D2 tool steel is a high-carbon, high-chromium, air-hardening cold-work steel engineered for strong wear resistance and excellent dimensional stability in tooling applications. For projects that prioritize edge life, abrasion resistance and minimal distortion during hardening, D2 is often the preferred choice. When toughness or impact loading takes priority, alternative grades may be more suitable.

1. Quick technical snapshot

- Grade name: D2 (often referenced by DIN 1.2379, JIS SKD11, EN X153CrMo12 and UNS notations depending on region).

- Family: Cold-work, high-carbon, high-chromium tool steels.

- Primary attributes: High abrasion resistance, good dimensional stability on hardening, moderate toughness.

- Common hardness after quench and temper: typically in the mid 50s to low 60s HRC depending on tempering practice.

- Typical use cases: blanking and forming dies, cutter knives, shear blades, extrusion tooling, cold work tooling, wear components.

If your project requires D2 tool steel, contact MWalloys for a free quote.

2. Chemical composition and international equivalents

Below is a concise composition table representing typical commercial D2 chemistry ranges. Suppliers may publish slightly different limits. Always confirm composition with the mill certificate for each lot.

| Element | Typical weight percent (range) | Notes |

|---|---|---|

| Carbon (C) | 1.40 - 1.60 | High carbon content builds carbide volume for wear resistance |

| Chromium (Cr) | 11.00 - 13.00 | High Cr forms hard chromium carbides and gives mild corrosion resistance |

| Molybdenum (Mo) | 0.70 - 1.20 | Improves hardenability and toughness |

| Vanadium (V) | 0.30 - 1.10 | Refines carbides and improves wear performance |

| Manganese (Mn) | 0.10 - 0.60 | Deoxidizer and hardenability aid |

| Silicon (Si) | 0.20 - 0.50 | Deoxidizer, strength aid |

| Phosphorus (P) | <= 0.03 | Impurity, kept low |

| Sulfur (S) | <= 0.03 | Impurity, kept low |

| Iron (Fe) | Balance | Primary matrix metal |

International equivalents

| Common designation | Country / Standard | Typical cross reference |

|---|---|---|

| D2 | AISI / ASTM (North America) | D2 |

| 1.2379 | DIN (Germany) | 1.2379 |

| SKD11 | JIS (Japan) | SKD11 |

| X153CrMo12 | EN (Europe) | X153CrMo12 |

Notes on equivalents: equivalence tables are a procurement convenience. While labels map, small chemistry or cleanliness differences between mills can change tool performance. For critical tooling, require a full mill certificate and, when possible, vendor-supplied impact and hardness verification.

3. Microstructure and metallurgical behaviour

D2’s microstructure in the normalized and annealed condition is a tempered martensitic matrix that contains a relatively high volume fraction of chromium-rich carbides. These carbides provide abrasion and sliding wear resistance. The matrix responds to heat treatment with low distortion when quenched correctly because D2 is an air-hardening grade. Key metallurgical points:

- Chromium promotes the formation of hard M7C3 and (Cr,Mo,V)-rich carbides that resist abrasive wear.

- Vanadium and molybdenum refine carbide size and distribution, improving wear resistance and edge retention.

- High carbon content increases carbide fraction but reduces overall toughness; this trade-off defines typical applications.

- D2 shows good dimensional stability during heat treatment compared with water-quenched grades, making it suitable for precision dies.

4. Mechanical properties and hardness ranges

Mechanical properties for tool steels depend on heat treatment. Tables below give practical target ranges used by toolmakers. Always test representative samples after processing.

Typical hardness targets and tempering effects

| Condition | Typical hardness (HRC) | Typical use |

|---|---|---|

| Annealed | 200 - 260 HB (~20 - 25 HRC) | Easier machining state |

| Hardened and tempered to 58 HRC | 58 HRC | General high-wear tooling |

| Hardened and tempered to 60 HRC | 60 HRC | High edge retention with care on toughness |

| Maximum achievable (laboratory) | up to ~63 HRC pre-temper | Not always suitable for production parts due to brittleness |

Representative mechanical property table (post heat treatment typical values)

| Property | Typical value | Notes |

|---|---|---|

| Tensile strength | 1500 - 2200 MPa | Estimated range based on hardness conversion |

| Yield strength (compressive) | high; depends on hardness | For cold work tooling compressive strength is critical |

| Fracture toughness | lower than A2 or S7 at same hardness | Trade-off with wear resistance |

| Wear resistance | High | Carbide volume key contributor |

D2 tool steel density

D2 tool steel has a density of approximately (7.70 g/cm³), (7700 kg/m³) or (0.278 lb/in³).Specific Gravity: 7.70, Melting Point: 1421℃ (2590℉).

5. Heat treatment and tempering recommendations

D2 is air-hardening. The following schedule is a practical production-oriented sequence. Exact temperatures and hold times depend on section size, furnace type and desired hardness.

Typical heat treatment sequence (production example)

- Anneal (for machining): Heat slowly to 800-900°C, hold to equalize, then cool in furnace at controlled rate to 600°C and then to room temperature. Target hardness ~200-260 HB.

- Preheat for hardening: Bring part to 750-800°C and hold for soak depending on section thickness.

- Austenitize (hardening): Heat to 1020-1050°C (some sources use 1010-1040°C) and soak time depending on thickness (typically 20-30 minutes per 25 mm of section).

- Quench (air cool or oil for certain section sizes): Because D2 is air-hardening, controlled air cooling from the austenitizing temperature is common. For small sections, forced air or still air is used; large sections may need slow cooling controls to minimize cracking.

- Tempering: Multiple temper cycles are common. Typical range 150-560°C depending on target hardness. For targets of mid 50s to low 60s HRC, temper at 150-250°C for lower tempering and then higher temperature steps if toughness improvement is required.

Tempering table (example setpoints)

| Tempering temperature (°C) | Approximate achieved hardness (HRC) | Typical comment |

|---|---|---|

| 150 | ~62 - 60 | Minimal softening, high wear hardness |

| 200 | ~60 - 58 | Good compromise for many tools |

| 300 | ~58 - 55 | Better toughness, slightly reduced hardness |

| 500 | ~54 - 50 | For parts requiring more toughness and shock resistance |

Notes: Use multiple temper cycles (two temperings are common) and measure hardness after each. Hold times and ramp rates must match part geometry. For large dies use controlled slow cooling to avoid thermal shock. Stress relief after rough machining reduces distortion during final hardening.

6. Machining, grinding and EDM guidelines

Machining in annealed condition

- Machine D2 after bright anneal to ease tool wear and avoid excessive tool consumption.

- Carbide tooling with coatings (TiN, TiCN) provides better tool life. Use low cutting speeds and high feed for roughing.

Grinding practices for hardened D2

- Use vitrified or resin bonded wheels rated for high carbide content steels. Dress the wheel frequently to maintain cutting efficiency.

- Coolant must be applied continuously to prevent thermal damage.

EDM considerations

- D2 is commonly processed by EDM for complex geometries. When EDM-ing hardened D2, plan for surface recarburization, white layer formation and potential residual stresses. Light grinding after EDM might be required to remove recast layer for final applications.

7. Typical applications and examples

Common applications where D2’s attributes are decisive:

- Blanking and forming dies: long tool life and small dimensional change after hardening makes D2 ideal for stamping dies and punches.

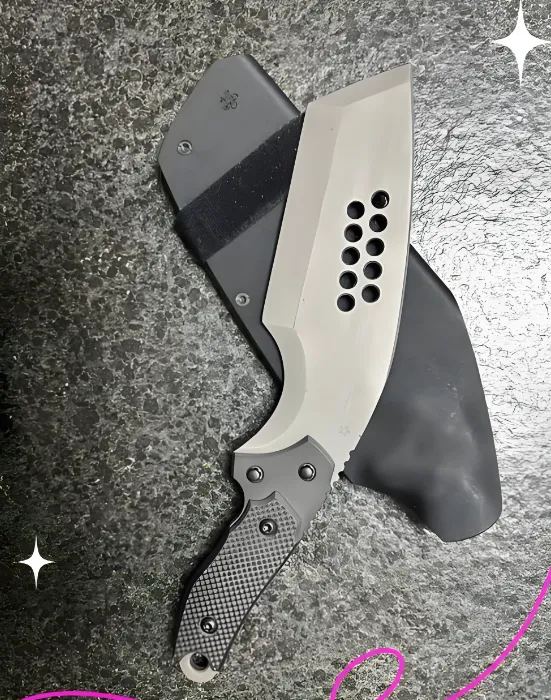

- Shear blades and slitter knives: edge retention in abrasive sheet metal cutting.

- Cold extrusion tooling components where wear dominates over impact.

- Wear strips, guides, and liners for applications with sliding abrasion.

Case note

A medium-sized automotive supplier replaced an existing lower-chrome grade with D2 for a blanking die set. The die set’s lifetime in production doubled before regrinding, reducing downtime and total cost per part despite higher initial material cost. The critical success factors were correct austenitizing temperature control and post-hardening straightening.

8. Manufacturing and processing flow

- Specification and procurement: define geometry, tolerance, finish, and mill certificate requirements.

- Receiving inspection: chemistry check via certificate and random spectro test, hardness check if required.

- Rough machining in annealed state: machine to near net shape at annealed hardness.

- Pre-heat and stress relief: if required for large sections.

- Austenitize and quench (air-hardening practice): ensure uniform heating and controlled cooling.

- Multiple tempers: temper to target hardness and stress relieve.

- Straightening and stress correction: correct any distortion via controlled heating and mechanical methods.

- Finish grind and EDM operations: to final dimensions and surface requirements.

- Final inspection and certification: hardness mapping, dimensional report, and microstructure checks if necessary.

9. Quality control and specification checks

Key inspection steps buyers should insist on:

- Mill certificate (MTC): chemical analysis traceable to standard.

- Hardness map: hardness at multiple locations if part is large.

- Microstructure report: especially for critical dies showing carbide distribution.

- Non-destructive checks: magnetic particle or dye penetrant testing for surface cracks after heat treatment when applicable.

- Dimensional report and heat treatment record: to ensure process traceability.

10. Pricing factors and procurement advice

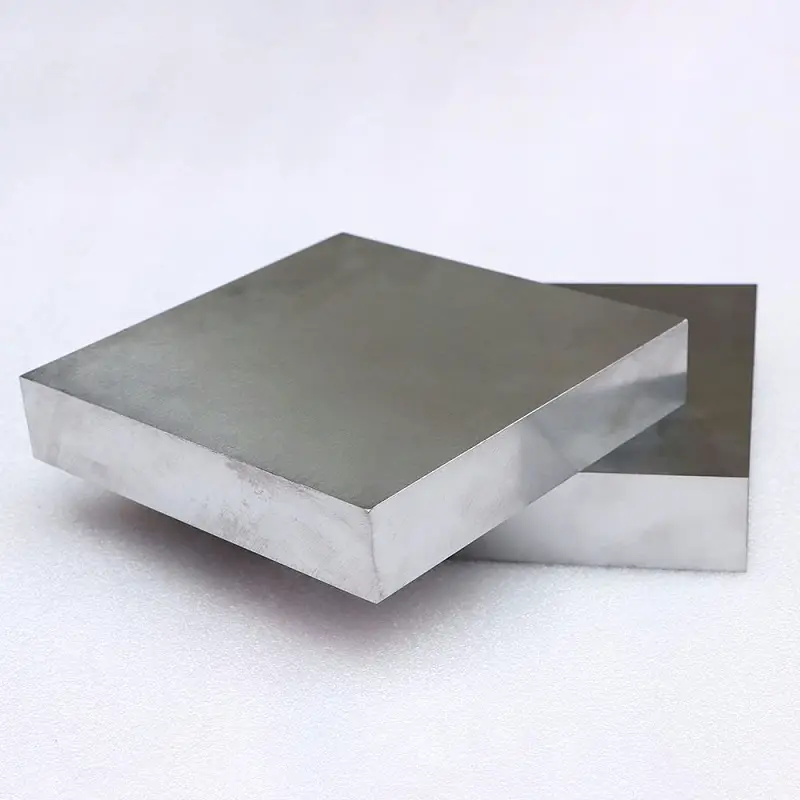

Price for D2 tool steel varies widely with form (bar, plate, block), supply channel (mill, distributor, small-lot supplier), and form factor (powder vs wrought). Key price drivers:

- Form and size: blocks and pre-hardened plates command a premium.

- Heat treatment and delivery state: pre-hardened material or EDM-ready blocks cost more.

- Specification tightness: close chemical tolerances, low impurities and premium supply chains add cost.

- Certificate and testing requirements: additional inspection increases price.

- Market raw material cycles: steel and alloying element price swings impact mill pricing.

Representative procurement ranges

| Region / channel | Typical price range (indicative) | Comment |

|---|---|---|

| China bulk (tonne scale) | US$2,000 - US$3,200 per tonne | Typical mill or large-trader FOB lots for standard D2 sheet or round bar |

| US distributors small-lot | US$8 - US$15 per kilogram retail | Small quantities and pre-cut blocks cost more per kg |

| D2 powder (additive manufacturing feedstock) | From around US$32 per kilogram (market niche) | Powder prices are higher and more volatile |

Notes: These ranges are indicative and depend on market conditions. For firm procurement, request quotes that specify the delivery condition, lot size, and required testing.

11. Safety, storage and handling

- Store billets and plates in a dry environment to minimize surface rust. Mildly oiled surfaces are standard for long-term storage.

- Maintain safe handling practices for heavy blocks. Use mechanical lifting equipment rated for load.

- During heat treatment, control furnace atmosphere and quench media to avoid surface decarburization or oxidation.

12. Data sheet checklist and purchase specification template

When issuing a purchase order for D2 tooling material, include the following minimum fields:

- Grade designation and standard (e.g., D2, DIN 1.2379, JIS SKD11).

- Required chemistry ranges and testing (attach target certificate template).

- Delivery condition (annealed, hardened and tempered to X HRC, pre-hardened block).

- Mechanical properties (minimum hardness, surface finish, permitted microstructure).

- Inspection and certifications required (MTC, hardness map, NDT).

- Packing, labeling and traceability requirements.

- Warranty and acceptance criteria (e.g., maximum inclusion size, permitted cracks).

D2 Tool Steel: Technical FAQ & Performance Guide

1. What is the main advantage of D2 over A2?

2. Can D2 be used for high-impact tools?

3. Is D2 corrosion resistant?

4. How should I order D2 for EDM-ready blocks?

5. What tolerances should I expect after heat treatment?

6. Can D2 be nitrided?

7. What are typical machining recommendations?

8. Is powder metallurgy (PM) D2 better than wrought D2?

9. How many tempers are recommended?

10. What inspection documents should I insist on?

Final notes for engineers and buyers

D2 is a proven workhorse for tooling where abrasive wear and dimensional stability are the main requirements. Correct heat treatment and procured material quality determine success. For critical dies define a clear specification, insist on traceable certificates, and partner with an experienced heat treater.

Prepared for MWAlloys. For custom D2 blanks, bars and pre-hardened blocks request a quotation that specifies required size, heat-treatment state and inspection scope.