Abrasion resistant steel pipe delivers far greater service life than ordinary carbon pipe in high-wear service; choosing the correct grade and manufacturing method can reduce total lifecycle cost by multiple factors and prevent costly downtime in mining, slurry transport, aggregate handling, and material transfer systems. For heavy sliding wear use AR400 to AR600 family products; for applications with combined impact and wear, pick through-hardened tubing or induction-hardened inner surfaces; for extreme multi-mode wear combine a wear overlay or ceramic lining. Proper material selection requires matching particle size, velocity, impact energy, chemical environment, and fit-for-purpose fabrication methods.

1. What is abrasion resistant steel pipe

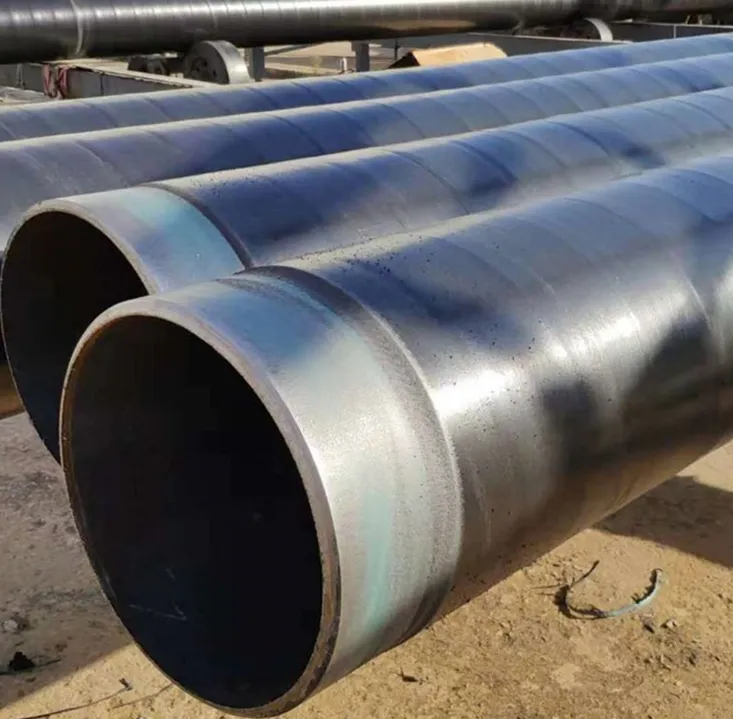

Abrasion resistant steel pipe refers to tubular products engineered to resist material loss from mechanical rubbing, sliding, cutting, and particle impact on the internal surface. Typical design strategies include through-hardening of the tube wall, induction hardening of the inner diameter (ID), application of hardfacing overlays, and use of ceramic or polymer internal liners. These pipes serve environments where abrasive solids in gas or liquid streams erode conventional mild steel quickly, for example slurry transport, tailings, mine paste backfill, dredging return lines, and heavy aggregate transfer. Industry vendors and plate makers offer pre-hardened tubes and pipes in controlled hardness ranges to deliver predictable wear performance.

Common grades and metallurgy

Key hardness families and what they mean

- AR400 / Hardox 400 family: nominal Brinell hardness near 400 HBW. Good balance between wear resistance and toughness for moderate sliding abrasion with some impact.

- AR450 / AR500: higher BHN numbers give increased sliding wear resistance; impact resistance decreases with higher hardness. Choose these when impact energy is low and sliding abrasion dominates.

- AR550 / AR600 and specialized induction-hardened pipes: for extreme sliding wear and fine particle slurries, grades with BHN above 500 or specialized induction-hardened inner surfaces are used. Certain induction-hardened products report ID hardness above 550 BHN while maintaining ductile outer walls.

| Grade name | Nominal hardness (HBW / BHN) | Typical tensile strength (MPa) | Typical yield (MPa) | Typical use cases |

|---|---|---|---|---|

| AR400 / Hardox 400 | 360 to 440 HBW | 900 to 1,100 | 600 to 750 | General mining pipe, chutes, moderate-impact slurry |

| AR450 | ~430 to 480 HBW | 1,000 to 1,250 | 700 to 900 | Higher wear conveyor components, heavier sliding loads |

| AR500 | ~480 to 540 HBW | 1,100 to 1,400 | 800 to 1,000 | Fine abrasive slurry lines, low-impact severe wear |

| AR550 / AR600 | 550+ HBW | 1,200 to 1,600 | 900+ | Extreme sliding abrasion, special induction-hardened IDs |

Product families and manufacturing methods

Principal categories

- Through-hardened tubes and pipes: Product made from wear plate or through-hardened steel that is rolled and welded or seamless. Uniform hardness through wall thickness gives consistent wear resistance and predictable fatigue behavior. Common when structural strength plus wear resistance are needed.

- Induction-hardened ID pipe: Inner surface undergoes heat treatment that raises BHN on the ID while leaving outer wall more ductile. This approach produces a hard wear face with a tougher backing to resist impact forces and hoop stresses. Vendors report life improvements multiple times over mild steel in the same service.

- Bimetal or hardfaced overlay pipe: A wear-resistant alloy layer, often chromium carbide or similar hardfacing, is metallurgically bonded to a ductile backing tube. This solution handles severe wear with targeted overlays in elbows, tees, or straight runs. Manufacturing control is critical to avoid delamination.

- Ceramic-lined pipes and brick-insert systems: For the most aggressive abrasive environments, high performance ceramics or WC based tiles are installed within a steel carrier. Ceramic lasts longer against fine, high-velocity slurries but requires careful joining of sections and attention to brittle failure modes.

- Polymer or composite liners: Where chemical attack supplements abrasion, engineered polymer liners or composite systems reduce both wear and corrosion. Useful in low-temperature systems or where noise and vibration reduction are desirable.

Wear modes, failure patterns, and testing

A buyer should understand whether abrasion is predominantly sliding, rolling, or impact; whether the material is wet or dry; and particle size distribution plus velocity. Typical failure patterns include inner surface thinning, crater formation, spalling of overlays, and accelerated wear at bends, valves, or flow disturbances.

Common test methods to request

- Hardness mapping (BHN/HBW) across ID to OD.

- Metallographic cross sections showing hardened layer depth for induction treatments.

- Slurry erosion testing with representative particles and velocities.

- Charpy V-notch or fracture toughness tests for applications with potential impact or shock loading.

- Ultrasonic thickness testing capability for in-service inspection of monolithic walls.

Selection checklist for engineers and procurement

Inputs procurement should collect

- Media composition: particle sizes, shapes, concentration, specific gravity, chemistry.

- Flow regime: velocities, laminar or turbulent, presence of air pockets.

- Operating pressures and temperatures.

- Required mechanical strength and allowable hoop stress margin.

- Weldability and field-join constraints.

- Repair options and expected service interval.

Decision flow (short)

- Determine wear severity by particle size and velocity.

- Decide whether impact energy warrants tough backing or through-hardening.

- For extreme wear, evaluate ceramic or high-chrome overlays.

- Balance capital cost, downtime cost, and life-cycle cost to choose final solution.

Example specification tables and weight calculations

| Product type | Inner treatment | Typical hardness ID / OD | Standard OD range (mm) | Typical wall thickness (mm) | Typical standard lengths |

|---|---|---|---|---|---|

| Through-hardened tube (Hardox Tube) | Through-hardening | 360 to 500 HBW across wall | 89.1 to 273.0 | 3 to 12 | 6 m, 12 m |

| Induction-hardened pipe (Ultra 600 style) | Induction-hardened ID | ID 500 to 600 BHN, OD ~250 BHN | 100 to 300 | 6 to 12 | 6 m |

| Bimetal overlay pipe | Welded overlay inner | Hardfacing layer >600 HBW on ID | 50 to 200 | overlay thickness 2 to 6 + backing | custom |

| Ceramic lined | Ceramic bricks bonded inside | Ceramic material rating | DN50 to DN800 | carrier thickness 6 to 16 | custom modular lengths |

Weight per meter examples

| OD (mm) | Wall thickness (mm) | Approx weight kg/m |

|---|---|---|

| 139.7 | 6 | 19.783 kg/m |

| 168.3 | 6 | 24.015 kg/m |

| 219.1 | 6 | 31.532 kg/m |

| 219.1 | 8 | 41.648 kg/m |

| 273.0 | 10 | 64.860 kg/m |

Installation, welding, and field repair guidance

- Welding: follow the supplier weld procedure qualification for preheat and interpass control when joining AR steels. High-hardness materials may require controlled heat input and post-weld heat treatment in certain cases. When joining induction-hardened pipe, avoid local overheating that could reduce ID hardness.

- Flanges and connections: use ductile flange materials or adapt transition pieces where wear-resistant pipe meets mild steel to avoid galvanic or brittle joints.

- Field repairs: hardfacing rods or weld overlays can extend life. For ceramic liners, replace damaged brick modules; do not attempt large-scale in-place ceramic repairs without manufacturer guidance.

Life-cycle cost, case notes, and buyer tactics

A short, high-level calculation often shows that abrasion resistant pipe reduces replacement frequency and maintenance downtime. Vendors report that properly matched induction-hardened products can last two to six times longer than mild steel, depending on duty cycle. This reduced REM replacement frequency often more than offsets higher initial cost for the wear pipe. For vertical paste backfill, keeping the line full reduces air pockets and pipeline hammer, extending life; some mine operators report doubling service life using induction-hardened pipes versus mild steel lines in heavy duty zones.

Buyer tactics

- Request certified hardness maps and metallography.

- Ask for a reference list of installations with similar duty.

- Negotiate trial lengths or staged replacement to validate predicted life.

- Insist on documented NDT protocols for delivery and receive inspection.

Quality checks, inspection and standards to request

- BHN hardness certificates for ID, mid-wall, and OD where relevant.

- Material test certificates (EN 10204 3.1 or equivalent) for chemical and mechanicals.

- Ultrasonic testing for wall uniformity and bonding quality in bimetal products.

- Weld procedure specifications and PWHT records where required.

- Slurry erosion test reports if vendor claims specific life multipliers.

- Traceability linking material heat numbers to certificates and weld records.

Frequently asked questions

- What grade should I use for a coal slurry at 5 m/s with sand fines?

If impact energy is low and sliding abrasion dominates, pick AR500 or an induction-hardened ID product with proven performance in fines slurry. Request manufacturer slurry tests with similar particle size and velocity. - Are induction-hardened pipes worthwhile for vertical paste backfill?

Yes. Induction-hardened IDs reduce wear and help keep full-line operation that prevents air pockets and pipeline hammer. Operators have reported 2x or more service life in extreme zones. - When should I use ceramic lining instead of AR steel?

Choose ceramic when particle hardness and velocity produce failure in alloys, commonly in abrasive fines at high velocity. Ceramic performs best when installation and modular maintenance are possible. - Can I weld AR500 pipe on site?

Welding is possible with qualified procedures. Local heating can reduce hardness locally, so follow the supplier’s welding procedure and consider transition pieces or post-weld treatment where necessary. - What inspection certificates should be required at delivery?

Request material test certificates traceable to heat numbers, hardness checks (ID/OD), ultrasonic thickness verification, and any NDT performed. For overlays request bond integrity test reports. - Is AR pipe magnetic and can it be nondestructively tested?

Yes; common AR steels are ferromagnetic. Ultrasonic and magnetic particle testing work for defect detection; however overlay adhesion and ceramic bonding need method-specific inspections. - How does pipe bend or elbow design affect wear?

Elbows, tees, and transitions concentrate wear. Long-radius bends, abrasion-resistant elbow inserts, or liner protection at bends reduce localized erosion. Induction-hardened long-radius bends are a preferred solution for severe elbows. - What is the effect of temperature on AR steels?

Elevated operating temperatures can reduce hardness and toughness; consult manufacturer data. High-temperature slurry applications often require specialized high-temperature wear alloys. - Do overlay and ceramic solutions have warranty limitations?

Yes, warranty terms vary. Overlay delamination and ceramic cracking are common warranty exclusions if thermal shock or impact beyond rated conditions occurs. Obtain written limits and recommended operating envelopes. - For procurement, what contract terms reduce risk?

Include sample acceptance tests, hardness mapping, NDT acceptance criteria, delivery inspection procedures, and agreed life expectancy trial periods or performance benchmarks tied to payment milestones.

Closing recommendations for MWAlloys buyers and spec writers

- Provide precise duty data to suppliers: particle size distribution, concentration, temperature, velocity, and impacts per minute.

- Request hardness mapping and microstructure reports for any hardened or hardfaced product.

- Consider induction-hardened pipe for long runs with fines or where internal replacement costs are high.

- For critical bends and drop points, specify elbow inserts or ceramic tiles.

- Build inspection points into the delivery plan and include in the purchase order a clear acceptance test procedure.

Selected manufacturer and technical references

- Hardox branded pipes and tubes technical pages.

- Induction-hardened abrasion-resistant pipe product notes (Ultra Tech / Ultra 600).

- Industry notes on abrasion-resistant steel grades and use.

- Ceramic lined pipe technologies and use cases.