ASTM A105 (ASME SA-105) is the industry’s standard forged carbon-steel grade for piping components — flanges, fittings and valves — where reliable strength, weldability and economy are required for ambient and elevated temperature pressure systems. It balances low-alloy chemistry and predictable mechanical properties, can be heat-treated to adjust toughness, and has widely accepted international equivalents (for example EN grades used in Europe).

What A105 is and where it applies

ASTM A105 (often written ASME SA-105 when referenced in code work) is a standard specification for carbon-steel forgings intended for piping applications — primarily flanges, fittings and valve bodies used in pressure systems at ambient and elevated temperatures. The standard covers chemical limits, required mechanical properties, permissible heat treatments, test methods and marking/identification. Forgings under this specification are limited in weight (generally up to 10,000 lb per forging) and are intended to provide reliable, code-accepted material for oil & gas, petrochemical, power generation and general industrial piping.

Short guidance for buyers and designers

If you need an economical, weldable forged carbon-steel material for pressure-retaining piping hardware that will be welded, machined and used at ambient to moderately elevated temperatures, A105 is the default choice in many regions. Specify A105 with any additional purchaser's supplementary requirements you need (e.g., normalization, impact testing, hydrostatic test, or reduced sulfur/phosphorus) and require Material Test Reports (MTRs) per ASTM A961 when code traceability is needed. For low-temperature service requiring notch toughness, consider SA-350 LF2 or specify A105 with specific toughness/impact testing requirements.

Chemical composition (limits and practical meaning)

Below is a concise table of the chemical limits called out by the A105/SA-105 specification, with practical commentary.

| Element | Composition (wt%) — A105 / SA-105 limits | Practical effect |

|---|---|---|

| Carbon (C) | ≤ 0.35% | Controls strength and hardenability. Low carbon preserves weldability. |

| Manganese (Mn) | 0.60 – 1.05% | Adds strength and hardenability; typical for forged carbon steels. |

| Phosphorus (P) | ≤ 0.035% | Kept low to reduce embrittlement and improve ductility. |

| Sulfur (S) | ≤ 0.040% | Controlled to avoid hot shortness; lower is better for toughness. |

| Silicon (Si) | 0.10 – 0.35% | Deoxidizer; small amounts give strength and improve casting/forging quality. |

| Copper (Cu) | ≤ 0.40% (note A) | Trace amounts permitted; small improvements in corrosion resistance. |

| Nickel (Ni) | ≤ 0.40% (note A) | Trace only — not an alloy steel; no significant alloying intended. |

| Chromium (Cr) | ≤ 0.30% (note A/B) | Trace only; limited contribution to strength. |

| Molybdenum (Mo) | ≤ 0.12% (note A/B) | Trace only; usually negligible in A105. |

| Vanadium (V) | ≤ 0.08% | Trace amounts may refine grain size. |

| Sum (Cu+Ni+Cr+Mo+V) | ≤ 1.00% (note) | Keeps A105 in the low-alloy / carbon category. |

| Sum (Cr+Mo) | ≤ 0.32% (note) | Additional constraint to avoid unintended alloying. |

(Table source: chemical limits summarized from the A105 / SA-105 specification and industry material datasheets.)

Commentary: A105 is fundamentally a low-carbon, low-alloy forging steel. The specification allows small additions of alloying elements but keeps their sum tightly controlled so the material behaves like carbon steel: good weldability, predictable forgeability and economical cost. The chemistry supports conventional heat treatment options (anneal, normalize, quench & temper) but does not make A105 a higher-alloy, corrosion-resistant or high-temperature creep steel.

Mechanical properties (standard requirements and typical ranges)

A105 mandates minimum mechanical performance to ensure safe use in pressure systems. The key properties (inch-pound units commonly used in purchasing) are:

| Region/Country | Standard | Equivalent Material | Tensile Strength | Yield Strength | Elongation | Hardness |

| Europe | EN 10213 | GS-C25 | 480–620 MPa | 250 MPa | 22% | HB 170 |

| EN 10025 | S235JR | 360–510 MPa | 235 MPa | 26% | HB 140 | |

| Japan | JIS G3454 | STPG370 | 370–510 MPa | 235 MPa | 20% | HRB 80 |

| JIS G3101 | SS400 | 400–510 MPa | 235 MPa | 26% | HB 140 | |

| Germany | DIN 17175 | St 35.8 | 490–630 MPa | 250 MPa | 20% | HB 170 |

| DIN 17200 | C 22.8 | 410–550 MPa | 230 MPa | 23% | HB 160 | |

| United Kingdom | BS 1501 | 1501-151 Grade 360 | 480–620 MPa | 250 MPa | 22% | HB 170 |

| China | GB 713 | Q245R | 490 MPa | 245 MPa | 22% | HB 160 |

| GB 699 | Q235B | 375–500 MPa | 235 MPa | 26% | HB 140 | |

| International | ISO 6505 | P245GH | 410–540 MPa | 245 MPa | 24% | HB 150 |

| ISO 4957 | 42CrMo4 | 850–1000 MPa | 600 MPa | 12% | HB 250 | |

| India | IS 2062 | E250 | 410–530 MPa | 250 MPa | 23% | HB 160 |

| South Korea | KS D 3503 | STPT370 | 370–510 MPa | 235 MPa | 20% | HRB 80 |

| United States | ASTM A105N | A105N | 485 MPa | 250 MPa | 20% | HB 160 |

Physical Properties

| Property | Value |

| Density | 7.85 g/cm³ (7850 kg/m³) |

| Melting Point | 1425–1540 °C |

| Thermal Conductivity | 50.9 W/m·K |

| Electrical Conductivity | 10.0 × 10⁶ S/m |

| Specific Heat | 0.460 J/g·K |

| Young’s Modulus | 200 GPa (approx. 29 × 10⁶ psi) |

| Poisson’s Ratio | 0.29 |

| Coefficient of Expansion | 11.7 × 10⁻⁶/°C |

Interpretation for designers: A105 provides robust tensile and yield levels for forged piping components; ductility (elongation) and hardness limits ensure the material can be machined, formed and welded without brittle behavior in typical ambient to moderately elevated temperature service.

Heat treatment, forging practice and A105 vs A105N

Forging temperature and typical heat treatments

-

Typical forging temperature range: about 900–1250 °C (≈1650–2300 °F) depending on forging practice. Controlled reheating/thermomechanical processing ensures proper grain flow for strength and toughness.

-

Post-forging heat treatments allowed by the spec: annealing (softening), normalizing (refine grain, boost toughness), quenching & tempering (raise strength/toughness), or other tempering as specified. The purchaser often specifies the exact heat-treatment sequence to meet design needs.

A105 vs A105N — what the “N” means

-

A105N (or SA-105N) indicates normalization (and usually temper) was performed — the “N” designator specifically means the forging was normalized after forging to produce a more uniform, refined grain structure and thereby improved toughness and more consistent mechanical properties.

-

Key practical difference: chemically the base limits are the same, but A105N is post-forging normalized/heat-treated and generally preferred where improved toughness, better grain structure and more consistent mechanical properties are required. Many purchasers now specify A105N as the default because it reduces the risk of variability in service.

Buyer tip: If the application involves cyclic loading, pressure surges, or low-temperature service, specify A105N or add supplementary requirements for impact testing. For general utility piping at ambient temperature, plain A105 is commonly accepted.

International equivalents and cross-references

While ASTM A105/ASME SA-105 is a U.S. standard, there are commonly used international equivalents. Equivalency is practical — chemistry and mechanical properties are compared — but true equivalence must be verified with the purchaser and code authority.

| Region/Country | Standard | Equivalent Material |

| Europe | EN 10213 | GS-C25 (Forged Carbon Steel for Pressure Parts) |

| EN 10025 | S235JR (Carbon Structural Steel, commonly used for pressure equipment) | |

| Japan | JIS G3454 | STPG370 (For Pressure Piping) |

| JIS G3101 | SS400 (General Structural Carbon Steel) | |

| Germany | DIN 17175 | St 35.8 (Carbon Steel Pipe, for Pressure Systems) |

| DIN 17200 | C 22.8 (General Carbon Steel) | |

| United Kingdom | BS 1501 | 1501-151 Grade 360 (Carbon Steel for Pressure Equipment) |

| China | GB 713 | Q245R (Boiler Carbon Steel) |

| GB 699 | Q235B (Structural Carbon Steel, commonly used for Pressure Vessels) | |

| International | ISO 6505 | P245GH (Forged Steel for Pressure Parts) |

| ISO 4957 | 42CrMo4 (Alloy Steel with High Strength) | |

| India | IS 2062 | E250 (Common Carbon Steel for Structural and Pressure Systems) |

| South Korea | KS D 3503 | STPT370 (Carbon Steel for Pressure Piping) |

| United States | ASTM A105N | A105N (Normalized Version of ASTM A105) |

Important: “Equivalent” tables are a starting point. Always confirm chemical ranges, required heat treatments and mechanical test regimes before accepting a foreign standard forging as a substitute for A105 in code work.

Manufacturing, welding and machining practical notes

Machining & fabrication

-

A105 machines readily in normalized or annealed states. Hardness limit (max 187 HBW) helps avoid excessive tool wear.

-

For tight-tolerance machining of flanges, request specified heat treatment and hardness reports on MTR.

Welding & weld practice

-

A105 is low-carbon and has good weldability with common filler wires (ER70S-x / E7018 etc.) when preheat and post-weld heat treatment are applied according to thickness and code requirements.

-

For thick sections or critical service, follow ASME B31.x or applicable code guidance for preheat, interpass temp and PWHT. If impact toughness is a concern, normalize prior to welding or specify impact testing.

Surface protection and corrosion

-

A105 is not corrosion resistant. For corrosive environments specify coatings (epoxy, galvanizing for non-pressure parts where allowed), painting, or choose corrosion-resistant alloys. For flanges used in buried service, consider protective coatings and cathodic protection.

Inspection, testing and certification

When purchasing A105 forgings, specify the tests and documentation you need. Typical requirements:

-

Material Test Reports (MTRs) — chemical and mechanical test results traceable to each heat/lot (ASTM A961 often specified for certification).

-

Tensile & hardness tests — per the standard.

-

Macroscopic/visual inspection — to reveal forging laps or cracks.

-

NDE (if required by purchaser) — UT or RT for pressure-critical parts, magnetic particle or dye-penetrant for surface defects.

-

Impact testing (Charpy V-notch) — only if purchaser specifies (A105 by default does not require impact testing for all forgings; for low-temperature service specify SA-350 LF2 or add the supplementary requirement).

-

Hydrostatic testing — mandated only if specified (ASTM A961 Supplemental S57 describes hydrostatic test requirements for forgings).

Specification clause examples to include in purchase order (PO):

-

"Material: ASTM A105 / ASME SA-105, normalized (A105N) per purchaser’s requirement."

-

"Certification: Full MTRs per ASTM A961, including heat number traceability."

-

"Supplemental: Charpy V-notch tests at −20 °F (or specified temp) for valves and fittings."

-

"NDE: Ultrasonic test per purchaser’s NDE plan for pressure-retaining parts."

Typical applications and selection checklist

Typical applications

-

Weld neck, slip-on and blind flanges for piping systems

-

Valve bodies (gate, globe, check) and bonnet components

-

Forged fittings (tees, elbows, reducers) used in oil & gas, petrochemical, refining, power plants and general industrial piping

Selection checklist for engineers

-

Operating temperature & pressure — confirm A105 meets design code allowable stresses at operating temperature.

-

Low-temperature service? — if yes, require impact testing or alternative alloy.

-

Corrosive environment? — if yes, additional surface protection or alloy upgrade required.

-

Welding / post-weld operations — specify preheat/PWHT if needed.

-

Traceability and testing — require MTRs and any supplementary NDE.

-

Material condition (A105 vs A105N) — specify normalization/heat treatment when uniform toughness is required.

-

Weight limits — forgings over ~10,000 lb may not be covered by A105; check alternative specs (A266 etc.).

Ordering, marking and purchaser supplemental requirements

Recommended PO language (concise)

-

Material: ASTM A105 / ASME SA-105, latest revision.

-

Heat treatment: Normalize and temper (A105N) OR as-forged with anneal per PO.

-

Certification: MTRs per ASTM A961; test report to include heat number, chemical analysis, tensile and hardness results.

-

NDE: Ultrasonic inspection of critical pressure-retaining surfaces; dye-penetrant on machined bores.

-

Marking: Heat number, material spec and manufacturer’s ID stamped on each forging.

Typical markings found on forgings

-

Manufacturer’s logo

-

Heat number (traceable to MTR)

-

Material spec (e.g., A105 or SA-105)

-

Size or special order code

Corrosion behavior, temperature limits, and common failure modes

-

Corrosion: A105 is carbon steel and will corrode in wet or aggressive environments. Use coatings, inhibitors or upgrade to stainless or alloy steels in corrosive media.

-

Service temperature: Suitable for ambient and moderately elevated temperatures. For high-temperature creep issues, select an alloy designed for sustained elevated temperature.

-

Failure modes to watch: stress corrosion cracking in chloride environments (rare for carbon steel but possible under certain chemistries/stresses), fatigue cracking from cyclic loading, brittle fracture if used below intended temperature without impact testing — specify conditions to avoid.

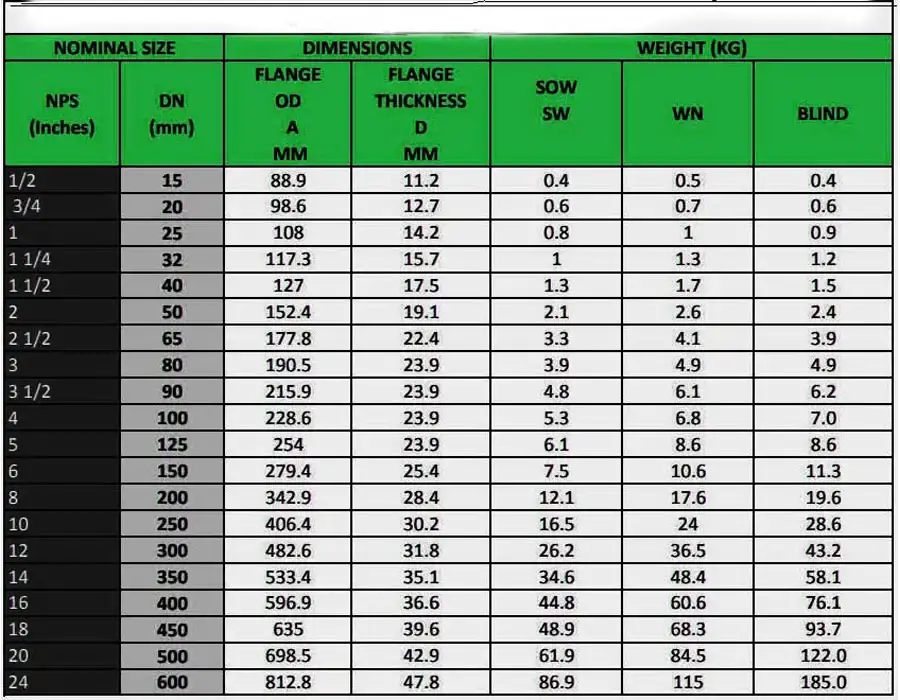

Quick reference tables (engineer’s pocket sheets)

Table A — Summary (quick)

| Item | A105 / SA-105 summary |

|---|---|

| Type | Carbon steel forging for piping |

| Max Carbon | 0.35% |

| Tensile (min) | 70 ksi (485 MPa) |

| Yield (min) | 36 ksi (250 MPa) |

| Hardness (max) | 187 HBW |

| Common forms | Flanges, fittings, valve bodies |

| Preferred finish for tougher parts | A105N (normalized) |

Table B — When to choose A105 vs alternatives

| Condition | Use A105 | Consider alternative |

|---|---|---|

| Ambient pressure piping | ✓ | |

| Low-temperature service (cryogenic) | Use SA-350 LF2 or specify impact tests | |

| Corrosive, seawater exposure | Use duplex/stainless alloys | |

| High temp creep service | Use creep-resistant alloys (e.g., 1.25Cr-0.5Mo, 316H etc.) | |

| Codework for pressure vessel with notch requirements | Consider SA-350 or supplemental testing |

Practical procurement and vendor questions

-

Q: Are raw bars available in A105? No — A105 refers to forgings; raw bars are typically supplied to other specifications. Some components machined from bar may be allowed only if the producer can show equivalent chemistry and mechanical testing per the standard.

-

Q: Is A105 magnetic? Yes — like other carbon steels, A105 is ferromagnetic.

-

Q: Can A105 be heat treated to increase strength? It can be quenched and tempered, but forging shops usually produce forgings with the desired post-forge heat treatment specified by purchaser. Check with manufacturer for achievable properties.

FAQs

-

What’s the difference between ASTM A105 and ASME SA-105?

They are essentially the same specification — ASME SA-105 is the format and designation used in ASME code publications; content is aligned with ASTM A105 (identify the exact revision years in the PO). -

Does A105 require impact (Charpy) testing?

Not by default. Impact testing is a purchaser’s supplementary requirement. For low-temperature duty, require impact testing or use SA-350 LF2. -

What does A105N mean?

The “N” indicates normalization heat treatment (A105N), giving refined grain structure and improved toughness compared to as-forged A105. -

What documentation should I demand with an A105 forging?

Full MTR (ASTM A961), heat number traceability, tensile and hardness test reports, and any NDE or hydrostatic tests required by the PO. -

Is A105 suitable for cryogenic service?

No — for cryogenic or subambient service you need materials with guaranteed impact toughness at the required temperature (e.g., LF series steels or specific low-temperature alloys). -

How does A105 compare with stainless flanges?

A105 is far less corrosion resistant but much cheaper. Use stainless when corrosion resistance is required or when process conditions demand. -

Can A105 forgings be used for high-pressure/high-temperature steam lines?

They are used in many steam and power plant applications but confirm allowable stresses at operating temperature per the governing pressure code (ASME, API etc.). -

Typical hardness of A105?

The spec limits Brinell hardness to ≤ 187 HBW. This helps ensure machinability and avoids brittle microstructures. -

What are common failures with A105 components?

Fatigue cracks from cyclic loading, corrosion-induced leaks if unprotected, and brittle fracture if used below intended notch toughness without testing. -

Are there standard substitutes for A105 in Europe?

Engineers frequently reference EN 10222-2 / P-grades (e.g., 1.0460 / P250GH family) as similar forging steels — but full cross-check of chemistry, mechanicals and heat treatment is mandatory.

Practical sample procurement clause (copy/paste)

Material: ASTM A105 / ASME SA-105, latest revision.

Heat treatment: Normalize (A105N) unless otherwise noted.

Certification: Furnish Manufacturer’s Test Report (MTR) per ASTM A961 with heat number traceability and results for chemical analysis, tensile, and hardness tests.

NDE/Testing: Ultrasonic test on pressure-retaining features; hydrostatic test and Charpy impact at −20 °F as supplementary requirements (if specified).

Marking: Each forging to be stamped with manufacturer ID, heat number and material designation.

Closing practical notes for MWAlloys

If you are the supplier like MWAlloys, make sure your mill and forging records are organized so you can supply complete MTRs and show heat-by-heat test results. Be explicit about whether forgings are delivered as-forged, normalized or quenched & tempered, and provide machining allowances and surface treatment options for pipeline fittings and flanges. For export customers, always identify any standard cross-references (EN/JIS) you can match and confirm any additional testing expected by import codes.