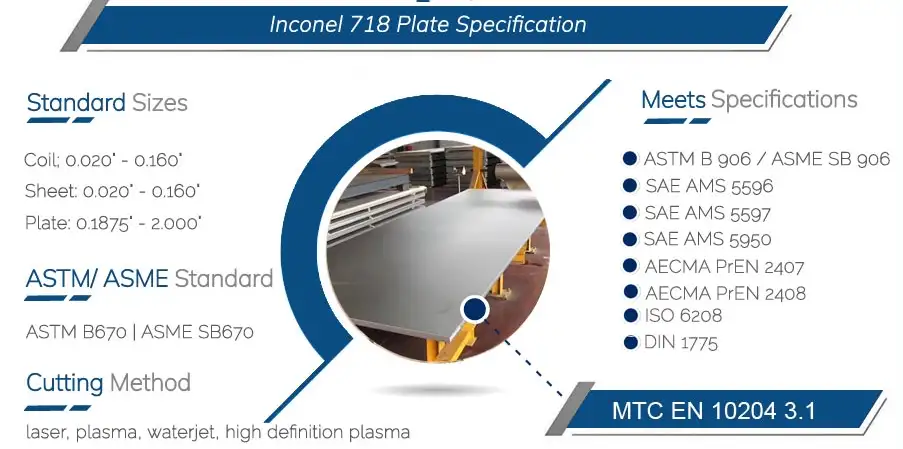

AMS 5597 is the specific Aerospace Material Specification for Nickel Alloy 718 (UNS N07718) in the form of sheet, strip, and plate. This specification mandates a precipitation-hardenable nickel-chromium alloy containing significant amounts of iron, niobium, and molybdenum. Engineers utilize AMS 5597 primarily for parts requiring high resistance to creep and stress-rupture up to 1300°F (704°C) and oxidation resistance up to 1800°F (982°C). MWalloys supplies this superalloy to guarantee superior fatigue strength and weldability in critical aerospace and gas turbine components.

Detailed Overview of AMS 5597 Specifications

Nickel Alloy 718 constitutes the backbone of modern aviation structural components. When procuring this material under the AMS 5597 designation, you obtain a product distinct from other 718 specifications like AMS 5662 (bars) or AMS 5596 (foil/sheet with different treatment). The defining characteristic of AMS 5597 remains its delivery condition and mechanical capabilities after heat treatment.

This alloy gains its strength through a heat-treatment process that precipitates a second phase into the metal matrix. The interaction between Niobium (Nb) and Molybdenum (Mo) within the Nickel-Chromium stiffens the matrix without reducing ductility to unacceptable levels. MWalloys prioritizes strict adherence to these chemical balances to ensure every sheet or plate performs predictably under extreme stress.

Why AMS 5597 Dominates Aerospace Engineering

Designers select this specification because it solves the cracking problems associated with other superalloys. The sluggish age-hardening response of AMS 5597 permits annealing and welding without spontaneous hardening during heating or cooling. This unique property allows MWalloys to provide complex flat-rolled forms that manufacturers can fabricate into intricate shapes before final hardening.

Chemical Composition of AMS 5597

The chemical makeup determines the alloy's ability to withstand corrosive environments and high pressure. The presence of Niobium remains the critical factor here. It combines with Nickel to form gamma double prime (γ''), the strengthening phase.

Review the precise chemical composition limits adhered to by MWalloys in the table below.

Table 1: Chemical Composition Requirements (Weight %)

| Element | Symbol | Min % | Max % |

| Nickel (plus Cobalt) | Ni + Co | 50.00 | 55.00 |

| Chromium | Cr | 17.00 | 21.00 |

| Iron | Fe | Balance | Balance |

| Niobium (plus Tantalum) | Nb + Ta | 4.75 | 5.50 |

| Molybdenum | Mo | 2.80 | 3.30 |

| Titanium | Ti | 0.65 | 1.15 |

| Aluminum | Al | 0.20 | 0.80 |

| Cobalt | Co | -- | 1.00 |

| Carbon | C | -- | 0.08 |

| Manganese | Mn | -- | 0.35 |

| Silicon | Si | -- | 0.35 |

| Sulfur | S | -- | 0.015 |

Note: Strict control of trace elements like Sulfur and Phosphorus is vital to prevent micro-cracking during welding.

Mechanical Properties and Performance Data

Buying AMS 5597 requires understanding the mechanical outputs. Material supplied by MWalloys typically arrives in the solution annealed condition. However, the material must pass capability tests to verify it meets the rigorous standards once precipitation hardened.

The following data represents the minimum requirements for the alloy after precipitation heat treatment.

Table 2: Mechanical Properties at Room Temperature (After Precipitation Hardening)

| Property | Metric Unit | Imperial Unit |

| Tensile Strength (Min) | 1241 MPa | 180 ksi |

| Yield Strength (0.2% Offset) | 1034 MPa | 150 ksi |

| Elongation in 2 inches | 12% | 12% |

| Hardness (Rockwell C) | 36 HRC (Min) | 36 HRC (Min) |

| Hardness (Brinell) | 331 HB (Min) | 331 HB (Min) |

High-Temperature Capabilities

The value of this alloy drops if it fails at operating temperature. At 1200°F (649°C), AMS 5597 retains exceptional yield strength. Stress rupture tests typically demand the material withstand 100 ksi (690 MPa) at 1200°F for a minimum of 23 hours with ductility exceeding 5%.

Heat Treatment Protocols for AMS 5597

Correct heat treatment dictates the final performance of the component. MWalloys advises clients to follow standard aerospace protocols to achieve maximum strength.

The standard cycle involves two main stages:

-

Solution Annealing: The material is heated to between 1700°F and 1850°F (927°C - 1010°C). The duration depends on the thickness of the plate or sheet. This step dissolves the hardening phases and prepares the matrix.

-

Precipitation Hardening (Aging):

-

Heat to 1325°F (718°C) and hold for 8 hours.

-

Furnace cool at a rate of 100°F (55°C) per hour down to 1150°F (621°C).

-

Hold at 1150°F for 8 hours.

-

Air cool.

-

This "double aging" process precipitates the gamma prime and gamma double prime phases essential for the strength specifications listed in Table 2.

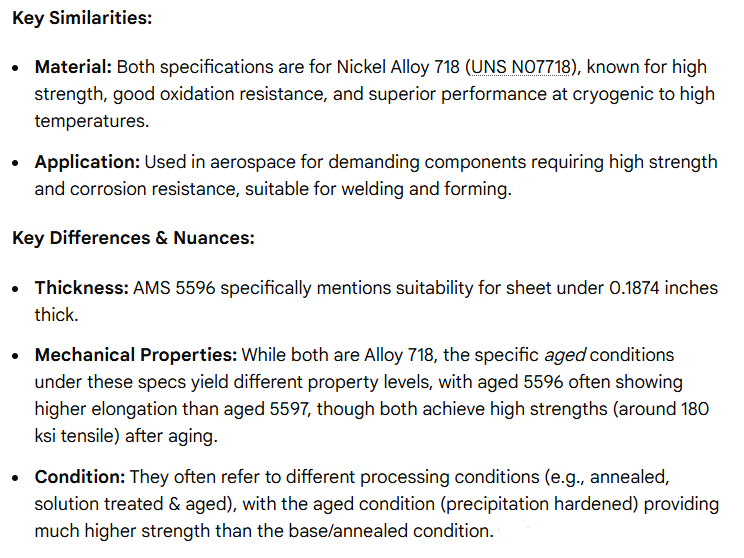

AMS 5596 vs. AMS 5597: The Distinction

Confusion often arises between AMS 5596 and AMS 5597. While both refer to Alloy 718, their application scope differs slightly based on grain size requirements and testing protocols.

AMS 5596 generally applies to sheet, strip, and foil where specific tensile properties and stress-rupture capabilities are the primary acceptance criteria. AMS 5597 historically allowed for slightly different grain size variations or specific buyer-imposed modifications suited for non-rotating parts. Today, the chemical compositions are virtually identical, but the certification dictates the usage. MWalloys ensures full traceability so you receive the exact specification requested by your quality control department.

Case Study: Rapid Deployment for Turbine Repair

Location: Tulsa, Oklahoma, USA

Date: November 2023

Client: Regional Gas Turbine Maintenance Facility

The Challenge:

A maintenance facility in Tulsa faced a critical shutdown. A combustion liner in a power generation turbine displayed unexpected fatigue cracking. The original OEM material was unavailable for six weeks. Every hour of downtime cost the facility over $15,000. They required 0.125" thick Inconel 718 sheet that met strict AMS 5597 standards for immediate fabrication.

The MWalloys Solution:

MWalloys identified the correct stock within our inventory. We verified the Mill Test Reports (MTRs) to ensure the material met the dual certification for AMS 5596/5597. We processed the sheets using waterjet cutting to rough dimensions to save the client fabrication time.

The Result:

The material arrived in Tulsa within 48 hours. The client performed the welding and subsequent heat treatment. Post-installation testing confirmed the creep rupture properties exceeded the turbine manufacturer's requirements. The plant resumed operations 24 days ahead of the projected schedule provided by alternative suppliers.

Fabrication and Machining Characteristics

Working with AMS 5597 requires specialized tooling and techniques. The alloy work-hardens rapidly.

Machining

Conventional machining requires heavy duty equipment. High-speed steel tooling wears out almost instantly. MWalloys recommends cemented carbide tools. Positive rake angles and sharp cutting edges help reduce the work-hardening zone. Never dwell the tool in the cut; constant feed prevents the material from glazing over.

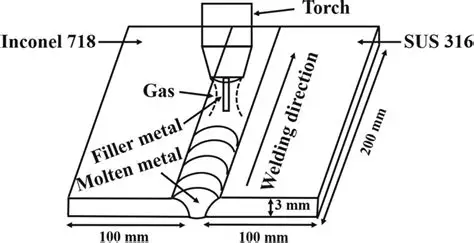

Welding

Weldability stands as a primary advantage of AMS 5597. Gas Tungsten Arc Welding (GTAW) remains the preferred method. Unlike Aluminum-Titanium hardened superalloys, the Niobium hardening mechanism in AMS 5597 retards cracking in the heat-affected zone. MWalloys recommends welding in the solution-annealed condition and performing the full aging treatment post-weld for maximum joint efficiency.

Comparison with Other Superalloys

Selecting the right alloy involves comparing options. Below is a comparison of AMS 5597 against other high-performance sheets supplied by MWalloys.

Table 3: Comparative Analysis of Nickel Superalloys

| Feature | AMS 5597 (Alloy 718) | AMS 5540 (Alloy 600) | AMS 5599 (Alloy 625) |

| Primary Strength | Precipitation Hardening | Solid Solution Strengthening | Solid Solution Strengthening |

| Max Service Temp | 1300°F (704°C) | 2150°F (1177°C) | 1800°F (982°C) |

| Tensile Strength | High (>180 ksi) | Moderate (~80 ksi) | High (~120 ksi) |

| Weldability | Excellent | Good | Excellent |

| Corrosion Resistance | Excellent | Good (Oxidation focus) | Superior (Marine/Chemical) |

| Typical Use | Turbine discs, fasteners | Furnace components | Sea-water piping, exhaust |

Quality Assurance and Testing Methods

MWalloys adheres to stringent testing protocols to maintain the integrity of AMS 5597 products. Every batch undergoes testing compliant with ASTM and AMS standards.

-

ASTM E8: Standard Test Methods for Tension Testing of Metallic Materials.

-

ASTM E21: Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials.

-

ASTM E139: Standard Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests.

We verify grain size (typically ASTM No. 5 or finer for sheet) and check for non-metallic inclusions. This rigorous vetting process ensures that when you integrate MWalloys materials into an aircraft engine or a pressure vessel, safety factors remain uncompromised.

Market Applications

The versatility of AMS 5597 extends beyond jet engines.

-

Aerospace: Exhaust liners, casing, and instrumentation parts.

-

Oil and Gas: Downhole shafting and wellhead parts requiring sour gas resistance.

-

Nuclear Engineering: Reactor core components and grid spacers.

-

Cryogenics: Storage tanks and fasteners. The alloy retains high toughness at cryogenic temperatures, unlike many ferritic steels that become brittle.

Supply Chain Management with MWalloys

Sourcing exotic alloys involves navigating a complex global supply chain. MWalloys simplifies this. We maintain strategic stock levels of AMS 5597 in various gauges. From thin strip (0.010") to heavy plate (2.00"), our inventory management system anticipates market shortages. We provide full traceability from the melt source to the final delivery, a non-negotiable requirement for aerospace contractors.

Frequently Asked Questions (FAQs)

1. What is the difference between Inconel 718 and AMS 5597?

Inconel 718 is the trade name for the alloy chemistry (UNS N07718). AMS 5597 is the specific technical standard (Aerospace Material Specification) that dictates the form (sheet/strip/plate), tolerance, and performance requirements for that alloy.

2. Is AMS 5597 magnetic?

No. In its standard annealed and aged condition, AMS 5597 is non-magnetic. However, some magnetic permeability may develop after heavy cold working or exposure to extremely low temperatures.

3. Can MWalloys cut AMS 5597 to custom shapes?

Yes. MWalloys utilizes waterjet and laser cutting technologies to provide near-net-shape parts. This reduces your machining time and material waste.

4. What welding filler should I use with AMS 5597?

Typically, matching filler metal is used. AMS 5832 (Inconel 718 wire) is the standard choice to match the base metal properties.

5. How does AMS 5597 perform in seawater?

It possesses good resistance to chloride-ion stress-corrosion cracking, though Alloy 625 (AMS 5599) is generally superior for pure marine environments. AMS 5597 is preferred where high strength is the priority alongside corrosion resistance.

6. What is the density of AMS 5597?

The density is approximately 0.296 lbs/in³ (8.19 g/cm³). This weight calculation is vital for aerospace weight-budgeting.

7. Does AMS 5597 require coating for oxidation protection?

Up to 1800°F (982°C), the alloy forms a stable oxide layer that protects the surface. For extended service at maximum temperatures, protective coatings may extend component life, but they are not always mandatory.

8. Why is AMS 5597 expensive compared to Stainless Steel?

The high cost stems from the raw materials (Nickel, Niobium, Molybdenum) and the complex vacuum induction melting (VIM) and vacuum arc remelting (VAR) processes required to produce clean, aerospace-grade metal.

9. Can I form AMS 5597 at room temperature?

Yes, the alloy has good ductility in the annealed condition. However, powerful equipment is necessary because the yield strength is significantly higher than that of mild steel or standard stainless steel.

10. What is the shelf life of AMS 5597?

The metal itself does not degrade over time if stored correctly to prevent surface contamination or corrosion. MWalloys ensures all stock is kept in climate-controlled environments.

Conclusion

AMS 5597 represents the gold standard for high-strength, high-temperature sheet and plate applications in the aerospace sector. Its unique ability to resist cracking during welding, combined with immense creep-rupture strength, makes it indispensable for modern engineering. MWalloys stands ready to supply this critical material with the documentation, speed, and precision your projects demand. Whether for urgent repairs or long-term production, rely on MWalloys for your superalloy requirements.