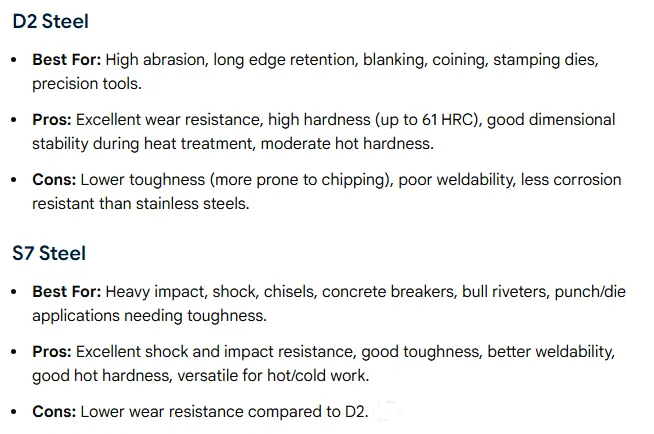

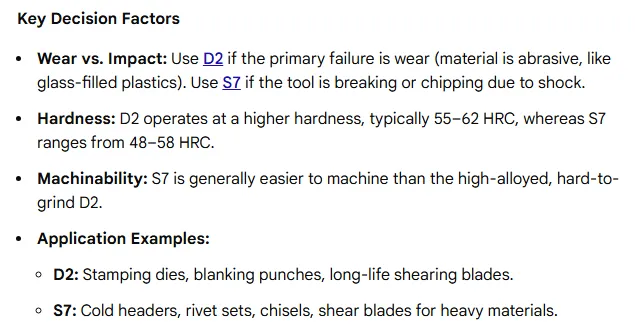

The selection between D2 and S7 tool steel comes down to a binary choice between wear resistance and impact toughness. D2 (AISI D2) is the superior choice for continuous cutting, shearing, and stamping operations where abrasive wear is the primary failure mode and impact loads are low; it holds an edge longer but is susceptible to chipping. S7 (AISI S7) is the requisite material for high-shock applications, such as chisels, heavy punches, and concrete breakers, where the tool must absorb kinetic energy without fracturing. If your application involves high-volume slicing of thin materials, specify D2. If your tool faces repeated hammer-like blows or heavy load shocks, specify S7. Do not substitute one for the other, as D2 will shatter under shock, and S7 will wear out prematurely in abrasive environments.

Metallurgical Composition and Alloy Chemistry Analysis

To understand why these steels behave differently in the workshop, we must examine their chemical architecture. The performance gap stems directly from the carbide formation driven by Chromium and Carbon levels.

If your project requires D2 and S7 tool steel, contact MWalloys for a free quote.

Chemical Composition Breakdown (AISI Standards)

The following table outlines the nominal chemical weight percentages that define these alloys. Note the massive disparity in Chromium content.

| Element | D2 Tool Steel (High Carbon/Chrome) | S7 Tool Steel (Shock Resisting) | Role in Microstructure |

| Carbon (C) | 1.40% - 1.60% | 0.45% - 0.55% | Determines maximum hardness and carbide volume. |

| Chromium (Cr) | 11.00% - 13.00% | 3.00% - 3.50% | Forms hard chromium carbides (wear) vs. corrosion resistance. |

| Molybdenum (Mo) | 0.70% - 1.20% | 1.30% - 1.80% | Deep hardening agent; improves toughness. |

| Vanadium (V) | 0.50% - 1.10% | 0.20% - 0.30% | Grain refinement and edge retention |

| Manganese (Mn) | 0.60% Max | 0.20% - 0.90% | Deoxidizer; aids in hardenability. |

| Silicon (Si) | 0.60% Max | 0.20% - 1.00% | Increases strength and toughness interplay. |

The Carbide Effect and Grain Structure

In D2 steel, the combination of 1.5% Carbon and 12% Chromium creates a microstructure packed with massive, primary chromium carbides. Under a microscope, D2 looks like concrete aggregate. These "rocks" (carbides) provide extreme abrasion resistance but act as stress risers. When D2 fails, it usually snaps or chips catastrophically because cracks propagate easily through these brittle carbides.

S7, with significantly lower carbon and chromium, relies on a martensitic structure with very fine carbides. This lack of massive carbides allows the steel lattice to deform slightly under stress without cracking. The addition of higher Silicon and Molybdenum in S7 imparts a unique balance where the steel can harden deep into the core while maintaining high tensile strength, preventing the "mushiness" seen in lower alloy steels.

Mechanical Properties and Performance Metrics

Engineers utilizing MWalloys inventory often ask for the trade-off numbers. Here is how they stack up in physical testing.

Hardness Capabilities (HRC)

-

D2 Working Hardness: Typically tempered to 58–62 HRC. It maintains this hardness even as it heats up during friction-heavy operations (air hardening).

-

S7 Working Hardness: Typically tempered to 54–58 HRC. While it can reach 60 HRC right out of the quench, tempering it down to the mid-50s is necessary to unlock its shock-resisting potential.

Toughness vs. Wear Resistance Matrix

This section addresses the primary LSI keywords regarding failure modes.

-

Charpy V-Notch Toughness: S7 offers roughly 125 ft-lbs of impact energy absorption at optimum hardness. D2 often registers below 20 ft-lbs. S7 is effectively 5 to 6 times tougher than D2.

-

Compressive Strength: D2 has superior compressive strength due to its high carbon content, making it ideal for stamping dies that must hold heavy static loads without deforming.

-

Dimensional Stability: D2 is known as a "Cold Work" steel with excellent stability during heat treatment. It barely moves. S7 is also relatively stable as an air-hardening steel, but D2 is the gold standard for intricate die sections that cannot tolerate size shifts.

Heat Treatment Protocols and Processing Nuances

Proper thermal processing is the difference between a high-performance MWalloys tool and scrap metal. The protocols for these two differ significantly.

Austenitizing and Quenching

D2 requires a higher austenitizing temperature (around 1850°F / 1010°C) to dissolve enough carbides into the matrix. It is strictly an air-hardening steel. Oil quenching D2 is risky and often leads to cracking.

S7 austenitizes lower (around 1725°F / 940°C). It can be quenched in air or oil (if the section is thick). The ability to air quench S7 is a major advantage over older shock steels like S1 or S5, which required oil or water and distorted heavily.

Tempering Strategies

-

The D2 Trap: D2 exhibits a phenomenon known as "secondary hardening" at higher tempering temperatures, but this drastically reduces toughness. For most cold work applications, low-temperature tempering (400°F) is preferred to maintain hardness.

-

The S7 Sweet Spot: S7 is usually tempered between 400°F and 500°F. Tempering S7 too high (above 800°F) causes a rapid drop in toughness, contrary to what some might expect.

Machinability, Grinding, and Fabrication

For the toolmaker and machinist, the cost of the steel is often secondary to the cost of machining it.

Machining in the Annealed State

-

D2: Rated at roughly 50-60% machinability compared to W1 water-hardening steel. It is abrasive on cutting tools even in the soft state. You will burn through more carbide inserts machining D2.

-

S7: Rated at roughly 75-85% machinability. It cuts cleanly and is less abrasive. However, S7 can be "gummy" if the spheroidizing anneal was not performed correctly at the mill.

Grinding and EDM (Electrical Discharge Machining)

Grinding hardened D2 is difficult. The chromium carbides resist the grinding wheel, leading to glazing and localized overheating (burning). Use CBN wheels or soft-bond aluminum oxide.

S7 grinds relatively easily, even when hardened. However, if using EDM, both steels require careful removal of the "white layer" (re-cast layer) to prevent surface micro-cracking which can lead to premature tool failure under fatigue.

Industrial Application Scenarios: Where to Use Which?

This section assists procurement officers in matching inventory to requisitions.

When to Specify D2 Tool Steel

Select D2 for "Non-Impact, High-Wear" environments:

-

Blanking Dies: Stamping thin sheet metal, stainless steel, or abrasive aluminum.

-

Rotary Slitters: Knives that cut continuously and generate heat.

-

Thread Rolling Dies: Where high compressive strength and wear resistance are needed (and threads are not prone to chipping).

-

Plastic Injection Molds: For molding abrasive plastics (glass-filled nylon) where the chrome content helps resist wear and mild corrosion.

When to Specify S7 Tool Steel

Select S7 for "High-Impact, Heavy-Load" environments:

-

Punches: Piercing thick plates where the punch undergoes compressive shock on entry and tensile shock on retraction.

-

Chisels and Pneumatic Tools: Concrete breakers, rivet sets.

-

Plastic Injection Molds: Specifically for large molds where the risk of cracking the mold body is high, or for zinc die-casting dies.

-

Shear Blades: For cutting heavy gauge scrap metal where the material might be unpredictable.

Where each steel is commonly used

| Application type | Typical choice | Reasoning |

|---|---|---|

| Precision shear blades, punching dies, blanking tools | D2 | Long-term edge retention under abrasive sliding and high compressive contact |

| Impact punches, cold chisels, driving elements | S7 | Superior shock absorption prevents brittle failure under repeated impacts |

| Drawing dies, forming rolls | D2 | Wear resistance and compressive strength maintain dimensional life |

| Hammering components, jackhammer bits | S7 | Toughness reduces catastrophic fractures in impact service |

| Long-run shear applications with moderate impact | Consider D2 with controlled temper | Tradeoff of wear life against occasional impact; careful design required |

Comparative performance table (typical ranges)

| Property | D2 (typical) | S7 (typical) |

|---|---|---|

| Tempered hardness (service) | 55–62 HRC | 45–55 HRC |

| Wear resistance | Very high | Moderate |

| Impact toughness | Low to moderate | High |

| Machinability (annealed) | Moderate | Good |

| Dimensional stability during quench | Excellent | Very good |

| Typical uses | Cutting, blanking, forming dies | Impact tools, punches, cold-work parts |

Comparative Cost and Supply Chain Availability

In the context of the current steel market, price fluctuates based on alloy surcharges (specifically Molybdenum and Vanadium).

-

Base Cost: Generally, D2 is slightly more expensive per pound than S7 due to the high volume of Chromium and Carbon, though market surges in Molybdenum can occasionally push S7 higher.

-

Availability: Both are standard "stock" items at MWalloys. D2 is widely available in rounds, flats, and plates. S7 is also common but sometimes harder to find in very large cross-sections (above 12 inches) compared to D2.

-

Machining Cost Factor: While D2 material might cost 20% more, the machining time for D2 can be 30-40% higher than S7. If the part requires complex geometry removal, S7 yields a lower total part cost.

Corrosion Resistance and Environmental Durability

A common misconception is that D2 is stainless steel because it has 12% Chromium. This is false.

-

D2 "Semi-Stainless": D2 has enough Chromium to resist atmospheric rust better than O1 or A2, but the carbon ties up much of that Chromium in carbides. It will rust if exposed to moisture or acids. It does not meet medical or food-grade stainless standards (like 440C).

-

S7 Corrosion: S7 has very low corrosion resistance. It must be kept oiled or plated (chrome/nickel) if used in humid environments or corrosive plastic molding.

MWalloys Selection Verdict: The Final Checklist

Use this checklist before finalizing your Purchase Order:

-

Is the workload abrasive? (Sand, glass, paper, sliding metal) -> Choose D2.

-

Is the workload impact-heavy? (Hammering, heavy punching, dropping) -> Choose S7.

-

Is the part intricate with thin walls? -> Choose D2 (for stability) IF no shock is present; otherwise S7 (to prevent wall fracture).

-

Do you need a knife edge? -> D2 for slicing; S7 for chopping (like an axe).

-

Is EDM being used? -> S7 is generally more forgiving of the EDM process if stress-relieved properly.

Which to choose for common failure modes

| Dominant failure mode | Preferred material | Brief justification |

|---|---|---|

| Abrasive wear or edge dulling | D2 | Carbide network resists material loss under sliding contact |

| Sudden fracture from impact | S7 | Higher fracture toughness prevents crack propagation under shock |

| Combination: wear plus repeated strikes | S7 substrate with hard coating or D2 with toughening treatments | Hybrid engineering yields best lifecycle in mixed regimes. |

| Dimensionally critical dies requiring little distortion | D2 | Low distortion after quench benefits precision tooling |

| Components requiring ease of machining pre-hardening | S7 | Lower carbide content gives better machinability in annealed state. |

D2 vs S7 Tool Steel: Technical FAQ

1. Can I use S7 for a knife blade?

2. Is D2 steel considered stainless?

3. Which steel is harder, D2 or S7?

D2 is harder. It can reach a maximum hardness of 62-64 HRC. S7 typically peaks at 59-61 HRC. In practice, D2 is prioritized for its wear resistance, while S7 is tempered lower (56-58 HRC) to maximize its shock resistance.

| Steel | Max Hardness | Primary Property |

|---|---|---|

| D2 | 64 HRC | Wear Resistance |

| S7 | 61 HRC | Shock Toughness |