric mapping and pressure characteristics are material-dependent and governed by plastic standards (e.g., ASTM D1785). Do not assume plastic schedule pressures match metallic schedule pressures.

Typical applications

-

SCH 40: general plumbing, HVAC, low-pressure process lines, structural scaffolding, conduit, many municipal water lines (where pressure is modest).

-

SCH 80: high-pressure hydraulic lines, high-temperature service, chemical feed lines, diesel/gas systems, cases where extra wall thickness is needed for erosion/corrosion allowance or mechanical impact resistance.

Fabrication & fittings compatibility

Because OD is the same for a given NPS, many external-fit components (flanges, clamps, some couplings) match either schedule — but ID differences affect flow and may require different gasket/face selections in tight tolerances. Thread engagement for threaded fittings changes with wall thickness; SCH 80 reduces internal thread depth and thus can affect tapered-threaded connections if not detailed. Welding practice is the same (but thicker walls may need different preheat/weld parameters). Always consult the fitting and code manufacturer for weld/fit guidance.

Corrosion and erosion planning

Selecting a schedule is often a simple way to add a “corrosion allowance.” If a line is expected to lose a predictable wall thickness over time to corrosion or abrasion, specifying SCH 80 rather than SCH 40 can postpone replacement and increase margin. However, material selection (corrosion-resistant alloys or coatings) is usually preferred if the chemistry or abrasive content will quickly attack carbon steel. Include corrosion allowance explicitly in the specification (e.g., “SCH 40 + 1.5 mm corrosion allowance”) to avoid ambiguity.

Cost, weight and logistics tradeoffs

SCH 80 material weight and unit cost are higher. Increased wall thickness means more steel per meter (heavier handling, more freight cost), slightly different welding time (more filler and heating) and sometimes different pipe end preparations. For large meterage projects budget carefully: SCH 80 increases installed cost but can reduce lifecycle cost in high-pressure or corrosive service. Supplier lead times for standard schedules are usually short when stock is available; custom or less common materials (e.g., low-alloy steels or oversized schedules) take longer.

MWAlloys commercial note — procurement & factory supply

MWAlloys manufactures steel pipe and related fittings. For buyers looking for China supply: MWAlloys offers direct factory pricing (100% factory outbound price), maintains stock for common SCH 40 and SCH 80 sizes, and provides rapid dispatch for stocked items. When ordering from MWAlloys, specify: NPS, schedule, material grade (ASTM or API designation), length, end finish (plain, beveled, threaded), testing requirements (hydrotest, PMI, mill test certificate), and finish (black, galvanized). Our production can accommodate both standard and project-specific grading; please request an official quotation that lists mill certificates and delivery terms.

Selection checklist & worked example

Checklist when choosing between SCH 40 and SCH 80:

-

Required maximum operating pressure and temperature (design conditions).

-

Media (corrosive/abrasive?) and expected corrosion rate.

-

Compatibility with existing fittings and flanges.

-

Weight and cost constraints (project budget & handling).

-

Welding/joining considerations and code requirements (B31.x).

Worked example (simplified):

-

System: 1" carbon steel line, 250°F, 400 psi required operating pressure.

-

SCH 40 (ID ~1.049 in) typical allowable pressures may be lower than needed. SCH 80 (ID ~0.957 in, thicker wall) increases allowable working pressure and provides a higher safety margin — it is likely the conservative choice. Always run exact ASME B31.3 calculations with material allowable stress at 250°F to confirm.

-

SCH 40 vs SCH 80 Table

| Criterion | SCH 40 | SCH 80 |

|---|---|---|

| Typical use | General plumbing and low/medium pressure process | Higher pressure, higher mechanical margin, corrosion allowance |

| Wall thickness | Thinner | Thicker |

| Internal bore | Larger | Smaller |

| Weight per metre | Lower (cheaper to ship) | Higher (higher material cost) |

| Weld prep / welding time | Less filler, faster | More filler, may need preheat in larger sizes |

| Standard fittings compatibility | Good | Good for OD-matching fittings; check thread depth |

| Typical spec references | ASTM A53, ASME B36.10M | ASTM A53, ASME B36.10M |

| When to pick | Lower pressure, budget-sensitive | Higher pressure, wear/corrosion concerns, hydraulic service |

(References for table values: ASME dimensional standards and manufacturer schedule tables.)

FAQs

1. Is schedule the same for all materials?

No. “Schedule” is a dimensional convention referring to wall thickness tables; the pressure performance for a given schedule depends on the material (carbon steel, stainless, PVC, etc.) and the applicable material standard. For example, Schedule 40 stainless has the same nominal wall thickness as Schedule 40 carbon steel, but allowable pressure at temperature is material-dependent.

2. Will a SCH 80 pipe always handle twice the pressure of SCH 40?

No. The pressure capacity increases with thickness, but the relationship is not linear and depends on material strength and temperature. Use code formulas (ASME B31.3/B31.1) or manufacturer pressure charts for exact allowable values.

3. Can I join SCH 40 and SCH 80 in the same system?

Yes — because OD is constant for a given NPS the external geometry matches for flanges and many couplings. However, check thread engagement, flow impacts, and code requirements for transitions. Consider reinforcement or reducer fittings where needed.

4. Is SCH 80 required for underground lines?

Not necessarily. Underground design depends on soil load, external physical hazards, internal pressure and corrosion risk. For some buried services a higher schedule or external protection (coating, cathodic protection) is selected. Consult pipeline standards (AWWA for water, API/ASME for other services).

5. Which standard tells me exact dimensions?

ASME B36.10M (and B36.19M for stainless) contains the schedule tables and dimensions (OD, nominal wall thickness).

6. Does schedule affect flange selection?

Flange faces and bolt patterns typically follow OD/NPS. But because ID changes, ensure gasket selection and pressure rating match the intended schedule/material. Manufacturers supply flange specs keyed to schedule and class.

7. How much more does SCH 80 cost?

Cost depends on size and material; SCH 80 uses more steel per metre so material cost increases proportionally to cross-sectional area plus extra handling/processing. For budget planning, request supplier weight/price per metre for both schedules.

8. Are PVC SCH 40 and SCH 80 interchangeable with steel?

No. PVC/CPVC schedule numbers are dimensionally similar but pressure/temperature limits and joint types differ. Do not mix materials without careful design.

9. Which schedules are “standard” to keep in stock?

SCH 40 is the most commonly stocked. Many suppliers also stock common SCH 80 sizes for industrial applications. Large diameters and exotic alloys are typically made to order. Confirm stock status with supplier (e.g., MWAlloys can confirm SKU availability).

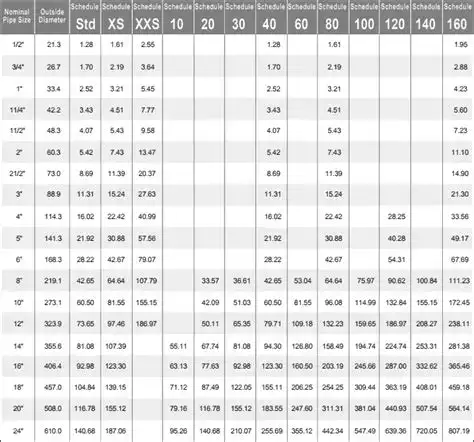

10. If I need more than SCH 80, what are the options?

You can specify higher schedules (SCH 160, XXS) or extra-strong classes (XS), or select a heavier wall custom thickness per ASME table. Alternatively, choose a higher-strength alloy to reduce wall thickness while meeting pressure.

Specification checklist (what to put onto your PO)

-

NPS and schedule (e.g., “1 in NPS SCH 80”)

-

Material spec (ASTM/AWWA/API grade and heat treatment) and Grade (e.g., ASTM A106 Gr. B)

-

End finish (plain, beveled, threaded)

-

Length or random/continuous length requirement

-

Hydrostatic test requirement and acceptance criteria

-

Mill test certificate (MTC) type required (EN 10204 3.1 / 2.2 etc.)

-

Surface finish, coating or galvanization if needed

-

Quantity and delivery schedule (stock vs made-to-order)

Closing summary

Choosing between Schedule 40 and Schedule 80 is a trade between internal bore/flow and structural/pressure capacity vs cost and weight. Use the design conditions (pressure, temperature, corrosivity, erosion, mechanical loads) as the primary driver; then check ASME B36.10M dimensional tables and the relevant ASTM material standards to finalize material and schedule. For procurement from China, MWAlloys provides factory pricing and stock options for common schedules with mill documentation available on request. asme.orgASTM International | ASTM

Authoritative references

- ASME B36.10M — Welded & Seamless Wrought Steel Pipe (ASME)

- ASTM A53/A53M — Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless (ASTM International)

- AWWA C200 — Steel Water Pipe (American Water Works Association)

- ANSI/ASME Pipe Dimensions Chart (PDF) — typical schedule table reference