16MnCr5 is a low-alloy case-hardening steel that offers an excellent balance between a wear-resistant surface and a tough ductile core after carburizing and heat treatment, making it a preferred material for gears, shafts, camshafts, and other components subjected to contact fatigue and sliding wear. This grade typically yields a hard outer case with a tempered martensitic surface and a resilient core when processed correctly, giving long service life in driven or loaded mechanical parts.

What is 16MnCrS5?

Chemical composition and the role of each element

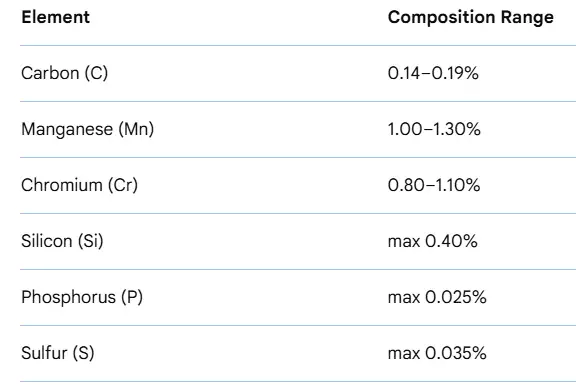

The nominal chemical composition range used by most European mills for 16MnCr5 (EN 1.7131) is shown below. These values form the basis for its behavior during heat treatment and performance after surface enrichment with carbon.

Table 1: Typical chemical composition (weight percent)

| Element | Typical range (wt%) | Primary metallurgical role |

|---|---|---|

| C (carbon) | 0.14 – 0.19 | Base carbon level that supports a hardenable case after carburizing; low core carbon helps retain toughness. |

| Si (silicon) | ≤ 0.40 | Deoxidizer; small influence on strength and tempering resistance. |

| Mn (manganese) | 1.00 – 1.30 | Improves hardenability and tensile strength, assists in forming martensite in the case and core. |

| P (phosphorus) | ≤ 0.025 | Controlled low level to avoid embrittlement and improve toughness. |

| S (sulfur) | ≤ 0.035 | Kept low for toughness; controlled free-machining variants will have higher S and altered designation. |

| Cr (chromium) | 0.80 – 1.10 | Raises hardenability, contributes to core strength and wear resistance near the surface. |

Notes on alloy balance: The Mn/Cr combination gives this grade predictable response to carburizing and core hardening. Chromium helps produce a sound, tough core after quench and temper cycles while manganese aids case hardenability. The low carbon content in the base steel avoids a brittle core after high-temperature processes.

Mechanical properties: delivered state and after treatment

Mechanical properties vary with section size, mill condition at delivery, and the specific heat-treatment cycle. The values below illustrate commonly observed limits from producer datasheets for normalized or soft-annealed deliveries and for carburized, quenched, and tempered parts.

Table 2: Representative mechanical properties

| Condition | Tensile strength Rm (MPa) | Yield strength Rp0.2 (MPa) | Elongation A (%) | Hardness HB |

|---|---|---|---|---|

| Soft annealed (+A), small bar | ~550 (typical) | ~420 | ≥21 | 170–230 HB (depending on treatment) |

| Normalized | 600–800 (dependent on section) | 350–600 | 10–20 | 200–300 HB |

| Carburized and quenched (case) | Case hardness up to 58–62 HRC (thin case) | Core tensile 800–1100 MPa typical after tempering for designed strength | core elongation reduced but acceptable for part function | case hardness measured in HRC after finishing. |

Important practice note: Mechanical property verification for carburized parts must include both surface hardness profiles and core toughness checks. A tensile test on a representative core, charpy impact tests for dynamic applications, and hardness-depth profiles are all common acceptance tests in purchasing specifications.

Heat treatment practice: carburizing, quenching, tempering, and microstructure

Overview of the objective

Carburizing transforms the near-surface chemistry by diffusion-driven carbon enrichment, giving a hard, wear-resistant case combined with a lower-carbon ductile core. Typical final microstructure after proper treatment includes tempered martensite in the case and tempered martensite or bainite in the core depending on the process and section thickness.

Typical process window and parameters

Table 3: Common heat-treatment parameters for carburized 16MnCr5

| Stage | Temperature (°C) | Purpose / notes |

|---|---|---|

| Pre-cleaning and inspection | ambient to 200 | Surface preparation; remove scale and contaminants |

| Carburizing (gas) | 880–980 | Typical temperature range for effective carbon diffusion; time depends on desired case depth. |

| Equalization | 20–60 min | Ensure uniform case formation through section before quench |

| Quench (oil or polymer) | From carburizing temperature | Fast cooling to form martensite in case; quenchant selection affects distortion and residual stress. |

| Tempering | 150–200 for high surface hardness; 150–560 when optimizing core properties | Low-temperature tempering helps relieve stresses and adjust surface toughness; core tempering often higher if ductility must be improved. |

Process control points:

-

Carbon potential in the furnace must be strictly controlled to prevent excessive case carbon that could cause retained austenite or cracking during quench.

-

Final tempering selection impacts surface toughness and fatigue life; a balance is required to maintain adequate case hardness together with case fracture resistance. Scientific studies have shown that post-carburizing heat treatment schedules influence core toughness, retained austenite content, and overall microstructure stability.

Microstructure details

-

Case: Typically tempered martensite with carbides if heavy carburization or improper tempering occurs. Desired microstructure is low retained austenite plus finely tempered martensite that yields case hardness while resisting brittle fracture.

-

Core: Lower carbon content produces a ductile core. After quench and temper, core hardness and strength depend on quench severity and tempering temperature; typical core tensile targets fall in the 800–1100 MPa range for many engineered parts.

Distortion, control methods, and residual stress management

Distortion control must be part of the production plan for dimensional-critical parts. Common mitigation techniques include:

-

Using tempering cycles that relieve quench stresses

-

Choosing polymer quenchants to reduce severity compared with oil

-

Applying sub-zero treatments only when retained austenite reduction is required

-

Designing fixtures that allow uniform cooling and minimal bending

Manufacturers must document quench media, agitation, part orientation, and fixture details in order to assure repeatable geometry after heat treatment.

Machinability, forming, and joining

Machinability

-

In the annealed condition, 16MnCr5 machines readily using conventional tooling. Machinability may be improved by vendor M-treatment (a microalloying/processing variant that improves chip control) for bar stock supplied for mass production.

-

After carburizing and hardening, final machining is typically limited to grinding, turning with carbide inserts on the non-hardened core, and finish grinding the case if tight geometries are required.

Cold forming and hot forming

-

Hot forging is common before final heat treatment for larger components. Recommended forging temperatures typically begin above 1100°C with controlled cooling to avoid excessive grain growth. Normalization after hot working improves microstructure refinement prior to final processing.

Weldability and joining

-

Welding of 16MnCr5 in the low-carbon delivered condition is feasible with appropriate filler metals and preheat/postheat routines, but caution is required because carburizing steels are designed for surface enrichment and not heavy weld repairs. Use matching or slightly higher alloyed filler wires, provide preheat to avoid hydrogen cracking, and temper the weld region to recover toughness. Welding on carburized components is normally avoided if possible since it negates the surface-case benefits and introduces local softening or distortion.

Typical applications and design guidance

Typical components manufactured from 16MnCr5

-

Spur and helical gears for transmissions

-

Shafts and pinions subject to rolling contact fatigue

-

Camshafts and piston rods for medium duty applications

-

Bearings sleeves, gear blanks, and splined shafts requiring a hard case and a ductile core.

Design considerations

-

Case depth selection: Case depth should be selected to carry the contact stress in the application, taking into account expected manufacturing loss from grinding. Standard case depths range from 0.5 mm for light duty to several millimeters for heavy gear applications.

-

Core strength and ductility: Core hardness targets must ensure sufficient toughness for shock loads. Typical procurement specs define both a hardness across the case depth and a minimum core tensile or hardness value near the centerline.

-

Surface finishing: After carburizing, grinding is often necessary for tight tolerances. Grinding parameters must avoid tempering the case or introducing thermal damage.

-

Surface treatments: Nitrocarburizing, shot peening, and coating systems can augment fatigue life beyond that achieved by carburizing alone.

Common failure modes and prevention

-

Surface pitting/rolling contact fatigue: Controlled surface hardness and compressive residual stress help; shot peening and controlled case hardness profiles reduce risk.

-

Case cracking: Caused by excessive carbon, rapid quench, or insufficient tempering; avoid by controlling furnace carbon potential, quench severity, and proper tempering.

-

Core brittle fracture: Preventable through correct base chemistry, normalized microstructure, and carefully selected tempering cycles.

Standards, naming, and international equivalents

Primary reference standards

-

16MnCr5 is covered by European material specifications such as EN 10084 (historical) and DIN EN ISO 683-series for case-hardening steels. Vendor datasheets and strip product information commonly reference DIN EN ISO 683-3 or ISO 683 family for technical delivery conditions.

Common equivalents and cross-references

Table 4: Common international equivalents

| EN designation | SteelNumber ID | SAE / AISI | Other references |

|---|---|---|---|

| 16MnCr5 | 1.7131 | SAE 5115 (commonly cited) | 17MnCr5 (close), 20MnCr5 family (variant) |

Keep in mind that slight chemistry or processing variations between providers can change hardenability, machinability, or suitability for specific processes. Always specify the exact standard, delivery condition, and any additional treatments in purchase orders.

Quality control, inspection methods, and acceptance criteria

Recommended acceptance tests for critical parts:

-

Chemical analysis: Spectrometric check to confirm alloying ranges.

-

Hardness profile: Surface and step coring hardness tests to validate case depth and core hardness. Microhardness traverse often used to profile from surface to core.

-

Microstructure exam: Metallographic inspection at case, transition, and core to confirm martensitic or tempered microstructure and identify undesired carbides or retained austenite.

-

Mechanical tests: Tensile tests on representative coupons, core impact tests (Charpy V-notch) for dynamic loading applications, and fatigue testing where required.

-

Non-destructive tests: Magnetic particle inspection for surface-breaking defects, ultrasonic testing for subsurface flaws in larger sections.

Documentation should include furnace carbon potential records, quenching media and temperatures, temper records, and dimensional control reports showing pre-and post-treatment tolerances.

Procurement and supply-chain advice for specifiers

-

Always specify grade designation + required standard + delivery condition. For example: “16MnCr5, EN 1.7131, normalized, bar stock, with chemistry to EN limits and M-treatment optional.”

-

Require a manufacturer’s heat-treatment protocol when heat-treated parts are supplied as finished components. Include detailed acceptance tests in the purchase order.

-

For high-volume or safety-critical programs, consider supplier audits to review furnace control methods, quench bath conditioning, and batch traceability.

-

When interchangeability with other suppliers is important, include an agreed equivalence table in the contract and require certification of critical attributes such as case depth, retained austenite %, and core tensile strength.

Summary tables

Table 5: Quick reference at a glance

| Topic | Key point |

|---|---|

| Base chemistry | Low carbon, chromium-manganese alloy; supports carburizing. |

| Main use | Gears, shafts, splines, components requiring a hard case and tough core. |

| Typical case hardness | Up to 58–62 HRC for thin cases; varies with process. |

| Core strength target | 800–1100 MPa after tempering for many designs. |

| Standards | EN / DIN / ISO family for case-hardening steels; EN 10084 references. |

FAQs

-

What does 16MnCr5 mean and where does the designation come from?

The number 16 indicates nominal carbon class and MnCr signifies manganese-chromium alloying. The suffix 5 is an older convention from DIN-derived nomenclature; the full European standard number is EN 1.7131. -

Can 16MnCr5 be induction hardened instead of carburized?

Induction hardening of the surface is possible for some geometries, but true case depth from carburizing is deeper and more uniform for complex gear teeth. Induction hardening suits localized surface hardening tasks. -

What case depth should I specify for gears?

Case depth selection depends on gear module, load spectrum, and expected life. Typical values range from 0.6 mm for light-duty gears to 3 mm or more for heavy-duty transmission gears; specify grinding allowance. Engineering design standards or contact fatigue calculations should guide exact choice. -

How is core toughness measured after carburizing?

Core toughness is often evaluated by Charpy V-notch testing using specimens from the core or by tensile testing of representative core material; suppliers may also provide hardness near centerline as a proxy. -

Is 16MnCr5 suitable for welded assemblies?

Welding is possible with proper preheat and postweld heat treatment, but welded regions will not retain the original carburized surface properties. For critical parts, avoid welding after final case hardening. -

What quench medium is recommended to control distortion?

Polymer quenchants or carefully controlled oil quenching with agitation are common choices. Polymer quenches can reduce distortion while maintaining sufficient hardenability in many production settings. -

How to check retained austenite in the case?

X-ray diffraction or magnetic saturation techniques quantify retained austenite. Microhardness traverses alone cannot reveal retained austenite content reliably. -

Are there higher machinability variants of 16MnCr5?

Yes. Some mills supply an M-treated bar grade or modified sulfur content variants to aid chip control, often denoted with an S in the grade (16MnCrS5) or vendor-specific trade names. -

What surface finish is recommended before carburizing?

A clean, scale-free surface is required. Grinding or shot blasting followed by degreasing ensures uniform carburization. Surface roughness should be consistent across parts in a batch. -

Which standards should be referenced in a purchase order?

Cite the relevant EN/DIN/ISO standard (for example EN 10084 or the DIN EN ISO 683 series), the exact grade (16MnCr5 / 1.7131), required delivery state, and acceptance tests for both chemistry and heat treatment.

Practical examples and case notes

-

Gearbox pinion for industrial reducer: Specify carburized case depth 1.0–1.5 mm, case hardness 60 HRC max at the surface, core hardness ≤ 300 HB, with vendor-supplied hardness-depth profile and Charpy V-notch core energy ≥ specified value at operating temperature. Supplier should provide full heat-treatment records.

-

Shaft with splines: For spline fatigue life, specify minimum core tensile or yield, and require grinding allowance prior to carburizing to ensure final geometry meets tolerance. Consider nitriding only when shallow, very hard surfaces are required without heavy case depth.

Recommended test matrix for acceptance

-

Chemical analysis report per heat

-

Hardness profile: surface (HRC) and stepped core hardness (HB)

-

Microstructure photos of case, transition, and core (etched)

-

Charpy V-notch on core material for dynamic applications

-

Dimensional check before and after heat treatment with documented fixtures and orientation

-

NDT: magnetic particle for surface cracks, ultrasonic for significant subsurface defects

Closing guidance for specification writers

When writing a specification for 16MnCr5 parts, include:

-

Exact grade and standard reference (16MnCr5 / EN 1.7131, reference to EN/DIN/ISO document number)

-

Delivery condition (soft-annealed, normalized, or final carburized and tempered)

-

Required case depth and hardness profile with measurement method (microhardness step test or case depth to a specified hardness)

-

Core mechanical targets and toughness requirements

-

Welding allowance and postweld heat-treatment if repairs are permitted

-

Traceability requirements, acceptance tests, and nonconformance disposition