For corrosion resistance, formability, and weldability choose 300-series (austenitic) alloys (e.g., 304, 316). For higher hardness, wear resistance, lower cost and magnetic/heat-treatable applications choose 400-series (ferritic or martensitic) alloys (e.g., 410, 420, 430). The correct choice depends on environment (chlorides, acids), mechanical load, fabrication route, heat treatment needs, and budget.

What the series numbers mean

“300-series” and “400-series” are shorthand families used in modern stainless-steel specification systems (UNS/ASTM/EN). They group grades by dominant crystal structure and typical alloying patterns:

-

300 series → Austenitic stainless steels. Contain significant nickel (and chromium) and are primarily non-magnetic in the annealed condition. Common examples: 304, 316, 321.

-

400 series → Ferritic and martensitic stainless steels. Contain little or no nickel, often higher carbon, and can be magnetic; many grades are hardenable by heat treatment. Examples: 410, 420 (martensitic), 430 (ferritic).

This classification is practical for engineers because it predicts behavior: corrosion resistance, weldability, formability, and whether heat treatment/hardening is available.

Core chemistry differences (what’s in the metal and why it matters)

Below are the most influential elements and how they create the series’ behavior:

-

Chromium (Cr) — provides the passive oxide film; both series have chromium (typically ≥11%), but presence alone does not equal equal corrosion resistance.

-

Nickel (Ni) — stabilizes the austenitic phase, improves ductility, toughness, and enhances general corrosion resistance. Present in 300 series (commonly 8–12% in 304/316), largely absent in standard 400 series.

-

Carbon (C) — higher carbon in many 400s increases hardenability and achievable hardness after heat treatment but can reduce corrosion resistance (carbide precipitation) if not controlled.

-

Molybdenum (Mo) — added in many 300-series variants (e.g., 316) to raise resistance to pitting and crevice corrosion in chloride environments.

Practical takeaway: Nickel and molybdenum are the “premium” corrosion-performance elements; chromium gives basic stainless behavior; carbon trades corrosion for hardness.

Microstructure and metallurgical behavior

-

Austenitic (300s) — face-centered cubic (FCC) structure at room temperature due to Ni stabilization. This gives excellent toughness, high ductility, and strain hardening during cold forming. Austenitics are not hardenable by conventional heat treatment (they can be strengthened by cold work).

-

Ferritic (some 400s) — body-centered cubic (BCC) structure, stable at room temperature. Ferritics are not hardenable by quench and temper; they are magnetic and have lower ductility than austenitics but better thermal conductivity.

-

Martensitic (some 400s) — can transform to martensite on quenching (hardenable). Martensitic grades are magnetic and can reach high hardness after heat treatment (used in knives, valves, shafts).

Knowing the microstructure informs fabrication choices: martensitics require heat-treat cycles; austenitics require attention to work-hardening and welding heat-input.

Corrosion resistance: where 300 series outperforms

Overall corrosion performance ranks generally: 316 ≥ 304 >> ferritic 430 ≈ some martensitics (410/420) — but specifics depend on environment and surface finish.

-

General atmospheric and sanitary environments: 300 series (304/316) is far superior; 316 is preferred where chlorides (salt, seawater spray) or pitting risk exist due to its molybdenum content.

-

Pitting/crevice resistance: 316 (and higher alloyed super-austenitics) resist pitting better than 304. Engineers use PREN (Pitting Resistance Equivalent Number) to compare alloys.

-

Oxidizing acids / high temperature: Some 400-series ferritics tolerate certain oxidizing atmospheres better and have higher creep strength at elevated temperatures, but are generally less durable in wet/chloride exposures than 300s.

Design note: If the component sees repeated exposure to chlorides, sewage, marine or salt-spray environments, prioritize 316 or higher austenitics. If the service is dry, low-corrosivity and hardness matters more, 400-series choices become attractive.

Mechanical properties & hardenability

300 series (austenitic):

-

Typical tensile strength and yield are moderate; high ductility and elongation.

-

Cannot be hardened by heat treatment; strength is increased primarily by cold working (work hardening).

400 series (martensitic/ferritic): -

Martensitic 400s (e.g., 410, 420): can be quenched and tempered to high hardness and strength. Useful for cutting tools, knives, shafts.

-

Ferritic 400s (e.g., 430): moderate strength, limited hardenability; better creep resistance and thermal conductivity in some temperature ranges.

Typical engineering values vary by grade and temper — always consult the producer/ASTM data sheet for design values.

Formability, cold work and welding behaviour

-

Formability / deep drawing: 300 series is generally excellent — low yield strength, high elongation and strain hardening make it preferred for seamless sinks, kitchenware, and complex shapes.

-

Machinability: Many 300 grades are hard to machine relative to some 400s because of high ductility and work hardening. Some 300 grades (303) include sulfur to improve machinability at the cost of some corrosion resistance.

-

Weldability: 300 series welds readily with matching filler metals (no pre-heat or post-weld anneal needed for 304/316 in most cases). 400-series martensitics require post-weld heat treatment in many applications to restore toughness and avoid cracking; ferritics can suffer brittle HAZ if mis-managed.

Practical guidance: For complex welded fabrications in corrosive service, 300 series simplifies fabrication. For hardenable components, accept extra heat-treatment steps to use 400 martensitics.

Magnetic properties and implications

-

300-series austenitics are typically non-magnetic when fully annealed (some cold work can induce weak magnetism).

-

400-series ferritic/martensitic grades are magnetic in most tempers. This matters for sensors, electromagnetic compatibility, and applications where magnetism is unacceptable (medical devices, some electronics).

Magnetism is also a quick field test to screen alloy family — inexpensive and useful during incoming inspection.

Short grade profiles (practical snapshots)

300-series

-

304 (UNS S30400) — the “workhorse” stainless: ~18% Cr, ~8% Ni. Excellent general corrosion resistance and formability. Widely used for kitchen equipment, architectural trim.

-

316 (UNS S31600) — similar Cr but with Mo (~2–3%): much better pitting resistance; used in marine, chemical, and medical implants.

-

304L / 316L — low carbon versions to reduce carbide precipitation after welding (better HAZ corrosion resistance).

400-series

-

410 (UNS S41000) — martensitic; can be hardened; used for cutlery, valves.

-

420 (UNS S42000) — higher carbon martensitic; takes very high hardness; used for knife blades and surgical instruments.

-

430 (UNS S43000) — ferritic; good formability, decorative finish, used in appliances and trim.

Typical industry applications and selection rules

-

Foodservice, medical equipment, and architectural interiors: 300 series (304/316) for hygiene and appearance.

-

Automotive trim, decorative panels, and oven interiors: 400 ferritics (430) for cost and appearance where corrosion is not severe.

-

Cutlery, scalpel blades, and wear parts: 400 martensitics (420, 440C) after heat treatment for high hardness and edge retention.

-

Exhaust systems (automotive): often ferritic 409 or 430 where cost matters and the environment is hot and mildly corrosive.

Selection rule of thumb: corrosion environment first, then mechanical requirement, then fabrication method and budget.

Surface finish, passivation and maintenance

-

Surface finish (2B, BA, No.4, mirror) affects apparent corrosion resistance — smoother finishes shed deposits and are easier to clean.

-

Passivation (nitric or citric acid) removes free iron and promotes a chromium-rich oxide; recommended for parts exposed to corrosive conditions after fabrication.

-

Repair of scratched surfaces: clean, pickled, and repassivate; in chloride exposure zones, consider replacing with 316 if pitting occurs.

Routine maintenance and proper cleaning agents dramatically extend service life for both series.

Cost and supply considerations

-

Material cost: 300-series alloys (especially 316 and high-Ni alloys) are more expensive due to Ni and Mo content. 400-series tend to be more economical. Market price volatility (nickel/molybdenum markets) can change relative pricing — plan procurement accordingly.

-

Form availability: 304/316 are widely stocked in sheet, plate, bar, pipe, and tube. Some 400 grades are more common in bar and cutlery blanks.

For long projects, lock pricing with suppliers or include alloy substitution clauses with clear acceptance tests.

Quick selection tables

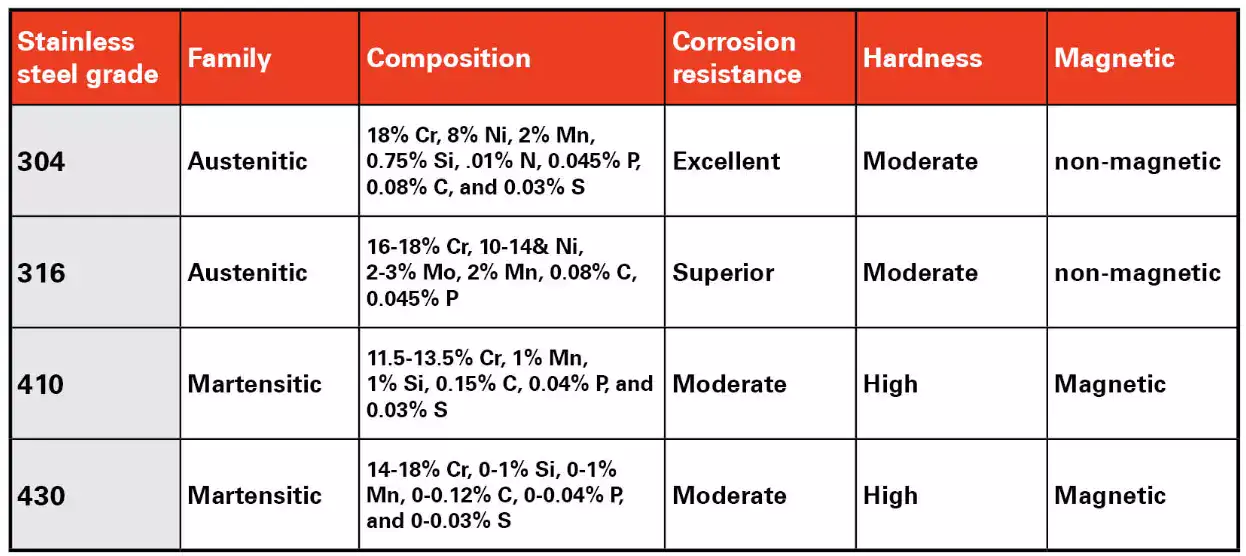

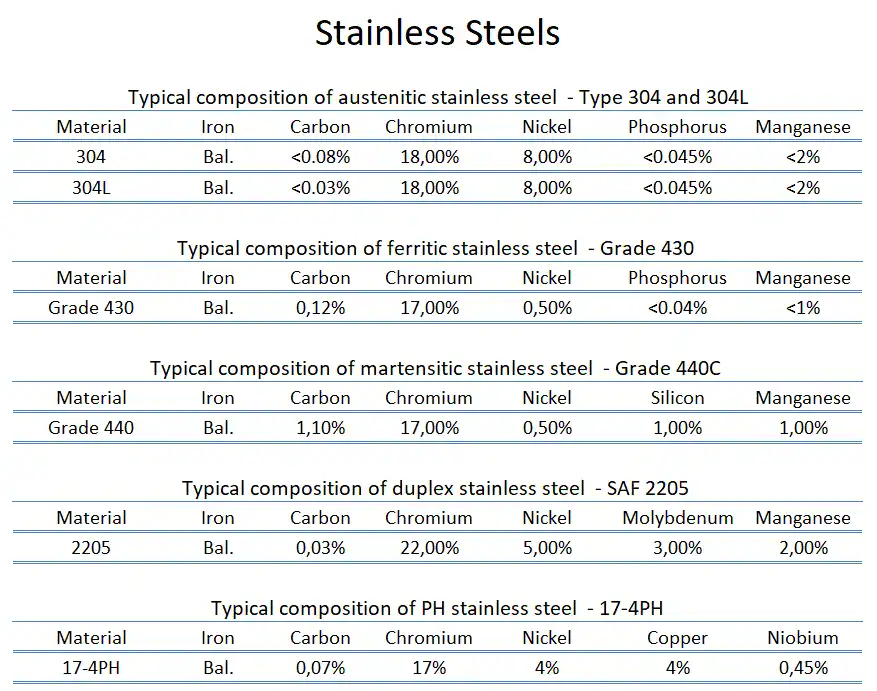

Table 1 — Composition snapshot (typical ranges)

| Alloy | Cr (%) | Ni (%) | Mo (%) | C (%) | Main family |

|---|---|---|---|---|---|

| 304 | 18–20 | 8–10 | 0 | 0.08 | 300 (austenitic) |

| 316 | 16–18 | 10–14 | 2–3 | 0.08 | 300 (austenitic) |

| 430 | 16–18 | 0 | 0 | 0.12 | 400 (ferritic) |

| 410 | 11.5–13.5 | 0 | 0 | 0.15 | 400 (martensitic) |

| 420 | 12–14 | 0 | 0 | 0.15–0.4 | 400 (martensitic) |

(Values are typical design ranges — consult production datasheets/ASTM standards for exact spec limits.)

Table 2 — Mechanical property snapshot (annealed unless noted)

| Alloy | Typical tensile (MPa) | Yield (MPa) | Hardness (HB) | Hardenable? |

|---|---|---|---|---|

| 304 | 520–700 | ~215–275 | 150–200 | No (work harden) |

| 316 | 520–700 | ~215–275 | 150–200 | No |

| 430 | 370–600 | ~210–250 | 120–200 | No |

| 410 (quenched & tempered) | 600–1100 | varies | 200–600 | Yes |

| 420 (HT) | up to >2000 (hardness scale dependent) | — | can exceed HRC 60 when heat treated | Yes |

(Actual values strongly depend on temper and heat treatment.)

Table 3 — Quick pros / cons summary

| Characteristic | 300 series (e.g., 304/316) | 400 series (ferritic/martensitic) |

|---|---|---|

| Corrosion resistance | Excellent (316 best) | Moderate to low |

| Cost | Higher | Lower |

| Magnetic | Generally no | Yes |

| Hardenability | No (cold work only) | Martensitic grades yes |

| Weldability | Excellent | Variable — martensitics need HT |

| Typical uses | Food, medical, marine | Cutlery, appliances, shafts |

Standards, testing and authoritative references to check

When specifying materials, reference the ASTM/EN/UNS designations and perform material tests (chemistry, mechanical, PMI, hardness, and pitting tests if needed). Key references:

-

ASTM specifications for common grades (e.g., ASTM A240 for stainless steel plate/sheet; ASTM A276 for bars; ASTM A182 for forgings).

-

UNS and EN numbers for cross-reference.

-

Technical design documents such as Nickel Institute selection guides and ASME/ISO design rules for high-temperature service.

Practical fabrication tips (engineer to engineer)

-

Use matching filler metals for welding (e.g., ER308/308L for 304, ER316L for 316).

-

For heat-sensitive applications, choose low-C variants (304L/316L) to minimize HAZ sensitization.

-

For parts that will be machined heavily, consider free-machining grades (303 or 416) only when corrosion exposure is low.

-

Surface control: specify finish and passivation steps in the purchase order; require surface tests when corrosion resistance is critical.

-

When substituting alloys to cut cost, always run application-specific corrosion tests (salt spray, cyclic corrosion or immersion tests) before adopting substitution.

FAQs

Q1: Can 430 be used instead of 304 to save cost?

A: Only when the environment is mild and corrosion risk is low (indoor trim, oven panels). 430 is less corrosion resistant and is magnetic; avoid substitution where moisture or chlorides are expected.

Q2: Is 316 always better than 304?

A: Not always—316 is superior in chloride/pitting resistance but costs more. If chloride exposure is limited, 304 is often adequate and more economical.

Q3: Why does 300 series remain non-magnetic while 400 series is magnetic?

A: Nickel stabilizes the austenitic phase (FCC), which is non-magnetic; absence of nickel and presence of ferrite/martensite (BCC) in 400s yields magnetism.

Q4: Which series is better for high-temperature strength?

A: Some 400 ferritics have better high-temperature creep resistance and lower thermal expansion, so pick based on max service temperature and oxidation environment.

Q5: Can 300 series be hardened by heat treatment?

A: No, austenitic 300 series are not hardenable by conventional quench/temper; they gain strength through cold working.

Q6: Are 400 series grades less weldable?

A: Ferritic 400s weld reasonably with precautions; martensitic 400s commonly require pre-heat/post-heat treatment to avoid cracking and to restore toughness.

Q7: Which alloy resists pitting best?

A: 316 and higher-alloy super-austenitics (with Mo and sometimes N) have the best pitting resistance; use PREN to compare. Penflex

Q8: How should I choose between 304 and 410 for fasteners?

A: For corrosion exposure choose 304; for high strength/hardenability and where some corrosion risk is acceptable, 410 may be used with heat treatment.

Q9: Are magnets a reliable field test to distinguish series?

A: Yes, magnetism is a practical screening test: 300-series are non-magnetic (annealed), 400-series are generally magnetic. Cold-worked 300s can show weak magnetism though.

Q10: Should I specify passivation in PO?

A: When corrosion resistance is critical after fabrication, specify passivation (acid choice depending on alloy) and require test certificates for validation.

Selection decision matrix

-

Need top corrosion resistance (chlorides/chemical) → 316 / 6Mo / super-austenitic.

-

Need non-magnetic, formable, economical → 304.

-

Need hardenable & high wear → 420 / 440C (heat treat).

-

Need decorative but lower cost → 430 (ferritic).

-

Need high temp creep strength → select specific ferritic or duplex grades based on ASME design guides.

Common mistakes and how to avoid them

-

Substituting on price alone — evaluate environmental exposure first.

-

Ignoring weld HAZ effects — use low-C grades or add post-weld treatment where required.

-

Assuming non-magnetic = 300 — remember severe cold work can induce magnetism in 300s.

-

Overlooking finish and cleanliness — surface contamination dramatically reduces corrosion life.

Final technical checklist for spec writers

-

State UNS/ASTM grade (not just “300 series”).

-

Specify required mill test reports (MTRs) with chemical and mechanical results.

-

Specify surface finish, passivation, and ferrite/microstructure tests if relevant.

-

Require traceability for critical parts and acceptance tests (pitting potential, hardness, PMI).

-

Include maintenance and cleaning guidance in the equipment manual.