Hastelloy® C-276 (UNS N10276) has a commonly quoted *room-temperature density of 8.89 g/cm³, which equals ≈ 0.321 lb/in³ (pounds per cubic inch). This value is the practical figure engineers use for weight and mass calculations for rods, plates, flanges and pressure parts made from C-276.

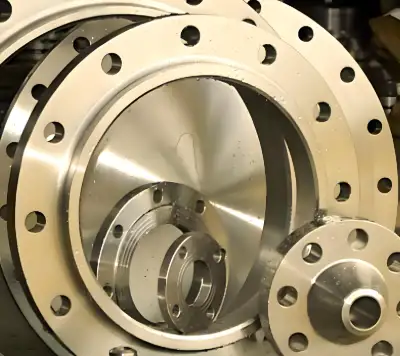

What is Hastelloy C-276?

Hastelloy® C-276 is a nickel-molybdenum-chromium superalloy (wrought) with tungsten and low carbon content, engineered for outstanding corrosion resistance in both oxidizing and reducing media. It is widely traded under the trademark HASTELLOY® C-276 and standardized as UNS N10276 (Werkstoff No. 2.4819 in some systems). Its chemistry typically centers on high Ni (balance), ~15–17% Mo, ~14.5–16.5% Cr, ~3–4.5% W and ~4–7% Fe (ranges vary by producer). These compositional features give it both the corrosion resistance and the relatively high specific gravity (density) that engineers rely on.

Canonical density values and unit conversions

Reported, manufacturer-backed physical property sheets list the density of Hastelloy C-276 at 8.89 g/cm³ (metric) at room temperature. When converted to imperial units that mechanical designers and fabricators commonly use in the United States, this equals ≈ 0.321 lb/in³. Multiple material data sources and manufacturer datasheets use the same nominal density.

Why both numbers are useful

-

g/cm³ is common in material science literature and international specifications.

-

lb/in³ is convenient for quick shop-floor and weight calculations (shipping weights, fixture forces, or estimating gravity loads in mechanical assemblies).

Conversion reference (how the two relate)

-

1 g/cm³ = 0.036127292 lb/in³ (exact conversion factor used for the calculation).

-

Therefore: 8.89 g/cm³ × 0.036127292 lb/in³ per g/cm³ ≈ 0.321 lb/in³.

Density table

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Nominal density (C-276, RT) | 8.89 g/cm³ | 0.321 lb/in³ |

| Typical modulus of elasticity (for reference) | 205 GPa | 29.8 Mpsi |

| Typical melting range | 1325–1371 °C | 2415–2500 °F |

(Numbers above are representative values from multiple manufacturer data sheets and standard material databases.)

Example calculations

Two practical examples engineers ask for often:

A. Weight of a 1-inch diameter rod, 1 foot long (solid C-276).

Steps:

-

Cylinder volume = π × r² × h. For diameter 1.00 in → r = 0.5 in; h = 12 in. So volume = π × (0.5²) × 12 ≈ 9.42478 in³.

-

Multiply by density 0.321 lb/in³ → mass ≈ 9.42478 × 0.321 ≈ 3.03 lb (rounded).

B. Weight per inch of a rectangular plate 0.250 in thick, 2 in × 12 in area (one-inch length considered).

-

Volume per inch length = 2 in × 0.25 in × 1 in = 0.5 in³.

-

Mass = 0.5 in³ × 0.321 lb/in³ ≈ 0.1605 lb per inch.

(These worked examples follow the same unit conversion and density reported in manufacturer datasheets; use the nominal density for planning — for final purchase order mass, request certificates from your mill.)

What can cause actual density to deviate from the nominal?

Although 8.89 g/cm³ is the accepted nominal value, the measured density of any fabricated part can differ slightly due to:

-

Porosity: cast or powder-processed parts may contain microscopic voids; wrought products typically have negligible porosity if produced correctly.

-

Impurities or slight composition variance: different producers have slightly different chemistries within the spec ranges; heavier alloying elements (e.g., higher tungsten) can raise specific gravity slightly.

-

Heat treatment and microstructure: phase changes (rare in this alloy under normal processing) have only tiny density effects compared with porosity.

-

Coatings, cladding or weld overlays: attached materials change the effective mass.

Best practice: for precision mass and balance work (e.g., rotors, instrumentation), request a certified test report (mill test cert) and, if critical, measure mass and volume of representative parts to derive the empirical density.

How to use density in engineering decisions

Density influences decisions about:

-

Weight budgeting: gravity loads, dynamic balances and support structures.

-

Shipping cost estimation: carriers bill by weight/volume; accurate densities allow correct quoting.

-

Buoyancy calculations in corrosive-service tanks or immersed rigs.

-

Tooling and machining: heavier alloys change fixture loads and may affect cutting forces.

-

Welding and thermal mass considerations: higher mass parts absorb more heat during welding.

Engineers commonly keep a “material properties” table in CAD/CAE models and use the 0.321 lb/in³ value for Hastelloy C-276 unless a project-specific test suggests otherwise.

Comparison: C-276 vs some commonly referenced materials

| Alloy | Density (g/cm³) | Density (lb/in³) | Comment |

|---|---|---|---|

| Hastelloy C-276 | 8.89 | 0.321 | High Ni-Mo-Cr alloy with heavy elements (Mo, W) → relatively high density. |

| 316L Stainless Steel | ~8.00 | ~0.289 | Stainless is noticeably lighter; many 316L parts weigh ~10–12% less. |

| Inconel 625 | ~8.44 | ~0.305 | Another nickel-base alloy but slightly less dense than C-276. |

| Carbon steel (e.g., A36) | ~7.85 | ~0.284 | Much lighter and far less corrosion-resistant than C-276. |

Takeaway: C-276’s density is higher than most austenitic stainless steels and many nickel alloys due to its heavy alloying (Mo, W). When substituting materials for cost or availability, expect a non-trivial mass difference.

Standards, codes and references that reinforce the data

-

UNS N10276 is the universal designation for C-276 in material listings.

-

Many datasheets and supplier pages document the density and other physical properties—Haynes International, MatWeb and authoritative alloy producers list the same nominal density.

-

For oil & gas and sour service, C-276 appears in relevant material approvals (check the latest editions of NACE/ISO documents and ASME code listings when designing pressure equipment).

When you prepare technical procurement documents, quote both the nominal density and require the supplier to provide a mill test certificate (chemical and physical) and, if needed, a dimensional / mass verification.

Fabrication, machining and welding notes related to density

-

Machining: the higher mass increases cutting energy and heat sink; carbide tools and optimized feeds help.

-

Welding: C-276 is designed to retain corrosion resistance after welding (low carbon, controlled composition). Thermal mass (related to density) affects preheat and cooling rates in large parts.

-

Handling: lifting devices and fixtures must be rated to the realistic mass — use the 0.321 lb/in³ value for conservative planning.

FAQs

-

Q: What is the density of Hastelloy C-276 in lb/in³?

A: ≈ 0.321 lb/in³ (nominal at room temperature). -

Q: What is the density in g/cm³?

A: 8.89 g/cm³ (nominal). -

Q: Is that density constant with temperature?

A: Density changes slightly with temperature (thermal expansion), but for most design work the room-temperature nominal value is used; if your operating range is extreme, use the published thermal expansion and recalculate. -

Q: How do I calculate weight from density?

A: Weight = volume × density. Use consistent units (volume in in³ × density in lb/in³). Example: a 1-in dia × 12-in rod ≈ 3.03 lb. -

Q: Do different mills report different densities?

A: Mills report the same nominal density but composition variations and porosity can cause small deviations. Request mill test data for critical components. -

Q: Can I substitute 316L or Inconel 625 to reduce weight?

A: 316L and Inconel 625 are lighter (roughly 8.0–8.44 g/cm³), but substitution must consider corrosion resistance, strength and cost; mass is just one factor. -

Q: Does welding change density?

A: Welding does not materially change the bulk specific gravity but can create local porosity or oxide entrapment—inspect welds for integrity. -

Q: Where can I find an authoritative datasheet?

A: Manufacturer datasheets from Haynes International, MatWeb, Zapp and Special Metals provide validated physical properties including density. -

Q: How precise is 0.321 lb/in³ for procurement (tolerance)?

A: It’s a nominal figure suitable for planning; if your application requires tight mass tolerances, define permitted mass deviation and require measurement reports. -

Q: Is Hastelloy C-276 approved for sour/oilfield service?

A: C-276 is listed in many corrosion and design approvals for chemical and oil & gas service — check current NACE/ISO and ASME listings for the exact service and temperature limits.