40Cr is a medium-carbon, chromium-alloy structural steel widely specified for parts that require a balance of strength, toughness and wear resistance after quenching and tempering. It is commonly considered equivalent to DIN 41Cr4 / W. Nr. 1.7035 and AISI/SAE 5140 in many supply chains, and when properly heat treated it achieves good hardness (typically ~28–36 HRC after Q+T for common sections) and reliable fatigue performance for shafts, gears and connecting components. Use 40Cr where moderate alloying plus hardenability is needed and follow EN/DIN or ASTM guidance for mechanical acceptance criteria and heat-treatment schedules.

What is 40Cr?

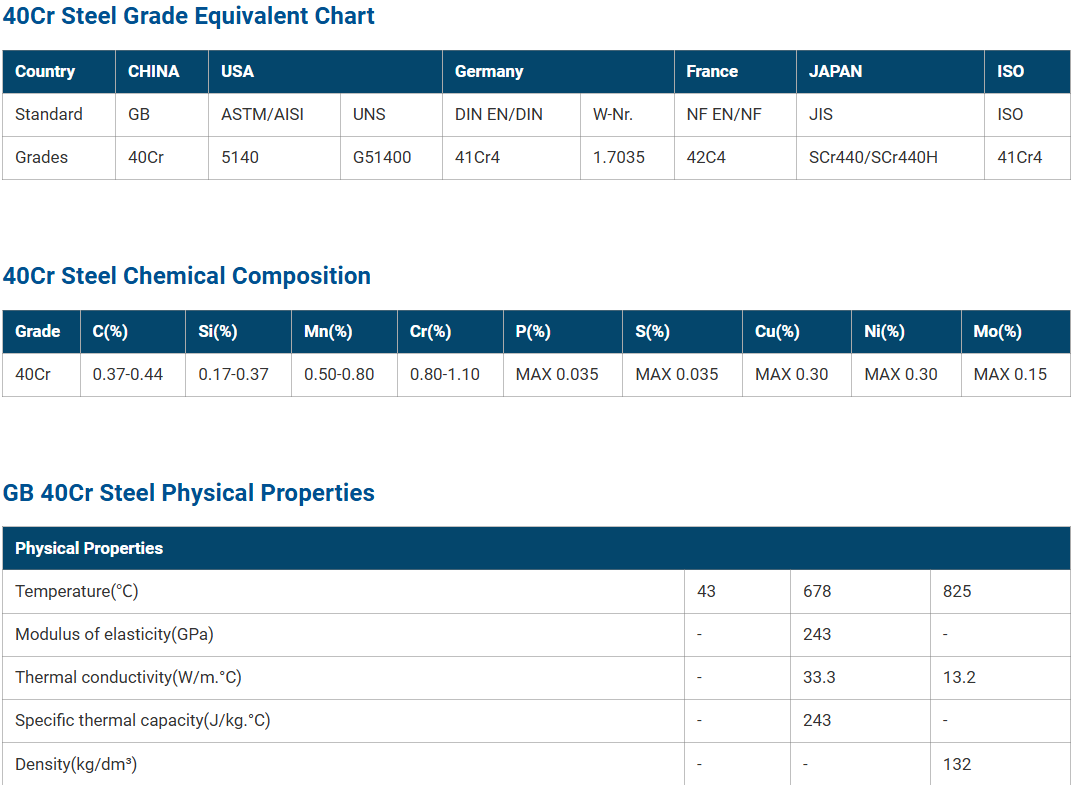

40Cr steel is a medium-carbon chromium alloy steel from the Chinese GB family that is engineered for quenching and tempering. It combines moderate carbon content with chromium to raise hardenability and wear resistance while keeping cost and machinability reasonable. The grade is used for medium-duty structural components that are subsequently heat treated to obtain a controlled balance of strength and toughness, such as shafts, axles, couplings, gears and heavy pins. In international practice, the grade is commonly cross-referenced to 41Cr4 (DIN/W. Nr. 1.7035) and to SAE/AISI 5140, though chemistry and permitted tolerances can vary slightly between standards; always check the supplying mill certificate for exact composition and mechanical test results.

Chemical composition and microstructure

Below is a condensed, practical chemical composition table showing typical ranges used for 40Cr (GB) with a direct mapping to DIN 41Cr4 / 1.7035 and the common SAE counterpart. These ranges are the working guidance used by mills and heat-treatment houses. Always verify the mill certificate (mill test report) for the actual delivered batch.

Table 1: Typical chemical composition (mass percent)

| Element | Typical 40Cr (GB/T) | Typical DIN 41Cr4 / 1.7035 | Typical SAE/AISI 5140 (approx) |

|---|---|---|---|

| C | 0.36 – 0.44 | 0.37 – 0.44 | 0.38 – 0.43 |

| Si | 0.17 – 0.37 | 0.20 – 0.40 | 0.15 – 0.35 |

| Mn | 0.50 – 0.80 | 0.60 – 0.90 | 0.60 – 0.80 |

| Cr | 0.80 – 1.10 | 0.95 – 1.20 | 0.80 – 1.10 |

| P (max) | ≤ 0.035 | ≤ 0.035 | ≤ 0.035 |

| S (max) | ≤ 0.035 | ≤ 0.035 | ≤ 0.040 |

| Mo, Ni (trace) | typically absent or ≤ 0.03 | typically absent | trace levels in some variants |

Microstructure notes: In the normalized or quenched-and-tempered state the ideal microstructure for 40Cr is tempered martensite (or bainite in thicker sections), with uniformly distributed carbides. Chromium promotes hardenability and refines carbide distribution, improving wear resistance and fatigue life.

Mechanical properties and performance

Mechanical properties depend strongly on heat treatment. The table below provides typical property targets for common conditions used in engineering design. These values are illustrative typical ranges used by designers and heat treaters. For contractual work use the exact numbers from the applicable purchase specification and material test report.

Table 2: Typical mechanical properties (representative values)

| Condition | Tensile strength, MPa (Rm) | Yield strength, MPa (Rp0.2) | Elongation A%, | Hardness (HB/HRC) |

|---|---|---|---|---|

| Normalized (approx) | 650 – 800 | 380 – 520 | 12 – 18 | 180 – 230 HB |

| Quenched (oil) and tempered (moderate) | 900 – 1200 | 700 – 1000 | 10 – 16 | 28 – 36 HRC (≈290–350 HB) |

| Quenched and tempered (higher temper) | 700 – 900 | 500 – 700 | 12 – 18 | 20 – 28 HRC |

When compared with common Western grades like AISI 4140, 40Cr shows broadly similar performance once heat treatment is controlled. Differences in alloying tolerances, trace elements and processing mean that specifying required hardness, toughness and fatigue requirements explicitly in purchase documents is best practice.

Heat treatment: practical schedules and effects

40Cr is intended for quenching and tempering. Hardness and toughness are controlled by a combination of austenitizing temperature, quench medium, and tempering temperature/time.

Table 3 — Typical heat treatment windows and resulting hardness (practical guidance)

| Process | Temperature (°C) | Quench | Typical resulting hardness (approx) |

|---|---|---|---|

| Normalizing | 840 – 880 | Air cool | 190 – 230 HB |

| Austenitize (Q) | 830 – 860 | Oil quench preferred | As-quenched ~55 HRC (surface) |

| Tempering low (high strength) | 150 – 250 | — | ~52–55 HRC (if low temper) |

| Tempering medium | 300 – 450 | — | ~42–50 HRC |

| Tempering high (good toughness) | 500 – 650 | — | ~20–35 HRC depending on temperature |

Practical recommendations

-

For shafts, medium sections and parts requiring ~30–36 HRC, a common recipe is austenitize 830–850 °C, oil quench, temper at 500–550 °C for 1–2 hours (adjust time for section size).

-

For parts that need higher toughness at lower strength, use tempering at higher temperatures (550–650 °C) to obtain ~20–30 HRC.

-

For thin parts or complex shapes, care is required to avoid quench cracking; step-cooling and controlling section thickness are common mitigations.

Hardenability and section size: Chromium increases hardenability. Typical 40Cr bars and forgings can be oil-quenched successfully up to moderate diameters without loss of mechanical property uniformity. For very large sections, consider pre-hardening, induction hardening or specify higher alloy grades (for example 42CrMo4) if through-hardening is required.

Equivalents and international cross-reference

40Cr is a regional designation. The equivalents below are commonly cited in cross-reference tables used by mills and material suppliers. Keep in mind that equivalence is approximate and acceptance must be based on chemistry and mechanical properties in the contract.

Table 4 — Rough equivalents

| China GB | DIN / W. Nr. | EN | AISI/SAE / ASTM | JIS |

|---|---|---|---|---|

| 40Cr | 41Cr4 | 1.7035 (EN 10083 family) | 5140 (approx) | SCr440 |

Notes: Many suppliers list 40Cr = 41Cr4 = 5140 in their catalogs. The EN variant may appear as 41Cr4 or under EN 10083-3 technical delivery conditions. Check tolerances for C, Cr and Mn — small variations influence heat treatment response.

Comparison: 40Cr vs 4140 vs 42CrMo4

-

40Cr vs AISI/SAE 5140 / 4140: 40Cr and 5140/4140 are close in carbon and chromium content; 4140 usually contains molybdenum and slightly different Mn/Si levels depending on spec which increases toughness and high-temperature strength. For many mechanical parts 40Cr and 5140 are interchangeable if the purchaser accepts the chemistry and mechanical guarantees. If the application has high fatigue or elevated temperature exposure, prefer 4140 or 42CrMo4 for the better alloy balance.

-

40Cr vs 42CrMo4: 42CrMo4 contains molybdenum and a slightly different alloy balance; it offers superior hardenability and toughness in large sections and higher tempering resistance. Use 42CrMo4 when higher core strength in thick sections or better impact resistance is required.

Design tip: Specify the required post-heat-treatment hardness/toughness and mechanical limits on the purchase order rather than naming an equivalent grade only. This reduces risk when suppliers use slightly different chemistries.

Machinability, welding and surface treatments

Machinability:

In the normalized condition 40Cr machines reasonably well for a medium-carbon alloy. Machinability decreases after quenching and tempering to higher hardness. For heavy machining, normalize or use intermediate anneal before high-volume cutting. Carbide inserts and rigid fixturing help when cutting in higher strength conditions.

Welding:

Welding of 40Cr requires preheating and post-weld heat treatment in many cases because of the carbon content and hardenability. For small, non-critical fabrications, preheat 150–250 °C and use controlled interpass temperatures. For safety-critical or large welded assemblies, stress relieve or perform PWHT according to the applicable welding code. Avoid welding when the design expects uniform quenched and tempered properties through the welded zone unless the weld procedure and PWHT are specified.

Surface treatments:

Common finishes include carburizing for wear surfaces (when a hard case and ductile core are needed), induction hardening of local zones, nitriding for improved surface fatigue and corrosion resistance, and phosphate or electroplated finishes for corrosion protection during storage and assembly.

Inspection, testing and quality control

For critical components, specify:

-

Mill Test Report (MTR) showing batch chemistry and heat treatment record.

-

Mechanical test results in the delivered condition (tensile, yield, elongation, hardness).

-

Charpy V-notch impact values at specified temperatures when toughness is critical.

-

Non-destructive testing (mag particle, UT, radiography) for forgings or critical sections.

-

Metallographic acceptance for microstructure and inclusion rating (when required).

Standards such as EN 10083 (steels for quenching and tempering) or specific ASTM purchase standards define acceptance criteria for many applications. Use them to define inspection hold points and acceptance limits.

Typical applications and engineering considerations

Common parts manufactured from 40Cr:

-

Drive shafts, transmission gears, couplings and axles.

-

Machine tool parts such as spindles, pins, mandrels.

-

Construction machinery parts—pins, bushings, and high-wear links.

-

General mechanical components requiring a combination of strength and toughness after Q+T.

Engineering considerations:

-

Fatigue: If parts are subject to high cyclic loading, specify fatigue limits or require shot peening and controlled surface finish to enhance life.

-

Wear: For sliding/wear surfaces consider a local surface hardening approach rather than hardening the entire component.

-

Size effects: Large section sizes require adjusted heat treatment cycles and possibly different grades for through-hardening.

-

Corrosion: 40Cr is not stainless; protect it where corrosion will degrade performance.

Practical procurement checklist

-

Specify required final condition: hardness range (HRC or HB), tensile/yield, Charpy energy (if needed).

-

Insist on Mill Test Report with actual chemistry and heat treatment records.

-

Define allowable equivalents and state whether small deviations in chemistry are acceptable.

-

Require NDT and (if required) metallography acceptance criteria.

-

Include finish, surface treatment and packing requirements.

-

If welding is required, specify welding procedure and PWHT.

Case example

A supplier offers a batch of 40Cr shafts for agricultural equipment. The drawing calls for 32–36 HRC and Charpy V-notch ≥ 27 J at room temperature. The purchaser should require: full MTR, sample Charpy reports, hardness map for multiple shafts, and a witness inspection or third party lab check for a first-article sample. If data show insufficient toughness, request tempering at a higher temperature to improve impact energy at the expense of some hardness.

Standards and authoritative references

40Cr and its equivalents are handled in several international standards. When specifying, reference the applicable standard and the edition/date.

Key standards and reference documents include:

-

EN 10083 family (steels for quenching and tempering) and national variants.

-

DIN 17200 / 41Cr4 (W. Nr. 1.7035) datasheets for mechanical and heat treatment guidance.

-

Supplier–published datasheets such as MatWeb and accredited labs for comparative mechanical data.

-

Equivalence tables published by reputable suppliers and metallurgical labs.

For final procurement or design, always cite the precise standard and revision used in the contract.

Frequently Asked Questions

-

Is 40Cr the same as 5140 or 4140?

They are close but not identical. 40Cr (GB) commonly maps to 41Cr4 (DIN 1.7035) and is often treated as similar to SAE 5140 or AISI 4140. Differences in trace elements and allowable ranges make it essential to verify the MTR and mechanical properties before interchange. -

What hardness can I expect after quenching and tempering?

Typical quenched and tempered hardness for many 40Cr parts is 28–36 HRC when using common recipes. Final hardness depends on austenitizing temperature, quench medium and tempering schedule. -

Can 40Cr be carburized?

Yes. 40Cr responds well to case carburizing followed by quench and temper, producing a hard, wear-resistant surface with a tough core. Process parameters must be chosen to avoid excessive distortion. -

Is welding OK on 40Cr?

Welding requires care. Preheat and controlled interpass temperatures are recommended and PWHT may be necessary for critical components due to hardenability and carbon content. -

When should I prefer 42CrMo4 over 40Cr?

Choose 42CrMo4 when higher through-hardening in large sections, better toughness, or higher service temperatures are required due to its Mo content and improved alloy balance. -

What testing should I require on delivery?

At minimum require MTR, tensile test, hardness measurements, and any NDT or impact testing specified in the purchase order. For critical parts add metallography and additional mechanical sampling. -

How does section size affect heat treatment?

Larger sections need longer soak times and may require different quench strategies to avoid soft cores or retained austenite; consider induction surface hardening if uniform through-hardening is impossible. -

Is 40Cr suitable for high-temperature applications?

No. 40Cr is not a heat-resistant alloy. For elevated temperature strength consider alloy steels specifically designed for service at temperature. -

What finishes are commonly applied on 40Cr?

Carburizing, nitriding, induction hardening, phosphate coating for corrosion protection during storage, and plating where corrosion protection is essential. -

How to ensure consistent supplier quality?

Use certified suppliers, specify standards and testing, require traceable MTRs and consider periodic third-party audits of heat treatment processes.

Quick summary and final selection checklist

40Cr is a versatile medium-carbon chromium alloy suitable for many mechanical parts after quenching and tempering. Use it where moderate alloying, controlled hardenability and cost effectiveness are priorities. For through-hardened large sections, high fatigue duty or higher temperature requirements, evaluate higher-alloy alternatives. Always lock mechanical targets, heat treatment conditions and inspection requirements into the procurement documents.