CPM 10V is a high-vanadium, powder-metallurgy (PM) cold-work tool steel designed to deliver industry-leading abrasive wear resistance while preserving good toughness and predictable fabrication behavior; it frequently outlasts conventional high-carbon, high-chromium die steels such as D2 in abrasive service and is often chosen where long tool life, fine detail, and reduced downtime are business priorities.

Historical background and the CPM process

CPM 10V was the first member of Crucible’s high-vanadium PM tool steel family and has been in industrial use since the late 1970s. The grade was developed to maximize the volume fraction of hard vanadium carbides in a fine, well-distributed microstructure that could not be achieved by conventional casting or ingot metallurgy. The CPM (Crucible Particle Metallurgy) production route creates a highly homogeneous powder-metal microstructure with uniformly distributed, fine carbides. The result is high abrasive wear resistance with improved toughness relative to conventional high-carbon, high-chromium die steels.

Chemical composition and microstructure

Typical chemical composition (nominal ranges)

| Element | Typical (wt.%) |

|---|---|

| Carbon (C) | 2.4–2.6 |

| Chromium (Cr) | 5.0–5.3 |

| Molybdenum (Mo) | ~1.25–1.35 |

| Vanadium (V) | ~9.5–10.0 |

| Manganese (Mn) | ~0.4–0.6 |

| Silicon (Si) | ~0.8–1.0 |

| Iron (balance) | ~78–83 |

Notes: different suppliers and datasheets present small variations in the nominal numbers, but all authoritative sources show very high vanadium (near 10 wt%) and very high carbon (~2.45 wt%), which together generate a very large population of vanadium carbides (VC) in the microstructure.

Microstructural features

-

Vanadium carbides (VC): Extremely abundant and very hard (high Hrc of carbide phase). These carbides are the principal source of abrasive wear resistance.

-

Matrix: A martensitic/tough tempered matrix that holds the carbides and provides resistance to crack propagation. Powder metallurgy yields very small, well-distributed carbides that minimize carbide clustering (which otherwise causes embrittlement).

-

Cleanliness and homogeneity: Reduced non-metallic inclusions and absence of coarse carbides create improved toughness and more predictable fracture behavior than traditional ingot steels with similar carbide volume.

Mechanical and physical properties

Typical physical properties (representative values)

| Property | Typical value |

|---|---|

| Density | ~7.41 g/cm³ |

| Elastic modulus (E) | ≈221 GPa |

| Annealed hardness (BHN) | ~255–277 HB |

| Maximum attainable hardness (HRC) | ~60–64 (depending on heat treatment and section size) |

Source: authoritative datasheets and distributor technical notes.

Toughness vs wear resistance (qualitative)

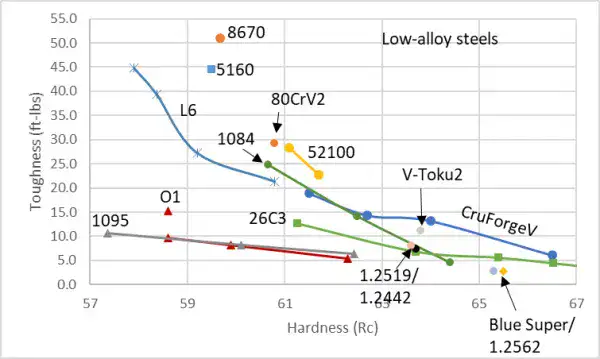

CPM 10V places priority on wear resistance while carefully maintaining reasonable toughness. In Charpy and fracture tests, CPM 10V shows toughness values that are competitive with many traditional tool steels at equivalent hardness, due to the PM microstructure. For many abrasive cold-work applications, CPM 10V will produce tool life multiples of D2, with comparable or superior toughness for many geometries.

Heat treatment, grinding, machining, and fabrication

Hardening (recommended austenitizing and quench)

| Operation | Typical parameter (recommended range) |

|---|---|

| Preheat | 1500–1550°F (815–845°C) equalize; second preheat 1850–1900°F (1010–1040°C) for vacuum/atmosphere operations |

| Austenitize (recommended) | 2050°F (1120°C) for best balance; 1950–2150°F (1065–1175°C) depending on desired hardness/toughness tradeoff |

| Hold time | 30–45 minutes at austenitizing temp (thin sections may require less) |

| Quench | Air or positive pressure gas quench (minimum 2 bar) to below ~50°C, or salt/oil quench with appropriate controls; vacuum quenching must ensure sufficient cooling rate through 1010–705°C to avoid retained austenite |

Tempering

-

Double tempering recommended. Temper at ≥1000°F (540°C) for two cycles of 2 hours each for stable properties. Lower tempering temperatures will retain higher hardness but reduce temper stability. Follow supplier recommendations for exact target hardness vs temper schedule.

Soft annealing (for machining/fabrication)

-

Heat uniformly to ~1600°F (870°C), hold 2 hours, cool slowly not faster than 30°F/hour to 1000°F (540°C), then furnace cool or cool in still air to room temperature. Typical annealed hardness ~255–277 BHN to facilitate machining and shaping.

Grinding and machinability

-

In the annealed condition, machinability resembles that of some high-speed steels (use appropriate tooling). For grinding, SG alumina or CBN wheels typically yield best performance on PM tool steels; produce small, controlled cuts, and manage wheel dressing frequently. CPM 10V’s high carbide content reduces grindability compared with low-carbide steels, so expect slower material removal rates.

Welding and repair

-

Welding of CPM 10V is possible but carries risk: high carbon and heavy carbide networks can cause cracking unless specialized preheat, filler metal, and post-weld heat treatment protocols are followed. Generally, large repairs are less economical than section replacement. Consult experienced welding metallurgists and use procedures qualified for high-carbon PM steels.

cpm 10v steel equivalent

CPM® 10V ≈ PM (A11 / AISI A11) — also sold as Carpenter Micro-Melt® A11 (and by other PM suppliers). These are all the same high-vanadium, powder-metallurgy A11 family used where extreme wear resistance is required.

Quick facts you’ll find useful

-

Typical chemical (approx.): C ~2.45%, Cr ~5.3%, Mo ~1.3%, V ~9.8% — very high vanadium for lots of hard vanadium carbides (edge/wear retention).

-

Typical use: cold-work tooling, slitter/blanking/shear knives, high-wear knives and tooling where long edge life is critical.

-

Performance note: CPM 10V (A11) gives much higher wear resistance than D2/D7 and good toughness for a very wear-resistant alloy because of the PM microstructure.

Common “equivalents” / names to look for

-

CPM 10V (Crucible): original trade name.

-

PM A11 / AISI A11: industry designation for the same PM A11 chemistry.

-

Micro-Melt® A11 (Carpenter/CarTech): explicitly marketed as equivalent to CPM 10V.

Substitution guidance

-

If you need maximum wear resistance, PM A11/CPM-10V is hard to beat.

-

If you need more toughness (impact resistance) at the cost of some wear resistance, consider CPM-3V or CPM-M4 choices.

-

If you need stainless properties, CPM-10V is not stainless — choose a high-vanadium stainless (e.g., some powder stainless tool steels) instead.

Comparative analysis: CPM 10V vs common alternatives

Quick comparison table

| Property / metric | CPM 10V | D2 (conventional) | CPM 15V | Carbide (WC-Co) |

|---|---|---|---|---|

| Vanadium content | ~9.5–10 wt% | ~0.9–1.2 wt% | ~14–15 wt% | N/A (carbide phase) |

| Abrasive wear resistance | Very high (often >> D2) | High | Higher than 10V | Extremely high |

| Toughness | Good for high-carbide steel due to PM | Lower (carbide clusters) | Lower than 10V (very high carbide volume) | Variable; brittle |

| Grindability | Moderate–difficult (carbides) | Easier than 10V | More difficult | Difficult; requires diamond tools |

| Fabrication complexity | Moderate (requires PM handling) | Moderate | High | Very high; often needs brazing/special tooling |

| Typical cost per kg | Higher than D2; lower than some advanced PM steels | Lower | Higher than 10V | Variable; often higher overall tooling cost |

Notes: CPM 10V commonly delivers multiple times the tool life of D2 in abrasive service and often outperforms D2 by margins of two to four times depending on environment and contact geometry. CPM 15V improves on wear resistance compared to 10V at the expense of fabrication difficulty and greater brittleness in some geometries. For many heavy-abrasion jobs, CPM 10V offers the best balance between life and workable toughness.

Practical guidance for choosing between grades

-

Choose CPM 10V when abrasive wear dominates and the tool has thin sections, intricate detail, or must resist fracture better than D2.

-

Choose CPM 15V when abrasive wear is extreme and tool geometry and fabrication permit a more carbide-rich grade.

-

Consider carbide tooling when absolute wear resistance is required and the application tolerates a brittle material and higher capital cost (or for long production runs where brazed carbide furnishes the best lifecycle cost).

Typical applications and design recommendations

Representative applications

-

Punching dies for abrasive sheet metal and high-speed blanking.

-

Fine blanking and trimming tools where edge stability and micro-feature retention are required.

-

Industrial knives, guillotine blades, and film/paper slitter blades needing excellent edge retention.

-

Cold forming and cold-work dies where abrasive particle content or high abrasion leads to premature failure in conventional dies.

-

Sinter-press tooling and densification tooling exposed to abrasive powders.

These application classes are repeatedly called out in manufacturer and distributor datasheets.

Design and geometry tips

-

Avoid sharp stress concentrators near thick carbide zones. Fillets and generous radii reduce crack initiation.

-

For intricate shapes, account for grinding time and wheel wear. Use final-size grinding rather than heavy stock removal to minimize heat build-up and preserve edge geometry.

-

For shear edges, use slightly higher section modulus to compensate for lower toughness at very high hardness levels. Consider tempering to a slightly lower hardness to gain fracture resistance if the tool sees shock loads.

Expected failure modes

-

Abrasive wear — progressive loss of material from carbide and matrix surfaces. CPM 10V delays this longer than D2.

-

Chipping or fracture — may occur if the part has severe impact or large stress raisers; mitigated by proper tempering and geometry.

-

Adhesive wear / galling — less common in CPM 10V than some stainless steels, but monitoring is required in mixed-metal contact.

Procurement, QA, and standards

Purchase specifications

When ordering CPM 10V, specify:

-

Exact grade (CPM® 10V® / AISI A11 if referencing AISI analog).

-

Required delivery condition (annealed, hardened and tempered, fine-milled).

-

Dimensional tolerances, straightness, and flatness needed for final processing.

-

Certificate of analysis (CoA) showing actual chemical composition and heat number traceability.

Inspection and testing recommendations

-

Incoming forge/bar stock inspection: measure hardness in annealed condition and verify composition by spark-OES or equivalent.

-

Ultrasonic or dye-penetrant inspection for critical tooling that cannot tolerate subsurface flaws. PM grades are generally cleaner, but vendor verification is prudent.

-

Hardness and microstructure checks after heat treatment to confirm target HRC and carbide distribution.

Relevant standards and guidance

-

Tool steel bar tolerances commonly follow ASTM A681 for tool steels (refer to your supplier for the exact edition used for stock tolerances).

-

Manufacturer datasheets should be attached to purchase orders for heat-treat and handling instructions.

Cost, lifecycle, and environmental notes

-

Upfront material cost for CPM 10V tends to be higher than conventional D2 bar, but total lifecycle can be lower due to much longer service life and fewer tool exchanges. Total cost analysis should include downtime, regrind time, and replacement frequency.

-

PM production is energy-intensive, and recycling stream handling must ensure segregation of high-vanadium scrap for proper remelting. Consult local scrap processors for PM tool steel recycling pathways.

Tables & quick references

Table A — Representative heat-treatment schedule (example)

| Condition | Austenitize (°F / °C) | Quench | Temper (two cycles) |

|---|---|---|---|

| Hard & wear-resistant | 2050°F / 1120°C | Air / positive pressure quench to <50°C | 1000°F (540°C) × 2 × 2 hr |

| Higher toughness (lower HRC) | 1950°F / 1065°C | Air / controlled | 1000–1050°F (540–565°C) × 2 × 2 hr |

| Soft anneal (for machining) | 1600°F / 870°C soak 2 hr then slow cool | N/A | N/A |

Table B — Quick specification checklist for purchase orders

-

Grade: CPM® 10V® (AISI A11)

-

Form: ground flat / round / fine-milled blocks

-

Condition: annealed / hardened & tempered / nitrided / coated

-

Tolerance: state numeric tolerances or “to customer drawing”

-

QA: CoA, heat number, hardness map, microstructure images (if required)

FAQs

-

Q: Is CPM 10V a stainless steel?

A: No. CPM 10V is a high-carbon, high-vanadium PM tool steel with modest chromium (~5 wt%); it is not stainless and will corrode in corrosive environments without protective finish. -

Q: Can CPM 10V replace carbide?

A: In many cold-work, abrasive situations CPM 10V can replace carbide when fracture risk or tooling complexity makes carbide impractical. However, for absolute maximum wear resistance in non-impact, high-temperature abrasive runs, carbide still leads. -

Q: Typical HRC after proper heat treatment?

A: Typical hardened and tempered hardness ranges 58–64 HRC depending on austenitizing temp and temper schedule. -

Q: Is CPM 10V good for cutting tools like knives?

A: Yes; CPM 10V is popular for industrial knives and specialty blades that require long edge life. It is used in large-volume shearing and slitting applications. -

Q: How does PM processing affect performance?

A: PM processing produces a very fine, uniform carbide distribution and high cleanliness, which increase toughness and produce predictable wear behavior versus conventional ingot steel. -

Q: What grind wheels are recommended?

A: SG alumina or cubic boron nitride (CBN) wheels give the best performance on PM vanadium steels. Diamond may be required for carbide surfaces or coated tools. -

Q: Can CPM 10V be nitrided or coated?

A: Yes, nitriding and PVD/CVD coatings can be applied to enhance surface hardness and reduce friction. Compatibility depends on coating process and substrate temper. -

Q: Is welding recommended?

A: Welding is technically possible but challenging due to high carbon and carbide content; repairs should be performed by specialists with qualified procedures. -

Q: What cold-work operations are ideal?

A: Fine blanking, slitting, shearing, guillotines, paper/film cutting, and certain forming dies where abrasive wear dominates and toughness is necessary. -

Q: Where to get authoritative data and heat-treat guidance?

A: Use the Crucible CPM® 10V® datasheet, ASM Alloy Digest articles, and distributor technical pages (e.g., Hudson, Diehl) for validated parameters and practical tips.

Practical case note

A cold-work press operator reported going from D2 to CPM 10V in a high-abrasion trimming die for a fiber-reinforced film. Tool life more than tripled, with fewer replacements and better edge geometry retention. The improvement was attributed to the high VC volume fraction and finer carbide distribution in CPM 10V. Such field reports match controlled test data from industry literature.

Final recommendations

-

Choose CPM 10V where abrasive wear is the dominant failure mode and tool geometry or cost prohibits carbide.

-

Specify vendor datasheet heat-treatment parameters and request manufacturer support when qualifying large tools.

-

Perform life-cycle costing rather than material-only cost comparison; CPM 10V frequently reduces total tooling cost per part.

-

For critical components, ask suppliers for a micrograph and CoA, and conduct hardness mapping after heat treatment.