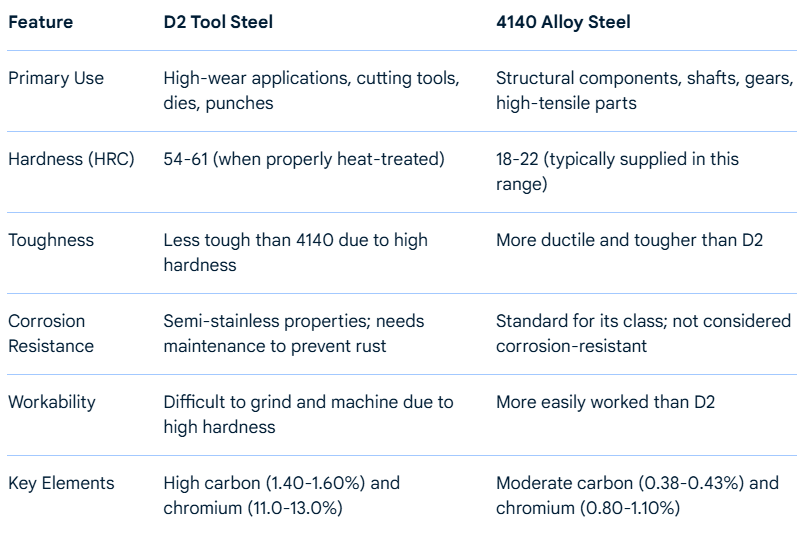

D2 and 4140 occupy distinct roles in the metalworking world. D2 is a high-carbon, high-chromium cold-work tool steel prized for abrasive wear resistance and edge retention; 4140 is a chromium-molybdenum low-alloy steel favored for balanced strength, toughness, and fatigue resistance. For tasks that demand long wear life under compressive abrasion and sharp edge performance, D2 commonly performs better. For components requiring ductility, shock resistance, or heavy machining, 4140 typically offers a safer choice. This article lays out evidence, technical comparisons, processing notes, selection criteria, and maintenance guidance to help engineers, procurement specialists, metallurgists, and maintenance teams choose the correct material for a given service condition.

What is D2 and 4140 steel?

D2 belongs to the cold-work tool steel family. Production routes include vacuum induction melting, controlled forging, normalization, and finish rolling to precise hardness targets. D2 contains elevated carbon and chromium that promote formation of hard carbides. That microstructural makeup drives its primary trait: excellent resistance to abrasive and adhesive wear when heat treated to high hardness.

4140 is an alloy steel in the chromium-molybdenum series manufactured for structural and powertrain components. Typical mills produce 4140 through standard carbon steel ingot or continuous casting followed by hot rolling and controlled cooling. 4140’s alloy blend yields a favorable combination of tensile strength, yield strength, ductility, and toughness after suitable heat treatment.

Engineers often weigh D2’s superior wear life versus 4140’s higher toughness. The choice depends upon loading type, expected stresses, manufacturing constraints, repairability, and total cost of ownership.

Chemical composition comparison with interpretive notes

| Element | Typical D2 (wt%) | Typical 4140 (wt%) | Technical implication |

|---|---|---|---|

| Carbon (C) | 1.40–1.60 | 0.38–0.45 | D2 high carbon forms abundant carbides, raising hardness potential. 4140 carbon level allows hardening while retaining ductility. |

| Chromium (Cr) | 11.00–13.00 | 0.80–1.10 | D2 chromium supports hard carbide stability and corrosion resistance improvement. 4140 chromium improves hardenability and strength. |

| Molybdenum (Mo) | 0.70–1.20 | 0.15–0.25 | In D2, Mo refines carbides and improves toughness of a brittle matrix. In 4140, Mo increases hardenability and high-temperature strength. |

| Vanadium (V) | 0.10–0.40 | 0.00–0.03 | Vanadium in D2 forms very hard vanadium carbides that boost abrasion resistance. 4140 typically lacks significant V. |

| Manganese (Mn) | 0.30–0.60 | 0.60–0.90 | Mn aids strength in both steels but excessive Mn can affect toughness. |

| Silicon (Si) | 0.20–0.60 | 0.15–0.35 | Deoxidation and strength impact. |

| Phosphorus, Sulfur (P, S) | ≤0.025 | ≤0.035 | Kept low to preserve toughness and fatigue life. |

Interpretation summary

D2 has a near tool-steel chemistry that favors carbide networks embedded in a hardened martensite matrix after quenching. That leads to excellent wear resistance while sacrificing notch toughness. 4140 features balanced alloying that yields both strength and ductility following quenching and tempering. Hardenability in 4140 permits thicker sections to be heat treated successfully.

Mechanical properties and performance in service

| Property | D2 (typical, heat treated) | 4140 (typical, heat treated) | Practical meaning |

|---|---|---|---|

| Hardness range | HRC 55–64 | HRC 28–55 (depending on treatment) | D2 commonly held at very high hardness for tool life. 4140 hardness tailored per strength and toughness needs. |

| Tensile strength (ultimate) | 1400–2200 MPa (depends on hardness) | 850–1400 MPa | D2 higher tensile strength at high hardness but lower ductility. 4140 offers better elongation. |

| Yield strength | High, but variable | 600–1100 MPa | 4140 often used where yield behavior matters. |

| Elongation (pct) | 2–8% | 10–25% | 4140 superior ductility for forming, shock loading, or bending. |

| Impact energy (Charpy) | Low to moderate | Moderate to high | 4140 preferable where shock or impact risk exists. |

| Fatigue limit | Moderate | Good to very good | 4140 often exhibits higher fatigue endurance in practical components. |

Key takeaways

For high hardness, dimensionally stable wear parts, D2 provides longer service life under abrasive contact. For components facing bending, torsional load, or cyclic impact, 4140 minimizes brittle fracture risk.

Heat treatment pathways, microstructure targets, tempering strategies

| Stage | D2 typical treatment | 4140 typical treatment | Microstructural objective |

|---|---|---|---|

| Austenitizing | 1000–1020°C with controlled soak | 820–870°C depending on section | Form austenite that will transform to martensite on quench; avoid grain growth. |

| Quench | Oil or high-speed polymer quenches to avoid cracking | Oil, polymer, or gas quench based on section | Rapid cooling to form martensite, but D2 needs care due to high carbon; risk of quench cracking higher. |

| Tempering | Multiple temp cycles at 150–250°C if highest hardness, or 200–550°C for toughness trade | Single to multiple temp cycles 400–650°C tailored for target hardness and toughness | D2 tempering seeks carbide stability while relieving stresses. 4140 tempering balances strength with ductility. |

| Subcritical anneal | Used for softening before machining | Anneal for improved machinability | Reduce hardness for cutting operations. |

Practical heat treatment notes

-

D2’s high carbide fraction means a fraction of hardness comes from carbides which do not temper away easily. That makes tempering response limited.

-

4140 responds over a wider tempering window, offering room to tune strength and toughness.

-

Stress relieving and preheating during machining or welding are critical for D2 to prevent cracking.

Wear resistance, toughness, fatigue behavior, impact performance

Wear mechanisms

-

Abrasive wear: D2 excels due to hard stable carbides that resist cutting and plowing by abrasive particles.

-

Adhesive wear: D2’s hard matrix reduces material transfer.

-

Fatigue wear: 4140 often outperforms D2 where cyclic surface stresses control life because of higher toughness and more forgiving microstructure.

Toughness and brittle fracture

D2, when hardened above HRC 60, becomes brittle in presence of stress concentrators. 4140 tolerates notches and repeated shocks better. For dies, punches, and shear blades with high compressive contact and limited tensile shock, D2 will prolong service. For crankshafts, shafts, gears, and structural parts where fracture risk is critical, 4140 remains preferred.

Fatigue evaluation

When fatigue is driven by surface roughness, microstructural inclusions, or tensile mean stress, 4140’s capacity for toughness improvement via tempering means improved endurance. Surface finishing, shot peening, and compressive surface treatments improve both steels’ fatigue life; selection should factor surface modification cost.

Machinability, grindability, tooling recommendations, and cost implications

| Aspect | D2 | 4140 | Practical advice |

|---|---|---|---|

| Machinability in annealed condition | Moderate to good after anneal | Good in annealed condition | Anneal D2 to ~HB 200 for machining. Use rigid setups, low chip load, and sharp carbide tooling. |

| Machinability in hardened condition | Poor | Poor to moderate | Grinding preferred for hardened D2. For 4140, single-point turning with CBN or cubic boron nitride allowed in some cases. |

| Grinding behavior | Carbide-rich abrasive behavior; requires diamond or CBN abrasives for best results | Easier with conventional abrasives | Wheel selection critical for D2 to prevent glazing and thermal damage. |

| Tooling choice | Carbide inserts coated with AlTiN for high speed; CBN for finish grinding | Carbide inserts, HSS for roughing; CBN for hardened finishing | Use high feed, low depth for ductile 4140; use slower cuts for D2 in pre-hardened state. |

| Cost per kg | Higher due to alloying and processing | Lower | Total cost of ownership must include machining time, tool life, and expected service life. |

Manufacturing recommendations

-

If fabricating from D2, plan heat treatment sequence: machine to near-net shape in soft condition, then harden, then do final grinding.

-

When using 4140 for heavy sections, consider normalized or quenched+tempered conditions that match required mechanical targets before final machining to avoid distortion.

Weldability, joining strategies, and repair practices

Weldability summary

-

D2 is not favorable for conventional welding in the hardened condition. High carbon and carbides promote cracking, heat-affected zone embrittlement, and dilution issues. Welding requires specialized filler metals, preheat, interpass temperature control, and post-weld heat treatment. Many fabricators avoid welding D2 and prefer mechanical fastening or brazing for repairs.

-

4140 is weldable with precautions. Preheat to moderate temperature, control interpass, and perform post-weld tempering or PWHT to restore toughness. For critical parts, matched filler alloys and qualified procedures must be used.

Repair strategies

-

For D2: localized brazing using suitable filler rods or using nickel-based brazes can repair small sections without heavy metallurgical damage. For larger damage, replace the component or use welded build-up followed by thermal cycling and rehardening, but this is complex.

-

For 4140: conventional weld repair using low hydrogen electrodes or NiCrMo fillers works if procedures adhere to preheat and postheat. After repair, re-tempering recommended to reduce residual stresses.

Typical applications and use cases with real-world examples

D2 common uses

-

Cold-work dies and punches for blanking, piercing, fine punching.

-

Shear blades, cutting dies, and feed screws that face heavy abrasive contact.

-

Knife and slicer edges within material processing where edge retention matters.

4140 common uses

-

Shafts, axles, couplings, gears for moderate loads.

-

Hydraulic piston rods, mandrels, and fasteners requiring high strength with some ductility.

-

Machine frames and components that must resist shock and fatigue.

Selection scenario examples

-

Example 1: A stamping die for high volume metal blanking will often use D2 for the cutting edge and a tougher steel for the die body.

-

Example 2: An industrial drive shaft subjected to torsion and bending is best made from 4140 quenched and tempered to required hardness to avoid brittle failure.

Standards, grade equivalents, and authoritative references

Common specifications and equivalents

-

D2 typically referenced under ASTM A681 (standard specification for tool steels), with international equivalents SAE/ISO designations present in various standards.

-

4140 commonly appears in ASTM A29 / A29M and SAE J404 or AMS specifications for alloy steels. Equivalent designations exist in EN, JIS, and ISO standards.

Practical note on procurement

When specifying material for purchase, include full standard numbers, heat treatment state, hardness range, batch traceability, chemical certificates, and inspection requirements to ensure the material conforms to critical service expectations.

Selection criteria, decision matrix, and failure mode analysis

| Criterion | Prefer D2 | Prefer 4140 | Rationale |

|---|---|---|---|

| Abrasive wear resistance | ✓ | Carbide reinforcement yields superior resistance. | |

| Edge retention | ✓ | D2 hardness preserves cutting geometry. | |

| Shock and impact resistance | ✓ | 4140 toughness reduces brittle fracture. | |

| Ease of welding/repair | ✓ | 4140 tolerates welding with standard procedures. | |

| Machining in annealed state | ✓ (after soft anneal) | ✓ | Both can be machined when softened; 4140 easier. |

| Cost sensitivity | ✓ | 4140 often lower raw cost. | |

| Thickness greater than 25–30 mm requiring through-hardening | ✓ | 4140 hardenability tends to permit thicker sections without cracking. |

Failure mode analysis

-

D2 failures often initiate from microstructural inclusions or brittle fracture under tensile or notched loading. Edge chipping may occur if impact present.

-

4140 failures typically occur from overload, excessive wear when not hardened properly, or from high cycle fatigue when surface conditions are poor.

Surface treatments, post-processing, and corrosion control

Surface enhancements to extend life

-

Carburizing: beneficial for 4140 when surface hardness needed with core toughness retained.

-

Nitriding: creates a hard wear-resistant layer while preserving core properties; works for suitably alloyed steels given process parameters.

-

Coatings: PVD or hard ceramic coatings applied to D2 can further reduce adhesive wear and lower friction.

-

Shot peening and laser shot peening: induce beneficial compressive residual stresses to improve fatigue life for both steels.

Corrosion considerations

D2’s elevated chromium delivers some passive behavior relative to plain carbon steel, yet it is not stainless. In corrosive service, apply protective coatings, cathodic protection, or use stainless alternatives.

Lifecycle considerations: inspection, maintenance, recycling

Inspection best practices

-

Visual inspections for chipping, spalling, pitting, and crack initiation.

-

Non-destructive testing such as dye penetrant inspection for surface cracks, magnetic particle testing for near-surface discontinuities.

-

Hardness mapping and micrograph checks for wear pattern analysis.

Maintenance strategies

-

Scheduled regrinding or reconditioning of edges for D2 components to restore geometry.

-

Rejuvenation of 4140 surfaces with shot peening and re-machining where wear occurred.

Recycling

Both steels have high scrap value and are compatible with standard steel recycling streams. Track alloy content during reclaim to maintain material quality.

When choose D2 or 4140 steel?

-

Use D2 when primary failure mode is abrasive wear and dimensional accuracy at high hardness is essential.

-

Use 4140 when components face combined bending, torsion, impact, or require routine welding and repair.

-

For hybrid needs, combine alloys: a D2 wear surface may be mounted upon a 4140 support frame, or use 4140 with case hardening for a wear surface plus tough core.

Frequently asked questions (FAQs)

-

Which material holds a sharper cutting edge longer, D2 or 4140?

D2 holds a sharper edge longer due to dense hard carbides and higher achievable hardness. For persistent abrasive contact, D2 delivers greater edge life. -

Can I weld D2 easily in the field?

Welding D2 poses challenges. High carbon and carbides lead to cracking risk. Use preheat, matched filler, rigorous interpass control, and post-weld heat treatment if welding is unavoidable. For many repairs, brazing or component replacement proves more reliable. -

What hardness should 4140 be tempered to for shaft applications?

Typical hardness targets range from HRC 28 to HRC 40 depending on performance demands. Balance hardness with required toughness; tempering around 450–600°C offers strength plus ductility. -

Is D2 corrosion resistant?

D2 contains significant chromium which improves resistance versus plain carbon steels, but it does not meet stainless definitions. Apply protective measures if environment includes moisture, acids, or salts. -

Which steel requires more careful quenching to avoid cracking?

D2. High carbon and carbide networks increase quench cracking risk. Use controlled austenitizing, appropriate quench media, and stress relieving cycles to minimize cracking. -

For heavy cyclic loading, which alloy should I pick?

4140 typically offers superior fatigue endurance under cyclic tensile or bending load because toughness helps blunt crack initiation and growth. -

How should I machine D2 to minimize tool wear?

Machine in annealed condition where possible. Use rigid fixturing, light depths of cut, sharp carbide inserts, and coolant. For hardened D2, grinding with CBN or diamond wheels is recommended. -

Can 4140 be nitrided or carburized to improve surface hardness?

Yes. Case hardening methods are commonly used on 4140 to produce a hard wear surface with a tougher core, controlling process parameters to avoid distortion and maintain required core properties. -

What inspection methods help detect early failure in D2 components?

Frequent visual checks, dye penetrant for surface cracking, magnetic particle inspection for near surface flaws, and hardness comparisons across regions to detect softening or overtempering. -

Which offers better total cost of ownership for a cutting tool—D2 or 4140?

If wear is the primary life limiter, D2 often yields lower total cost of ownership due to fewer replacements. If impact or repairability matters, 4140 may reduce downtime and repair expense. Perform life cycle cost modeling to decide.