When it comes to premium knife steels, 154CM and S35VN are among the most popular choices, each offering unique advantages for different types of knives and users. The decision between 154CM and S35VN typically depends on a balance between edge retention, toughness, corrosion resistance, and ease of sharpening. S35VN is considered by many to be the superior steel for heavy-duty use due to its enhanced toughness and wear resistance, while 154CM is often favored for its ease of sharpening and slightly better corrosion resistance. In this article, we will delve into a detailed comparison of these two steels, exploring their chemical compositions, properties, performance in various conditions, and which one is best suited for specific knife applications.

1. What is 154CM Steel?

154CM is a high-carbon, high-chromium stainless steel, originally developed for the aerospace industry. It is a close relative to the popular 440C steel but with a higher content of molybdenum, which enhances its wear resistance. 154CM is primarily known for its excellent balance of edge retention and corrosion resistance, making it suitable for knives that require a reliable, tough edge.

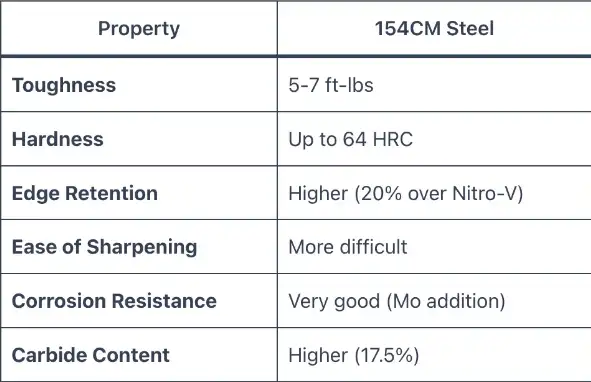

Properties of 154CM:

-

Chromium Content: 14%, providing strong corrosion resistance.

-

Carbon Content: 1.05%, which helps maintain a sharp edge.

-

Molybdenum Content: 4%, enhancing wear resistance and toughness.

-

Hardness: Can be heat-treated to 58-61 HRC for an optimal balance of durability and sharpness.

-

Toughness: Moderate; while 154CM has decent toughness, it is more prone to chipping under heavy impact compared to tougher steels like S35VN.

Common Uses of 154CM:

-

Everyday Carry (EDC) Knives

-

Utility Knives

-

Outdoor and Hunting Knives

-

Folding Knives

2. What is S35VN Steel?

S35VN is a steel alloy developed by Crucible Industries as a modified version of S30V, aimed at improving toughness without sacrificing edge retention. S35VN is composed of high carbon, high chromium, and vanadium, with the addition of niobium to enhance the toughness and strength of the steel. This steel is considered one of the best options for premium, heavy-use knives.

Properties of S35VN:

-

Chromium Content: 14%, providing excellent corrosion resistance.

-

Carbon Content: 1.40%, offering great edge retention.

-

Vanadium and Niobium Content: Vanadium enhances wear resistance, while niobium improves toughness.

-

Hardness: Typically hardened to 58-61 HRC, but due to niobium, it exhibits superior toughness at these hardness levels.

-

Toughness: S35VN is renowned for its higher toughness, making it resistant to edge chipping and breakage, especially under heavy use.

Common Uses of S35VN:

-

Tactical Knives

-

Survival Knives

-

Heavy-Duty Utility Knives

-

Custom and High-End Knives

3. Chemical Composition Comparison

| Element | 154CM | S35VN |

|---|---|---|

| Carbon (C) | 1.05% | 1.40% |

| Chromium (Cr) | 14.00% | 14.00% |

| Molybdenum (Mo) | 4.00% | 2.00% |

| Vanadium (V) | 4.00% | 3.00% |

| Niobium (Nb) | - | 0.50% |

| Manganese (Mn) | 0.90% | 0.50% |

| Silicon (Si) | 0.50% | 0.50% |

Key Differences:

-

Carbon Content: S35VN has a slightly higher carbon content, leading to better edge retention.

-

Niobium in S35VN: Niobium improves the steel's toughness, making S35VN more resistant to chipping.

-

Molybdenum in 154CM: Molybdenum increases wear resistance and contributes to better corrosion resistance.

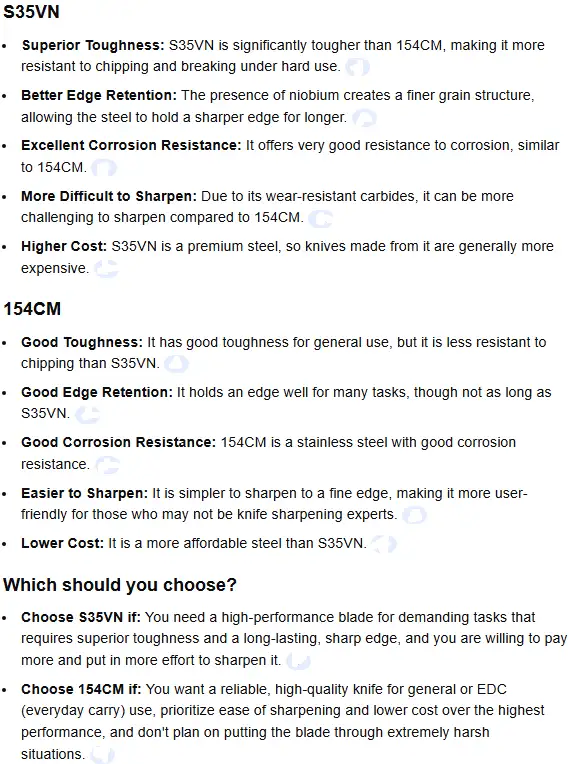

4. Toughness and Durability: Which Steel Performs Better?

Toughness refers to a material's ability to resist chipping, cracking, and breaking under stress. While both 154CM and S35VN are tough steels, S35VN typically performs better due to the addition of niobium. Niobium prevents brittleness, giving S35VN better resistance to heavy-duty impacts, making it more suitable for knives subjected to high-stress applications.

-

S35VN: Superior toughness, ideal for high-impact tasks and heavy-duty use.

-

154CM: Moderate toughness, excellent for general use but may chip under extreme stress.

5. Corrosion Resistance: A Critical Factor

Both 154CM and S35VN are stainless steels, meaning they are resistant to corrosion, but there are slight differences.

-

154CM: Excellent corrosion resistance due to high chromium content. However, it may show some signs of rust when exposed to extreme moisture or salt.

-

S35VN: Slightly better corrosion resistance, particularly in harsh, salty environments, due to the higher molybdenum content in comparison to 154CM.

6. Edge Retention: Which Steel Keeps Its Sharpness Longer?

Edge retention is critical for knives used in tasks requiring sustained cutting performance. S35VN, with its higher carbon and vanadium content, offers superior edge retention compared to 154CM. This makes S35VN the preferred choice for knives used in tough environments where maintaining a sharp edge is paramount.

-

S35VN: Excellent edge retention, making it ideal for heavy-use knives.

-

154CM: Good edge retention, but will need sharpening more frequently than S35VN.

7. Ease of Sharpening: An Overview

The ease of sharpening is important for users who prefer low-maintenance knives. Both 154CM and S35VN are relatively easy to sharpen compared to other high-hardness steels like M390 or Elmax, but 154CM is generally easier to sharpen due to its simpler carbide structure.

-

154CM: Easier to sharpen, making it a better option for those who need quick maintenance.

-

S35VN: More difficult to sharpen but holds an edge longer once sharpened.

8. Heat Treatment and Hardness of 154CM vs S35VN

Both steels can be heat-treated to a hardness of around 58-61 HRC, which is optimal for balancing edge retention and toughness. However, due to the inclusion of niobium in S35VN, its heat treatment process results in a more stable and durable blade, especially under heavy impact.

9. Applications: Best Use Cases for Each Steel

| Steel Type | Best Applications |

|---|---|

| 154CM | Everyday carry knives, utility knives, outdoor knives, folding knives |

| S35VN | Tactical knives, survival knives, hunting knives, heavy-use blades |

10. Price Comparison: Cost of 154CM vs S35VN

S35VN tends to be more expensive than 154CM, largely due to its enhanced performance properties and the added cost of materials such as niobium. While 154CM is often chosen for its affordability and good all-around performance, S35VN is the preferred choice for premium knives where top-notch toughness and edge retention are critical.

-

154CM: More affordable, ideal for users on a budget.

-

S35VN: More expensive, but offers superior performance for high-end applications.

11. Pros and Cons of 154CM and S35VN

154CM:

-

Pros: Excellent corrosion resistance, easy to sharpen, affordable.

-

Cons: Lower toughness compared to S35VN, not as durable under heavy impact.

S35VN:

-

Pros: Superior edge retention, higher toughness, better wear resistance.

-

Cons: Harder to sharpen, more expensive.

12. Which Steel is Better for Different Knife Types?

The choice between 154CM and S35VN depends on the specific needs of the user. For everyday carry (EDC) knives and general utility knives, 154CM is a solid choice due to its balance of corrosion resistance, ease of sharpening, and affordability. For tactical, survival, and heavy-duty knives, S35VN’s superior toughness, wear resistance, and edge retention make it the better option.

13. Conclusion: Final Thoughts on 154CM vs S35VN

Both 154CM and S35VN are excellent steels, with their own strengths and weaknesses. If you prioritize toughness and durability for heavy-duty tasks, S35VN is the steel to choose. If you're looking for an affordable steel that offers good corrosion resistance and is easy to maintain, 154CM is a great option.

14. FAQs

What is the main difference between 154CM and S35VN?

The key difference lies in their toughness and edge retention. S35VN has better toughness and longer-lasting sharpness due to its higher carbon and niobium content.

Which steel is better for outdoor knives?

S35VN is better for outdoor knives due to its higher toughness and superior resistance to chipping under heavy use.

Does S35VN rust faster than 154CM?

No, S35VN generally has better corrosion resistance than 154CM, especially in harsh, salty environments.

Is 154CM harder to sharpen than S35VN?

No, 154CM is easier to sharpen than S35VN due to its simpler carbide structure.

How do you maintain a knife made from 154CM or S35VN?

Regularly clean and dry the blade to prevent corrosion. Sharpen the blade as needed, with 154CM requiring sharpening more frequently than S35VN.

Can S35VN hold an edge longer than 154CM?

Yes, S35VN has superior edge retention, making it better for long-term use without frequent sharpening.

What are the best uses for 154CM steel knives?

154CM is ideal for everyday carry knives, utility knives, and folding knives.

Why is S35VN more expensive than 154CM?

S35VN’s higher cost is due to its advanced alloy composition, which includes niobium and provides superior toughness and edge retention.

Which steel is better for kitchen knives: 154CM or S35VN?

S35VN is better for kitchen knives due to its superior edge retention, which is essential for chopping and cutting tasks.

Can both 154CM and S35VN be used for folding knives?

Yes, both 154CM and S35VN are commonly used in folding knives. 154CM is favored for more budget-friendly, general-purpose knives, while S35VN is preferred for high-end, tactical, and custom folding knives.