18-8 stainless steel commonly refers to the group of austenitic chromium-nickel alloys that contain roughly 18% chromium and 8% nickel, and in practical use this term most often denotes Type 304. For general corrosion resistance, formability, weldability, and cost-effectiveness, Type 304 remains the default choice. When service requires improved resistance to pitting, crevice corrosion, or chloride environments, Grade 316 (with added molybdenum) is the superior selection despite higher material cost. Engineers selecting between 18-8/304 and 316 should weigh environmental aggressiveness, fabrication needs, required lifetime, and budget before specifying material.

Introduction and brief historical context

Stainless steels in the 300 series have shaped modern fabrication, food processing, chemical equipment, and architectural finishes. The “18-8” label arose from early industry shorthand that emphasized the two dominant alloying additions: roughly 18% chromium plus roughly 8% nickel. That shorthand predates modern unified numbering systems that use precise grade names such as Type 304 or UNS S30400. Over time Type 304 became the common practical embodiment of 18-8 alloys. Grade 316 evolved later with molybdenum added to better resist localized corrosion in chloride-bearing environments. Reliable guidance on which grade fits a particular service requires linking alloy chemistry, microstructure, environmental exposure, and fabrication methods.

What “18-8” means in practice

“18-8” is a descriptive phrase that captures a common chemistry point within the austenitic 300 series. It does not constitute a formal specification. Common practice equates 18-8 with Type 304, though other 300-series alloys may show similar chromium-nickel levels. Engineers should avoid using “18-8” on procurement documents when precise material properties or standards must be enforced; specify the grade and reference standard instead (for example, Type 304 per ASTM A240).

Chemical composition comparison (concise table)

The table below compiles typical composition ranges for each grade using common specification limits (values taken from widely used material tables and ASTM summaries). These ranges represent industry-typical values for wrought 304 and 316; consult purchase specifications for mill test certificate limits.

| Element (wt%) | 18-8 (typical) | Type 304 (UNS S30400) | Type 316 (UNS S31600) |

|---|---|---|---|

| Carbon (C) | ≈0.06–0.08 | ≤0.08 (304); ≤0.03 (304L) | ≤0.08 (316); ≤0.03 (316L) |

| Chromium (Cr) | ≈17.5–19.5 | 17.5–19.5 | 16.0–18.0 |

| Nickel (Ni) | ≈8.0–10.5 | 8.0–10.5 | 10.0–14.0 |

| Molybdenum (Mo) | 0 | 0 | 2.0–3.0 |

| Manganese (Mn) | ≤2.0 | ≤2.0 | ≤2.0 |

| Silicon (Si) | ≤0.75 | ≤0.75 | ≤0.75 |

| Phosphorus (P) | ≤0.045 | ≤0.045 | ≤0.045 |

| Sulfur (S) | ≤0.03 | ≤0.03 | ≤0.03 |

| Nitrogen (N) | ≤0.10 | ≤0.10 | ≤0.10 |

Notes:

-

18-8 shorthand reflects approximate chromium and nickel content; modern procurement should reference ASTM A240 or equivalent.

Microstructure and metallurgy fundamentals

Both 304 and 316 belong to the austenitic family. Their matrix is face-centered cubic (FCC) austenite at room temperature, stabilized by nickel. That microstructure grants ductility, good low-temperature toughness, non-hardening behavior during heating, and near-nonmagnetic response in annealed state. Carbide precipitation can occur at grain boundaries when material spends time within roughly 425–850°C; this leads to chromium depletion and potential intergranular corrosion. Low-carbon variants (304L, 316L) or stabilised grades (316Ti, 321) are used to mitigate sensitization during welding or heat exposure. The addition of molybdenum in 316 raises resistance to pitting and crevice corrosion by improving the stability of the passive oxide layer in chloride-containing solutions.

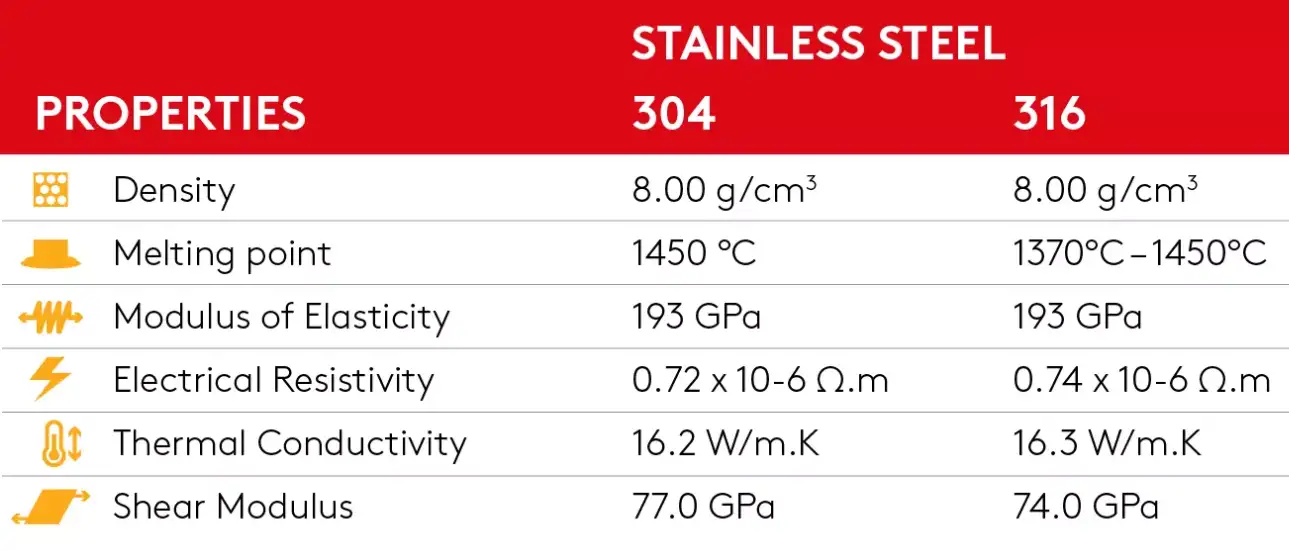

Mechanical properties comparison (table)

Typical annealed mechanical properties for common wrought forms (sheet, plate, strip) provide guidance for design. Actual values depend on product form, cold work, and supplier test data.

| Property | Type 304 (annealed) | Type 316 (annealed) |

|---|---|---|

| Tensile strength (min) | ~515 MPa (≈75 ksi) | ~515 MPa (≈75 ksi) |

| Yield strength 0.2% (min) | ~205 MPa (≈30 ksi) | ~205 MPa (≈30 ksi) |

| Elongation (in 50 mm) | ≥40% | ≥40% |

| Hardness (HRB) | ≤95 | ≤95 |

| Density | 7.93 g/cm³ | 8.00 g/cm³ |

Interpretation:

Both grades show similar bulk mechanical behavior in the annealed condition. Selection driven by environment, not tensile strength, in most cases.

Corrosion behaviour and resistance mechanisms

Passive film and general corrosion

Chromium presence forms a thin, adherent chromium-oxide film that protects substrate steel against many oxidising environments. Nickel improves film stability and ductility of the matrix.

Localized corrosion (pitting, crevice)

Chloride ions challenge the passive film and may initiate localized attack. Molybdenum in Type 316 improves repassivation kinetics and raises the threshold potential for pitting, making 316 markedly better than 304 in marine and chloride-bearing process streams.

Stress corrosion cracking (SCC)

Austenitic grades can experience chloride SCC at elevated temperatures under tensile stress. Control strategies include material choice, residual stress relief, and chloride control.

Passivation and maintenance

Chemical passivation (nitric or citric acid treatments) removes free iron and promotes formation of a chromium-rich passive layer. Regular inspection and routine cleaning extend service life in many applications.

Fabrication: forming, welding, machinability, heat treatment

Forming and cold work

304 typically forms and deep-draws readily. Work hardening rate is moderate; dies and forming tools should account for springback. 316 forms well too but has slightly higher work hardening and springback.

Welding

Both 304 and 316 are readily welded by common fusion processes. Heat input control and filler metal selection matter; for 304 welds, matching filler (304) or low-carbon filler can avoid sensitization. For 316 in chloride service, use 316 filler to maintain corrosion performance. Low-carbon grades (304L, 316L) reduce risk of intergranular attack after welding.

Machinability

Austenitic stainless steels have lower machinability than mild steel due to work hardening and low thermal conductivity. Free-cutting variants with added sulfur exist (e.g., 303) but sacrifice corrosion resistance. For critical components, tool selection and cutting parameters are essential.

Heat treatment

Austenitic stainless steels cannot be hardened by conventional heat treatment. Solution annealing followed by rapid cooling restores ductility and dissolves carbides. Aging at certain temperatures can cause precipitation of sigma phase in heavily alloyed steels, reducing toughness.

Typical applications and industry use cases (table)

| Service domain | Typical grade choice | Rationale |

|---|---|---|

| Cutlery, cookware, consumer goods | 304 (18-8) | Good forming, polishability, food contact safety. |

| Food processing equipment | 304 or 316 | 304 for many foods; 316 for salt or acidic conditions. |

| Chemical processing | 316 when chlorides present | Mo improves resistance to halide attack. |

| Marine fittings and fasteners | 316 | Superior resistance to seawater pitting. |

| Architectural components | 304 | Cost vs appearance balance. |

| Medical devices & implants (non-implant applications) | 304L/316L | Low carbon grades reduce sensitization, biomedical alloys chosen per regulation. |

| Pharmaceutical, biotech equipment | 316L | High corrosion resistance, cleanability. |

Interpretation:

-

Grade choice must match both environment and regulatory hygiene requirements; traceability through mill test certificates and standards is important.

Standards, specifications, and international equivalents

Key standards commonly cited in procurement and design:

-

ASTM A240 / ASME SA-240 — Specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications. Reference for 304 and 316 wrought products.

-

UNS numbering — UNS S30400 (304), UNS S31600 (316) used in global material databases.

-

EN / ISO equivalents — EN 1.4301 (304), EN 1.4401 (316). Crosswalk charts help matching standards between regions.

-

Material datasheets — ASM, MatWeb, manufacturer certificates for mechanical, physical, and chemical data.

Recommendation:

-

Always specify grade plus standard (for example: Type 316 stainless steel, ASTM A240), request mill test certificates (chemical analysis, tensile test), and include surface finish, heat treatment, and testing requirements.

Cost and procurement considerations

Material cost typically follows this order (price sensitive to market conditions): 304 < 316. Nickel and molybdenum content drive price differences. Long lead times may appear for specific surface finishes or certified test documentation. For budget constrained projects, specify 304 only when service environment does not include chloride exposure or strong acids. When life-cycle costing shows frequent replacement risk, specifying 316 can be economically justified.

Sourcing tips:

-

Confirm supplier traceability and mill test certificates.

-

Consider local availability of low-carbon or stabilized variants if welding is frequent.

-

For critical pressure equipment, ensure conformity to ASME, PED, or other regional codes.

Selection matrix and decision checklist

Quick checklist for engineers writing a material callout:

-

Will component see chlorides, halides, or seawater? → prefer 316.

-

Is welding heavy and unavoidable? → consider 304L or 316L to reduce sensitization risk.

-

Does project require sanitary finish or regulatory compliance? → 316L often preferred for pharma/biotech.

-

Is cost the dominant constraint and environment mild? → 304 acceptable.

-

Does component require highest ductility and ease of forming? → 304 may be marginally easier.

-

Are fasteners involved? → 316 fasteners recommended for marine service.

Use this checklist to produce a specification note that states grade, standard (ASTM/EN/UNS), surface finish, and required testing.

Environmental, safety, recycling, and passivation notes

Recycling and sustainability

Both 304 and 316 are highly recyclable. End-of-life recovery contributes to circular economy goals.

Passivation

Following fabrication, chemical passivation removes embedded iron and promotes a robust passive oxide film. Citric acid passivation is an alternative to nitric acid in some regulated industries.

Safety

Cutting, grinding, or welding stainless produces dust and fumes; local extraction and PPE are required per occupational safety regulations. Waste streams from pickling and passivation must be handled under environmental law.

Variants and special grades

-

304L / 316L: low carbon grades that reduce carbide precipitation risk during welding. Preferred for heavy welded fabrications.

-

316Ti: titanium stabilized to resist sensitization for prolonged high-temperature service.

-

Precipitation hardened, duplex, and super-austenitic grades: chosen when strength or corrosion resistance beyond 316 is required.

-

Cast equivalents: CF-8 (304 cast) and CF-8M (316 cast) used where castings are required.

Frequently Asked Questions (FAQs)

1) Is 18-8 the same thing as 304?

Short answer: in common industry usage, yes. The 18-8 shorthand refers to the approximate chromium and nickel content typical of Type 304. For procurement, specify “Type 304” plus the governing standard to avoid ambiguity.

2) Which grade resists seawater better: 304 or 316?

316 offers superior seawater resistance due to molybdenum content that increases resistance to pitting and crevice corrosion in chloride environments. Use 316 for long-term marine service.

3) Can either grade be hardened by heat treatment?

No. Austenitic stainless steels are not hardened by traditional quench-and-temper cycles. Strength increases require cold working or selection of precipitation-hardening alloys.

4) When should I use 304L or 316L?

Use low-carbon L variants for heavy welded fabrications or when post-weld heat treatment is not practical, to decrease carbide precipitation risk and preserve corrosion resistance.

5) How big is the price difference between 304 and 316?

Price varies with market conditions. Molybdenum and higher nickel content make 316 more expensive. Perform a material takeoff and consult current metal market pricing for exact figures.

6) Are 304 and 316 magnetic?

Both are essentially non-magnetic in the fully annealed state. Cold working can induce slight magnetic response.

7) Can I use 18-8 cookware safely for food?

Yes. Many food-contact products use 304 (18-8) grade. For highly acidic or salty food preparation, 316 offers additional corrosion protection.

8) What happens if a 304 component corrodes in chloride service?

Localized pitting or crevice corrosion may occur. Repair typically requires replacement with a more resistant material (316 or higher) and addressing chloride sources or design flaws that trap corrosive media.

9) Which grade is easier to machine?

Neither is particularly easy compared with mild steel. 304 tends to machine slightly more readily than 316. Use appropriate tooling and cutting parameters to limit work hardening.

10) What test certificates should I request from suppliers?

Request mill test certificates showing chemical composition and mechanical test results keyed to the referenced standard (for example ASTM A240). For critical services, include corrosion testing, hardness, and traceability data.

Practical selection examples

Case A — Food processing tank

Service: cleaning with caustic solutions, periodic acid cleaning, no chlorides. Recommendation: Type 304 or 304L with sanitary finish and proper passivation.

Case B — Shipboard railing and fittings

Service: continuous seawater spray, chloride exposure. Recommendation: Type 316 or duplex stainless steels for long service life; consider cathodic protection for severe exposure.

Case C — Chemical plant heat exchanger in chloride-bearing fluid

Service: hot chloride solution at elevated temperature. Recommendation: Investigate 316L or higher-alloy stainless steels, possibly nickel-based alloys, plus engineering tests for pitting potential.

These examples show that grade selection depends on operating media, temperature, mechanical loading, and maintenance regime.

Final practical recommendations

-

Use precise grade names plus standard references in procurement documents.

-

For general usage in domestic, architectural, or light food service, 304 (18-8) is cost-effective.

-

For chloride exposure or heavy chemical service, specify 316 or higher-alloy grades.

-

For welded structures, prefer low-carbon variants (304L, 316L) or specify post-weld solution annealing where permitted.

-

Require mill test certificates and surface finish specifications for hygienic or pressure-containing equipment.