For corrosion resistance, formability, and general-purpose industrial use choose austenitic (e.g., 304 / 316). For high hardness, wear resistance and heat-treatable parts choose martensitic (e.g., 410 / 420). For magnetic applications, thermal stability, and cost-sensitive fabrication where moderate corrosion resistance is acceptable choose ferritic (e.g., 430). Each family has distinct crystal structure, alloy chemistry, heat-treatment response, and common uses; selecting the right family depends on the required combination of corrosion resistance, strength, toughness, heat treatment, machining, and cost.

What is the Austenitic Martensitic and Ferritic mean?

The three labels — austenitic, martensitic, and ferritic — come from the dominant crystal structure (phase) present in the steel at room temperature or after cooling. That phase controls how carbon and alloying elements are accommodated and therefore controls the steel’s mechanical and corrosion behavior. Austenitic steels have a face-centered cubic (FCC) austenite structure stabilized by nickel and other austenite stabilizers; ferritic steels have a body-centered cubic (BCC) ferrite microstructure stabilized by chromium with little or no nickel; martensitic steels are formed when austenite is rapidly cooled and the crystal lattice distorts into a supersaturated, hard martensite phase — this is the basis for heat-treatable stainless steels.

Typical chemistries & representative grades

Below are concise chemical tendencies and representative commercial grades you will encounter in specifications and procurement.

-

Austenitic (nickel-bearing)

-

Key elements: chromium (≈16–20%), nickel (≈6–12%), low carbon (≤0.08% unless stabilized).

-

Representative grades: 304, 316, 321, 310 (300-series).

-

Uses: food equipment, tanks, piping, architectural, cryogenic vessels.

-

-

Martensitic (heat-treatable chromium steels)

-

Key elements: chromium (≈11–17%), carbon higher than austenitics (0.1–1.2%) to enable hardening; nickel low/absent.

-

Representative grades: 410, 420, 440A/C, 416 (sometimes free-machining).

-

Uses: knife blades, shafts, bearings, valve parts, wear components.

-

-

Ferritic (chromium stabilized, low-nickel)

-

Key elements: chromium (≈10.5–27%), very low carbon, nickel minimal.

-

Representative grades: 430, 409, 446 (high chromium).

-

Uses: automotive trim, exhaust systems, appliances, furnace components where thermal conductivity and magnetic response matter.

-

Mechanical behavior & heat-treatment response

Austenitic: typically not hardenable by conventional quench hardening. They remain ductile and tough over a wide temperature range, and many austenitics remain ductile even at cryogenic temperatures. Strength can be increased by cold work or by using precipitation-hardening alloys, but typical 300-series are annealed or cold-worked rather than quenched/hardened.

Martensitic: designed to be heat treatable — austenitize, quench, temper — which produces high hardness and strength due to martensitic transformation. Martensite is much harder but generally less corrosion-resistant and tougher than austenite. Heat treatment schedules strongly affect toughness vs. hardness tradeoffs.

Ferritic: not hardened by conventional quenching (like austenitic), but they have better thermal conductivity and lower thermal expansion. Mechanical properties are moderate; many ferritics are chosen for stability and magnetic properties rather than peak strength.

Corrosion resistance & environment guidance

-

Austenitic steels (304, 316) offer the best general corrosion resistance among the three, especially when nickel and molybdenum are present (316 contains Mo for chloride resistance). Choose austenitics for wet chloride environments, food, and sanitary service.

-

Martensitic grades have poorer corrosion resistance than austenitics because increased carbon and less nickel reduce passive film stability; they require protective coatings or specific alloy choices if corrosion is a concern.

-

Ferritic steels offer good resistance to stress-corrosion cracking and have acceptable general corrosion resistance when chromium is sufficient; they are often a cost-effective alternative where extreme corrosion resistance is not critical.

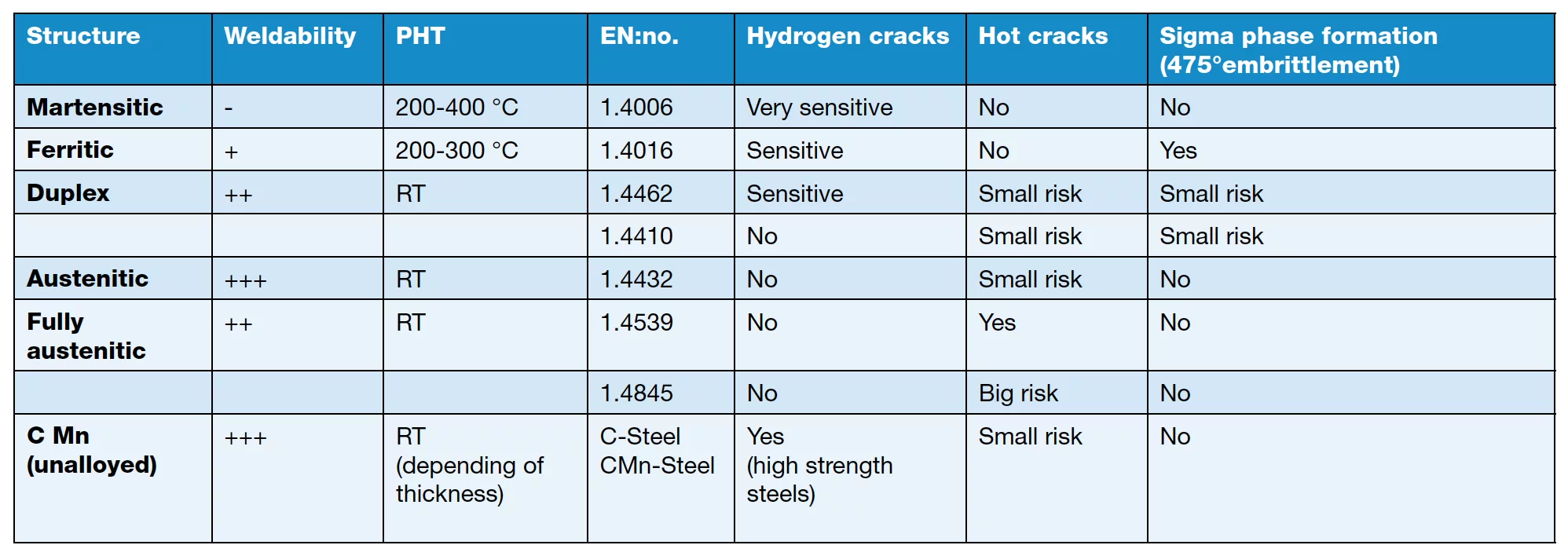

Fabrication notes — welding, forming, machining, surface finish

-

Welding:

-

Austenitics weld very well; filler metals and post-weld practices are well developed. Sensitization (grain-boundary chromium carbide precipitation) can be an issue in certain heat-affected zones unless stabilized or low-C grades are used.

-

Martensitics generally require preheat and controlled post-weld heat treatment to avoid cracking and to control hardness. Welding martensitic stainless steel is more demanding.

-

Ferritics can be welded but can develop grain growth and reduced toughness if overheated; correct filler selection and heat input control are important.

-

-

Forming & deep drawing: Austenitics are the best for heavy forming and deep drawing due to high ductility. Ferritics are workable but less ductile; martensitics in annealed condition can be formed but final hardening follows.

-

Machining: Martensitic and some ferritic alloys can machine well when in the proper condition; austenitics can be gummy and require optimized tooling and parameters.

Magnetic response & NDT considerations

-

Austenitic: typically non-magnetic in the annealed condition (some cold work may induce slight ferromagnetism). This is useful for applications where magnetic neutrality is required.

-

Martensitic & ferritic: both magnetic in most conditions; this is diagnostically useful in manufacturing and NDT (magnetic particle testing).

Typical applications — practical selection rules

-

Choose austenitic (300-series) if: corrosion resistance, hygiene, high ductility, cryogenic toughness, or complex fabrication are priorities (e.g., food, pharma, chemical plant equipment).

-

Choose martensitic if: wear resistance, edge retention or high hardness are required (e.g., cutlery, pump shafts, valve discs). Expect post-processing heat treatment.

-

Choose ferritic if: magnetic response, good thermal conductivity, lower cost, and moderate corrosion resistance suffice (e.g., automotive trims, exhaust parts, furnace components).

Practical procurement & MWAlloys offering

MWAlloys supplies stainless and alloy steels from our China production network with stock inventory for common grades in austenitic (304/316), martensitic (410/420) and ferritic (430/409) families. We provide factory direct pricing (100% factory price advantage), fast inventory-based delivery for standard sizes, and custom heat treat or surface finish services on request. Typical services we can include: material certificates (EN/ASTM/GB), hardness testing, cold-drawn or annealed tempers, and custom cutting to length for fabrication. If you want quotes for specific sizes/thicknesses/heat treatment, MWAlloys can produce a detailed quote with lead time and MOQ.

Comparison table (useful for procurement/specification)

| Property / Attribute | Austenitic (e.g., 304 / 316) | Martensitic (e.g., 410 / 420) | Ferritic (e.g., 430) |

|---|---|---|---|

| Dominant phase | FCC austenite | Martensite (quenched from austenite) | BCC ferrite |

| Key alloying | Cr ~16–20%, Ni ~6–12% (316 also Mo) | Cr ~11–17%, higher C (0.1–1.2%) | Cr ~10.5–27%, very low Ni |

| Hardenable by quench | No (cold work / PH alloys only) | Yes (heat treatable) | No |

| Corrosion resistance | Excellent (best of three) | Moderate to low | Moderate |

| Welding | Excellent | Difficult (preheat/post-weld HT) | Good with controls |

| Ductility/formability | Excellent | Moderate (annealed ok) | Good |

| Magnetic | Generally non-magnetic (annealed) | Magnetic | Magnetic |

| Typical uses | Food, pharma, architecture, piping | Blades, shafts, wear parts, valves | Auto exhaust, trims, furnaces |

| Cost (typical) | Higher (Ni content) | Moderate | Lower (low Ni) |

| Typical standards/grades | ASTM/EN 304/316 series | ASTM/EN 410/420/440 | ASTM/EN 430/409 |

Sources for chemistry, common grades and behavior summarized from industry technical pages and datasheets.

How to choose?

-

Is corrosion the top priority? → Austenitic (316 for chlorides).

-

Is hardness/wear critical? → Martensitic + proper heat treatment.

-

Do you need magnetic material with low cost? → Ferritic.

-

Will the component be welded heavily? → Prefer austenitic or design for ferritic with controlled heat input.

FAQs

-

Which stainless family is best for kitchen equipment?

Austenitic 304 is the common choice; 316 is used when chloride or salt exposure is expected. -

Can martensitic stainless steels be welded?

Yes, but welding martensitic grades usually requires preheat and post-weld heat treatment to avoid cracking and control final hardness. -

Are ferritic stainless steels magnetic?

Yes, ferritics are magnetic, and that property is commonly used in applications and NDT. -

Why are austenitic steels not hardenable by quenching?

Because their alloy chemistry (high Ni and Cr stabilizers) keeps the FCC austenite stable on cooling; they don’t transform to martensite on quench like carbon steels. -

Which family has the best toughness at low temperatures?

Austenitic steels maintain excellent toughness at cryogenic temperatures. -

What are common martensitic stainless grades for cutlery?

420 and 440-series are typical choices for knives because they take a fine hardening response. -

Is 304 stainless steel magnetic?

Usually not when annealed, although cold work or certain processing can produce slight magnetism. -

Which family resists stress-corrosion cracking best?

Ferritic and duplex stainless steels often resist chloride stress-corrosion cracking better than standard austenitics. -

Can you plate, polish or finish martensitic steels?

Yes; martensitic steels can be polished to a high finish and accept plating, but surface treatment must consider hardness and residual stresses. -

If budget is limited but some corrosion resistance is needed, which is best?

Ferritic grades (e.g., 430) often deliver acceptable resistance at lower cost than nickel-bearing austenitics.