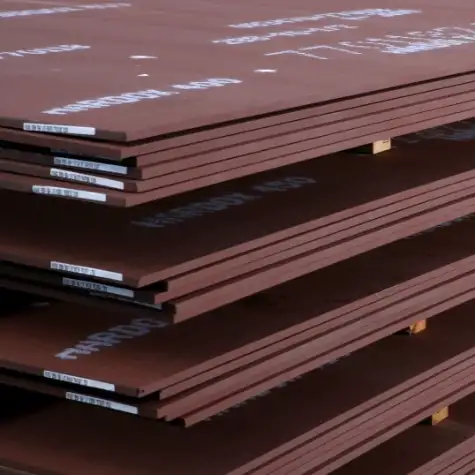

When it comes to wear-resistant steel, AR400 and Hardox 400 are among the most commonly used materials in heavy-duty applications. These two steels are renowned for their hardness, impact resistance, and ability to withstand wear in demanding environments. However, choosing the right material between the two can be challenging due to their similar characteristics and overlapping uses.

What is AR400 Steel?

AR400 steel, also known as Abrasion Resistant 400 steel, is a high-carbon alloy steel specifically designed for applications that require high wear resistance. This steel is used in environments where abrasive wear is a concern, such as in the construction, mining, and material handling industries. The AR400 steel offers hardness levels of approximately 400 Brinell, making it highly resistant to surface wear and impact.

AR400’s mechanical properties include a high tensile strength and yield strength, ensuring that the material remains strong and stable under heavy loads. However, it should be noted that AR400 is primarily designed for wear resistance rather than overall strength and impact toughness.

What is Hardox 400 Steel?

Hardox 400 is a wear-resistant steel made by SSAB, a renowned Swedish steel manufacturer. It shares many similarities with AR400 in terms of hardness but stands out due to its superior toughness and ability to withstand severe impact forces. Hardox 400 is frequently used in applications such as mining, quarries, and construction where both wear resistance and the ability to absorb impact stress are essential.

Hardox 400 combines excellent hardness (400 Brinell) with greater flexibility and higher yield strength, which allows it to endure both abrasive wear and high-impact forces. These characteristics make it particularly suitable for more demanding industrial applications where AR400 might fall short.

Chemical Composition Comparison: AR400 vs Hardox 400

The chemical compositions of AR400 and Hardox 400 are similar, but slight differences give each steel its unique properties. Below is a side-by-side comparison of their key elements:

| Element | AR400 Steel | Hardox 400 Steel |

|---|---|---|

| Carbon (C) | 0.28 - 0.36% | 0.22 - 0.28% |

| Manganese (Mn) | 0.90 - 1.30% | 0.80 - 1.40% |

| Silicon (Si) | 0.40 - 0.60% | 0.50 - 0.70% |

| Phosphorus (P) | ≤ 0.020% | ≤ 0.025% |

| Sulfur (S) | ≤ 0.010% | ≤ 0.010% |

| Chromium (Cr) | 0.50 - 1.00% | 0.50 - 1.00% |

Key Takeaways:

-

AR400 has a slightly higher carbon content, contributing to a harder surface, but Hardox 400 features a lower carbon range, which improves toughness.

-

Both steels share similar manganese and chromium levels, enhancing their overall strength and wear resistance.

Mechanical Properties Comparison

Both AR400 and Hardox 400 exhibit outstanding wear resistance, but their mechanical properties differ slightly:

| Property | AR400 Steel | Hardox 400 Steel |

|---|---|---|

| Hardness (Brinell) | 400 HBW | 400 HBW |

| Yield Strength (MPa) | 1350 MPa | 1450 MPa |

| Tensile Strength (MPa) | 1700 MPa | 1800 MPa |

| Elongation at Break (%) | 12% | 14% |

| Impact Toughness (J) | Lower | Higher |

Key Takeaways:

-

Hardox 400 offers better yield strength, tensile strength, and elongation at break, making it more suitable for applications requiring both wear and impact resistance.

-

AR400, with its higher hardness, excels in abrasion resistance but is slightly more brittle in high-impact conditions.

Wear Resistance and Toughness: Key Differences

While both AR400 and Hardox 400 are designed for wear-resistant applications, Hardox 400's superior toughness and impact resistance make it more versatile in extreme environments. AR400, on the other hand, excels in surface wear resistance but may crack or break under sudden impact, especially in environments that involve high-stress loads or shock.

Applications of AR400 Steel

AR400 steel is commonly used in industries where surface wear is the primary concern. Typical applications include:

-

Mining equipment (e.g., chutes, liners)

-

Construction machinery (e.g., dump trucks, excavators)

-

Material handling equipment (e.g., conveyor systems, hoppers)

-

Agricultural equipment (e.g., tillage blades, plows)

Applications of Hardox 400 Steel

Hardox 400 is more versatile and is used in applications that require both wear resistance and impact toughness, such as:

-

Heavy-duty trucks and trailers

-

Mining and quarrying equipment

-

Construction and demolition machinery

-

Cranes, excavators, and other earth-moving equipment

Service Life and Durability

The service life of both steels is heavily influenced by the specific environment in which they are used. AR400’s higher hardness makes it ideal for light to moderate wear conditions, while Hardox 400’s ability to handle high-impact stresses makes it more durable in harsher conditions. Hardox 400, therefore, generally outperforms AR400 in terms of long-term durability, especially in applications that involve dynamic loading or shock.

Global Price Comparison: AR400 vs Hardox 400

The prices of AR400 and Hardox 400 steel can vary based on market conditions, geographic location, and the scale of procurement. Below is an estimated price comparison:

| Region | AR400 Price (per ton) | Hardox 400 Price (per ton) |

|---|---|---|

| United States | $800 - $1,000 | $1,100 - $1,300 |

| Europe | €750 - €950 | €1,050 - €1,250 |

| China | ¥6,000 - ¥7,500 | ¥8,000 - ¥9,500 |

Key Takeaways:

-

AR400 is more affordable compared to Hardox 400, making it a cost-effective choice for applications with lower wear or impact demands.

-

Hardox 400’s price is higher due to its superior toughness and durability.

AR400 vs Hardox 400 Steel Equivalent Materials

When selecting a material that offers similar properties to AR400 or Hardox 400, the following equivalent materials may be considered:

-

AR400 Equivalent:

-

ASTM A514

-

Quenched and tempered steel grades

-

T-1 steel

-

-

Hardox 400 Equivalent:

-

SSAB’s Hardox 450 (slightly tougher)

-

Dillidur 400

-

Quenched and tempered plates

-

AR400 vs Hardox 400 Size and Weight Comparison

The available thickness, width, and weight of both steels are important considerations when choosing the right material. Both AR400 and Hardox 400 come in various forms, including plates, sheets, and custom cuts. Below is a size comparison:

| Size (Thickness) | AR400 Steel | Hardox 400 Steel |

|---|---|---|

| 10mm | 40 kg/m² | 42 kg/m² |

| 20mm | 80 kg/m² | 85 kg/m² |

| 50mm | 200 kg/m² | 210 kg/m² |

Key Takeaways:

-

Hardox 400 is slightly heavier than AR400 for the same thickness, due to its denser microstructure.

FAQs

-

What is the main difference between AR400 and Hardox 400?

-

AR400 offers better wear resistance, while Hardox 400 excels in both wear resistance and impact toughness.

-

-

Can AR400 and Hardox 400 be welded?

-

Yes, both can be welded, but pre-heating and post-weld heat treatment are recommended for Hardox 400.

-

-

Which steel is more cost-effective?

-

AR400 is more affordable compared to Hardox 400.

-

-

What is the best application for AR400 steel?

-

AR400 is ideal for applications that involve moderate wear and no high-impact forces.

-

-

How long does Hardox 400 last?

-

Hardox 400 typically lasts longer in high-impact applications than AR400 due to its increased toughness.

-

Conclusion: Which Steel is Right for You?

In conclusion, both AR400 and Hardox 400 offer excellent abrasion resistance, but the choice between the two depends on the specific requirements of your application. If you need a material for heavy-duty operations with high impact and toughness demands, Hardox 400 will be your best option. For more cost-effective wear resistance in lighter-duty applications, AR400 is a suitable choice.

For industries requiring custom solutions, MWalloys provides both AR400 and Hardox 400 at factory prices, with customizable sizes and specifications tailored to your needs. Contact us for a quote or to discuss your specific requirements.