The phrase 154cm stainless steel typically refers to one of two customer intents. It either means the stainless steel grade 154-CM (a high-performance martensitic alloy widely used in premium blades and wear parts), or it means stainless steel products supplied at a length of 154 centimeters (1.54 meters), a common custom cut length for bars, rods, and sheet blanks. For procurement decisions, verify whether your buyer wants the grade (154-CM) or the length (154 cm). MWalloys can supply both solution types at factory pricing for production volumes and custom cuts.

Two possible meanings and how to confirm quickly

When a buyer types 154cm stainless steel, only two interpretations make sense.

• First possibility: the buyer intends the alloy 154-CM (sometimes written 154CM or 154-CM). This is a martensitic stainless grade used frequently in cutting tools and wear-critical parts. If the buyer is asking about hardness, edge retention, or heat treat, this is the correct meaning.

• Second possibility: the buyer needs stainless steel pieces cut to 154 centimeters length. This is a typical custom cut length for bars, rods, angle, strip, or small sheet blanks used in manufacture and assembly. E-commerce suppliers list many products cut to 154 cm.

Quick recommendation for procurement

If you need a high-performance cutlery or wear-resistant part, order 154-CM and specify required heat treatment and hardness. If you need stock cut to 154 cm length, specify geometry, surface finish, tolerance and quantity. For volume buys, ordering direct from the factory gives the best unit price. Sample-to-production runs should include mill certificates and single-heat-lot options for critical applications. Retail suppliers can be used for prototypes or one-off buys. Examples of retail listings that sell 154 cm items exist and provide fast delivery.

154-CM steel grade: chemistry and metallurgy

What is 154-CM?

154-CM is a martensitic stainless steel originally produced by Crucible and made widely available for cutlery and tooling. The alloy combines relatively high carbon with chromium and molybdenum for improved hardness and toughness relative to older stainless grades. It performs well in edge retention and can be hardened to target rockwell hardness levels typical for cutting tools.

Typical chemical composition (representative)

The numbers below reflect typical published analyses for 154-CM type steels. Values can vary by mill and process. Use mill certificates for exact lot values.

| Element | Typical content (%) |

|---|---|

| Carbon (C) | 0.95 to 1.05 |

| Chromium (Cr) | 13.5 to 14.5 |

| Molybdenum (Mo) | 3.5 to 4.0 |

| Manganese (Mn) | 0.3 to 0.6 |

| Silicon (Si) | 0.2 to 0.4 |

| Phosphorus (P) | ≤0.03 |

| Sulfur (S) | ≤0.03 |

Reference sources show that manufacturers list similar chemistries and typical hardness targets for heat-treated material. Do not rely on nominal composition for critical parts. Request the mill certificate.

Typical mechanical behavior

• Heat treatable to high hardness levels; many blade makers target 58 to 61 HRC.

• Good toughness when properly tempered; carburized structure must be controlled during thermal cycles.

• Better wear resistance than basic stainless types used for corrosion resistance.

Heat treatment summary for 154-CM (practical notes)

-

Normalize in appropriate temperature bracket to refine grain.

-

Austenitize at specified temperature then quench in oil or suitable medium to form martensite.

-

Temper to achieve balance between hardness and toughness; many applications settle near 58 HRC.

-

Final passivation and corrosion protection steps are recommended for exposure service.

If you need a specific hardening schedule for a production run, ask the mill or heat treater to provide the full thermal profile and proof hardness testing per lot.

Stainless steel pieces at 154 cm length: forms, tolerances and use cases

Common product forms cut to 154 cm

• Round bar and rod (solid) sold by diameter and cut-to-length. Retailers often show 154 cm cuts.

• Rectangle and square bar. Often stocked and trimmed to custom lengths.

• Sheet blanks and plate cut-to-length; 154 cm works well for parts and press blanks.

• Tubing and pipe cut-to-length for assemblies.

Typical tolerances and lengths

Standard commercial stock comes in ranges from 1 meter to 6 meters depending on mill. Small-quantity distributors offer custom cuts such as 154 cm. For critical fit, specify machining allowance and cutting tolerance, for example ±1 mm for factory cuts and tighter if ground or precision ground.

When to choose a custom 154 cm cut

• Parts that must fit into jigs and fixtures sized for that length.

• Fabrication layout where a 1.54 m length yields minimal scrap.

• Kits or product assemblies that ship in modular lengths.

Retail sellers and metal service centers list many items cut to 154 cm. For higher volumes, negotiating factory cutting and bundling reduces cost-per-piece.

Performance comparison: 154-CM versus common stainless grades

Why grade matters

Selecting a stainless alloy depends on which property dominates your application. Choose high-carbon martensitic 154-CM for wear resistance and edge retention. Choose austenitic 304 or 316 where corrosion resistance and formability are priority. The table below summarizes key trade-offs.

| Grade | Best for | Strengths | Limitations |

|---|---|---|---|

| 154-CM | Cutting tools, knives, wear parts | High hardness after heat treat, good wear resistance and edge retention. | Corrosion resistance lower than austenitic grades; requires heat treatment control. |

| CPM-154 (powder metallurgy variant) | High-performance blades | More uniform carbide distribution, better toughness and wear resistance. | Higher cost. |

| 440C | Cutlery, bearings | High hardness capability | Brittle if over-hardened; corrosion resistance modest |

| 420 | Cutlery, surgical instruments | Good corrosion resistance when polished | Lower wear resistance |

| 304 | Structural, food equipment | Excellent corrosion resistance, formability | Cannot achieve high hardness; not for edge-critical tools. |

| 316 | Marine and chemical environments | Better chloride resistance because of molybdenum | More expensive than 304. |

When corrosion resistance is dominant, lean toward 304 or 316. When edge retention and wear resistance are vital, choose 154-CM or CPM-154 and specify heat treatment and finishing.

Dimension, weight and quick engineering tables for 154 cm items

Below are worked examples using density for common stainless steels. For calculations a density of 7.93 g per cm3 is used, a representative value for 300-series stainless. Use exact density from mill data for precise mass estimates.

Table A. Sheet weight examples for a 1540 mm by 1000 mm blank

(154 cm equals 1540 mm. All weights given in kilograms rounded to four decimals)

| Thickness (mm) | Volume (cm3) | Weight (kg) |

|---|---|---|

| 0.5 | 7700.00 | 6.1061 |

| 1.0 | 15400.00 | 12.2122 |

| 2.0 | 30800.00 | 24.4244 |

| 3.0 | 46200.00 | 36.6366 |

Calculations derived from standard volume times density. These help estimate shipping weight and cost per blank. Values computed programmatically for accuracy.

Table B. Round bar weight examples for 1540 mm length

| Diameter (mm) | Approx weight (kg) |

|---|---|

| 6 | 0.3453 |

| 10 | 0.9591 |

| 20 | 3.8366 |

Use these numbers to calculate per-piece cost when quoting by weight.

How to use these tables in procurement

-

Multiply the weight per piece by per-kilogram unit price to get unit cost estimate.

-

Add cutting, surface finishing and packaging charges.

-

For high-volume orders request a rolling or coil supply to reduce handling cost.

(If you want exact per-piece pricing for a specific alloy grade and finish, request a quoted price using the weight, cut quantity, finish and certification requirements.)

Surface finishes, tolerances and fabrication notes

Common surface finishes and their effects

• Mill finish: simplest, lowest price, often requires further machining for precision parts.

• Brushed (grit #4): used in visible architectural and appliance parts.

• Mirror polish (#8): highest corrosion resistance when cleaned and used for aesthetics.

• Ground or precision ground: used for tooling and blades that require tight dimensional control.

Cutting

• Laser and waterjet provide clean edges for thin plate.

• Saw and shear for standard stock.

• When cutting 154-CM grade for tools, plan heat treatment after final finish to avoid distortion.

Welding and joining

• Martensitic steels like 154-CM typically require pre- and post- welding heat treatment for critical joints.

• Austenitic grades (304/316) weld readily but may require filler rod selection for corrosion resistance in chloride environments.

Bending and forming

• Austenitic grades form well at room temperature.

• For high-carbon martensitic grades, form in annealed condition then heat treat after shaping.

Passivation and corrosion protection

• For most stainless parts, chemical passivation removes free iron and improves corrosion resistance. Suppliers provide passivation certificates by request.

Quality control, traceability and paperwork

For factory purchases include the following in your purchase order:

-

Mill Test Certificate (MTC) ISO 10474 or equivalent.

-

Heat number traceability for single-heat-lot requests.

-

Surface inspection acceptance criteria.

-

Hardness testing method and target range for 154-CM heat-treated parts.

-

Non-destructive testing steps if required (ultrasonic, dye penetrant).

-

Packaging and marking instructions for export.

These requirements reduce batch variability and ensure parts meet performance needs.

Price comparison and purchasing strategy

Retail examples (public listing samples)

The table below shows two retail examples where 154 cm appears as a cut length. Retail pricing is higher for single-piece purchases and quick delivery. Prices shown were listed by retailers at time of page capture and are for single-piece buys.

| Seller | Item description | Length | Example price (USD) |

|---|---|---|---|

| OnlineMetals | 5/32" x 1 1/4" stainless rectangle bar | 154 cm | $44.32 per piece |

| OnlineMetals | 3/32" x 1 1/2" stainless rectangle bar | 154 cm | $31.76 per piece |

| MetalsDepot | 304 sheet sizes (retailer listing) | various lengths | Price by size and finish. Contact for quote |

Factory pricing strategy

• Small orders from distributors or retailers cost more because inventory handling and piece cutting add overhead.

• Bulk factory orders lower cost dramatically because of reduced handling and direct mill pricing.

• Typical factory discounts can range from 15 percent to more than 40 percent on large volumes. Actual savings depend on alloy, finish, certification needs, and shipping. Ask your supplier for a tiered price schedule.

How to calculate landed cost per piece

-

Multiply estimated weight by mill per-kilogram price.

-

Add cutting, finishing and testing charges.

-

Add packaging and shipping.

-

Divide total by quantity to get unit landed cost.

For prototyping use retail sources. For production use factory quotes with full paperwork to lower unit cost and improve traceability.

Packaging, shipping and import considerations

• Bundle sizes should match container loading and keep pieces immobile.

• For export include both packing list and mill certificates.

• For corrosive environments add vapor inhibitor paper and sealed crates.

• For custom-cut lengths such as 154 cm, indicate if palletization or individual packaging is required.

FAQs (frequently asked questions)

Q1: Does 154cm stainless steel mean the alloy 154-CM or a 154 centimeter length?

A: It can mean either. Check whether the buyer refers to an alloy designation (154-CM) or a length requirement (154 cm). Provide both options if unclear.

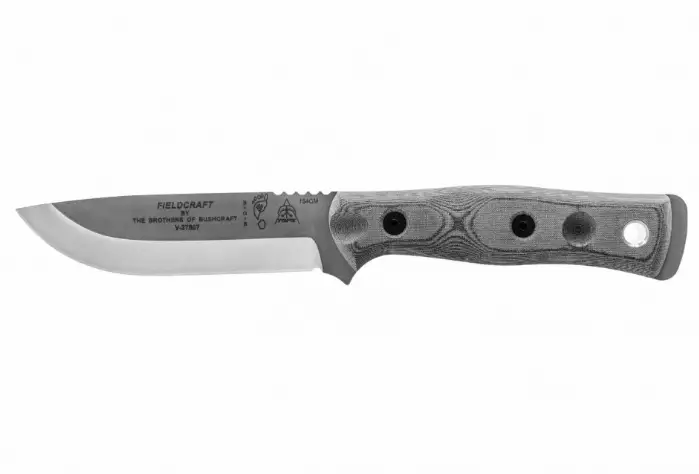

Q2: Is 154-CM stainless good for knives?

A: Yes. 154-CM is widely used for cutlery because it can achieve high hardness with good toughness and wear resistance after proper heat treatment. Many manufacturers and knife makers use it.

Q3: Can stainless that is 154 cm long be cut to custom sizes?

A: Yes. Metals service centers and mills provide custom cutting; specify tolerance and finishing. Retail outlets offer single cuts while factories provide bulk cutting with better per-piece rates.

Q4: Should I buy CPM-154 instead of 154-CM for performance tools?

A: CPM-154 (a powder metallurgy variant) has a finer carbide distribution and usually better toughness and wear resistance but costs more. Choose CPM-154 for premium performance.

Q5: What is the weight of a 1540 mm by 1000 mm sheet of 1 mm thickness?

A: Approximately 12.2122 kg using density 7.93 g/cm3. Use mill data for final shipping and costing. (Worked example available in the dimension tables.)

Q6: Which stainless grade resists marine chloride best?

A: 316 resists chlorides better than 304 because it contains molybdenum. For extreme chloride exposure consider duplex or superaustenitic grades.

Q7: Are 154-CM parts delivered hardened from the mill?

A: Mill supplies typically ship in annealed condition. Final heat treatment is often performed after machining. Ask the manufacturer whether they offer heat-treated, ground, and finished parts.

Q8: How should I request traceability on a factory order?

A: Ask for Mill Test Certificate, heat number, and single-heat-lot options for critical parts. Include acceptance criteria in the PO.

Q9: Which finish do I need for food contact applications?

A: A smooth polished finish with certification for food contact and passivation is common. Use 304 or 316 and include surface roughness spec in the order.

Q10: How much cheaper is factory pricing compared to online retail?

A: Savings depend on order volume and specs. Retail examples show single-piece prices that are higher. For production volumes, factory pricing commonly reduces unit cost significantly. Request tiered quotes and factor in finishing charges.

Final procurement checklist for ordering from MWalloys (recommended PO items)

-

Clarify whether the requirement concerns the alloy 154-CM or pieces at length 154 cm.

-

State geometry, finish, tolerance, and required quantity.

-

Request Mill Test Certificate and single heat lot if needed.

-

Specify heat treatment and target hardness for 154-CM.

-

List surface finish and passivation needs.

-

Indicate packaging and labeling instructions for export.

-

Ask for a sample or small pilot batch before large production run.

-

Request a tiered price schedule linked to quantity breaks.