Ceramic foam filters (CFF) utilizing phosphate-bonded high-purity alumina are the singular most effective method for removing non-metallic inclusions in aluminum casting operations. Implementing the correct Alumina CFF reduces scrap rates by an average of 15% to 40% while significantly improving the mechanical properties of the final alloy. For aluminum foundries operating at temperatures up to 1100°C, the optimal filtration strategy involves selecting a specific Pores Per Inch (PPI) density—typically between 10 and 60 PPI—based directly on the required flow rate and the criticality of the end component. MWalloys validates that precise filter sizing and correct gasket placement prevent metal bypass, ensuring that oxides, dross, and flux residues are mechanically blocked and physically captured within the filter's tortuous path structure.

The Physics of Filtration in Molten Aluminum

Filtration is not merely a sieving process. It is a complex interaction of physical blocking and deep-bed filtration mechanisms. Understanding these physics allows foundry engineers to move beyond basic error correction and towards process perfection.

Mechanical Sieving vs. Cake Filtration

The primary mechanism most operators recognize is mechanical sieving. This occurs when solid particles in the molten aluminum stream are larger than the pore openings on the face of the ceramic foam filter. These large inclusions remain on the intake surface. Over time, these captured particles form a "filter cake."

This cake itself becomes a secondary filter. It has finer permeability than the ceramic filter substrate. While this increases filtration efficiency, it also exponentially increases flow resistance. MWalloys engineers emphasize calculating the "blinding point"—the moment where the cake restricts flow enough to cause a fill-time failure.

Deep Bed Filtration and Surface Adhesion

The true value of a high-quality MWalloys ceramic foam filter lies in deep bed filtration. This mechanism handles particles smaller than the filter pores. As molten aluminum navigates the intricate, reticulated web of the ceramic foam, the flow path is tortuous. The molten metal must change direction rapidly and frequently.

Due to density differences, microscopic inclusions do not change direction as quickly as the liquid metal. They impact the ceramic struts. High-quality alumina filters possess specific surface chemistries that promote adhesion. Once an inclusion strikes a strut, van der Waals forces or chemical sintering hold it in place. This allows a 30 PPI filter to successfully capture inclusions significantly smaller than its pore diameter.

Material Composition: Why Alumina Reigns Supreme

In the sector of aluminum foundry work, the material composition of the filter dictates performance. While Silicon Carbide (SiC) and Zirconia exist, they are chemically and thermally suited for iron and steel respectively.

The Chemistry of Phosphate-Bonded Alumina

For aluminum alloys, Alumina (Al2O3) is the standard. MWalloys utilizes a specialized phosphate-bonded high-alumina composition. This material choice offers specific advantages:

-

Chemical Inertness: Aluminum is highly reactive. The filter material must not react with the melt to create new inclusions. Alumina remains stable in reducing atmospheres common in aluminum processing.

-

Thermal Shock Resistance: The filter undergoes a rapid temperature spike from ambient (or preheated) temperatures to roughly 700°C-800°C in seconds. The low coefficient of thermal expansion in our specific alumina formula prevents cracking during this shock.

-

Cost-Efficiency: Compared to Zirconia, Alumina offers a superior cost-to-performance ratio for metals with melting points below 1100°C.

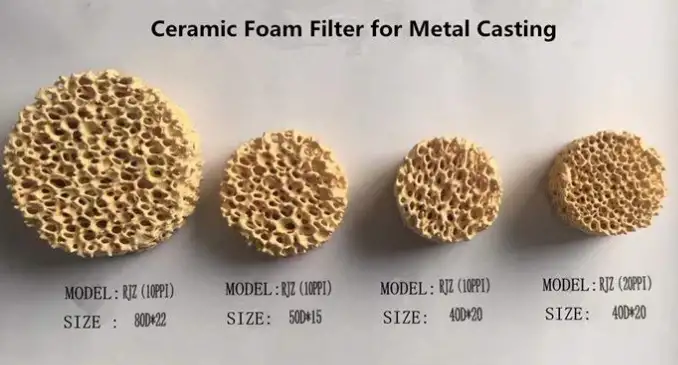

Decoding PPI: Selecting the Correct Pore Density

PPI stands for Pores Per Inch. It is the defining metric for filter coarseness or fineness. Selecting the wrong PPI is the most frequent error identified in foundry audits.

The Correlation Between PPI and Flow Rate

There is an inverse relationship between PPI and flow rate. A higher PPI means more pores, but smaller openings, resulting in higher resistance to flow.

-

10-20 PPI: These are coarse filters. They are utilized for high-volume, continuous casting operations or large sand castings where fill speed is critical, and microscopic inclusion removal is secondary to preventing gross dross ingestion.

-

30-40 PPI: The industry standard for gravity die casting and high-quality sand casting. This offers a balanced trade-off between flow rate and filtration efficiency.

-

50-60 PPI: Reserved for aerospace, aviation, and thin-wall automotive applications. The flow restriction is significant, but the cleanliness of the metal is superior.

Application Specific Selection Strategy

Foundry managers must analyze the casting geometry. Thin-walled castings require fast fill times to prevent cold shuts. High PPI filters might restrict flow too much, causing defects. Conversely, thick blocks (like engine heads) solidify slowly, allowing for the use of higher PPI filters to ensure maximum purity.

Technical Specifications and Performance Data

To make informed engineering decisions, one must examine the raw data. Below is the technical specification sheet for MWalloys standard Alumina Ceramic Foam Filters.

Table 1: MWalloys Alumina CFF Technical Specifications

| Parameter | Specification Value | Note |

| Main Component | Al2O3 (Alumina) > 85% | Ensures high refractory properties |

| Service Temperature | ≤ 1100°C | Ideal for all Aluminum alloys |

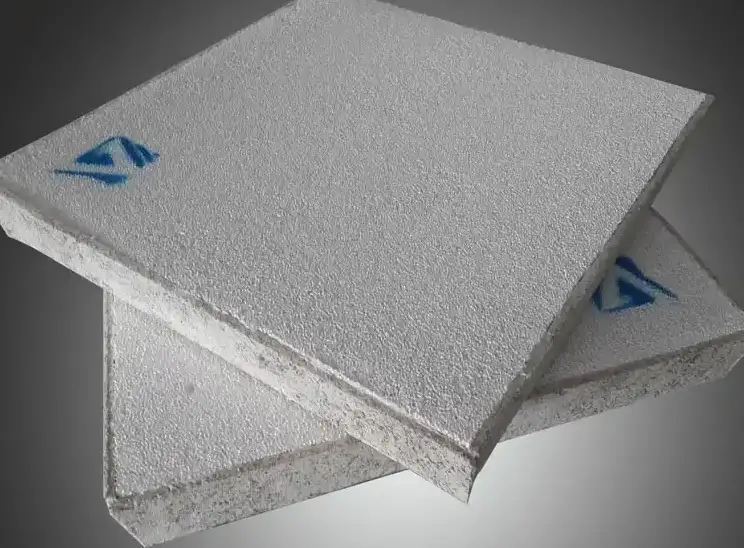

| Color | White / Pinkish | Indicative of purity |

| Porosity | 80% - 90% | High open porosity for flow |

| Bulk Density | 0.35 - 0.55 g/cm³ | Lightweight structure |

| Compressive Strength | > 1.0 MPa | Resists metal pressure head |

| Thermal Shock | 20°C to 950°C (5 times) | No cracking or spalling |

This data confirms that the structural integrity of the filter remains uncompromised even under the severe conditions of a foundry pour. The compressive strength is particularly vital. A weak filter can collapse under the weight of the molten metal, introducing catastrophic ceramic inclusions into the casting.

Optimization of Filter Placement and Gating Systems

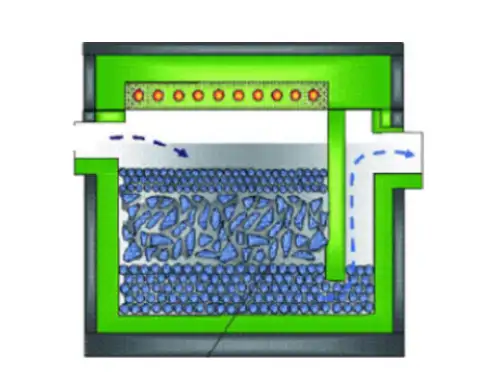

A filter is only as effective as its installation. If molten aluminum can flow around the filter rather than through it, the entire process is futile.

The Necessity of Expanding Gaskets

Bypass is the enemy of filtration. MWalloys filters come equipped with expanding gaskets. These are typically made of a fiber material that expands when heated.

When the molten metal hits the filter, the heat triggers the gasket to swell against the print (the seating area in the mold). This creates a hermetic seal. Without this, metal follows the path of least resistance, which is often the gap between the filter and the mold wall.

Gating Ratio Adjustments

Inserting a filter changes the fluid dynamics of the mold. It introduces a pressure drop. The gating system (sprue, runner, and gates) often requires redesigning.

Engineers should apply a runner cross-section expansion immediately after the filter. This ensures that the metal exiting the filter does not jet or spray, which causes turbulence. Turbulence introduces air into the stream, creating oxide bifilms. The area after the filter should allow the flow to stabilize before entering the mold cavity.

Calculating Flow Capacity

Understanding how much metal a specific filter size can handle before clogging is essential for sizing. Overloading a filter leads to blockage and short pours.

Table 2: Flow Capacity Guidelines for Aluminum Filtration

| Filter Dimensions (mm) | Recommended PPI | Max Flow Rate ( kg/sec ) | Total Capacity (kg Aluminum) |

| 40 x 40 x 15 | 20 | 0.5 | 10 - 15 |

| 50 x 50 x 22 | 20 | 1.0 | 25 - 35 |

| 75 x 75 x 22 | 10 | 2.5 | 60 - 80 |

| 75 x 75 x 22 | 30 | 1.8 | 40 - 60 |

| 100 x 100 x 22 | 20 | 4.0 | 100 - 150 |

| 150 x 150 x 22 | 10 | 8.0 | 250 - 350 |

Note: Capacities reduce by approximately 20-30% when filtering recycled aluminum due to higher inclusion loads.

Case Study: Quality Turnaround in Ohio

Date: April 2023

Location: Cleveland, Ohio, USA

Client Profile: Tier 1 Automotive Supplier (Cylinder Heads)

The Challenge:

The foundry was experiencing a rejection rate of 18% on their V6 cylinder head line. The primary defect was identified as "hard spots"—clusters of corundum and oxide films revealed during the machining phase. These inclusions were breaking CNC tooling, causing downtime and damaging client relationships.

The Investigation:

MWalloys technical team conducted an on-site audit. The foundry was using a 10 PPI fiberglass mesh filter. While cheap, the mesh was only capturing large dross. It failed to stop the fine oxides generated during the turbulent pouring process. Furthermore, the mesh would occasionally melt or deform, releasing captured inclusions back into the stream.

The Solution:

We transitioned the process to MWalloys 50x50x22mm 30 PPI Ceramic Foam Filters.

-

PPI Upgrade: Moving from mesh to 30 PPI foam increased the surface area for deep-bed filtration.

-

Print Modification: The mold pattern was slightly modified to accommodate the 22mm thickness of the ceramic filter compared to the thin mesh.

-

Process Adjustment: Pouring temperature was raised by 15°C to compensate for the thermal mass of the ceramic filter.

The Results:

Within two weeks of implementation:

-

Scrap rate dropped from 18% to 4%.

-

Tooling life in the machine shop extended by 200%.

-

The overall cost savings from reduced scrap far outweighed the higher unit cost of ceramic filters compared to fiberglass mesh.

Production Standards: The MWalloys Difference

Not all ceramic foam is created equal. The consistency of the pore structure is paramount.

The Polyurethane Foam Precursor Method

Our manufacturing process begins with reticulated polyurethane foam. This foam serves as the skeleton.

-

Selection: We source foam with precise cell sizing to guarantee accurate PPI.

-

Slurry Application: The foam is impregnated with our proprietary alumina-phosphate slurry.

-

Compression: The foam is compressed to expel excess slurry, ensuring the struts are not too thick (which blocks flow) or too thin (which causes weakness).

-

Sintering: The coated foam is fired. The polyurethane burns away completely, leaving behind the ceramic negative—a perfect replica of the foam structure.

Strict quality control involves weighing filters to ensure density consistency. A heavy filter implies clogged pores; a light filter implies weak struts. MWalloys maintains a tight tolerance window that exceeds industry norms.

Troubleshooting Common Casting Defects

Even with filters, problems can arise if other variables are uncontrolled. Here is how to diagnose issues related to filtration.

Table 3: Defect Diagnosis and Filtration Solutions

| Defect Symptom | Probable Cause | Filtration Solution |

| Filter Breakage | Thermal shock or excessive metal head height | Preheat the filter; Lower the pour height; Switch to high-strength MWalloys Alumina. |

| Short Pour (Misrun) | Flow restriction too high | Switch to a lower PPI (e.g., 30 to 20); Increase filter area size; Increase metal temperature. |

| Inclusions Post-Filter | Filter Bypass | Check gasket seating; Ensure mold print is dimensionally accurate; Inspect for filter damage prior to placement. |

| Turbulence / Air Entrapment | High velocity exit | Redesign runner system to expand after the filter; Ensure filter is not placed at the very bottom of the sprue where velocity is highest. |

Economic Analysis: Cost vs. Value

Procurement departments often focus on the unit price of consumables. However, the "cost per casting" is the only metric that matters.

A fiberglass mesh might cost $0.20, while a ceramic foam filter costs $0.80. If the casting sells for $50.00:

-

Saving $0.60 on a filter is meaningless if the casting is scrapped.

-

One scrapped casting pays for 62 ceramic filters.

If a foundry produces 1,000 parts a day and reduces scrap by just 1%, the ROI on switching to high-quality MWalloys filters is immediate. Additionally, the value of brand reputation—delivering defect-free parts to customers—is incalculable.

Handling and Storage Best Practices

Ceramic foam is brittle. Mishandling leads to dust and broken pieces, which become inclusions themselves.

-

Dry Storage: Filters must be kept in a dry environment. Moisture absorption can cause steam explosions upon contact with molten metal.

-

Freeze Protection: Avoid freezing temperatures if the filters have any residual moisture, as this weakens the internal bonds.

-

Gentle Handling: Operators should not toss filters. Packages should be opened carefully to avoid chipping corners.

-

Pre-use Inspection: Every filter should be visually inspected. Blow off any loose ceramic dust with compressed air before placing it in the mold.

The Future of Aluminum Filtration

The industry is moving toward higher purity requirements, driven by the electric vehicle (EV) market. EV components, such as battery trays and motor housings, require structural integrity that tolerates zero porosity.

MWalloys is currently developing "functionalized" filters. These future products will not only filter physically but will have active coatings that chemically attract specific impurities like dissolved hydrogen or alkali metals. This represents the next frontier in metallurgical purity.

Frequently Asked Questions (FAQs)

Q1: What is the maximum temperature MWalloys Alumina filters can withstand?

A1: Our Alumina filters are rated for continuous service up to 1100°C. For higher temperature applications like copper or iron, Silicon Carbide or Zirconia filters are required.

Q2: Can I reuse a ceramic foam filter?

A2: No. Ceramic foam filters are single-use consumables. Once the metal solidifies, the filter is trapped in the runner system. Even if retrieved, the thermal cycle weakens the ceramic structure, and the pores are blocked.

Q3: How do I choose between 20 PPI and 30 PPI?

A3: Start with 30 PPI for general casting. If you experience misruns or slow fill times, switch to 20 PPI. If the metal is not clean enough, move to 40 PPI. 30 PPI is the versatile standard for aluminum.

Q4: Do I need to preheat the filter?

A4: Preheating is recommended but not always mandatory for small aluminum castings. It helps remove moisture and reduces the thermal shock. For large castings, preheating is critical to prevent the metal from freezing when it hits the cold filter.

Q5: What is the shelf life of these filters?

A5: When stored correctly in a dry warehouse, MWalloys filters have a shelf life of 2 years. High humidity can degrade the binder over long periods.

Q6: Why is my filter floating in the mold?

A6: Aluminum is dense, and ceramic foam is light. If the print (seat) is too loose or the mold does not clamp down on the filter securely, it will float. Ensure tight dimensional tolerances on the pattern print.

Q7: Can these filters remove hydrogen gas?

A7: Standard ceramic filters do not remove dissolved gas. They remove solid inclusions. Hydrogen removal requires degassing units (rotary degassers) used prior to pouring.

Q8: What is the "priming" of a filter?

A8: Priming refers to the initial moment molten metal enters the filter. High surface tension can prevent metal from entering the pores. Sufficient metallostatic head (pressure) is needed to overcome this tension and "prime" the filter.

Q9: Does the filter affect the mechanical properties of the aluminum?

A9: Yes, positively. By removing stress-concentrating inclusions, the fatigue life, tensile strength, and elongation of the casting are significantly improved.

Q10: How does MWalloys ensure PPI consistency?

A10: We use automated optical inspection during the foam selection phase and conduct flow rate testing on statistical samples from every fired batch to ensure the pressure drop matches the specification.

Advanced Rheology: The Flow Dynamics

To fully grasp the operation of MWalloys filters, we must examine the rheology of molten aluminum. Aluminum creates a thin oxide skin almost instantly upon exposure to air. When turbulence occurs, this skin folds over on itself, creating "bifilms."

A ceramic foam filter acts as a laminar flow straightener. As the metal exits the chaotic sprue and enters the filter, the cellular structure forces the stream to separate and recombine. This action kills the velocity and smooths the flow. The metal exiting the back of the filter is laminar (smooth). Laminar flow prevents the formation of new oxides in the runner system. Therefore, the filter does two jobs: it removes old oxides from the furnace and prevents the creation of new oxides in the mold.

Comparison with Extruded Strainers

Some foundries use extruded ceramic strainers (honeycomb style). While robust, these have straight channels.

-

Honeycomb: Metal shoots straight through. Inclusions can pass if they are smaller than the hole.

-

Foam (MWalloys): Metal must twist and turn. Even small inclusions hit the walls.

For critical applications, foam offers superior filtration efficiency compared to extruded strainers, even if the strainer has the same theoretical open area.

Environmental Impact and Sustainability

Modern foundries are under pressure to be sustainable. Reducing scrap is the most effective way to lower a foundry's carbon footprint. Every scrapped casting represents wasted energy (melting), wasted sand, and wasted labor.

By implementing high-efficiency filtration with MWalloys, foundries reduce their energy consumption per usable ton of casting. Furthermore, our manufacturing facility adheres to strict environmental protocols, ensuring that the production of the filters themselves has a minimal ecological impact.

Conclusion: The MWalloys Commitment

In the competitive landscape of aluminum casting, the margin for error is non-existent. MWalloys ceramic foam filters provide the reliability, consistency, and technical superiority required to produce world-class castings. From the precise chemistry of our phosphate-bonded alumina to our rigorous quality assurance protocols, we are dedicated to solving the most difficult filtration challenges.

Investing in the right filtration technology is not an expense; it is a profit generator. By eliminating inclusions, reducing scrap, and enhancing surface finish, MWalloys empowers foundries to deliver excellence.