A516 Grade 70 is a pressure-vessel carbon steel plate chosen for welded vessels that require good notch toughness; A572 Grade 50 is a high-strength, low-alloy structural plate optimized for weight-sensitive structural builds. For pressure containment, pick A516-70; for structural framing where higher yield is beneficial, pick A572-50. MWAlloys supplies both grades from Chinese mills at 100% factory pricing with stock availability and rapid shipment for standard sizes.

A516 Grade 70 vs A572 Grade 50 comparison

| Feature | ASTM A516 Grade 70 | ASTM A572 Grade 50 |

|---|---|---|

| Principal use | Pressure-vessel plates for moderate and lower temperature service | High-strength structural plates for buildings, bridges, heavy equipment |

| Minimum yield | ~ 38 ksi (260 MPa) typical for Grade 70 pressure-vessel practice; depends on thickness and spec | 50 ksi (345 MPa) minimum yield for Grade 50. |

| Tensile strength | Typical ultimate ~ 70–90 ksi (485–620 MPa) range | Typical ultimate ~ 60–80 ksi range depending on thickness |

| Notch toughness | Specified, Charpy/V-notch requirements common | Toughness variable; often focused on strength and weldability |

| Standard family | ASME/ASTM PVQ steels (A516 / SA516) | High-strength low-alloy (A572 / A572M) |

| Typical heat treatment | Normalized or controlled rolling options; mechanical property controls | Controlled rolling; produced to meet yield/tensile targets |

| Common equivalents | EN pressure-vessel grades (P355NH / P355GH / similar) — approximate | EN S355JR family often used as nearest counterpart — approximate |

Key sources for baseline data: SSAB product notes on A516; manufacturers’ A572 summaries.

What the ASTM standards cover

ASTM A516 (also referenced in ASME code as SA516) comprises carbon-manganese plates for moderate or lower temperature service where improved notch toughness is required for pressure vessels. The grade numbering (55, 60, 65, 70) denotes increasing tensile/yield capability. Suppliers commonly produce A516 Grade 70 for welded boilers, storage vessels, and heat exchangers.

ASTM A572 is a high-strength low-alloy steel family intended for structural applications. Multiple grades exist (42, 50, 55, 60, 65). Grade 50 is the most widely used because of its combination of higher yield strength and good weldability.

Chemical composition comparison

Below are typical composition windows for design and procurement checks. Exact limits depend on the mill certificate and thickness.

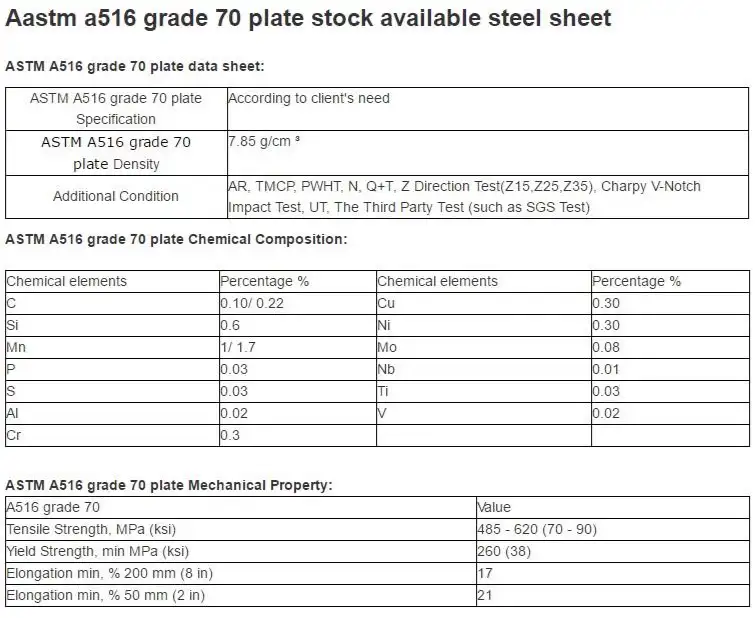

A516 Grade 70 (typical composition ranges)

-

Carbon (C): ~0.26% (varies)

-

Manganese (Mn): ~0.85–1.20%

-

Phosphorus (P): max ~0.03–0.04%

-

Sulfur (S): max ~0.03–0.05%

-

Silicon (Si): trace to ~0.35%

Notes: manufacturers optimize chemistry to meet notch toughness requirements.

A572 Grade 50 (typical composition limits)

-

Carbon (C): max ~0.23%

-

Manganese (Mn): up to ~1.35%

-

Phosphorus (P): max ~0.03–0.04%

-

Sulfur (S): max ~0.03–0.05%

-

Silicon (Si): 0.15–0.40% typical

-

Small additions of columbium (niobium) or vanadium sometimes present for strength control.

Important procurement note: request Mill Test Report (MTR / EN 10204 3.1) to verify chemical limits for the batch being shipped.

Mechanical properties: yield, tensile, elongation, toughness

A516 Grade 70

-

Typical minimum yield: around 260–300 MPa depending on thickness and heat treatment.

-

Typical tensile: ~485–620 MPa (ultimate).

-

Charpy impact: notch toughness requirements commonly specified for pressure-vessel service; mill practice often includes impact testing at specified temperatures.

A572 Grade 50

-

Minimum yield: 345 MPa (50 ksi).

-

Tensile strength: typical range 450–620 MPa depending on grade and thickness.

-

Toughness: good weldability; impact testing requirements depend on project specs but not always as stringent for pressure containment.

Practical implication: when brittle fracture risk is a major design concern for pressure equipment, A516-70 is usually preferred because of its certified notch toughness behavior. When structural members require higher yield to reduce section sizes, A572-50 often wins.

Typical applications and selection rationale

When to choose A516 Grade 70

-

Pressure vessels, boilers, and liquid storage where vessel codes require PVQ steels.

-

Environments with cyclic loading where notch toughness matters.

-

Projects where ASME Section II/Section VIII specifications or equivalent are invoked.

When to choose A572 Grade 50

-

Building frames, bridges, cranes, heavy machinery rails, and structural elements where higher yield reduces weight.

-

Projects focusing on structural codes and weldment strength.

Hybrid use cases occur: structural members that interface with pressure parts should be specified carefully to meet both strength and toughness needs.

Fabrication, welding, heat treatment, and toughness considerations

Weld procedures and preheat/postweld heat treatment should be decided from the specification and project code. Short practical notes:

-

A516-70 fabrication: preheat and PWHT (post-weld heat treatment) decisions hinge on thickness, carbon equivalent (CE), and design temperature. Pressure vessel codes often require impact testing at design temperature.

-

A572-50 fabrication: better out-of-the-box weldability. Preheat may not be required for thinner sections. Avoid aggressive heat input that could reduce local toughness.

Ask your welding engineer to compute carbon equivalent (CE) for any large weldment to determine need for preheat or PWHT.

What is ASTM A516 Grade 70 equivalent to?

ASTM A516 Grade 70 ≈ ASME/SA516 Grade 70 (same spec) and is most commonly treated as approximately equivalent to EN pressure-vessel grades such as P355GH / P355NH (EN 10028). Other regional near-matches frequently cited are BS 1501 224-490 A/B, 16Mo3 (for some high-temp uses) and Chinese Q345R for general pressure-vessel applications — but these are only approximate equivalents.

What is ASTM A572 GR 50 equivalent to?

ASTM A572 Grade 50 ≈ EN S355 (commonly S355JR / S355J2), and is also commonly treated as roughly equivalent to Chinese Q345B, JIS SM490/SS490, DIN St52-3 and other 345-MPa class structural steels.

| Region / Standard system | Typical equivalent name |

|---|---|

| Europe (EN) | S355JR / S355J2 (EN 10025-2) |

| China (GB/T) | Q345B / Q345 (≈345 MPa yield) |

| Japan (JIS) | SM490 / SS490 (JIS G3106) |

| Germany (DIN) | St52-3 (historical DIN equivalent) |

| UK / Older BS | BS 4360 Grade 50A / 50B (legacy equivalents) |

| International cross-refs | SteelNumber / equivalence tables list A572 Gr50 ⇄ S355 family |

Procurement, quality control, and MWAlloys supply advantage

MWAlloys offers both plate families from vetted Chinese mills. Procurement checklist MWAlloys enforces:

-

Mill Test Reports (EN 10204 / 3.1) for chemistry and mechanicals.

-

Certified thickness and flatness tolerances per ASTM / mill standard.

-

Traceability by heat number with stamping and paperwork.

-

Optional Charpy impact reports when required by buyer.

-

100% factory pricing: no middleman markup for standard stocked sizes.

-

Rapid dispatch from local warehouses for common thicknesses and widths.

Selection checklist for engineers and buyers

Before ordering, confirm the following:

-

Design code requirement (ASME, EN, local code) and whether PVQ certification is mandatory.

-

Required minimum yield and tensile values for the component.

-

Required impact temperature and test type.

-

Plate thickness and width tolerances.

-

Welding procedure specification (WPS) and heat-treatment needs.

-

Traceability level and required document type (MTR, 3.1 certificate).

-

Surface finish and any post-fabrication treatments (coating, shot blast).

-

Quantity, packaging, and shipping constraints.

-

Budget limits and whether 100% factory price is needed.

-

Delivery schedule — confirm stock availability.

MWAlloys provides a pre-purchase checklist and will attach MTRs for quality assurance.

Frequently asked questions

-

Which grade resists brittle fracture better for cold service?

A516 Grade 70 typically has certified notch toughness performance that makes it preferable for pressure vessels in colder service when specified Charpy tests are provided. Check the test temperature on the MTR. -

Can I weld A572-50 to A516-70 directly?

Yes, welding is possible with correct procedure, filler metal, and thermal control. However, thin sections and service conditions may require preheat or PWHT. Perform a weld procedure qualification when joining dissimilar grade plates. -

Are the EN equivalents interchangeable without testing?

No. Equivalent grade names only provide a starting point. Always verify mechanical and impact test data before substituting. -

Which grade gives more weight savings?

A572-50 gives higher yield, enabling lower section sizes for equivalent strength, which can reduce weight in structural applications. -

Do both grades need the same inspection regime?

Inspection depends on project code. Pressure equipment using A516 often requires stricter PVQ controls and impact testing. Structural projects using A572 may have different NDE and inspection expectations. -

What welding consumables should be used?

Choose low-hydrogen consumables that match or exceed base metal strength. Follow qualified WPS and consider filler matching for impact properties if required. Consult your welding engineer. -

Can A516-70 be normalized?

Yes. Some mill practices include normalizing or controlled rolling to achieve required toughness. Check mill’s heat treatment statement. -

How to check carbon equivalent (CE)?

Use accepted CE formulas (IIW or others) on the chemical composition provided by the mill. CE informs preheat and PWHT requirements. Ask MWAlloys for CE calculation upon request. -

What surface protection do you recommend for outdoor structural use?

For structural A572, common practices include primer plus topcoat systems or hot-dip galvanizing depending on longevity needs. For pressure vessels, coatings depend on process fluids and insulation plans. -

How long is delivery from MWAlloys?

Stocked standard plates ship rapidly. Custom orders depend on mill rolling schedules. Contact MWAlloys for a firm lead time based on thickness, width, and quantity.