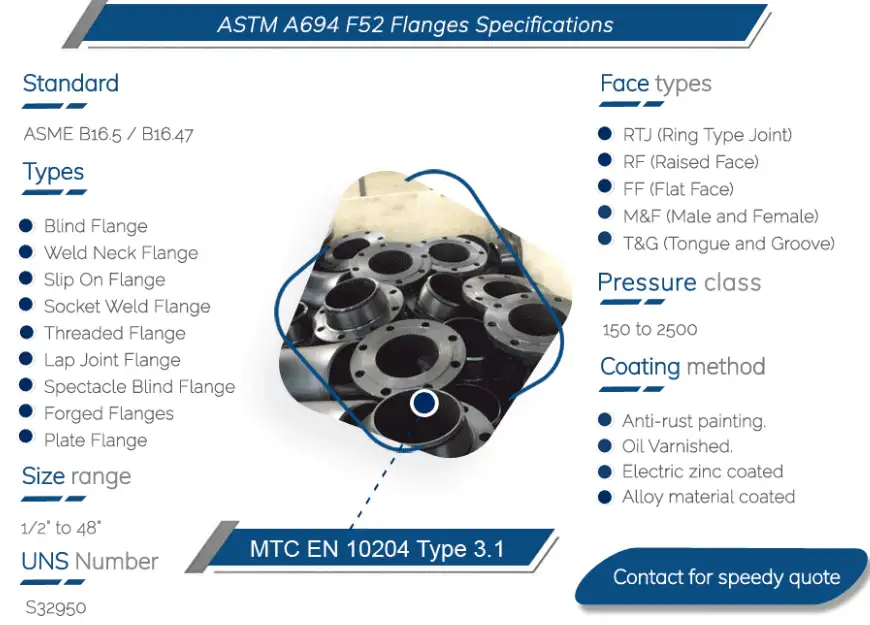

ASTM A694 Grade F52 is a high-yield carbon/low-alloy forging grade intended for high-pressure transmission service (minimum yield ≈ 52 ksi / 360 MPa, minimum tensile ≈ 66 ksi / 455 MPa, minimum elongation 20%). In practice it is frequently used with API 5L X52 line pipe and A860 WPHY-52 fittings, and is often treated as approximately equivalent to EN/ DIN fine-grain grades used for pressure forgings (for example P355N/P355NH family) — but that “equivalence” must be verified case-by-case because composition, toughness, heat-treatment, and mandatory tests (CVN, fracture toughness, product vs. heat analysis) differ between standards. Always confirm the part’s MTRs (material test reports) and the standard(s) actually shown on purchase orders before specifying substitution.

What is ASTM A694 F52

ASTM A694/A694M is the ASTM specification covering carbon and alloy steel forgings for pipe flanges, fittings, valves and parts intended for high-pressure transmission service. The different grades in A694 are numbered by their minimum yield strength in ksi (F42, F46, F50, F52, F56, F60, F65, F70). F52 requires a minimum 0.2% offset yield of ~52 ksi (≈360 MPa) and a minimum ultimate tensile of ~66 ksi (≈455 MPa), with minimum elongation typically 20% in 2 in (50 mm). These requirements and the overall scope are defined in the ASTM A694 standard text.

Why F52 exists

A694 grades were created to provide flange/fitting materials that match the high-yield mechanical properties of contemporary pipeline steels (X-grades), so joints and connected fittings do not become the weak link in high-pressure transmission systems. Compared with traditional A105 flanges (≈36 ksi yield), A694 F-grades give a much higher allowable stress and permit thinner wall designs or smaller flanges for the same working pressure.

Key guaranteed properties (what the spec enforces)

Below are the most frequently referenced guaranteed properties for F52 (representative — confirm actual edition and purchase POs/MTR):

| Property | Typical A694 F52 requirement (min) |

|---|---|

| 0.2% offset yield strength | 52 ksi (360 MPa). |

| Tensile strength | 66 ksi (≈455 MPa). |

| Elongation (in 2 in / 50 mm) | 20% (min). |

| Maximum Carbon (heat/product) | ≈ 0.26–0.30% (heat/product analysis tolerances vary). |

| Mn | ≈ ~1.6% (max range). |

| Si | 0.15–0.35% (typical). |

| P, S | ≤ 0.025–0.030% (low levels). |

Note: the values above are summary targets collected from the standard and commonly used supplier tables — always verify the exact limits printed on the ASTM edition or the supplier’s MTR.

Chemical composition — practical table

Different editions and supplier product/heat analyses can vary. The following is a practical consolidation used by fabricators and flange suppliers (do not use as a replacement for the standard text or MTR):

| Element | Typical A694 F52 (representative) |

|---|---|

| Carbon (C) | ≤ 0.26–0.30%. |

| Manganese (Mn) | ≈ 1.4–1.8% (commonly ≤1.6%). |

| Silicon (Si) | 0.15–0.35%. |

| Phosphorus (P) | ≤ 0.025–0.030%. |

| Sulfur (S) | ≤ 0.025–0.030%. |

| Alloying (Cr, Mo, Ni, V, Nb) | Usually trace to low levels; specific grades or product forms may add controlled amounts for toughness/hardening. See supplier MTR. |

Mechanical table (concise)

| Property | Value (typical/min) |

|---|---|

| Yield (0.2% offset) | 52 ksi / 360 MPa |

| Tensile (ultimate) | 66 ksi / 455 MPa |

| Elongation | 20% (min) |

| Hardness (typical as-forged/quenched) | Brinell around ~180–200 HB (varies by heat treatment). |

Heat treatment, notch toughness & low-temperature service

-

Heat treatment: A694 forgings are typically normalized and/or quenched & tempered depending on the grade and producer process to obtain the required yield/tensile and toughness. Typical furnace temperatures for tempering/normalizing are in the ~540 °C (1000 °F) region for some products — check supplier data.

-

Impact testing / CVN: A694 does not by itself fix a single Charpy temperature for all grades; the purchaser may specify CVN requirements (temperature and minimum energy). Many pipeline applications require low-temperature toughness; if so, call out the required CVN temperature and value on the purchase order and MTR.

-

Design note: If the flange or component is to be used in cold climates or cryogenic service, select a material and acceptance test (A350 LF grades or special impact requirements) appropriate for the temperature — A694 F52 is not inherently a “low-temperature” grade unless the specific part and supplier provide CVN data covering the needed temperature range.

Equivalents — how engineers commonly map F52 to other standards

Short answer: F52 is commonly considered functionally compatible with API 5L X52 / A860 WPHY-52 and, in some procurement contexts, grouped with EN/DIN fine-grain high proof strength steels (P355 family). But exact equivalence is never automatic — you must compare chemical limits, tensile/yield, required CVN levels, heat-treatment, and inspection/testing requirements.

Below is a concise cross-reference table used in procurement discussions (approximate; verify per application):

| ASTM A694 F52 | Common cross-reference / near-equivalent (notes) |

|---|---|

| API 5L X52 / A860 WPHY-52 | Frequently matched to F52 for pipeline/flange compatibility because both specify ~52 ksi yield. Use only after checking PSL level (PSL1 vs PSL2) and CVN tests. |

| EN / DIN — P355N/P355NH (EN 10222-4 / EN 10025 family) | In Europe, engineers map A694 F-grades to various EN fine-grain / high-proof steels for forgings; mapping depends on the product standard and required proof strength. Treat as approximate and confirm. |

| ASME / A860 WPHY grades | A860 WPHY 52 fittings are used with API 5L X52; A694 F52 flanges are commonly used with those pipe/fitting grades (matching mechanical properties). |

Practical guidance: When a piping spec says “use A694 F52 flange with X52 pipe,” that is a standard and common pairing. When an owner’s spec requests “material equivalent to A694 F52,” require the seller to provide MTRs showing A694 or explicit equivalence rationale (chemical, mechanical and impact data).

Why equivalence can be misleading — five pitfalls

-

Different test programs: API/EN/ASTM may require different mandatory tests (PSL2 additional testing, EN forgings may require different heat analysis or NDT).

-

Different acceptance temperatures for toughness: CVN temperature and acceptance values vary; a “52 ksi” yield doesn’t guarantee equal fracture toughness.

-

Composition differences: Carbon and microalloying differences influence weldability and HAZ toughness; small % changes matter for critical service.

-

Heat treatment variance: “As-forged,” “normalized,” or “quenched & tempered” products show different microstructures/toughness. Confirm processing.

-

Product form vs. heat/lot traceability: Some standards accept product analysis vs. heat analysis; procurement should require heat-by-heat MTRs for critical spools.

Typical applications (where F52 is a good choice)

-

Transmission pipeline flanges and high-pressure piping (oil & gas pipeline headers).

-

High-pressure pumps, valves and forged fittings where flange tensile/yield must track pipeline grade.

-

Compressor and gas-transmission stations where weight savings and higher allowable stress are desired.

Manufacturing notes (for buyers / QA teams)

-

Forging practice: A694 forgings are typically produced by hot forging from ingot/billet followed by machining and heat treatment. Critical dimensions should reference ASME/ANSI dimensional standards (B16.5, B16.47) when flanges are specified.

-

Traceability: Request full MTR traceability: heat number, product/heat analysis, CVN test reports (if specified), hardness, and any NDT (RT/UT) required by the purchaser.

-

Marking: Supplier should mark flanges with grade, heat number, and standard to avoid confusion between A105, A350, A694, etc. (A694 parts often marked with “A694 F52” or ASME SA694 equivalents).

Welding, machining and repair recommendations

-

Pre- and post-weld heat treatment (PWHT): Whether PWHT is required depends on part thickness, element content (Cr/Mo), and the purchaser’s welding procedure spec (WPS). Many A694 carbon/low-alloy forgings do not require PWHT for typical flange thicknesses, but pipeline or pressure vessel welds may require PWHT per code. Confirm with the welding engineer.

-

Weld filler selection: Choose a filler metal with compatible strength and toughness; for high-yield combinations, select matching or slightly lower strength filler to avoid brittle HAZs.

-

Machining: F52 has higher strength than A105-class flanges — use consistent cutting tools/feeds. Avoid removing material that would reduce the net section in the flange neck below design margins.

Inspection and testing checklist for procurement

-

MTR: heat number, product/heat analysis, test reports.

-

Mechanical test certificates: tensile, yield, elongation.

-

CVN/impact test reports at purchaser-specified temperature (if called out).

-

Hardness test(s).

-

NDT (RT/UT/MT) if required by purchaser or applicable standard.

-

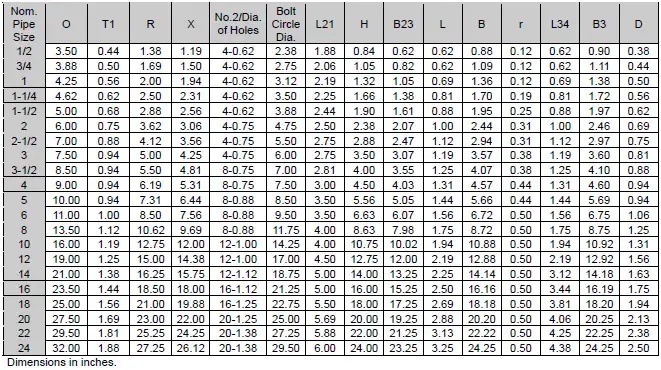

Visual & dimensional inspection to ASME B16.5 / EN1092 or the specified flange dimension standard.

Practical equivalence examples

-

Case A — pipeline tie-in: Engineer specified API 5L X52 pipe and A694 F52 flanges — this is an accepted and common pairing (mechanical properties align). Still require that the flange supplier furnishes A694 MTRs and matching bolt/gasket selection.

-

Case B — pressure vessel with low-temperature loading: Do not substitute F52 blindly for low-temperature pressure vessel forgings — use EN / ASME low-temperature grades (A350 LF2 / LF3) with certified CVN performance.

Comparative quick-reference: A694 F52 vs common alternatives

| Material | Yield (ksi / MPa) | Typical use | Notes |

|---|---|---|---|

| A694 F52 | 52 ksi / 360 MPa. | High-yield flanges/fittings for pipeline service. | Requires MTR and specific testing as buyer dictates. |

| API 5L X52 | 52 ksi / 360 MPa. | Line pipe. | PSL2 vs PSL1 testing affects equivalence. |

| A105 | ~36 ksi / 250 MPa. | General-purpose flanges (lower pressure). | Not suitable where high yield is required. |

| A350 LF2 | ~36 ksi but tested for low-temp toughness. | Low-temperature flanges. | Choose LF2/LF3 for cryo service, not F52 unless certified. |

Procurement wording

“Material to be ASTM A694/A694M Grade F52 (ASME SA694 F52 permitted). Supplier to provide full MTRs referencing ASTM A694 and the heat number; product/heat chemical analysis; tensile/yield/elongation test reports; hardness and CVN impact reports at purchaser specified temperature (if shown). Flange dimensions per ASME B16.5 (or EN 1092-1 where called out). Any substitution must be agreed in writing with complete test documentation.”

Common questions engineers ask

-

Can I use A694 F52 flanges with X52 pipe? — Yes in normal pipeline service; confirm PSL level and CVN requirements.

-

Is F52 stainless or duplex? — No. A694 F52 is a high-yield carbon/low-alloy forging; do not confuse with duplex stainless F-numbers sometimes used by other suppliers. Verify MTR keywords.

-

Does A694 guarantee low-temperature performance? — Not automatically; purchaser must specify CVN/temperature acceptance.

-

Is A694 F52 same composition as X52? — Approximately, but microalloying and required tests differ; treat as practical pairing, not literal chemical identity.

Frequently Asked Questions

-

Q: What is the exact yield and tensile for A694 F52?

A: Minimum 0.2% offset yield 52 ksi (≈360 MPa) and minimum tensile 66 ksi (≈455 MPa); elongation minimum 20%. These are the core mechanical thresholds that define “F52”. -

Q: Is API 5L X52 identical to A694 F52?

A: No single-to-one identity; both target ~52 ksi yield. API 5L is a pipe standard (PSL1/PSL2) with specific chemical/toughness testing; A694 is a forging/flange standard. They are commonly paired, but you must confirm PSL, CVN, and MTRs. -

Q: Can I weld A694 F52 to A105 flanges or A106 pipe?

A: Welding is possible but note the yield mismatch: A105 (≈36 ksi) is much softer; flange neck/bore machining can overstress the A105 part. For high-stress systems, match strength or design to accommodate differences. Engineering review recommended. -

Q: What tests should I insist on when buying F52 flanges?

A: Minimum: MTR (heat number), tensile test, yield, elongation, and any CVN impact tests specified by purchaser. Hardness and NDT per contract. Require the supplier to state which edition of ASTM A694 they used. -

Q: Are there EN/DIN equivalents I can order in Europe?

A: Engineers often map A694 F52 to EN fine-grain / high-proof steels (P355 family / 1.0562 or related designations) but check the EN product standard (EN 10222-4 or EN 1092-1) for forging and flange acceptance. These maps are approximate. -

Q: Does A694 cover socket weld and threaded fittings?

A: Yes — the specification covers forged fittings, valves and parts. Socket-weld/threaded forms may have different product analysis allowances; check the specific product packaging and MTRs. -

Q: What heat treatment should I expect?

A: Normalizing or quench & temper depending on producer and part geometry; the supplier should note heat treatment on the MTR. If the design requires a specific microstructure/toughness, call it out. -

Q: Are A694 F52 flanges common in offshore service?

A: They are used in transmission and oil & gas contexts; for offshore or corrosive environments, additional corrosion allowances or stainless/CRA lining may be preferable. Confirm suitability for seawater and corrosion conditions. -

Q Can an A694 F52 flange be used in high-temperature steam service?

A: Possibly, but high-temperature creep resistance depends on alloying and design; consult code (ASME) and specify any elevated temperature mechanical requirements. -

Q: What documentation proves equivalence?

A: Heat-by-heat MTRs with standard reference (A694 or API/EN), full chemical analysis, tensile/yield/elongation results, and CVN test reports where specified. Written acceptance from purchaser/engineer required for substitutions.

Buying checklist & sample PO language

-

Specify ASTM A694/A694M — Grade F52 (or permit ASME SA694 F52) on PO.

-

Require MTR referencing the ASTM/A860/API standard used.

-

Specify required CVN temperature (if any), NDT, and acceptance levels.

-

Call out flange dimensional standard (ASME B16.5 or EN 1092-1) and rating class.

Final engineering recommendations

-

Treat A694 F52 → API X52 as a practical pairing, not a blind substitution.

-

For critical / low-temperature / fatigue-sensitive systems, require impact/fracture data in the contract.

-

Insist on heat-traceable MTRs and supplier process notes (forging schedule, heat treatment).

Authoritative references

- ASTM A694/A694M — Standard Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service (ASTM International).

- API Specification 5L — Line Pipe (API). (See grades X52 and PSL1/PSL2 requirements.)

- Materials comparison (cross-reference) — DIN / EN / ASTM equivalence tables (example reference showing P355 / A694 alignments).