For most applications, precipitation-hardened 17-4 PH (UNS S17400 / AISI 630) delivers stable strength and corrosion resistance with continuous service recommended up to about 600 °F (≈316 °C). Longer exposures or continuous use above this range cause progressive loss of toughness and altered mechanical properties; short, intermittent exposures to higher temperatures (up to ~1,100 °F / 593 °C and above) are sometimes tolerated for oxidation resistance, but they normally require design justification, requalification, or alternate alloy selection.

What is 17-4 PH Stainless

17-4 PH is a martensitic precipitation-hardening stainless steel engineered to combine high strength with moderate corrosion resistance. It attains most of its desirable mechanical characteristics through a two-step metallurgical approach: solution treatment (to make a martensitic matrix) followed by controlled aging (to precipitate copper and other phases that raise strength). Because the useful properties depend on precise thermal histories, elevated service temperatures alter the microstructure in time-dependent ways that can either relieve desirable strengthening or create embrittlement mechanisms. Practical limits therefore depend on the condition of the alloy (Condition A, H900, H1025, H1150, etc.), the duration at temperature, and the service environment (chlorides, H₂S, oxidizing atmospheres).

Chemical composition (typical ranges)

| Element | Typical wt.% |

|---|---|

| Chromium (Cr) | 15.0 – 17.5 |

| Nickel (Ni) | 3.0 – 5.0 |

| Copper (Cu) | 3.0 – 5.0 |

| Columbium/Tantalum (Nb+Ta) | 0.15 – 0.45 |

| Carbon (C) | 0.07 max |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 1.00 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| (Typical composition window for UNS S17400 / AISI 630.) |

Heat-treat conditions and temperature landmarks

17-4 PH is most commonly supplied in the following conditions:

| Condition | Aging temperature (°F / °C) | Typical intent |

|---|---|---|

| Condition A (solution annealed) | Solution treat ~1900 °F (1038 °C), cooled | Soft, ductile starting microstructure (not recommended for service). |

| H900 | 900 °F (482 °C) | Maximum strength, lower toughness |

| H925 / H1025 | 925–1025 °F (496–552 °C) | Strength/toughness balance; improved SCC resistance at higher aging temps |

| H1075 / H1150 | 1075–1150 °F (579–621 °C) | Lower strength, higher toughness, enhanced corrosion resistance in some environments |

Aging (precipitation) temperatures were chosen to control the size, distribution, and volume fraction of strengthening precipitates. When used for service, components should normally be in an age-hardened condition rather than Condition A.

What “maximum service temperature” really means for 17-4 PH

Three distinct temperature concepts must be separated:

-

Continuous service temperature for mechanical integrity: the temperature below which long-term tensile, yield, fatigue and toughness performance remain acceptable without significant property drift. Industry practice places this near 600 °F (≈316 °C) for 17-4 PH in typical aged conditions.

-

Aging/tempering temperatures used during manufacture: these are higher (900–1150 °F) and intentionally change properties. Components deliberately aged to H1025 or H1150 have been exposed to higher temperatures under controlled conditions to reach desired properties.

-

Short-term oxidation or annealing exposures: short spurts at higher temperatures (hundreds of °F above 600 °F) may not immediately destroy corrosion resistance, but they typically degrade mechanical performance and, in many cases, require re-qualification or re-aging to restore properties. Carpenter Technology reports oxidation resistance up to roughly 1,100 °F for short intervals but warns long-term exposure reduces toughness.

Practical recommended temperature bands (rules of thumb)

| Purpose | Recommended continuous max temp | Notes |

|---|---|---|

| Preserve as-aged mechanical properties (H900 or H1025) | ~600 °F (316 °C) | Conservative, industry-accepted upper bound for general service. |

| Minimize chloride stress corrosion cracking (choose higher aging) | Age to ≥ 1025 °F (552 °C), then limit continuous service to ~600 °F | Higher aging improves SCC resistance but service limit still governed by toughness/strength. |

| Occasional short oxidation exposure | Up to ~1100 °F (593 °C) for limited durations | May alter properties; re-aging might be needed. |

| Do not operate continuously in the 700–900 °F (371–482 °C) band for long periods | N/A | Extended exposure in this band often produces a sharp drop in room-temperature impact toughness for PH martensitic stainless steels. |

Engineering note: specific limits must be established through design review and, when needed, coupon testing for the expected time-temperature profile and environment.

Metallurgical mechanisms behind temperature sensitivity

-

Precipitation coarsening and overaging. At temperatures near or above aging temperatures, strengthening precipitates coarsen. Coarse precipitates reduce yield strength and can change fracture behavior. Controlled factory aging (H900–H1150) yields a targeted precipitate state; uncontrolled service heating can produce undesirable overaging.

-

Tempering of martensite. Heating martensitic 17-4 PH causes tempering reactions that increase ductility but lower strength. The specific mechanical balance depends on the peak temperature and time at temperature.

-

Phase transformations and embrittlement. Long exposures in 700–900 °F can produce embrittling phases or cause hydrogen effects that reduce impact toughness and ductility. Several studies document sharp drops in impact toughness after prolonged exposure in this range.

-

Stress corrosion cracking (SCC) sensitivity. Aging temperature influences SCC susceptibility. Higher aging temperatures (≥1025 °F / 552 °C) generally improve resistance to chloride SCC. This is why offshore, marine, and NACE MR0175 contexts often call for double aging or high-temperature aging protocols.

Environment-specific considerations

Chloride-bearing environments (marine, salts)

-

Use higher aging (H1025 or above) for enhanced SCC resistance.

-

Even so, continuous service temperature should remain conservative; SCC is a function of stress, environment, and microstructure.

Sulfide / H₂S exposure (oil & gas)

-

NACE MR0175 / ISO 15156 guidance applies; 17-4 PH can be used under limited conditions, often requiring double aging or specific heat treatment to meet sulfide stress cracking (SSC) criteria. Vendor certification is recommended.

Elevated temperature oxidizing atmospheres (air, steam)

-

Oxidation resistance permits brief high-temperature exposure. Long durations at high temperatures promote scale formation and embrittlement; therefore, limit continuous exposure. Carpenter notes oxidation stability up to ~1,100 °F for short durations but cautions about toughness loss with long exposure.

Design and inspection guidance

-

Specify final heat-treat condition in procurement documents (H900, H1025, H1150, etc.). Don’t accept Condition A parts for service unless re-treated.

-

Define a maximum continuous service temperature for the part and specify any allowable short transient exposures with durations.

-

If the application includes chlorides or H₂S, demand aging at ≥1025 °F, or follow NACE/ISO guidance.

-

For components that may see accidental heating (welding, localized heating, nearby processes), include re-aging instructions or qualification tests to verify retained properties.

-

Use coupon testing (accelerated aging, fatigue, SCC tests) when designlife or safety is critical.

-

Non-destructive testing (NDT) frequency should increase when operating near the upper recommended temperature band.

-

Maintain traceability of mill heat, condition, and heat treatment records.

Comparative table — 17-4 PH vs other common stainless alternatives (temperature emphasis)

| Alloy | Typical continuous temp limit | Key reason to choose over 17-4 PH |

|---|---|---|

| 17-4 PH (aged) | ~600 °F (316 °C) | Best strength + good corrosion resistance in this band |

| 304 / 316 | ~800–900 °F (427–482 °C) for corrosion behaviour; mechanical properties degrade earlier | Better general corrosion resistance but lower strength |

| 321 / 347 (stabilized austenitics) | ~800–1200 °F (427–649 °C) for high-temp service | Better creep/oxidation resistance at elevated temperatures |

| 15-5 PH | Similar to 17-4 but different aging curve; sometimes preferred for toughness | Slightly better toughness at comparable strengths |

Selection must weigh strength, corrosion, toughness, and thermal stability together.

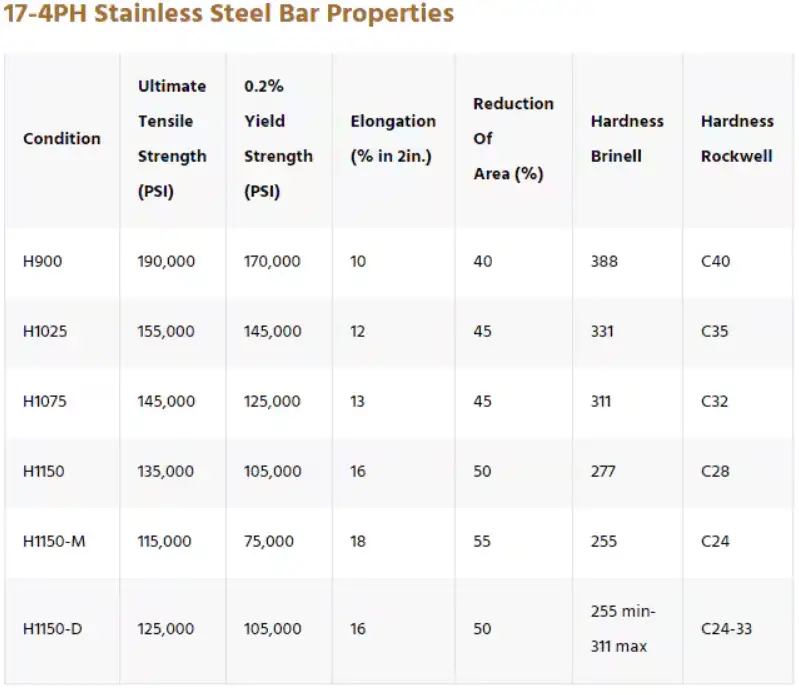

Tables: Typical mechanical properties vs aging condition (representative)

| Condition | 0.2% Y.S. (ksi) | Tensile UTS (ksi) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|

| H900 | ~170–190 | ~200–220 | 8–12 | ~40–45 |

| H1025 | ~140–160 | ~170–190 | 10–18 | ~34–40 |

| H1150 | ~100–140 | ~120–160 | 15–25 | ~28–36 |

(Values are representative; consult supplier datasheets for guaranteed minima.)

Long-term thermal exposure: experimental findings

Multiple industrial technical notes and research reports show that extended exposure in the 700–900 °F (371–482 °C) band often produces a steep decline in impact toughness for precipitation-hardened martensitic stainless steels; hence, designers should avoid specifying parts to live for long durations in that interval without proof testing. NIST case studies and fabrication guides provide empirical datasets demonstrating this effect and recommending re-aging or design changes after high-temperature excursions.

Alternatives and mitigation strategies

-

If continuous service >600 °F is mandatory: consider substitution with stabilized austenitic grades (321/347) or higher-alloy creep/heat-resistant steels (e.g., 310, expended Ni-base alloys) depending on corrosion needs.

-

If SCC risk is high: use higher aging (H1025/H1150), surface treatments, cathodic protection, or alternative materials.

-

For intermittent high temps: design with removable components that can be re-aged, or specify post-exposure re-heat treatment requirements.

Standards and specifications

-

UNS S17400 / SAE Type 630 (nomenclature) — commonly used reference.

-

AMS 5643 / AMS 5604 — aerospace and high-quality wrought product specifications covering 17-4 PH form and heat treatment practices.

-

ASTM A564 / A693 — covers certain product forms and requirements.

-

NACE MR0175 / ISO 15156 — for sour service considerations (H₂S).

FAQs

1. What is the single safe maximum operating temperature for 17-4 PH?

No single number fits all designs, but industry practice uses ~600 °F (316 °C) as a conservative continuous service ceiling for typical aged material. Short exposures higher than this may be allowable with caveats.

2. Can I use 17-4 PH in Condition A (solution annealed) for service?

No. Condition A is softer and more sensitive to hydrogen embrittlement and SCC; age-hardening is recommended before service.

3. What happens if a component is accidentally heated above its aging temperature?

Properties will change: controlled aging yields predictable strength; uncontrolled heating can overage or temper the martensite, lowering strength and possibly reducing toughness—re-qualification or re-aging may be required.

4. Is 17-4 PH suitable for marine shafting or seawater?

It has seen marine use with cathodic protection and careful aging; for critical seawater service, evaluate pitting/crevice resistance and SCC risk, and consider higher aging temperature to reduce SCC sensitivity.

5. How does aging temperature affect SCC resistance?

Higher aging temperatures (≥1025 °F / 552 °C) generally improve chloride SCC resistance, at the price of some strength reduction relative to H900.

6. Can I weld 17-4 PH and keep properties?

Welding introduces thermal cycles that alter local microstructure; post-weld solution treatment and re-aging are commonly required to restore uniform mechanical properties.

7. What non-destructive tests should be used for elevated-temperature components?

Regular visual inspection, dye-penetrant or MPI (for applicable geometries), and periodic mechanical coupon checks; frequency increases near the upper permitted temp band.

8. Will 17-4 PH creep at 600 °F?

17-4 PH is not a creep-resistant alloy for prolonged high-temperature loads; if sustained high temperatures and stresses are expected, choose a creep-resistant alloy.

9. Are there standard aging cycles for H900, H1025, H1150?

Yes; typical aging times are several hours at the target temperature (e.g., ~4 hours), but the exact cycle depends on section size and the governing specification (AMS/ASTM). Always follow the referenced heat-treat spec.

10. How should I document the temperature limits in procurement?

Specify the required final temper, maximum continuous service temperature, allowable transient peaks (magnitude & duration), SCC environment constraints, and post-exposure re-heat treatment requirements.

Short summary and takeaways

-

Use ~600 °F (316 °C) as a conservative continuous service upper limit for aged 17-4 PH.

-

Avoid long continuous exposure in 700–900 °F (371–482 °C) due to toughness loss risks.

-

Higher aging temperatures improve SCC resistance but lower maximum achievable strength relative to H900; manufacturing aging and in-service heating are not interchangeable.

-

Short high-temperature exposure is possible for oxidation reasons, but designers must plan for property changes and potential re-treatment.