ASTM A108 is the principal American specification for cold-finished carbon and alloy steel bars used where tight tolerances, reliable machinability, and consistent mechanical performance are required; it spans many commonly used grades (1010 → 1144 and other designations), supports multiple heat-treatment conditions, and is the industry choice for shafts, fasteners, axles, spindles, and turned components in general engineering. Selecting the correct A108 grade and condition delivers a predictable balance of strength, machinability, and finish for high-volume manufacturing or one-off precision components.

What is ASTM A108 covers

ASTM A108 is a specification that defines requirements for cold-finished carbon and alloy steel bars produced in straight lengths and coils. The primary intent is to provide standard quality bars suitable for heat treatment, for machining into finished parts, or for use in the as-finished condition for shafting and similar constructional uses. The document sets chemical composition limits, identifies grades by numerical designation (many matching common AISI/SAE numbers), and defines required tests and acceptance criteria.

Brief history and current edition

ASTM A108 has a long history (first adopted in the early 20th century) and is periodically revised. The most recent approved edition was released in 2024 (A108-24), reflecting clarifications and editorial updates while retaining the core coverage for cold-finished bars. Buyers and engineers should quote the full designation and year (for example: “ASTM A108-24”) on purchase orders to avoid ambiguity.

How A108 is organized: grades, numbering, and equivalents

A108 lists many grades—typically expressed by the familiar AISI/SAE numbers such as 1010, 1018, 1020, 1045, 1060, 1117, 1144, 12L14, 1215 and others. Each grade specifies composition limits and, in some cases, typical mechanical properties or heat-treatment instructions. Many suppliers and mills will reference the equivalent AISI or SAE designation in tandem with the A108 grade to make material selection straightforward for machinists and designers. Supplier catalogs often map A108 grades to commercially available bar products.

Common A108 grade → equivalents

Note: “Equivalent” means commonly used cross-reference designations. Always confirm chemical limits and mechanical properties for your application.

-

A108 Grade 1018

-

Typical designation: AISI/SAE 1018, UNS G10180. Widely supplied as A108 cold-finished 1018.

-

-

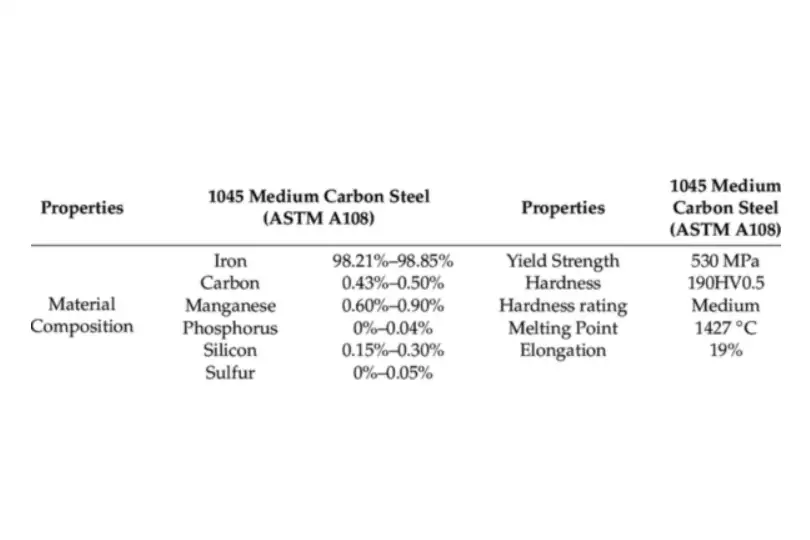

A108 Grade 1045

-

Typical designation: AISI/SAE 1045, UNS G10450. Common European equivalent: EN C45 / 1.0503 (C45).

-

-

A108 Grade 1117

-

Typical designation: AISI/SAE 1117, UNS G11170. Cross-referenced in many ASTM/SAE specs (e.g., A29, A576).

-

-

A108 Grade 1215

-

Typical designation: AISI/SAE 1215 (resulfurized free-machining carbon steel). Also appears in A108 listings.

-

-

A108 Grade 4140 (when called under A108 as alloy option)

-

Typical designation: AISI/SAE 4140 (chromium-molybdenum alloy steel). European equivalents: various EN 1.7225 etc. (verify specifics).

-

Typical chemical compositions

Note: composition ranges below are representative; final acceptance is governed by the edition of ASTM A108 quoted on the purchase order and the supplier’s test certificates.

Table 1 — Representative chemical ranges for common A108 grades (wt %)

| Grade (A108 / common AISI) | C (carbon) | Mn (manganese) | Si (silicon) | P (max) | S (max) | Special notes |

|---|---|---|---|---|---|---|

| 1010 | 0.08–0.13 | 0.30–0.60 | ≤0.10 | 0.04 | 0.05 | low carbon, good formability |

| 1018 | 0.15–0.20 | 0.60–0.90 | ≤0.10 | 0.04 | 0.05 | general purpose machining steel |

| 1020 | 0.18–0.23 | 0.30–0.60 | ≤0.10 | 0.04 | 0.05 | slightly stronger than 1018 |

| 1045 | 0.42–0.50 | 0.60–0.90 | 0.15–0.35 | 0.04 | 0.05 | medium carbon for higher strength |

| 1117 | 0.12–0.18 | 0.60–0.90 | ≤0.10 | 0.04 | 0.05 | leaded variant for superior machinability |

| 1144 | 0.40–0.50 | 0.60–1.00 | 0.15–0.35 | 0.04 | 0.05 | free-machining, high strength in turned condition. |

| 12L14 | 0.10–0.15 | 0.60–1.00 | ≤0.10 | 0.04 | 0.06 | leaded, excellent chip control for high speed turning. |

Interpretation: choose low-carbon (1010/1018) for deep drawing, bending and moderate machining; select medium carbon (1045) for parts that need higher core strength or hardness after heat treatment; pick leaded grades (1117/1144/12L14) for high productivity turning operations.

(Sources: ASTM A108 composition tables and common material datasheets.)

Mechanical properties and heat-treatment conditions

Mechanical attributes depend heavily on grade and condition (annealed, normalized, quenched & tempered, or turned/ground). A108 covers standard quality cold-finished bars and permits a variety of finishes and heat treatments per grade.

Table 2 — Typical mechanical ranges

| Grade | Condition | Tensile strength (ksi / MPa) | Yield (0.2% offset) (ksi / MPa) | Elongation (%) |

|---|---|---|---|---|

| 1018 | turned, annealed | 60–75 ksi (415–520 MPa) | ~48–60 ksi (330–415 MPa) | 15–20% |

| 1045 | normalized | 80–110 ksi (550–760 MPa) | 60–90 ksi (415–620 MPa) | 10–16% |

| 1144 | turned, stress relieved | 90–130 ksi (620–900 MPa) | 70–110 ksi (480–760 MPa) | 8–14% |

| 12L14 | turned, annealed | 70–110 ksi (480–760 MPa) | 50–90 ksi (345–620 MPa) | 10–16% |

Notes:

-

The values above are typical mill data and vary by heat treatment and section size. For design, always use supplier test reports (mill test certificates) tied to the specific heat number.

Dimensional tolerances, surface finishes, and available forms

A108 defines tolerances for cold-finished bars (round, square, hex, flat) and permits drawings to specify turned-, ground-, or polished finishes. Cold-finishing yields closer dimensional control and improved surface integrity compared with hot-rolled bars.

Common forms:

-

Straight lengths (cut to length).

-

Coiled cold-finished bars (for some grades).

-

Turned, ground, and polished bars for bearing and shaft applications.

Tolerance classes are frequently quoted in supplier catalogs; when tight fits are required, call out the finish and tolerance class (e.g., “turned & ground to ±0.002 in”) on the order. McMaster and major distributors list stock sizes and tolerances for A108 items.

Manufacturing routes and quality controls

Typical production steps for an A108 cold-finished bar:

-

Hot-wrought billet production (melting, casting, hot rolling).

-

Cold-finishing by drawing, cold rolling, or turning to achieve dimensions and surface finish.

-

Heat treatment (if required by grade).

-

Testing — chemical analysis, tensile testing, hardness checks, and sometimes PMI (positive material identification) or ultrasonic testing for critical parts.

-

Mill test report (MTR) accompanying each lot, documenting compliance with the specified edition of ASTM A108.

Buyers should require a full MTR and, where necessary, third-party inspection or witness testing for critical structural components.

Typical applications and selection rules

A108 bars serve industries including automotive, agricultural machinery, general engineering, power transmission (shafts, pins), fasteners, and tooling mandrels. Selection rules:

-

For high throughput turning operations, pick free-machining grades (1117, 1144, 12L14).

-

For parts requiring higher core strength or case hardening, use 1045 or a higher carbon variant and specify the heat treatment.

-

For shafts requiring tight concentricity and finish, specify turned & ground finish plus appropriate tolerance band.

Case note: A manufacturer switching from 1018 to 1144 for a turned coupling saved 22% cycle time per part due to improved chip control and lower tool wear — an example of how material choice affects manufacturing economics.

Fabrication, machining, welding, and surface finishing

Machining: low-alloy, low-carbon grades machine easily; leaded grades provide excellent chip control and higher feed rates. Tooling selection: carbide inserts for high speed; HSS acceptable for small shops.

Welding: many A108 grades are weldable, but expect reduced weldability with increasing carbon content (e.g., 1045). Preheat, interpass control, and post-weld heat treatment may be required for thicker sections or critical applications.

Surface treatments: common treatments include nitriding, carburizing (on medium carbon grades), phosphating, and various plating or painting systems for corrosion protection.

Inspection, certification, and traceability best practices

Always request:

-

Full mill test report (chemical analysis and mechanical tests).

-

Heat number traceability on each bundle or piece.

-

Dimensional inspection reports if tight tolerances were ordered.

-

Certificate revision matching the ASTM edition cited on the PO.

For safety-critical parts, add third-party inspection or non-destructive testing (NDT) clauses into the contract.

Procurement checklist and ordering example

Checklist:

-

ASTM designation and year (e.g., ASTM A108-24).

-

Grade (AISI/SAE number e.g., 1018).

-

Condition and finish (turned, ground, polished).

-

Heat treatment (annealed, normalized, tempered).

-

Quantity, lengths, and tolerance band.

-

Inspection requirements (MTR, NDT, witness test).

-

Packaging and shipping instructions.

Ordering example:

“Supply ASTM A108-24, Grade 1045, cold-finished turned & ground bars, 1.25 in diameter ±0.002 in, lengths 300 mm ±5 mm, normalized condition, MTR per heat number, 2,000 pieces.”

Shipping, storage, and handling guidance

-

Store in dry, ventilated areas to avoid corrosion.

-

Protect turned/ground surfaces with paper wrapping or corrosion preventatives for overseas shipments.

-

Label bundles by grade and heat number to maintain traceability.

Cross-reference and substitution guidance

-

ASTM A29 covers hot-wrought bars and is often used when hot-rolled stock is acceptable. A108 generally gives closer tolerances for cold-finished applications.

-

European equivalents: EN standards differ in enumeration; direct one-to-one equivalents may not exist for every A108 grade. When substituting, match chemistry and mechanical properties, and document the equivalence in the PO.

Practical selection matrix (table)

Table 3 — Quick selection matrix

| Requirement | Typical A108 grades | Why |

|---|---|---|

| High machinability, short cycle time | 12L14, 1117, 1144 | Leaded grades reduce tool wear and improve chip breaking. |

| Higher core strength, can be heat treated | 1045, 1060 | Medium carbon; responds to quench/temper. |

| Low carbon, good formability | 1010, 1018 | Easier forming and welding. |

| Tight dimensional tolerance, bearing finish | Turned & ground 1018 or 1045 | Cold finishing gives surface integrity and concentricity. |

Practical tips from production engineers

-

When ramping production, run comparative trials for tool life between 1018 and 1144; sometimes slightly higher material cost is offset by lower machining cost.

-

For small batches of precision shafts, specify turned & ground and require a surface roughness target (e.g., Ra ≤ 0.8 µm).

-

If parts will be plated, run adhesion tests after final heat treatment to verify coating compatibility.

Tables for quick reference

Table 4 — Representative tolerance bands for turned & ground A108 round bars

| Nominal diameter (in) | Typical tolerance (turned & ground) |

|---|---|

| 0.125 – 0.500 | ±0.001–0.003 in |

| 0.501 – 1.000 | ±0.002–0.004 in |

| 1.001 – 2.000 | ±0.003–0.005 in |

(Confirm exact tolerance bands with supplier or reference the A108 tolerance tables in the standard.)

Common pitfalls and how to avoid them

-

Pitfall: Ordering “A108” without edition year. Fix: Always include the year (e.g., A108-24).

-

Pitfall: Assuming identical properties between turned & ground product and hot-rolled bar. Fix: Specify finish and tolerance class.

-

Pitfall: Omitting MTR requirement. Fix: Make MTR mandatory for each lot.

FAQs

1. What’s the main difference between ASTM A108 and ASTM A29?

A108 covers cold-finished bars with tighter tolerances and finishes; A29 addresses hot-wrought bars and general requirements. Quote the standard edition on the PO.

2. Can I heat treat any A108 grade?

Many A108 grades accept heat treatment; medium carbon grades respond best. Confirm with the mill and specify the desired heat-treatment process in the order.

3. Are leaded grades suitable for structural parts?

Leaded grades improve machinability but can reduce toughness; avoid for safety-critical or fatigue-sensitive structures. Use them for turned, non-structural parts.

4. How do I ensure material traceability?

Request mill test reports (MTRs) with heat numbers, and require the supplier to mark bundles with heat numbers and grade. Include traceability clauses in contracts.

5. What finish should I order for precision bearings?

Turned & ground with a specified surface roughness (e.g., Ra ≤ 0.8 µm) and runout tolerance. Confirm by sample approval.

6. Can A108 material be cold-formed after delivery?

Low-carbon grades (1010, 1018) can be bent and formed; medium carbon grades will be less ductile and may crack without annealing.

7. Does grade 1045 accept carburizing?

Yes. 1045 is a common choice for case hardening provided section size and cycle parameters are controlled. Always specify post-treatment checks.

8. Are there EN equivalents for A108 grades?

No exact universal one-to-one mapping exists; choose EN grades by matching chemistry and mechanical properties and document the substitution.

9. What tests are typical on receipt?

Visual, dimensional, certificate cross-check, hardness (spot checks), and sample tensile tests when required by the contract.

10. How should I store bars to prevent corrosion?

Keep in dry indoor spaces, use VCI (volatile corrosion inhibitor) paper for long storage and avoid direct contact with concrete floors.