CPM M4 is a premium powder-metallurgy high-speed tool steel that delivers an uncommon mix of very high wear resistance and excellent toughness for a high-carbon, non-stainless tool steel. Properly heat treated, CPM M4 reaches working hardnesses in the low 60s HRC and gives outstanding edge retention for demanding cutting tools, punches, and knives, while still tolerating shock better than classic M2-type steels. For buyers and engineers who need maximum abrasion resistance with good resistance to breakage, CPM M4 is an industry-leading choice — provided users accept the need for corrosion control and careful heat treatment.

What is CPM M4

CPM M4 is Crucible Industries’ powder-metallurgy version of the classic AISI M4 high-speed steel. It was engineered to retain the desirable high-carbon/high-alloy characteristics of M4 while improving toughness, cleanliness, and carbides distribution through particle-metallurgy processing. The powder route yields a finer carbide dispersion, reduced segregation, and improved transverse toughness compared with ingot-processed equivalents. These traits make CPM M4 especially suitable where repeated cutting at elevated loads or shock is encountered.

If your project requires CPM M4 steel, contact MWalloys for a free quote.

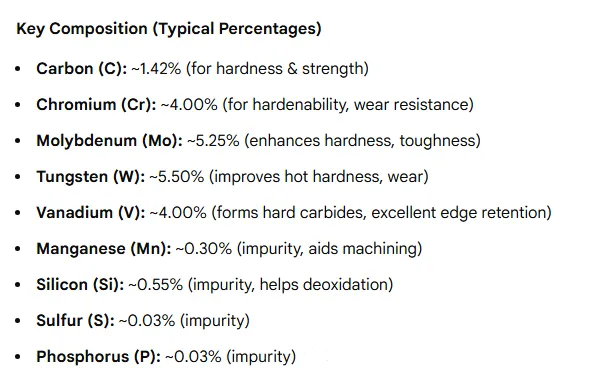

Chemical composition and microstructure

Key chemistry (typical ranges)

| Element | Typical range (wt%) | Role |

|---|---|---|

| C (Carbon) | 1.30 – 1.50 | Carbide-former controlling hardness and wear resistance |

| Cr (Chromium) | 3.75 – 4.50 | Hardenability and tempering resistance |

| Mo (Molybdenum) | 4.00 – 5.00 | Solid solution strengthening, carbide formers |

| V (Vanadium) | 1.75 – 2.20 | Very hard vanadium carbides for abrasion resistance |

| W (Tungsten) | 5.00 – 6.50 | High-speed properties and hot hardness |

| Co (Cobalt) | 8.00 – 9.50 (in some variants) | Increases hot hardness and red hardness in some M4 variants |

| Others (Si, Mn, P, S) | trace levels | Process control and machinability balance |

Typical datasheets and crucible product specifications report these ranges and note small manufacturing variations between CPM REX M4 HC or HS variants and other vendor equivalents. The high vanadium and tungsten content generates a matrix populated with multiple carbide types (MC-type vanadium carbides and complex alloyed carbides) that are fine and uniformly distributed thanks to the CPM process.

CPM M4 Steel Equivalent (High-Speed Tool Steel)

CPM M4 steel equivalents include European standards like S690 (DIN 1.3343) and Japanese SKH51, which share similar high-speed tool steel properties, while in the knife world, steels like CPM-M4 ( Crucible Industries' proprietary version of M4) offer comparable performance to non-stainless M4, with stainless options like M390/20CV/CTS-204P providing similar edge retention but trading some toughness for corrosion resistance, and newer steels like MagnaCut aiming for a balance of toughness, wear, and corrosion resistance, though M4 generally surpasses them in pure wear.

S690 / DIN 1.3343: European standard for M4.

JIS SKH51: Japanese equivalent.

ASTM A600 / FED QQ-T-590: Older US standards for Molybdenum High-Speed Steels.

Similar Performing Steels

CPM Rex M4 HC:

A variant of M4 with enhanced toughness and cleanliness via powder metallurgy, noted for excellent wear resistance.

M390 / CPM-20CV / CTS-204P:

Stainless steels offering comparable edge retention to M4, but M4 is tougher and less corrosion-resistant.

CPM-3V:

Known for exceptional impact toughness, approaching shock steels, with excellent wear, but not as wear-resistant as M4.

MagnaCut:

A modern stainless steel balancing high wear, toughness, and corrosion resistance, outperforming M4 in corrosion but generally lower in extreme wear.

Mechanical properties and performance characteristics

Summary of performance traits

-

Wear resistance: Very high for carbon, non-stainless steels because of abundant hard vanadium and tungsten carbides.

-

Toughness: Significantly better than cast/ingot M2 at equivalent hardness owing to powder-metallurgy microstructure.

-

Edge retention: Excellent; holds a keen cutting edge under abrasive service.

-

Hardness range: Typical working hardness after recommended heat treat is in the mid-to-low 60s HRC.

-

Corrosion resistance: Low compared with stainless tool steels. Requires maintenance or surface protection.

Representative mechanical table (typical values)

| Property | Typical value / note |

|---|---|

| As-annealed hardness | ~220–260 HB (depends on anneal schedule) |

| Heat-treated hardness | 58–65 HRC depending on tempering and austenitizing |

| Transverse rupture strength | Higher than ingot M4 or M2 at same hardness (PM benefit) |

| Wear resistance index | High relative to M2 and many tool steels |

| Recommended working hardness for knives | 61–64 HRC for balance of edge retention and toughness |

(Exact numbers should be confirmed with product datasheet and test reports for the supplied lot.)

Heat treatment — practical recipes and expectations

Heat treatment decisively controls the performance of CPM M4. Because of its alloy balance and carbide population, the steel requires higher tempering temperatures than many carbon steels and benefits from prompt tempering cycles to avoid retained austenite or cracking.

Recommended heat-treat summary (industry-consensus)

| Step | Typical parameter (range) | Notes |

|---|---|---|

| Preheat / soak | 650–760°C ramp to austenitize | Soak time depends on section size |

| Austenitize (solution treat) | 1120–1149°C (2050–2100°F) typical | Higher austenitizing raises hardenability; for larger cross sections HC variant helps |

| Quench | Oil quench to below 200°F (93°C) or recommended cooling | Avoid severe quench stresses in complex shapes |

| Temper | 538–593°C (1000–1100°F) x 2 hours, double temper; triple temper if austenitized at high end | Do not temper below 538°C; temper immediately after quench |

| Expected hardness (2 hr x2) | ~62–64 HRC at around 1000–1050°F temper (depending on austenitizing) | See datasheet curves for exact numbers |

Notes:

-

Double tempering is common practice; triple temper recommended if high austenitizing was used.

-

For maximum toughness some shops use slightly lower HRC targets (58–61) using tempering at the upper end of the listed range.

-

Neutral salt bath or vacuum furnace adjustments: when using neutral salt baths reduce temperature slightly per vendor instructions.

Machinability, grinding, and fabrication tips

Because CPM M4 is a high-speed, high-carbon, high-vanadium steel with a dense carbide population, it is more abrasive on tooling than softer steels. Follow these best practices:

-

Pre-heat-treatment shaping: Bulk shaping, heavy stock removal, and rough milling are easier in the annealed condition. Final finishing should be minimized prior to heat treatment to avoid work hardening.

-

Cutting tools: Use carbide tooling and take light, steady cuts. Use flood coolant or misting to reduce heat buildup.

-

Grinding: Diamond or CBN wheels are recommended for hardened CPM M4 due to its carbide content. Adjust dressing intervals — carbide pull-out occurs with dull wheels.

-

Welding: Not recommended for final repair without special procedures; brazing or mechanical joining is often used. If repair welding is necessary, consult experienced tool-steel welders and preheat/postheat as required.

-

Polishing: Start with coarse steps before moving to finer grits; hardened M4 will require time-consuming polishing if high polish is required. Use lubricant and cooling to avoid overheating.

Surface treatments, coatings, and corrosion control

Corrosion management

CPM M4 is not stainless. For field service where humidity or wet cutting is present, provide corrosion protection using:

-

Light oil film or anti-corrosion rust preventatives on stored items.

-

Passivation is not effective because steel is carbon type; mechanical protection and coatings are more useful.

-

Regular maintenance for cutting tools in wet environments is mandatory.

Surface treatments

-

Nitriding: CPM M4 tolerates nitriding well. Nitriding builds a hard surface layer that complements interior toughness. Because M4’s tempering temperatures are high, nitriding is often used for additional surface life.

-

PVD/CVD coatings: PVD coatings (TiN, TiAlN, etc) are commonly used after proper tempering. CVD processes can exceed hardening temperatures and may cause dimensional change, so follow supplier guidance.

-

Plasma nitriding or ion nitriding: Often selected for dies and punches for surface hardening without risking core properties.

Typical and high-value applications

CPM M4 is chosen when abrasive wear and shock are both concerns. Common uses include:

-

Cutting tools for abrasive materials (knife blanks for competition and industrial cutters).

-

Cold-work punches and dies where high wear resistance and resistance to chipping are required.

-

Shear blades, slitter knives, and circular knives for paper, textiles, and plastics.

-

Specialized tooling for metal forming when toughness and wear resistance must be balanced.

-

High-end custom knife blades where edge retention and break resistance are prioritized over stainless properties; such knives require active corrosion control.

CPM M4 vs similar steels — fast comparison table

| Steel | Type | Key strengths | Typical working HRC | Corrosion resistance |

|---|---|---|---|---|

| CPM M4 | PM high-speed tool steel | Exceptional wear resistance with high toughness | 58–65 | Low |

| AISI M2 / Ingot M2 | Conventional high-speed steel | Good wear; lower toughness vs CPM M4 | 60–64 | Low |

| CPM S30V / S35VN | PM stainless powder steels | Good corrosion resistance and toughness for stainless; less abrasive wear than M4 | 58–62 | High |

| CPM M390 | PM stainless microclean steel | Very high wear resistance + stainless; more costly | 60–64 | High |

| CPM S90V | PM stainless with high vanadium | Exceptional edge retention; poor toughness relative to others | 59–64 | High |

Takeaway: CPM M4 sits near the top for wear resistance among carbon/non-stainless tool steels while offering superior toughness compared with ingot M2. Stainless PM steels trade corrosion resistance for comparable or slightly lower abrasion resistance depending on chemistry.

Procurement, specification checks, and quality considerations for buyers

When buying CPM M4 or equivalent PM M4 from any supplier including MWAlloys, require the following to ensure repeatable performance:

-

Mill/test certificate (MTC): Material batch certificate listing chemical analysis, traceability to melt/cast, and heat number.

-

Hardness checks: Confirm as-supplied and post-heat-treated hardness ranges.

-

Microstructure report: For critical tooling request micrographs showing carbide distribution or a vendor microstructure note. PM steels should show fine, evenly distributed carbides.

-

Supply form: Specify bar, flat, plate, or blanks and required dimensions/tolerances. Include acceptance tolerances for straightness, squareness, and surface finish.

-

Heat-treated or pre-hardened options: Decide if you want stock pre-hardened to a particular HRC or annealed for in-house heat treat. Pre-hardened parts must be shipped with packing preventing corrosion.

-

Coating or nitriding options: If you need surface treatment, specify process, thickness, and post-process dimensions.

-

Quality clauses: For critical high-wear tooling include acceptance tests: Rockwell hardness, metallographic verification, and possibly coupon wear tests.

MWAlloys — when presenting factory-direct pricing — should be prepared to provide full MTCs, datasheets, and traceability to support procurement teams and quality audits.

Full technical specification tables

Typical supply forms and standard sizes (examples)

| Form | Typical lengths | Typical widths/thickness | Remarks |

|---|---|---|---|

| Round bar | 1 m to 3 m | Ø6 mm to Ø200 mm | Hot-rolled or forged bar, tolerance per EN/ASTM on request |

| Flat bar | 1 m to 3 m | 6 mm to 150 mm thickness | Ground flat and polished available |

| Plate | up to 2000 mm x 6000 mm | 3 mm to 100 mm | Custom sawing or waterjet blanks available |

| Blanks/preforms | Customer-specified | As per drawing | Factory cutting and pre-machining available |

Typical dimensional tolerances (industry guidance)

| Dimension | Tolerance (annealed) | Tolerance (hardened) |

|---|---|---|

| Length | ±2 mm | ±3 mm |

| Flatness/straightness | ≤ 0.5 mm/m | ≤ 1.0 mm/m |

| Thickness | ±0.2 mm for thin; ±1.0 mm for thicker | ±0.5–1.5 mm depending on size |

(Notes: Actual tolerances must be agreed on the order. Provide drawings and acceptance criteria.)

FAQs

1. What is CPM M4 used for?

2. Is CPM M4 stainless?

3. What hardness can CPM M4 reach?

4. How should CPM M4 be heat treated for knives?

5. Can CPM M4 be nitrided or coated?

6. Is CPM M4 better than M2?

7. How difficult is CPM M4 to grind or polish?

8. Can CPM M4 be used for food-contact knives?

9. What certifications should I request from a supplier?

10. Does CPM M4 need special storage or packaging?

Closing notes for engineers and procurement teams

CPM M4 fills a niche where abrasion resistance and toughness must coexist. It is not an all-purpose steel; its carbon and alloy level give it non-stainless behavior that must be accounted for in product lifecycle planning. For applications requiring both high wear life and resistance to breakage, CPM M4 delivers performance that justifies its premium positioning. When ordering from MWAlloys or other factory-direct suppliers, demand complete datasheets, heat-treat guidance, and traceability. If you want, MWAlloys can prepare pre-cut blanks, perform heat treatment to a specified HRC, and apply surface treatments such as nitriding or PVD prior to shipping.