If you need slightly higher tensile strength and wear resistance for light to moderate loads, choose AISI 1020; if you prioritise slightly better ductility, carburizability and easier machining (and often marginal cost savings), choose AISI/SAE 1018. Both are low-carbon, easy-to-fabricate steels that overlap in many uses; the final choice usually comes down to the specific carbon content/heat-treatment you can procure and the dimensional/finish state (hot-rolled, cold-rolled, cold-drawn) of the stock.

1018 vs 1020 Steel Comparison

| Feature | AISI/SAE 1018 | AISI/SAE 1020 |

|---|---|---|

| Typical carbon | ~0.14–0.20 wt% | ~0.17–0.23 wt% |

| Mn, P, S (typical) | Mn ≈0.60–0.90%; P ≤0.04; S ≤0.05 | Mn ≈0.30–0.60%; P ≤0.04; S ≤0.05 |

| Typical use | Carburized parts, shafts, pins, general machining | Shafts, lightly stressed gears, turned parts, slightly stronger cores |

| Mechanical tendency | Slightly more ductile; very good surface hardening response | Slightly higher tensile/yield in many conditions |

| Machinability & weldability | Very good; easy to machine/weld | Very good; welds well but slightly less ductile |

| Typical buyers’ choice | When surface case + ductility are priorities | When core strength and slightly higher UTS/yield are needed |

Why these grades matter

1018 and 1020 are among the most commonly stocked low-carbon steels worldwide. They are favoured for parts that require economical material cost, good surface finish (cold-drawn or ground stock), and straightforward fabrication — for example shafts, pins, studs, fasteners, bushings (after case hardening), and low-stressed machine components. Their ubiquity means short lead times and broad availability from Chinese millls and global distributors.

Chemical composition

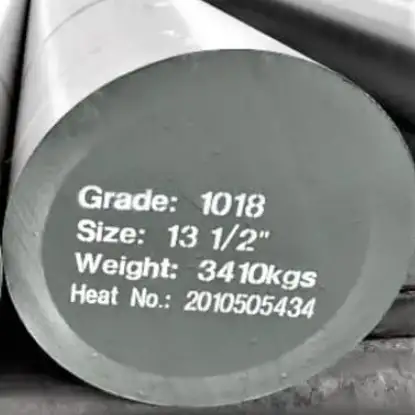

The following table consolidates commonly published ranges from material datasheets (note: specific mill certificates can have slightly different limits — always request the mill test certificate / chemical analysis with the order).

| Element (wt%) | AISI/SAE 1018 (typical) | AISI/SAE 1020 (typical) |

|---|---|---|

| Carbon (C) | 0.14 – 0.20 | 0.17 – 0.23 |

| Manganese (Mn) | 0.60 – 0.90 | 0.30 – 0.60 |

| Phosphorus (P) | ≤ 0.04 | ≤ 0.04 |

| Sulfur (S) | ≤ 0.05 | ≤ 0.05 |

| Iron (Fe) | Balance | Balance |

Notes for buyers

-

1018’s higher manganese (vs typical 1020) helps uniformity and case hardening response.

-

Mill certificates (chemical analysis) are decisive; don’t rely on catalog “typical” values if critical. Ask suppliers for the MTC.

Mechanical properties

Mechanical values depend strongly on delivery condition (hot-rolled, cold-rolled, cold-drawn) and any heat treatment (anneal, normalized, carburized + quenched). The numbers below give commonly cited ranges; use them for preliminary design and buyer comparison only.

| Property | AISI/SAE 1018 (typical ranges) | AISI/SAE 1020 (typical ranges) |

|---|---|---|

| Ultimate tensile strength (UTS) | ~430–480 MPa (≈63–70 ksi) for cold-drawn references | ~410–460 MPa (≈60–67 ksi) depending on condition |

| Yield strength (0.2% offset) | ~240–380 MPa (varies with cold working) | ~330–380 MPa in cold-worked conditions; hot-rolled yields are lower. |

| Elongation (in 50 mm / 2") | ~15–27% (higher for hot-rolled/annealed) | ~17–36% (condition dependent) |

| Brinell hardness (typical) | ~116–140 BHN (cold-drawn ~126 BHN) | ~111–143 BHN depending on form |

Interpretation

-

In cold-drawn/finished conditions, 1018 and 1020 can be very close; 1020 often reads a hair higher in UTS/yield due to carbon content, but 1018’s composition and heat treatment give it superior case hardening behavior for carburized surfaces.

Microstructure, hardenability & heat treatment

-

As-supplied microstructure: Both are ferrite + pearlite microstructures. The minor carbon difference results in slightly more pearlite in 1020 than in 1018.

-

Hardenability: Low — neither steel is highly hardenable by through-hardening; both are chosen for their response to surface hardening (carburizing/carbonitriding) rather than deep section hardening. 1018 is frequently used for carburized components because it carburizes to produce a hard case with a tough core.

-

Recommended heat processes: Carburizing / carbonitriding for surface wear parts (1018 preferred); simple anneal/normalizing for machinability; do not expect large increases in core hardness without alloying or thicker quenches.

Machinability, weldability & forming

-

Machinability: Both are considered good. 1018 is often listed as having slightly better machinability thanks to its manganese + processing and is used widely in lathe turning, drilling and threading operations.

-

Weldability: Excellent for both grades in common processes (MIG/TIG/stick) because of low carbon; preheat is rarely required except for very thick sections or critical weldment geometries.

-

Forming: Very good ductility; cold forming and drawing are routine for both — 1018 is commonly used as cold-drawn ground shaft stock.

Price & procurement 2025

Market note: Steel raw material pricing fluctuates rapidly (scrap/coil prices, shipping, tariffs). The figures below are market snapshots compiled from commonly used B2B Chinese supplier listings as a procurement reference — obtain a current quote for firm pricing.

| Format | Typical China FOB / ex-works range (2025 market snapshot) |

|---|---|

| Hot-rolled bar / flat (1018 / 1020) | ≈ US$420–750 / ton (bulk, depending on size & finish) |

| Cold-drawn / ground bar (smaller qty) | Higher: US$550–900 / ton depending on tolerances & MOQ |

Buyer guidance

-

MOQ: Chinese mills/traders often have minimums (1–5 tons) for custom cut lengths; small qty buyers should expect premium pricing.

-

Lead time: Because both grades are widely stocked, many Chinese suppliers can ship standard sizes in days to a few weeks if they hold inventory; cold-finished or precision ground bars may take longer.

MWalloys procurement note (your requested brand paragraph)

MWalloys supplies both AISI 1018 and 1020 steel in standard stock sizes directly from Chinese mills. We offer: 100% factory pricing, documented mill test certificates on request, and fast inventory dispatch for common diameters and lengths. Contact our sales team for an itemized quote (MOQ, finish, and shipping options) so we can lock a live price for your exact requirement.

Equivalents & cross-references

Common cross-references and regional equivalents to help with global procurement:

| AISI/SAE | UNS | Common regional equivalents / notes |

|---|---|---|

| 1018 | G10180 | AS 1442 K1018 (Australia), AMS/ASTM mentions in supplier data sheets. |

| 1020 | G10200 / S20C | Japanese S20C is commonly referenced; metric vendors may list EN-equivalents for designations. |

Tip: For specification on orders, reference both the grade (1018 or 1020) and the delivery condition (hot-rolled, cold-rolled, cold-drawn) plus the test standard (e.g., ASTM A108 for cold-finished bars) to avoid ambiguity.

How to choose 1018 or 1020 steel?

Quick checklist for grade selection

-

Need case-hardened surface + ductile core (e.g., carburized pin/gear) → 1018 (or 1018 that will be carburized/carbonitrided).

-

Need slightly higher as-machined core strength or marginally higher tensile performance without alloying → 1020.

-

Need maximum machinability in as-received stock → both acceptable; 1018 often favored for finish turning and fine grinding.

Sample use cases

-

Shafts for light machinery: 1018 cold-drawn or 1020 cold-drawn both common; select based on required core strength & surface treatment.

-

Pins & small gears (case hardened): 1018 carburized parts are industry standard due to controlled case formation.

-

Structural, non-critical fabricated parts: Use whichever stock offers the best price/lead time — both have excellent weldability and formability.

Stock forms, machining tolerances & inspection tips

-

Common stock forms: Hot-rolled bars, cold-rolled bars, cold-drawn ground stock, annealed coils, flat bars, plates for thicker sizes.

-

Inspection: Always request Mill Test Certificate (MTC) with chemical analysis, and request hardness or mechanical test reports when mechanical performance is critical. For precision shafts or ground rods, request roundness/diameter tolerance certificates.

FAQs

1. Is 1018 better than 1020?

Neither is categorically “better.” 1018 is preferred when superior carburizing performance and ductility are wanted; 1020 gives a slightly higher as-received tensile/yield strength. Choose based on the functional need.

2. Can I weld 1018/1020 without preheat?

Yes — for typical thicknesses both weld well with standard processes; thicker sections or restrained weldments may need preheat.

3. Which grade machines easier?

Both machine well; 1018 often feels a touch easier/cleaner in chip formation for finish work.

4. Can 1020 be carburized?

Yes, but 1018 is more commonly selected for carburizing due to composition and industry practice.

5. Are 1018 and 1020 the same as mild steel?

They are both low-carbon (mild) steels; “mild steel” is a generic term. 1018/1020 are specific SAE/AISI designations.

6. Which has higher carbon content?

1020 typically has the slightly higher carbon content (upper range ≈0.23% vs 1018 up to ≈0.20%).

7. What standards should I reference on a PO?

Specify grade (1018/1020), delivery condition (cold-drawn/hot-rolled), and the relevant standard (for bar: ASTM A108, or the applicable national/industry standard) and request MTC.

8. Typical surface hardness after carburizing?

Surface hardness after carburizing/carbonitriding varies with cycle; expected hardened case can reach HRC 55–62 on appropriately processed parts; check process specs.

9. Where can I source these in China quickly?

Many manufacturers and trading companies (e.g., vendors on Made-in-China, Alibaba) stock both; MWalloys also supplies factory-priced stock with fast dispatch. Always verify MTC.

10. Can these steels be nitrided?

Low-alloy steels respond better to nitriding; 1018/1020 have limited nitriding response — carbonitriding or carburizing is usually chosen instead.