In practical terms, ASTM A36 and ASME SA-36 refer to the same basic carbon structural steel grade, their chemical limits and mechanical requirements are effectively identical. however, SA-36 carries ASME endorsement and is used when material must satisfy the Boiler & Pressure Vessel / code-fabrication pathway and its purchasing records (MTRs) must show the applicable ASME/ASTM designation; for ordinary structural work, ASTM A36 remains the common specification.

What are ASTM A36 and ASME SA-36?

-

ASTM A36 / A36M is the ASTM International standard titled Standard Specification for Carbon Structural Steel. It controls chemical composition, tensile/yield requirements, elongation, and the testing regime for hot-rolled structural shapes, plates, and bars used in bridges, buildings, and general structural work.

-

ASME SA-36 / SA-36M is the ASME-published version of that specification, placed into the ASME materials catalog so the SA-36 designation may be referenced by ASME Boiler & Pressure Vessel Code and other ASME codes. Many users and mills treat SA-36 as identical to the ASTM A36 text in the relevant edition.

Practical rule: when a code or contract calls for “SA-36”, supply material must have the ASME designation or an MTR that explicitly certifies compliance with the ASME/ASTM revision cited by the purchaser; when the contract calls for “A36”, standard ASTM A36 compliance is acceptable.

Why the two names exist and why it matters

Technical communities publish standards under different organizational umbrellas. ASTM issues material specifications principally for commerce and engineering practice; ASME repackages important material specifications under “SA-” designations so they can be explicitly referenced inside ASME Codes. The steel chemistry and mechanical limits typically match, but the contract requirement for SA-36 implies the buyer needs ASME traceability and code acceptance, which affects inspection, documentation, and sometimes mill acceptance testing.

Chemical composition

Below is a compact, engineer-focused comparison table showing the commonly quoted chemistry limits for A36/SA-36 (values are maxima where noted). These are for guidance; always check the edition of the standard cited in the purchase order because limits are edition-dependent.

| Element | Typical maximum (%) — A36 / SA-36 (nominal) |

|---|---|

| Carbon (C) | 0.25–0.29 (max depends on thickness and supplier) |

| Manganese (Mn) | 0.60–1.20 |

| Phosphorus (P) | 0.04 (max) |

| Sulfur (S) | 0.05 (max) |

| Silicon (Si) | 0.40 (max) |

| Copper (Cu) | 0.20 (may be optional) |

Notes:

-

The exact maximums depend on the standard edition and any supplementary purchaser requirements. The ASTM text defines heat analysis and product analysis paths and allows some variability tied to thickness and product form.

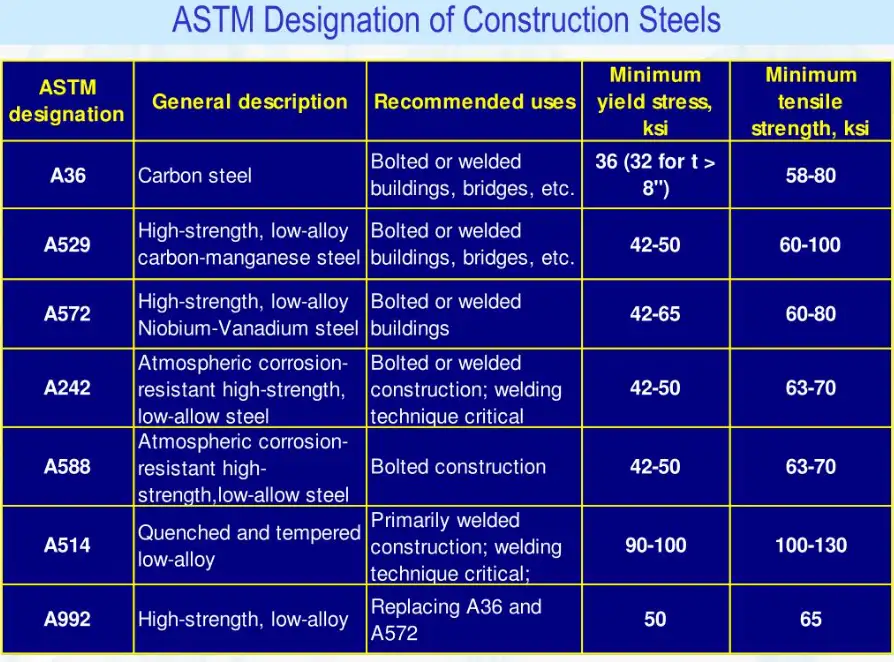

Mechanical properties

A36/SA-36 are commonly described by a minimum yield strength of 36 ksi (≈ 250 MPa) and an ultimate tensile strength range roughly 58–80 ksi (≈ 400–550 MPa) depending on product thickness and test method. Elongation requirements are typically ≥20% (on standard gauge lengths) for plates and shapes.

| Property | Typical value (imperial) | Metric equivalent |

|---|---|---|

| Minimum yield strength | 36 ksi | 250 MPa |

| Tensile strength (range) | 58–80 ksi | 400–550 MPa |

| Elongation (in 200 mm) | ≥20% | ≥20% |

| Modulus of elasticity (typical steel) | 29,000 ksi | 200 GPa |

Engineering note: design codes often adopt the minimum yield for allowable stress/section checks. When fatigue, fracture, or brittle-fracture risk is critical (cold service, thick sections), choose a grade with validated Charpy V-notch data and fracture toughness — A36 does not guarantee such toughness at low temperatures unless supplementary requirements are specified.

(Citations: property ranges consolidated from standard summaries and material handbooks.)

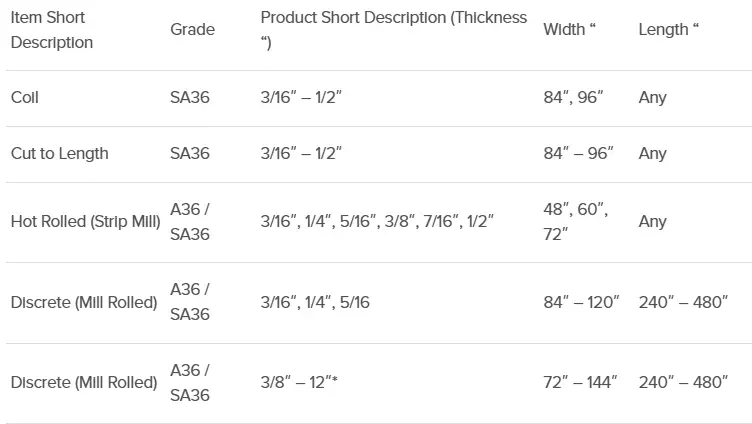

Forms, thickness ranges, and tolerances

A36/SA-36 is available in rolled plates, structural shapes (I-beams, channels), bars, and wide flats. Common plate thicknesses vary from thin sheet ranges up to several inches (typical mill ranges 3/16" to 12-1/2" in common inventories), but availability depends on mill capability and market stock. Tolerances follow general rolled-product practices or specific tables in the standard referenced.

| Product form | Typical stock range | Typical use |

|---|---|---|

| Hot-rolled plate | 3/16" – 12½" (mill ranges) | Structural plates, base plates, machine bases |

| Structural shapes | Standard beam/flange sizes | Building frames, girders |

| Bars | Round/flat bars up to ~4" dia | Details, bracketry |

| Sheet (thin) | thinner gauges | Light fabrications (less common for A36) |

Key technical differences

Although chemistry and mechanical values are essentially the same, the practical differences appear in:

-

Code endorsement and allowed use — SA-36 is the recognized ASME designation for code applications (pressure vessels, boilers) where the ASME Code calls for SA-listed materials. In many ASME Code tables SA-36 is listed as “identical with ASTM A36/A36M-YY” (edition-specific).

-

Mill test reports (MTRs) — for SA-36 orders the MTR may need to state the ASME designation and the specific Code edition. For A36 supply the MTR is against the ASTM text. If the project requires ASME documentation, an A36 mill certificate alone may not satisfy the inspector.

-

Supplementary purchaser requirements — ASME code work may demand additional heat treatment controls, testing, or Charpy testing. If such requirements are needed they must appear in the purchase order. ASTM A36 allows purchaser-specified supplementary requirements; ASME code projects often set those requirements in the code or contract.

Rule of thumb: SA-36 = ASTM A36 content + ASME registration/endorsement and the paperwork that supports code fabrication.

Welding, fabrication, and heat treatment

-

Weldability: A36/SA-36 is mild low-carbon steel with good weldability by standard processes (SMAW, GMAW, FCAW). Use low-hydrogen consumables when restraint or thickness invites hydrogen cracking risk. Preheat is rarely required for thin plate but consider preheat and post-weld heat treatment for highly restrained joints or heavy sections.

-

Cutting and forming: Standard hot-rolled practice: bending is straightforward across reasonable bend radii; avoid cold forming on the thickest gauges without anneal.

-

Heat treatment: These steels are normally supplied in the as-rolled condition; A36 is not typically heat-treated for strength (no quench-and-tempered requirement). When higher hardness or strength is required, a different grade should be specified.

-

Weld procedure qualification: For code work (when SA-36 is specified), ensure welding procedures (WPS) are qualified to the applicable ASME Code section, and welding inspectors accept the MTRs that show the SA-36 designation where required.

(Technical sources and standard practice summarized from material handbooks and the ASTM/ASME specifications.)

Quality assurance, inspection, and MTR wording

When you buy material for a code job, procurement wording drives compliance. Example snips:

-

For ASME code use (pressure vessel): “Material to be ASME SA-36/SA-36M, heat treated/normalized if required, with full MTR traceability to ASME BPVC Section II, Part A, and test reports stamped for the ASME Code edition YYYY.”

-

For general structural use: “Material to be ASTM A36/A36M; furnish MTRs showing heat number, chemical analysis, and mechanical test results per ASTM A36/A36M-YYYY.”

Inspection checklist (minimum):

-

Mill test report showing standard and revision (A36 or SA-36 and year).

-

Heat number traceability to product.

-

Chemical analysis and tensile/yield test results.

-

Visual and dimensional inspection per purchase drawings.

-

Any additional Charpy or toughness testing if required by contract.

Equivalents and international comparisons

A36/SA-36 is a common US standard; comparable grades in other norms include:

| US | Europe | Germany | China | Japan | India |

|---|---|---|---|---|---|

| A36 / SA-36 | S235JR (EN 10025) | St 37-2 | Q235B | SS400 | E250 |

Be careful: yield/tensile curves and guaranteed chemical limits vary across standards; for critical designs convert strengths and check guaranteed properties and testing regimes before substitution.

Procurement checklist and sample PO language

Decide before issuing PO:

-

Do you need ASME code acceptance? If yes, specify SA-36 and the ASME edition.

-

Are low-temperature toughness or Charpy values required? If yes, add those tests as supplementary requirements.

-

Any dimensional or mill surface finish criteria? State them.

-

Is welding procedure qualification necessary to a specific Code section? State joint types and PQR requirements.

Sample PO clause for ASME code job:“Supply SA-36/SA-36M material per ASME BPVC Section II, Part A (edition YYYY). Furnish MTRs referencing SA-36 and including chemical analysis, tensile and yield test reports, heat numbers, mill stamp, and the manufacturer’s declaration of conformity.”

Price, availability, and market practice

-

Availability: A36/SA-36 is one of the most widely stocked carbon steels; lead times are usually short for common plate and shapes, longer for unusual sizes or certified heat treatment.

-

Price drivers: thickness, plate size, market scrap price for carbon steel, special testing (Charpy), and added paperwork for ASME certification. SA-36 orders can carry a small premium for the extra documentation and possible mill certification procedures.

Tables engineers use

Table A — Quick mechanical comparison (typical)

| Grade | Min yield | Tensile range | Typical elongation |

|---|---|---|---|

| ASTM A36 / ASME SA-36 | 36 ksi (250 MPa) | 58–80 ksi (400–550 MPa) | ≥20% |

Table B — When to choose which designation

| Situation | Recommended designation |

|---|---|

| Building framing, general structural | ASTM A36 |

| Fabrication that must meet ASME BPVC code | ASME SA-36 |

| Project requiring formal code MTRs and explicit code edition | ASME SA-36 |

| Non-code work where buyer does not require ASME paperwork | ASTM A36 |

FAQs

1. Are ASTM A36 and ASME SA-36 interchangeable?

Short answer: For material chemistry and mechanical properties they are practically the same; however, do not interchange them where the contract or code explicitly requires the SA-36 designation and ASME traceability.

2. Can I use A36 plate to build a pressure vessel?

If the pressure vessel code or contract requires SA-36 or other ASME-listed materials, do not accept plain A36 certificates. SA-36 wording in the MTR and the referenced ASME edition are typically required for code acceptance.

3. What is the minimum yield and why 36 ksi?

A36/SA-36 is specified with a minimum yield of 36 ksi (≈250 MPa). The “36” in the name reflects that yield number in ksi; design codes use that figure for strength checks.

4. Does A36 need preheat for welding?

Usually not for thin plates; for thick, restrained joints or cold environments, engineering judgment should set preheat/post-heat. For code work, follow the qualified WPS and ASME Code rules.

5. Are Charpy tests required?

Not by default. If the purchaser needs impact toughness (e.g., cold service), add Charpy V-notch testing as a supplementary requirement in the PO.

6. Is SA-36 stronger than A36?

No, strength limits are essentially the same; the difference lies in code designation and required documentation.

7. What should appear on an acceptable MTR?

Heat number, chemical analysis, tensile and yield results, standard and revision (A36 or SA-36 and year), mill stamp, and signature of authorized mill representative. For ASME jobs, the MTR should reference the ASME code edition when SA-36 is required.

8. Equivalent grades in Europe or China?

Common equivalents include EN S235JR and Chinese Q235B, but always verify the guaranteed mechanical and chemical properties before substitution.

9. Which suppliers usually stock A36/SA-36?

Most major mills and service centers stock A36/SA-36 plates and shapes; availability varies by geographic region and plate thickness. Expect broad stock in major industrial markets.

10. Any pitfalls for procurement teams?

Yes. failing to specify the required standard edition, neglecting to require SA-36 where the code demands it, and not listing supplementary tests (toughness) when needed. Clear PO language solves most issues.

Practical selection guidance

-

If the job is code-governed (ASME BPVC, Section I/II, VIII, etc.), specify SA-36 and the ASME edition.

-

If the job is non-code structural, A36 is typically sufficient and more common in RFQs.

-

For low-temperature, high-fracture-risk service, request supplemental toughness testing and consider a different grade designed for fracture resistance.

-

Always require MTRs and confirm the mill’s capability to supply the correct designation and the revision year cited.

Closing technical remark

ASTM A36/ASME SA-36 is the workhorse low-carbon structural steel for many industries. The metallurgy is simple, the fabrication properties are friendly, and global availability is high. The main engineering decision is not the chemistry or strength but whether the project needs ASME traceability and code-level documentation. Where code traceability is mandatory, call for SA-36 and be explicit about the ASME edition and MTR expectations.

Authoritative references

- ASTM A36/A36M — Standard Specification for Carbon Structural Steel (ASTM International)

- ASME — Codes & Standards (including material listings and BPVC references)

- ASME — Boiler & Pressure Vessel Code brochure (context for material designations)

- ASTM A36 Mild/Low Carbon Steel — material overview and typical properties (AZoM)