ASTM A350 (A350/A350M) is the ASTM/ASME specification for carbon and low-alloy forgings that require notch-toughness testing for piping components — most commonly used for low-temperature flanges, fittings and valve forgings (the widely used grade in industry is LF2, Class 1). Parts made to A350 are specified for guaranteed low-temperature impact toughness, specified heat-treatment/delivery conditions and controlled chemical limits; these requirements and the test matrix are defined in the A350 standard.

Scope and intended use

ASTM A350/A350M is written specifically for forgings and ring-rolled forgings used as piping components that must demonstrate notch toughness for low-temperature service. The intent is to ensure the raw material (the forging) has consistent melting practice, chemistry, and mechanical/impact properties adequate for the design temperature and mechanical loadings of pressure piping systems. The standard is commonly referenced by ASME piping and flange standards and in order specifications for valve and fitting manufacturers.

Relationship to ASME / designation notes

In practice you will see the material referenced as ASTM A350 or ASME SA350 (the ASME designation mirrors the ASTM specification when used in pressure piping code work). The document is published and maintained by ASTM International; ASME publishes matching SA designations for materials used in pressure equipment. For procurement and code compliance, many purchasers list both (e.g., "ASTM A350 / ASME SA350, Grade LF2, Class 1").

Grades and classes

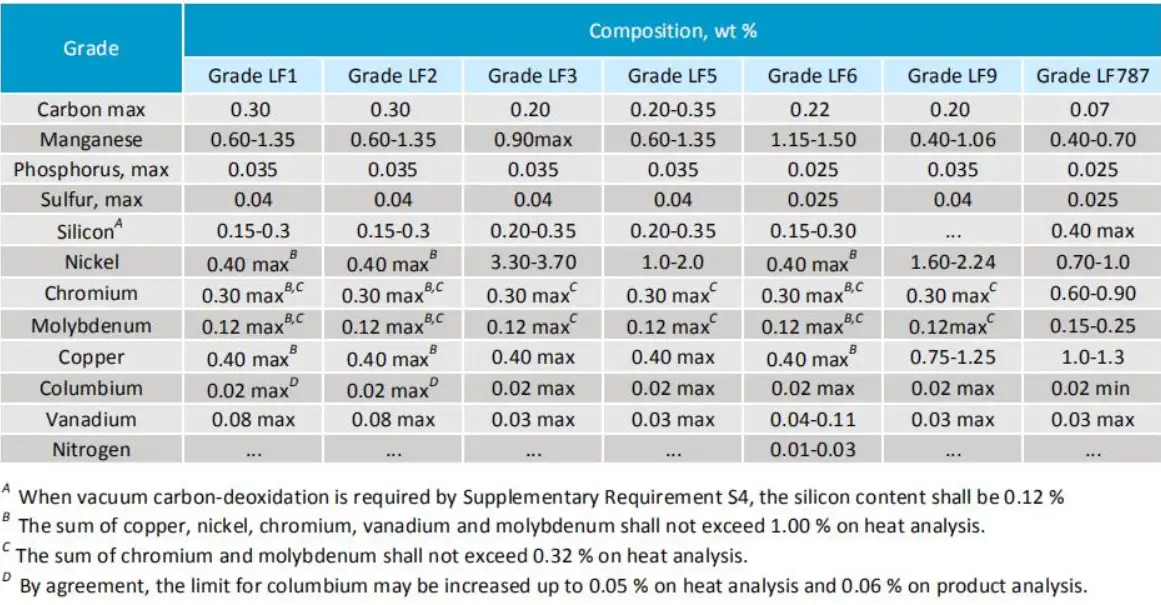

A350 covers multiple grades (LF1, LF2, LF3, LF5, LF6, LF9, LF787, etc.) and each grade may be produced to different classes depending on test/thermal treatment requirements (Class 1, Class 2, etc.). In industry the most commonly specified grade is:

-

LF2 (Class 1) — the mainstream low-temperature carbon steel forging grade used for flanges, fittings and valves requiring good toughness down to typical low-temperature service requirements. LF2 is frequently normalized or normalized + tempered in delivery and has defined limits for carbon, Mn, Si and trace alloying.

Other grades (LF1, LF3, LF5, LF6, LF9, LF787) exist to cover different chemical and mechanical categories (e.g., different alloying, vacuum de-oxidation requirements, or low-alloy variants). The specific test, acceptable heat treatments and impact test temperatures may vary by grade and product thickness — always confirm the grade/class in the order and review the standard clauses for the grade you require.

Chemical composition — limits & carbon equivalent

Below is a concise, practical chemistry table for ASTM A350 LF2 (typical limits) drawn from the standard and common mill data (use this as a design / procurement reference; always verify the controlling edition of the standard and the final mill heat analysis). Values are maximum unless otherwise noted.

| Element | Typical limit (%) — LF2 (example) |

|---|---|

| C (carbon) | ≤ 0.30 |

| Si (silicon) | 0.15 – 0.30 (max often 0.30) |

| Mn (manganese) | 0.60 – 1.35 |

| P (phosphorus) | ≤ 0.035 |

| S (sulfur) | ≤ 0.040 |

| Cu (copper) | ≤ 0.40 |

| Ni (nickel) | ≤ 0.40 |

| Cr (chromium) | ≤ 0.30 |

| Mo (molybdenum) | ≤ 0.12 |

| V (vanadium) | ≤ 0.08 |

| Nb (niobium) | ≤ 0.02 (may be by agreement) |

| SUM (Cu+Ni+Cr+Mo+V) | ≤ 1.00 (typical constraint) |

Carbon equivalent (CE) is limited (typical CE formula used in standard guidance):

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15 — max CE around 0.47 (thickness dependent; confirm specific clause). These chemical constraints and CE limits exist to ensure weldability and low-temperature toughness and are explicitly called-out in the specification.

Note: Many manufacturers publish very similar chemistries in LF2 data sheets; exact maxima and special-case allowances (e.g., Nb increases by agreement) must be resolved in the purchase order.

Mechanical properties and toughness testing

ASTM A350 requires minimum mechanical properties (yield and tensile) and notch toughness (usually Charpy V-notch) at specified temperatures depending on grade, class and product thickness. Typical mechanical ranges for LF2 (indicative):

-

Yield strength (Rp0.2): ~240–255 MPa (≈35 ksi) minimum, depending on heat treatment and class.

-

Tensile strength (UTS): often in the range ≈ 480–655 MPa (≈70–95 ksi) depending on class and heat treatment.

-

Impact testing (Charpy V-notch): specified minimum KV value tested at a given temperature (e.g., −18°C or −46°C; many LF2 Class 1 forgings require impact testing at −46°C or −45°C depending on purchaser).

These values vary by grade, class and thickness. The standard provides the detailed tables that combine product thickness, grade/class and required Charpy test temperature and energy values. Always refer to the clause tables in the controlling edition of ASTM A350 when writing a specification or reviewing an MTC.

Heat treatment and delivery conditions

Common delivery conditions allowed by A350 include:

-

Normalized (N) — common for LF2 forgings to stabilize grain structure and deliver low-temperature toughness.

-

Normalized and tempered (NT) — in some cases used to tailor mechanical properties.

-

Quenched and tempered (Q+T) — for some low-alloy grades (not the usual LF2 carbon variant unless specified).

-

As-forged or other conditions may be permitted by agreement, but the purchaser must ensure required toughness is achieved.

The standard also identifies melting practices (open-hearth, basic oxygen, electric furnace, vacuum-induction melting) and calls out vacuum carbon deoxidation for certain grades to control silicon and inclusion content. Heat-treatment cycles (temperatures and cooling media) are covered in the standard and in mill practice sheets.

Typical applications & industries

ASTM A350 forgings are used where low-temperature impact toughness is essential. Typical applications include:

-

Flanges, forged fittings and valve bodies for natural gas and crude oil transmission at low temperatures.

-

Cryogenic or sub-ambient piping systems (when specified for appropriate test temperature).

-

Petroleum, petrochemical and process industries where flanged connections and valve bodies require forged shapes with verified toughness.

Equivalents and caution on "equivalent" claims

There is no single direct global “drop-in” equivalent — but there are near-equivalents depending on chemistry and required tests. Documents that compare standards map LF2 to a handful of EN/DIN grades by application, but these mappings are approximate and must be validated for the required impact temperature, thickness and welding conditions. Typical comparisons that appear in engineering cross-reference tables:

-

LF2 ≈ some EN pressure-vessel low-temperature steels (e.g., P355NL1 / P355NL2 or P355 variants for low temperature service) — but the microstructure, Charpy test requirements and welding restrictions differ and must be validated.

Important guidance: Never specify an “equivalent” without checking all three axes: (1) chemistry/CE, (2) mechanical & toughness test temperature(s) for the given thickness, and (3) the manufacturing route (forged vs rolled vs cast). When in doubt, buy to the actual A350 standard (or require manufacturer cert with the full A350 clause references).

Inspection, testing and mill paperwork

For code and procurement clarity, typical documents and tests buyers require with A350 forgings include:

-

Mill Test Certificate (MTC): heat number, product analysis and heat analysis, heat treatment record.

-

Charpy V-Notch impact test results: sample orientation, temperature, and energy values per standard.

-

Tensile/Hardness tests: when required by the standard or purchaser.

-

Chemical analysis on heat and product: confirming limits and carbon equivalent calculation.

-

Nondestructive examination (NDE): radiography or UT if required by purchaser or code (A350 itself focuses on forging chemistry and toughness rather than mandatory radiography).

-

Traceability and forging records: melt practice (EAF/BOF/VIM) and forming records.

Fabrication and welding notes

-

Weldability: LF2 is a low-carbon, low-alloy steel with CE limits to retain reasonable weldability. Preheat/post-weld heat treatment and PWHT must follow the welding procedure and the CE/weldability assessment.

-

Machinability: typical for forged carbon steels; tool choices and feeds should reflect the grade and heat-treatment.

-

Thermal cycles: avoid excessive local overheating during fabrication — toughness can be degraded by improper local heat exposure.

-

Coatings & corrosion protection: A350 is not a corrosion-resistant alloy; choose coatings (epoxy, zinc, galvanizing by agreement) or material upgrades for corrosive services.

Selection checklist for purchasers

When you create a purchase order or a drawing note, specify:

-

Full material designation: “ASTM A350/A350M — Grade LF2, Class 1, normalized” (or the grade/class/delivery you need).

-

Charpy test temperature and minimum energy (per thickness).

-

Required melting method (e.g., vacuum one-time deoxidized vs VIM if needed).

-

Heat treatment record requirement and MTC data fields.

-

Any additional NDE or dimensional tolerances, flange face finish and pressure class.

-

Warranties and traceability needs (e.g., mill heat traceable to MTC).

Practical tables

Table A — Common grades summary (short)

| Grade | Typical use | Low-temperature behaviour |

|---|---|---|

| LF2 | Flanges, valve bodies — most common | Good impact toughness at sub-ambient temperatures (depends on class/test temp) |

| LF1, LF3, LF5, LF6, LF9, LF787 | Variants for specific chemistries/low-alloy requirements | Varies — check clause in A350 for each grade |

Table B — Example mechanical (indicative only; final values per A350 clause and PO)

| Property | Indicative LF2 (typical) |

|---|---|

| Yield (Rp0.2) | ≥ 240 MPa |

| Tensile (UTS) | ≈ 480–655 MPa |

| Charpy test temp | −18°C, −29°C or −46°C (per clause / purchase) |

(These numbers must be verified in the controlling clause and product thickness tables in the standard.)

FAQs

1) What is the main difference between ASTM A350 LF2 and A105?

A105 is a general carbon steel forging grade for piping at ambient/higher temperatures; A350 LF2 is formulated and tested for low-temperature toughness (sub-ambient service) and requires Charpy impact verification at lower temperatures. For cryogenic or low-temperature service always prefer A350 LF2 and the correct test temperature.

2) Can I substitute LF2 with an EN steel like P355NL1?

Only with technical review. Some EN grades are similar in application, but you must confirm chemistry, specified Charpy temperature and required tests across thicknesses before accepting an “equivalent.” Don’t assume interchangeability without a documented equivalency assessment.

3) What Charpy temperature should I demand?

Demand the Charpy V-notch test temperature that matches your lowest expected service temperature plus an engineering margin. Typical purchase temperatures for LF2 forgings are −18°C to −46°C depending on design; specify the required temperature in the PO.

4) Is LF2 weldable?

Yes — LF2 is designed with CE limits for reasonable weldability, but appropriate preheat and procedure qualification per welding code must be followed. Higher CE or added alloying may require special controls.

5) How is LF2 delivered (heat treat)?

Commonly normalized or normalized and tempered; quench/tempering are used for low-alloy variants when higher strength is required. State the desired condition on the order and ensure impact requirements are met in that delivery condition.

6) Do I need mill Charpy tests for every forging?

The standard requires representative Charpy sampling per lot and thickness; many purchasers require Charpy results for each heat and product lot to ensure traceable toughness data. Specify acceptance criteria in the contract.

7) What documentation should the supplier provide?

At minimum: MTC with heat & product analysis, Charpy test reports (with notch orientation, sampling details and temperature), and heat-treatment records. Additional NDE or certification language may be required by purchaser.

8) Are LF2 forgings suitable for cryogenic LNG service?

LF2 can be used for sub-ambient service if the specified Charpy test temperature meets the design temperature; for extreme cryogenic (e.g., LNG at −162°C) specialized cryogenic steels and validated procedures are usually required — consult metallurgists/code requirements.

9) What does “Class 1” mean?

Class 1 usually identifies the required product/test matrix and acceptance criteria in A350 for a specific grade; Class 1 is the most commonly used construct for typical LF2 forgings. See the standard tables for exact definitions by grade/class.

10) Where should I put A350 requirements on drawings?

On material callouts and under “Material & Heat Treatment” notes include the exact designation (ASTM A350/A350M — Grade LF2 — Class 1 — Delivery condition), Charpy test temperature and required documentation (MTC, Charpy reports, NDE). State any special coating, PWHT or welding requirements.

Practical procurement wording

“Material: ASTM A350/A350M — Grade LF2 — Class 1. Delivery condition: normalized. Chemical composition and product/heat analyses to conform to A350 clauses X–Y. Charpy V-notch specimens to be tested at −46°C with minimum energy of [X J] per A350, sampling per clause Z. Mill Test Certificate: EN 10204/3.1b (or purchaser's required format) with heat number traceability and heat-treatment record.”

This kind of concise clause avoids ambiguity at order placement and reduces risk of out-of-spec supply.

Limitations & closing practical advice

-

Standards update: Standards are periodically revised — always reference the edition (year) of the standard in your purchase order (e.g., “ASTM A350/A350M — 20XX edition”).

-

Do not rely on “equivalent” alone: confirm testing, CE and delivery treatment before accepting a non-A350 standard.

-

Design margin: specify Charpy testing below expected service temperature and require documented test reports — that is the core safety benefit of A350.

Official references

- ASTM A350/A350M — Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components (ASTM)

- ASTM A350/A350M — Full text (example PDF copy of the A350 standard, 2023 revision)

- ASTM A350 / ASME SA350 — Specification (procurement & comparison PDF)

- EN / DIN / ASTM material comparison (useful cross-reference tables for equivalents)

- A350 Grade LF2 — Technical data and typical chemical/mechanical summary (metaldata.info)