AISI 8740 is a medium-carbon, nickel-chromium-molybdenum low-alloy steel that delivers an excellent balance of tensile strength, toughness, fatigue resistance and hardenability; it is specified frequently for aerospace and other high-reliability components (fasteners, shafts, axles, piston rods) and is commonly produced to AMS/SAE aircraft grades (for example AMS 6322). For designers who need greater notch toughness than standard Cr–Mo grades, 8740’s nickel content makes it an appropriate choice — provided correct heat treatment and quality control are applied.

What is 8740 steel

AISI 8740 (UNS G87400) sits in the family of medium-carbon low-alloy steels alloyed primarily with nickel (Ni), chromium (Cr) and molybdenum (Mo). In the AISI/SAE designation system the leading digits suggest a high-strength series with roughly 0.40% carbon (the “40” family). In practical shop practice 8740 is supplied both in annealed (machinable) and quenched-and-tempered conditions and is frequently produced to aircraft-quality specifications (AMS variants) when used for critical parts.

Why nickel? Nickel in small amounts (≈0.4–0.7%) improves impact toughness and ductility without sacrificing strength; this is the primary difference that distinguishes 8740 from some Cr–Mo steels used in general industry. The combined Cr–Mo additions provide improved hardenability and elevated-temperature strength.

Chemical composition (specification ranges and engineering interpretation)

Typical composition ranges (weight %)

| Element | Typical range (wt%) |

|---|---|

| Carbon (C) | 0.38 – 0.43 |

| Manganese (Mn) | 0.75 – 1.00 |

| Silicon (Si) | 0.15 – 0.35 |

| Chromium (Cr) | 0.40 – 0.60 |

| Nickel (Ni) | 0.40 – 0.70 |

| Molybdenum (Mo) | 0.20 – 0.30 |

| Phosphorus (P) | ≤ 0.035 (max) |

| Sulfur (S) | ≤ 0.04 (max) |

| Copper (Cu) | ≤ 0.35 (max) |

Interpretation for engineers

-

Carbon near 0.40% places 8740 solidly in the medium-carbon class, enabling good strength after quench & temper.

-

Chromium and molybdenum provide effective hardenability (ability to form martensite through the cross-section) and higher temper resistance.

-

Nickel is the distinguishing element vs many Cr–Mo grades: it raises toughness and reduces brittle tendencies, especially in larger forgings or parts with section variations.

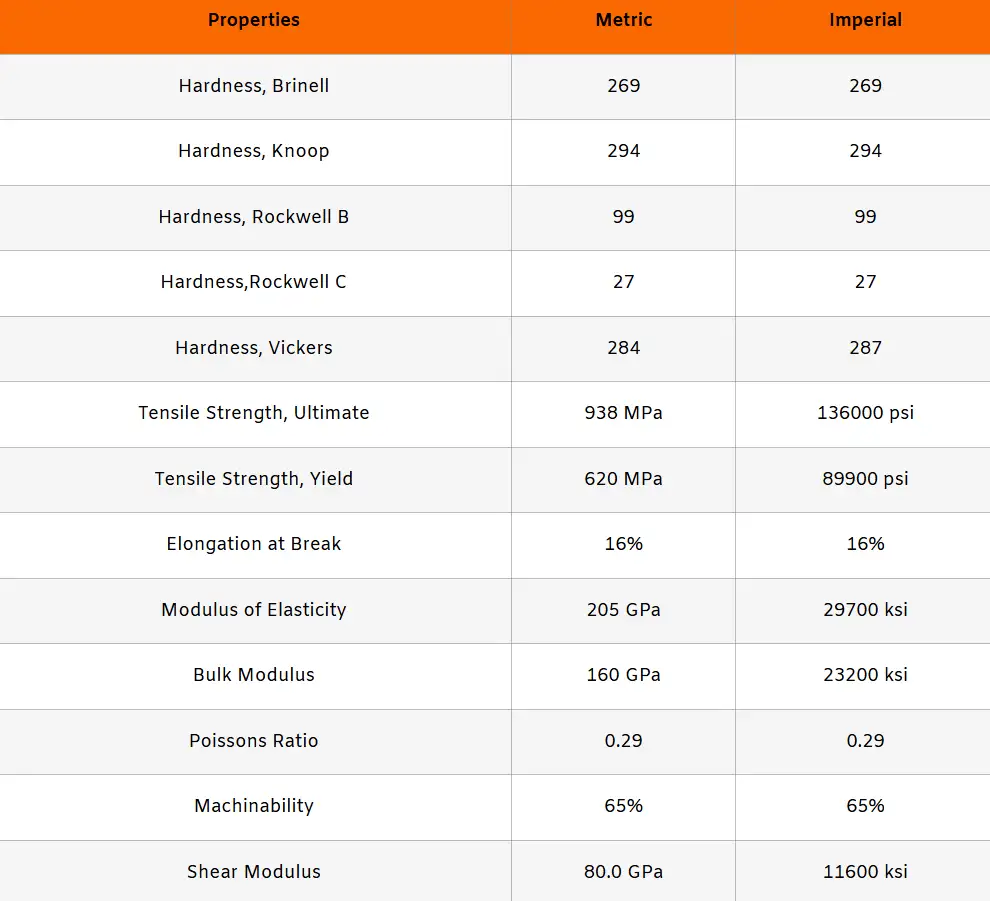

Physical and mechanical properties

Important: mechanical values vary with heat treatment, section size and test method. The numbers below are typical ranges engineers will see in supplier data sheets and technical handbooks.

Representative mechanical properties (annealed / quenched & tempered examples)

| Condition | Tensile strength (UTS) | Yield strength (0.2% proof) | Elongation (A%) | Brinell / Rockwell |

|---|---|---|---|---|

| Annealed (hot-rolled, lamellar pearlite) | ~550–700 MPa (80–101 ksi) | ~350–450 MPa (50–65 ksi) | 12–22% | ~220–260 HB |

| Quenched & tempered (typical Q&T) | 800–1000 MPa (116–145 ksi) | 550–800 MPa (80–116 ksi) | 10–18% | 250–300 HB (≈ HRC 25–35) |

| Oil-quenched, tempered (example) | UTS up to ~930–940 MPa reported | Yield ≈ 550–620 MPa reported | ~16% | BHN ≈ 248–269 reported. |

(Data consolidated from MatWeb, AZoM and supplier datasheets — use material certificates for contract values.) AZoM+1

Typical elastic & thermal properties (engineering references)

-

Modulus of elasticity: ≈ 200–210 GPa.

-

Density: ≈ 7.85 g/cm³.

-

Thermal conductivity and expansion roughly similar to other medium-carbon steels — consult handbooks for thermal stress calculations.

Heat treatment practice and processing windows

Common heat treatment sequence (practical notes)

-

Anneal (if supplied for machining): heat to 820–860°C (1508–1580°F) followed by slow cooling (furnace cooling) to produce spheroidized/lamellar pearlite for good machinability.

-

Austenitize (for hardening): typical austenitizing range 810–860°C (1490–1580°F) depending on section size and target hardness.

-

Quench: oil quenching is common for through-hardening; larger sections may need interrupted cooling or special quench schedules. Air cooling is not sufficient for full hardenability except for very small sections.

-

Temper: chosen by hardness target — tempering between 400–600°C (752–1112°F) to balance strength vs toughness; multiple tempers may be used to relieve stresses.

Typical hardness vs temper (example guide)

| Tempering temperature (°C) | Typical HRC (approx.) |

|---|---|

| 200 | 60–62 HRC (very high hardness, lower toughness) |

| 300 | 55–58 HRC |

| 400 | 48–54 HRC |

| 500 | 38–46 HRC (balanced toughness/strength) |

| 600 | 30–38 HRC (high toughness, lower strength) |

(These are simplified engineering targets — actual values depend on initial microstructure and section size.)

Machining & forming guidance

-

8740 in annealed condition machines with reasonably good machinability (reported around 60–70% relative to low-alloy machining standards). Finish machining should be done in the annealed or tempered condition; heavy forming in the fully hardened state is not recommended.

Stress relief and distortion control

-

Because 8740 is often heat-treated to high strength, pre- and post-heat-treatment machining allowances and controlled quench fixtures are critical to meet dimensional tolerances and avoid cracks. Use sub-critical stress relief cycles and tempering for dimensional stability.

Comparisons with other grades

8740 vs 4140

-

Nickel content: 8740 typically contains nickel (~0.4–0.7%) while 4140 generally does not. That nickel improves toughness in 8740 relative to 4140 for similar carbon and Cr–Mo levels.

-

Hardenability & heat treatment: both have similar Cr and Mo levels, but 8740’s Ni can yield better toughness at equivalent strength levels. For many applications 8740 and 4140 are interchangeable after careful heat treatment selection, but 8740 is preferred where notch toughness or aerospace quality is demanded.

8740 vs 4340

-

4340 is a high-strength Ni-Cr-Mo steel with higher Ni (≈1.65%) and Cr/Mo content; 4340 achieves higher toughness at higher strength levels and is often used in the highest performance applications (landing gear, heavy crankshafts). 8740 can be considered a mid-range Ni-Cr-Mo grade where extreme strength of 4340 is not required.

When to choose 8740

-

Choose 8740 when you need: aircraft-quality material, improved toughness over Cr-Mo alloys, good fatigue resistance, and reliable hardenability for moderate to large cross-sections. Choose other grades (4140, 4340) when specific mechanical or cost tradeoffs dictate.

Typical applications and examples

Common uses

-

Aerospace and aircraft fasteners, bolts, and engine components (when supplied to AMS/aircraft specs).

-

Shafts, axles, piston rods, gear blanks and high-load pins.

-

High-strength forged bolts, studs, and mechanical components where toughness and hardenability are demanded.

Design notes

-

For fatigue-sensitive parts (shafts, crank pins) specify surface finish controls, shot peening and fillet radii. 8740’s good fatigue resistance is fully realized when surface treatments and proper heat treatment are specified in the purchase order.

-

Size matters: in large cross-sections, ensure specification of AMS/SAE acceptance tests (hardness maps, microstructure checks) because hardenability gradients may occur. Utilize ASTM/SAE guidance for quench rates and forgings.

Case example (typical component spec)

-

A piston rod might be specified as 8740, annealed for machining, rough-turned, then quenched and tempered to 50–55 HRC with shot peening and final grind. NDE such as magnetic particle inspection (MPI) or dye penetrant is used to detect surface cracks before final assembly.

Procurement, standards and equivalency

When procuring 8740 for critical applications, call out the exact specification to ensure material quality and traceability.

Common standards & designations

-

SAE / AISI designation: 8740 (UNS G87400).

-

AMS / Aircraft specs: AMS 6322 (and AMS 6322 variants) are used for aircraft-quality bars/forgings/rings in this alloy. Purchase orders that demand aerospace quality should reference the relevant AMS revision or equivalent military spec.

-

Equivalent international grades: DIN 1.6546, UNI 40 NiCrMo2, British BS Type 7 are commonly listed as near equivalents (but always verify composition/tolerance differences).

What to specify to get predictable results

-

Exact chemical limits and acceptance testing (spectral analysis certificate, hardness maps)

-

Required condition at delivery (annealed, normalized, Q&T)

-

Heat treatment certificate and traceability to heat number and mill test reports (MTR).

-

NDT requirements (MPI, ultrasonic, hardness testing and microstructure), especially for aerospace or safety-critical parts.

Quality controls, non-destructive testing and metallurgy pitfalls

Defect modes to watch for

-

Quench cracking in improperly supported parts or with overly aggressive quench schedules.

-

Segregation and banding in large forgings — request mill microstructure acceptance criteria if critical.

-

Inclusion content and sulphur hotspots that reduce fatigue life.

Recommended quality steps

-

Require MTRs and chemical analysis for each heat / lot.

-

Specify hardness checks and full-section or step-section hardness maps for critical parts.

-

Use NDT (MPI/UT) for safety critical items and require acceptance criteria in the procurement spec.

-

For aerospace parts insist on AMS certifications and supplier NADCAP or equivalent process approvals when applicable.

Quick reference tables (handy engineering cheat sheets)

Table A — Composition (short)

| C | Mn | Si | Cr | Ni | Mo |

|---|---|---|---|---|---|

| 0.38–0.43 | 0.75–1.00 | 0.15–0.35 | 0.40–0.60 | 0.40–0.70 | 0.20–0.30 |

Table B — Typical mechanicals (annealed vs Q&T)

| Condition | UTS (MPa) | Yield (MPa) | Elongation |

|---|---|---|---|

| Annealed | 550–700 | 350–450 | 12–22% |

| Q&T (typical) | 800–1000 | 550–800 | 10–18% |

(Values aggregated from supplier and materials databases; confirm with certificates for contract acceptance.)

Practical notes for shop floor and metallurgists

-

Preheat and interpass control: when welding 8740 (typically requires matching low-hydrogen processes and preheat) follow welding procedure specifications (WPS) with controlled interpass temperatures and post-weld heat treatment as required.

-

Surface treatments: to maximize fatigue life use shot peening, nitriding (if compatible with core hardness) or carburizing only after careful metallurgical review (carburizing changes case chemistry).

-

Corrosion: 8740 is not stainless, for corrosion resistance consider protective coatings or stainless alternatives when corrosion exposure is significant.

FAQs

-

What is the main difference between 8740 and 4140?

8740 contains nickel which improves toughness; 4140 is a Cr–Mo grade without significant nickel. For many parts they are interchangeable with correct heat treatment, but 8740 is preferred when extra notch toughness or aircraft-quality certification is required. -

What standards cover 8740?

SAE/AISI designation 8740 (UNS G87400) and aerospace standards such as AMS 6322 (and its revisions) are commonly used. Verify the specific AMS revision when sourcing for aerospace. -

Can 8740 be induction hardened?

Yes — small sections can be surface hardened by induction, but process parameters must be tuned to avoid surface cracking; subsequent tempering is necessary to balance hardness and toughness. -

What hardness can be achieved after quench & temper?

Typical Q&T hardnesses range from HRC ~25 to >55 depending on temper temperature; common strong engineering targets are in the HRC 25–35 range for balance of strength and toughness. -

Is 8740 suitable for forgings?

Yes, 8740 is commonly supplied as forged bars and rings for heavy duty components; aerospace variants are produced to AMS standards with forging controls. -

What heat treatment is recommended for critical shafts?

Austenitize in the 820–860°C range, oil quench, then temper at 450–550°C depending on required toughness; final stress relief and shot peening are common for fatigue life. -

Can 8740 be welded?

Welding is possible but requires preheat, use of suitable low-hydrogen filler metal, and often PWHT (post-weld heat treatment) to avoid cracking. Welding affects properties locally; avoid welding in highly stressed or fatigue-loaded areas if possible. -

What inspection should I require for aerospace parts?

Request AMS certificates, full chemical analysis, hardness mapping, and NDT (MPI or UT) as specified by the procurement document; NADCAP-approved processes are preferred for critical suppliers. -

Is 8740 corrosion resistant?

No, it is not stainless. It has moderate resistance compared to plain carbon steel due to Cr/Ni content but requires coatings or corrosion protection for aggressive environments. -

Which industries most use 8740?

Aerospace, heavy machinery, oil & gas equipment (where high toughness and fatigue life are necessary), automotive performance components, and general industrial shafts/fasteners.

Procurement-ready specification snippet

“Material: AISI 8740 (UNS G87400), produced to AMS 6322 (or purchaser’s specified AMS revision). Chemical composition to meet AMS limits. Condition at delivery: Annealed or Quenched & Tempered per purchaser drawing. Required documentation: Mill Test Report (MTR), hardness map, MPI (or UT) report, and certificate of conformance traceable to heat number.”

Include explicit acceptance criteria for hardness, microstructure and NDT based on application criticality.

Closing engineering judgement

8740 is a mature, well-documented alloy steel that occupies a useful middle ground between Cr–Mo steels and higher-alloy NiCrMo steels. Its combination of nickel-boosted toughness and Cr–Mo hardenability makes it particularly suited for components where both toughness and reliable through-hardening are necessary and where aircraft or high-reliability specifications are a factor. Correct specification of AMS/SAE standards, heat treatment, and NDE is essential to capture the alloy’s benefits and to avoid metallurgical pitfalls.