CPM 154 is a premium martensitic stainless steel engineered by Crucible Industries using the Crucible Particle Metallurgy (CPM) process, delivering a superior working hardness range of 58–62 HRC and a uniform carbide structure that outperforms conventional 154CM. For engineers and procurement specialists, this alloy represents the optimal intersection of wear resistance and machinability, serving as a high-performance upgrade to 440C and a direct powder metallurgy improvement over ATS-34. At MWalloys, we supply certified CPM 154 to ensure consistent metallurgical standards, providing a material that exhibits distinct advantages in grindability, polishing, and toughness while maintaining the corrosion resistance required for industrial food processing, medical instrumentation, and high-end cutlery. The closest CPM 154 steel equivalent in the powder metallurgy market is RWL-34, while standard 154CM and ATS-34 remain its conventional ingot counterparts.

Chemical Composition and Metallurgical Makeup

The performance characteristics of CPM 154 are dictated by its precise elemental formulation. While the chemistry mirrors conventional 154CM, the particle metallurgy process ensures that these elements are distributed evenly throughout the matrix. This eliminates the banding and segregation issues often found in ingot steels.

The high Molybdenum content drives the secondary hardening response, allowing the steel to maintain its CPM 154 steel hardness even after exposure to elevated temperatures during manufacturing or use. The Carbon volume ensures the precipitation of hard chromium carbides, which provide the wear resistance necessary for industrial cutters.

If your project requires CPM 154 steel, contact MWalloys for a free quote.

Table 1: Nominal Chemical Composition of CPM 154 (Weight %)

| Element | Symbol | Percentage (%) | Metallurgical Function |

|---|---|---|---|

| Carbon | C | 1.05% | Primary hardening element; forms carbides for wear resistance. |

| Chromium | Cr | 14.00% | Provides corrosion resistance (stainless >10.5%) and hardenability. |

| Molybdenum | Mo | 4.00% | Enhances pitting resistance, toughness, and secondary hardening. |

| Manganese | Mn | 0.50% | Deoxidizer that refines grain structure and aids hardenability. |

| Silicon | Si | 0.30% | Used for deoxidation during the melting process. |

| Vanadium | V | Trace (0.4 max) | Grain refinement (lower content than S30V to favor polishability). |

CPM 154 Steel Hardness and Tempering Response

Achieving the correct CPM 154 steel hardness is critical for ensuring the longevity of the cutting edge. This alloy is capable of reaching a maximum hardness of 63-64 HRC straight out of the quench, but the usable working hardness is typically tempered down to 58-62 HRC to balance toughness.

Factors Influencing Hardness

The final hardness relies heavily on the austenitizing temperature and the cooling rate. A rapid quench is necessary to form martensite. Because CPM 154 is an air-hardening steel, it can harden in still air, but a vacuum quench with positive pressure nitrogen is preferred by MWalloys to minimize oxidation and ensure maximum uniformity.

Cryogenic processing is another vital variable. Cooling the steel to -300°F (-184°C) or at least -100°F (-73°C) immediately after the quench transforms retained austenite into martensite. This process typically adds 1 to 2 points of HRC hardness and significantly improves dimensional stability.

Table 2: Tempering Data and Resulting Hardness

(Austenitized at 1950°F / 1065°C, Deep Freeze included)

| Tempering Temperature | Hardness (HRC) | Primary Application |

|---|---|---|

| 400°F (204°C) | 60 - 62 | Surgical Tools, Fine Cutlery (Peak Corrosion Resistance) |

| 500°F (260°C) | 59 - 61 | General Purpose Knives, EDC Blades |

| 600°F (316°C) | 57 - 59 | Heavy Duty Outdoor Tools (Increased Toughness) |

| 900°F (482°C) | 58 - 60 | Industrial Slitters (Secondary Hardening Peak) |

| 1000°F (538°C) | 55 - 57 | High Impact Machinery Components |

The Secondary Hardening Phenomenon

Unlike simple carbon steels, CPM 154 exhibits secondary hardening due to its Molybdenum content. When tempered at higher temperatures (around 900°F-950°F), the hardness actually increases or stabilizes rather than dropping linearly. This makes CPM 154 suitable for applications where the tool might be exposed to high heat, such as friction cutting or high-speed machinery, as it resists softening.

CPM 154 Steel Equivalent and Market Substitutes

Sourcing materials often requires knowledge of alternatives. When identifying a CPM 154 steel equivalent, one must distinguish between exact chemical matches and performance-based alternatives. MWalloys helps clients navigate these options to ensure supply chain continuity.

Direct Powder Metallurgy Equivalent: RWL-34

The most direct equivalent to CPM 154 is RWL-34, manufactured by Damasteel in Sweden. RWL-34 utilizes a similar Rapid Solidification Powder (RSP) technology. The chemical composition of RWL-34 is virtually identical to CPM 154. Both steels offer the same exceptional polishability, corrosion resistance, and heat treat response. Manufacturers can often swap these two materials without altering their grinding or heat treating protocols.

Conventional Ingot Equivalents: 154CM and ATS-34

Before particle metallurgy became dominant, 154CM (Crucible) and ATS-34 (Hitachi) were the industry standards. These are chemically equivalent to CPM 154 but are produced using traditional ingot casting.

- Structure: They have coarser carbides and potential alloy segregation.

- Performance: They hold an edge similarly but are less tough and harder to polish than CPM 154.

- Status: They are generally considered lower-cost alternatives rather than premium upgrades.

Performance Comparisons

Sometimes an equivalent is sought based on performance metrics rather than chemistry.

Table 3: CPM 154 vs. Common Equivalents and Alternatives

| Steel Grade | Manufacturing Method | Corrosion Resistance | Edge Retention | Toughness | Comparison to CPM 154 |

|---|---|---|---|---|---|

| CPM 154 | Particle Metallurgy | High | High | High | Baseline |

| RWL-34 | Particle Metallurgy | High | High | High | Exact Premium Equivalent |

| 154CM | Ingot Cast | High | High | Medium | Lower Toughness/Polishability |

| ATS-34 | Ingot Cast | High | High | Medium | Japanese Equivalent to 154CM |

| 440C | Ingot Cast | High | Medium | Low | Legacy Standard (Inferior) |

| CPM S35VN | Particle Metallurgy | High | Very High | Very High | Superior Upgrade (Higher Cost) |

Physical and Mechanical Properties

Engineers must utilize accurate physical data when calculating stress loads. CPM 154 maintains structural integrity under significant stress, which is why it is preferred over 440C for bearing applications.

Table 4: Physical Properties

| Property | Metric Value | Imperial Value |

|---|---|---|

| Density | 7.75 g/cm³ | 0.280 lbs/in³ |

| Modulus of Elasticity | 200 GPa | 29 x 10⁶ psi |

| Thermal Conductivity | 16.5 W/m·K | - |

| Coefficient of Thermal Expansion | 11.0 µm/m°C (20-100°C) | 6.1 x 10⁻⁶ in/in°F |

Toughness and Wear Resistance Correlation

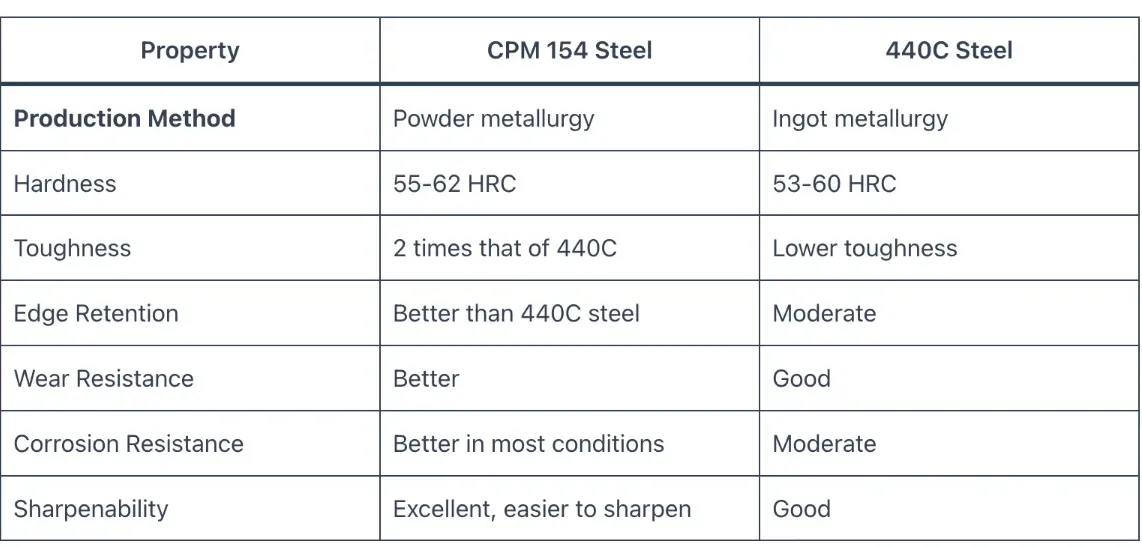

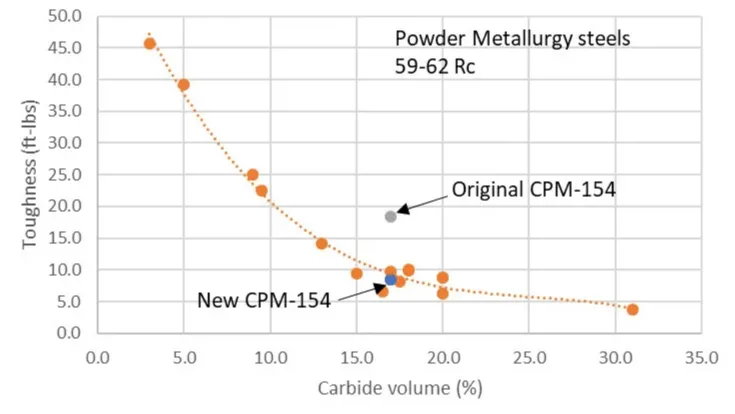

CPM 154 offers a distinct toughness advantage. In Charpy C-Notch impact testing, CPM 154 typically exhibits 28 Joules (20 ft-lbs) of transverse toughness at 58 HRC. This is approximately double the toughness of 440C. When the CPM 154 steel hardness is pushed to 61 HRC, toughness decreases slightly but remains superior to conventionally cast steels of similar alloy content.

Wear resistance is measured using the CATRA testing method. CPM 154 consistently rates 120% to 125% of the wear resistance found in 440C, placing it in the high-performance category without becoming difficult to sharpen.

Heat Treatment Protocols

MWalloys recommends the following protocols to optimize the steel for knife blades and industrial components.

Austenitizing

Preheating is required to minimize distortion. Heat to 1400°F (760°C) and equalize. Then ramp to the austenitizing temperature. Standard range is 1900°F (1038°C) to 2000°F (1093°C). Holding time should be 30 to 60 minutes depending on cross-section thickness.

Quenching

Plate quench, air cool, or interrupted oil quench. For maximum dimensional stability and corrosion resistance, a vacuum furnace with a nitrogen gas quench is ideal. Cool to below 125°F (50°C) before tempering.

Tempering Guidelines

Double tempering is mandatory. Triple tempering is preferred for high-stress applications. Each temper should last 2 hours minimum. To maintain corrosion resistance, tempering below 800°F is recommended to avoid the formation of chromium-rich carbides that deplete the matrix of corrosion-fighting chromium.

Machinability and Grinding Operations

CPM 154 is favored by machinists because the uniform carbide structure reduces tool wear compared to ingot steels like D2 or 440C. When grinding, the steel produces a clean "break" at the burr. This characteristic is directly linked to the particle metallurgy process, which prevents the formation of large carbide clusters that typically cause micro-chipping during the finishing stages.

Case Study: Improving Uptime in Food Processing

The following case demonstrates the practical application of CPM 154 in an industrial setting, validated by MWalloys engineering consultation.

Project: Industrial Meat Slicer Blade Optimization

Location: Chicago, Illinois, USA

Date: February 2024

The Problem: A large-scale meat processing facility was utilizing D2 tool steel for their high-speed circular slicer blades. While D2 provided adequate hardness, the blades suffered from two critical issues. First, the acidic nature of meat proteins caused pitting corrosion. Second, the coarse carbides in D2 led to micro-chipping at the cutting edge, resulting in frequent sharpening stoppages.

The Solution: MWalloys recommended transitioning to CPM 154. We specified a heat treatment targeting a CPM 154 steel hardness of 60 HRC with a low-temperature temper (400°F) to maximize corrosion resistance.

The Evidence: The facility ran a pilot line with CPM 154 blades alongside the existing D2 inventory. Maintenance logs tracked "Time Between Sharpening" (TBS) and visual inspection for corrosion over 90 days.

The Results:

- Corrosion: Zero pitting observed on CPM 154 blades. D2 blades showed oxidation within 48 hours if not oiled immediately.

- Uptime: The TBS increased by 40%. The CPM 154 blades maintained a razor edge longer because the finer carbide structure supported a thinner, more stable edge geometry without chipping.

- Cost Savings: Despite the higher raw material cost of CPM 154, the reduction in downtime resulted in a 15% net annual saving for the slicing department.

Applications in Modern Manufacturing

The versatility of CPM 154 allows it to function across various sectors. MWalloys supplies this material for:

- Cutlery: Folding knives, hunting fixed blades, and kitchen cutlery.

- Bearings and Bushings: Corrosion-resistant bearing races in aerospace applications.

- Plastic Injection Molds: The ability to take a high polish makes it excellent for molds requiring a mirror finish.

- Industrial Cutters: Food processing blades, textile cutters, and packaging knives.

Frequently Asked Questions (FAQs)

1. What is the typical CPM 154 steel hardness after heat treatment?

2. What is the best CPM 154 steel equivalent?

3. Does CPM 154 rust easily?

4. Is CPM 154 better than S30V?

5. Can CPM 154 be used for kitchen knives?

6. How does Cryogenic treatment affect CPM 154?

7. Is CPM 154 magnetic?

8. Why is CPM 154 more expensive than 440C?

9. Can CPM 154 be welded?

10. What abrasive is best for sharpening CPM 154?

Procurement and Supply Chain Considerations

When sourcing CPM 154, verifying the provenance of the steel is vital to ensure you are receiving the true powder metallurgy product and not a conventional equivalent. Counterfeit materials often mimic the composition but lack the CPM process, resulting in inferior performance.

MWalloys provides CPM 154 in various forms:

- Sheet/Plate: Precision ground or hot rolled finish.

- Bar Stock: Round and flat bars for machining.

- Custom Sizes: Available upon request for specific tooling needs.

Engineers should specify "CPM 154" explicitly in blueprints rather than just "154 steel" to avoid receiving the conventional ingot version. The "CPM" designation is the guarantee of the particle metallurgy microstructure that delivers the requisite toughness and finish. For detailed datasheets regarding CPM 154 steel hardness curves or availability of a specific CPM 154 steel equivalent, contact the MWalloys engineering support team.