API 5L Grade B PSL2 is a widely used, reliable carbon steel line-pipe specification for onshore and many offshore transmission systems that require higher material consistency, enhanced testing and full traceability compared with PSL1. In practice, Grade B (sometimes designated L245) delivers a minimum yield in the region of ~245 MPa (≈35,000–35,500 psi) and a minimum tensile strength around ≈415 MPa (≈60,000 psi); the PSL2 product level adds mandatory non-destructive inspection, tighter chemical and mechanical limits, and Charpy impact (notch toughness) testing where required — features that make PSL2 the usual choice when operator regulations, pipeline codes or public authorities demand documented, verifiable quality and fracture-control behavior.

What is API 5L?

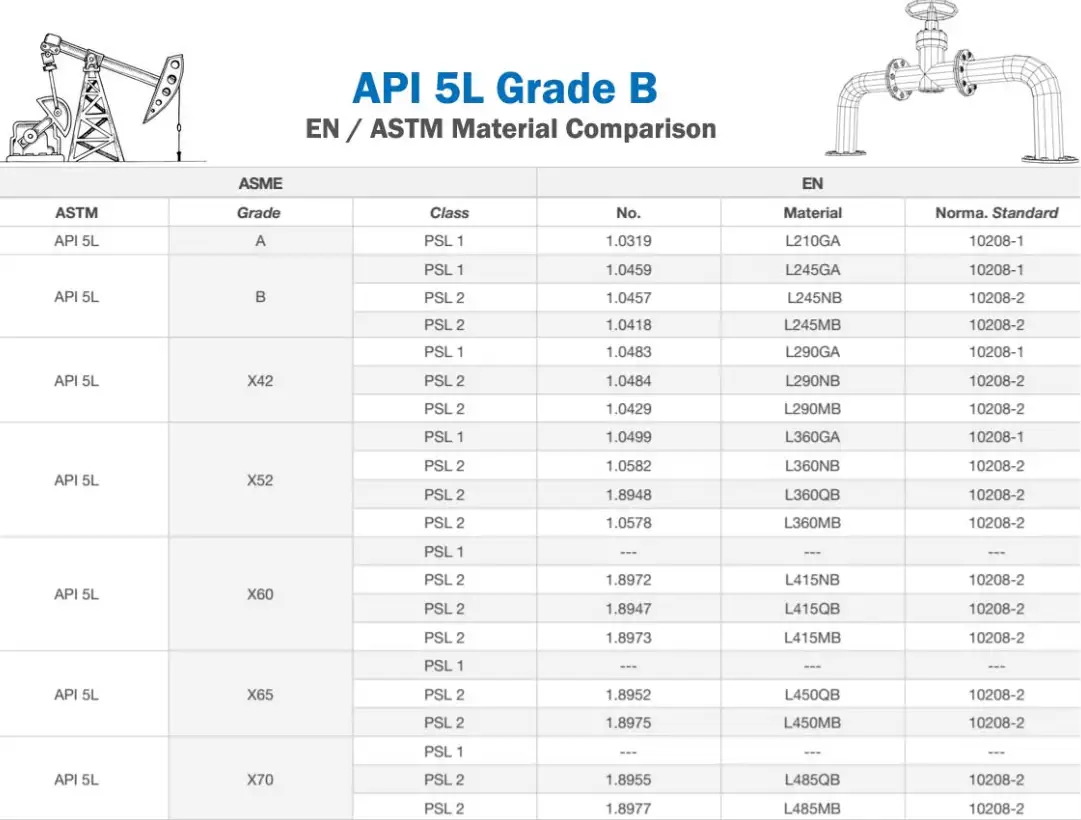

API Specification 5L is the industry standard for line pipe used to transport petroleum and natural gas. It defines material grades, product specification levels (PSL1 and PSL2), acceptance criteria, testing and marking for seamless and welded pipe. The API standard is periodically revised; the most recent complete editions and errata should be referenced when writing procurement documents. For international procurement it is common to cross-reference ISO 3183, which harmonizes many requirements and also defines PSL1/PSL2 product levels.

Key points:

-

API 5L covers seamless and welded carbon and carbon-manganese steel pipes for pipeline transportation systems.

-

Product Specification Level (PSL) distinguishes routine versus enhanced requirements; PSL2 brings additional testing, traceability and tougher acceptance limits.

MWalloys Offer: API 5L Gr B Casing and Tubing Pipe

Grade nomenclature and how “Grade B / L245” maps to properties

API 5L uses grade names that historically mapped to minimum yield values. “Grade B” is commonly tied to a minimum yield ≈245 MPa (hence the ISO designation L245). In API tabulations you will see Grade B listed with typical minimums expressed in both MPa and psi. Typical mechanical values used in design and procurement are:

-

Minimum yield strength (Rt0.5): ~245 MPa (≈35,000–35,500 psi).

-

Minimum tensile strength (Rm): ~415 MPa (≈60,000 psi).

-

Elongation: depends on diameter and wall thickness; usually a specified minimum percent in a 2-inch gauge length.

These values are expressly tabulated in API 5L and in public technical data sheets from certified suppliers — always quote the edition and PSL level when specifying to avoid ambiguity.

PSL1 versus PSL2 — technical differences and when to specify each

Quick comparison (summary)

PSL1 = standard product level (basic requirements).

PSL2 = enhanced product level (tightened chemistry/mechanics, mandatory NDT, impact testing, mill traceability and certification).

| Topic | PSL1 (typical) | PSL2 (typical) |

|---|---|---|

| Material certification | Basic mill test report | Full certified material test report with additional traceability |

| Chemical controls | Broad limits | Tighter chemical element limits |

| Mechanical limits | Minimum only | Min and sometimes max limits for yield/UTS for fracture control |

| Notch toughness (Charpy CVN) | Not required for many grades | Required where specified (temperature/grade/size dependent) |

| Non-destructive testing (NDT) | Not mandatory for pipe body | Mandatory (e.g., UT or RT depending on process and customer SRs) |

| Traceability & serialization | Simple heat/batch | Full end-to-end traceability (heat → coil → plate → pipe) |

| Typical applications | Low-risk service lines, non-regulated lines | High-integrity pipelines, regulated transmission, high consequence lines |

PSL2 is increasingly the default for regulated oil & gas transmission lines and for operators that require documented fracture control capabilities.

Chemical composition and mechanical properties

Note — values vary with edition, product form (seamless vs welded) and thickness. Below are representative tables for Grade B under PSL2 intended for specification drafting; always reference the exact API/ISO edition and the manufacturer’s certified data for procurement.

Typical chemical limits (representative for Grade B, PSL2)

(These are illustrative ranges — verify in the current API/ISO tables for procurement contracts.)

| Element | Max (typical) |

|---|---|

| Carbon (C) | ~0.20 – 0.25 % |

| Manganese (Mn) | ~0.60 – 1.30 % |

| Phosphorus (P) | ≤ 0.030 % |

| Sulfur (S) | ≤ 0.030 % |

| Silicon (Si) | ≤ 0.40 % |

| Niobium, Vanadium, Titanium | ≤ small controlled amounts (if microalloyed) |

(Exact permitted values are given in API 5L tables which also differentiate by pipe thickness and manufacturing route.)

Representative mechanical properties (Grade B / L245; typical PSL2 values)

| Property | Minimum typical value |

|---|---|

| Yield strength (Rt0.5) | 245 MPa (≈35,000–35,500 psi). |

| Tensile strength (Rm) | 415 MPa (≈60,000 psi) minimum. |

| Elongation (2 in/50 mm) | Typically ≥20% (varies with OD and WT) |

| Hardness | No explicit maximum for Grade B unless specified in supplementary requirements; PSL2 may include limits for weld seam hardness and HAZ. |

Manufacturing methods, dimensions and common production routes

API 5L line pipe is produced by several primary processes — seamless (SMLS) and several welded processes (ERW, EFW, LSAW, SSAW). Each process has different characteristic limitations and inspection expectations.

-

Seamless (SMLS): typically used for heavier wall or higher grades where absence of a weld is preferred for notch toughness or sour-service demands. Seamless pipe is usually available in a wide range of diameters and thicknesses.

-

ERW (Electric Resistance Welded): common for smaller diameters and thinner walls; manufacturing improvements have produced high-quality ERW for many pipeline applications, but PSL2 requires seam inspection/testing.

-

LSAW/SSAW (Longitudinal/Spiral Submerged Arc Welded): used for medium to large diameters; seam properties, heat input and post-weld heat treatment (if required) are important considerations.

Standard sizes & tolerances

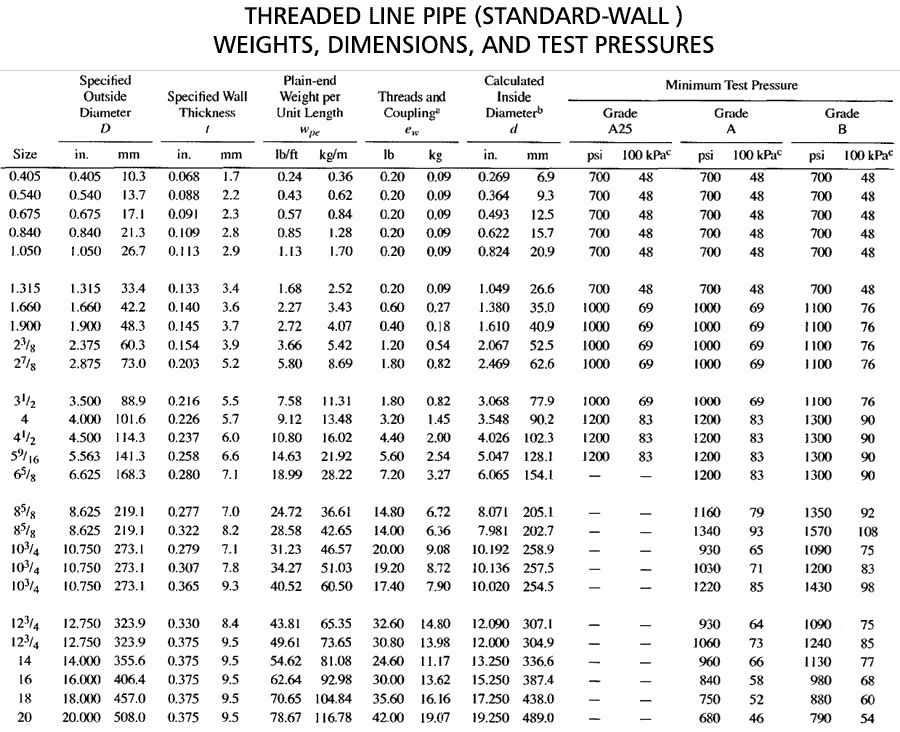

API 5L provides dimensional tolerances (OD, wall thickness, ovality, length) and permissible variations for weight per unit length. Standard nominal pipe sizes commonly used for pipelines range from small bore up to 48" and larger; procurement should specify the dimension standard (API/ANSI, ISO or customer spec).

Mandatory tests and inspection for PSL2

PSL2 is distinguished by several mandatory or commonly applied enhanced tests. Below are the typical test items you will see in a PSL2 purchase specification:

-

Chemical analysis (heat and product analysis) — tighter element limits and reporting.

-

Tensile testing — to confirm Rt0.5 (yield) and Rm (UTS).

-

Charpy V-notch (CVN) impact testing — required for certain grades, thicknesses and service temperatures to control fracture toughness behavior. PSL2 lists temperatures and the number of specimens per lot.

-

Hydrostatic testing — volumetric/hydrostatic test per length or heat, to verify mechanical integrity and leak tightness. Hydrostatic strength test pressure calculations follow recognized engineering codes and the API tables.

-

Non-destructive testing (NDT) — PSL2 commonly requires inspection of the weld seam (RT or UT) and additional volumetric UT for some processes. Radiography (RT) or ultrasonic testing (UT) choices depend on pipe type and customer SRs.

-

Flattening, flaring, hardness tests and reverse-bend tests — as applicable for confirming formability and hardness limits.

Traceability and documentation: PSL2 requires full traceability from heat to finished product and certification that the mill performed all required tests and inspections. Mill Test Reports (MTRs) and serialization of ends/lengths are standard requisites.

Welding, fabrication and fitness-for-service considerations

Weld procedure qualification, welder qualification, and pre-/post-weld heat treatment (if specified) must be addressed in the fabrication plan for pipelines built using API 5L material. Key practice notes:

-

Seam weld inspection: For PSL2 welded pipe, ensure the supplier provides the weld-seam NDT records (RT/UT) and any corrective action reports for seam repair.

-

Weldability: Grade B has good weldability with standard carbon steel welding procedures; carbon equivalent controls (CE) are relevant for HAZ hardness and susceptibility to hydrogen cracking. PSL2 often requires reporting of CE indices (e.g., CEIIW, Pcm) in MTRs.

-

Welding filler selection: For welds joining Grade B pipe, choose filler metals that meet required mechanical compatibility and toughness at the service temperature. For sour service, select weld consumables qualified per NACE/ISO 15156 guidance.

Corrosion, coatings and sour-service issues

Selecting coatings, linings and corrosion-control measures depends on soil, fluid chemistry, temperature and whether H₂S or CO₂ is present.

-

Coatings & linings: Fusion bonded epoxy (FBE), multi-layer polyethylene, bituminous coatings and internal linings are commonly used depending on application (onshore vs offshore, buried vs exposed). Supplier datasheets should be requested and validated for adhesion, cathodic disbondment and thickness.

-

Sour service (H₂S): Where H₂S is present, material selection must conform to NACE MR0175 / ISO 15156 to avoid sulfide stress cracking (SSC), hydrogen induced cracking (HIC) and stress oriented hydrogen induced cracking (SOHIC). This often means specifying PSL2 material that is qualified or restricting service conditions and requiring supplementary tests.

Procurement, marking and quality assurance best practices

When preparing a purchase order or technical specification for API 5L Grade B PSL2, include the following minimum items to ensure traceable, auditable quality:

-

Reference edition of API 5L (exact edition and errata).

-

Product Specification Level (PSL2) stated explicitly.

-

Grade (Grade B / L245) and required mechanical/impact properties, including test temperatures for CVN.

-

Manufacturing route allowed (SMLS, ERW, LSAW, SSAW) and any restrictions.

-

NDT scope (RT/UT), hydrostatic test pressure, and number/location of sample tests.

-

Traceability: mill heat number → coil/plate → finished pipe; MTR content required.

-

Certificates: Include requested certificates (EN 10204 3.1/3.2 equivalents, API monogram requirements if applicable).

Best practice: attach an ITP (inspection & test plan) and require supplier sign-off on test results and non-conformance reporting procedures. For critical pipelines, include third-party inspection or field witness points at key tests (CVN, hydrostatic, NDT).

Practical selection examples & application scenarios

Example A — Onshore transmission pipeline under regulatory oversight

Recommendation: Specify API 5L Grade B PSL2 (or higher grade depending on MAOP and fracture control) with mandatory seam RT/UT, CVN at the lowest anticipated operating temperature, hydrostatic test per engineering code, and full traceability (MTRs with CE values). Rationale: PSL2 provides documented integrity and fracture-control evidence required by many regulators and operators.

Example B — Low-risk gathering line with limited operating temperature

Recommendation: PSL1 may be acceptable where the operator’s risk assessment shows low consequence of failure and local regulations permit. However, consider specifying key supplementary requirements (e.g., seam inspection, MTRs) even for PSL1 to reduce lifecycle risk.

Example C — Sour service (H₂S present)

Recommendation: API 5L Grade B may require additional qualification; reference NACE MR0175/ISO 15156 to select appropriate metallurgy and welding consumables; in many cases higher corrosion-resistant grades or inhibited designs are necessary.

Frequently asked questions

-

Q: Is Grade B the same as L245?

A: Yes — Grade B corresponds to the ISO designation L245, reflecting a minimum yield around 245 MPa. Always state the applicable standard edition to avoid ambiguity. -

Q: When is PSL2 required instead of PSL1?

A: PSL2 is required by many transmission pipeline operators, regulatory bodies and for services where fracture control, enhanced NDT and traceable quality are critical. Use PSL2 for regulated, high-consequence lines. -

Q: What are the principal tests a PSL2 pipe must pass?

A: Typical tests include detailed chemical analysis, tensile testing, Charpy (CVN) impact tests where applicable, hydrostatic test, and mandatory NDT (RT or UT) of weld seams and/or the pipe body. -

Q: Does PSL2 always require Charpy impact testing?

A: Not always. CVN requirements depend on grade, thickness and the lowest service temperature. API 5L lists when CVN is mandatory; PSL2 makes CVN more likely than PSL1. -

Q: Are ERW pipes acceptable for PSL2?

A: Yes — ERW pipes can meet PSL2 if they pass the required seam NDT and other PSL2 tests; specify seam inspection and any heat/UT/RT acceptance criteria in the PO. -

Q: How should I control carbon equivalent?

A: Include CE limits or require CE reporting on the MTR; control CE to avoid excessive HAZ hardness and hydrogen cracking risk. PSL2 commonly requests CE indices (e.g., Pcm, CEIIW). -

Q: What documentation should the mill supply?

A: Mill Test Reports (with heat and product analysis), NDT reports (RT/UT), hydrostatic test records, CVN reports, and serialization/traceability logs; for some projects, third-party certificates (EN 10204 3.1/3.2–equivalents) are requested. -

Q: Is API 5L equivalent to ISO 3183?

A: ISO 3183 and API 5L are harmonized in many respects; ISO 3183 explicitly references product specification levels PSL1/PSL2 and is often used as the international counterpart to API 5L. Careful cross-reference is required when mixing standards. -

Q: What should I specify for sour service?

A: Follow NACE MR0175 / ISO 15156 guidance for material selection and testing; you may need alternative grades, additional testing (HIC, SOHIC) and qualified weld procedures and consumables. -

Q: How to avoid buying non-conforming pipe?

A: Specify the API/ISO edition, PSL level, detailed ITP, mandatory witness points for key tests, serialization and acceptance of MTRs; consider a third-party inspector for critical projects.

Practical procurement checklist

-

Reference edition (API 5L, e.g., 46th ed., and errata).

-

Specify Grade (B / L245) and PSL2.

-

State manufacturing routes allowed and seam inspection method (RT/UT).

-

Define CVN temperatures and sampling plan.

-

Set hydrostatic test method and acceptance criteria.

-

Demand full traceability and required certificates (MTRs).