12L14 is a leaded, resulfurized low-carbon free-machining steel engineered for very high throughput turning and screw-machine work; it delivers outstanding cut rates and surface finish while trading off some strength and weldability, so engineers should select it when efficient precision machining and close tolerances take priority over heavy load bearing.

1. What 12L14 is, and why it matters

12L14 belongs to the family of low-carbon, free-machining steels created for rapid automatic machining. Manufacturers intentionally add small amounts of sulfur, phosphorus, and lead in controlled quantities to produce a steel that shears into short, broken chips and produces consistent finishes at high spindle speeds. This microalloying yields productivity gains in high volume turning, screw-machine, and automated CNC workholding.

Common trade names and identifiers include AISI 12L14, UNS G12144, and designations from mills under names such as Ledloy and similar free-cutting labels. Typical supply forms include hot-rolled bar, cold-drawn/cold-finished bar, and turned/centerless ground rod.

2. Development history and practical rationale

Leaded free-machining steels appeared during the 20th century to address the growing demand for parts manufactured on high-speed automatic lathes. The controlled inclusion of lead creates internal solid-lubricant islands that promote short chips and reduce tool wear. Sulfur and phosphorus further enhance chip breakability and improve machinability numbers used in shop estimating. These alloys became standard stock for small turned components such as fasteners, pins, bushings, fittings, and threaded parts where machining time dominates cost.

3. Chemical composition (typical ranges)

The following table summarizes typical chemistry ranges used by producers. Values are industry typical, not a guaranteed certificate, therefore final purchase orders should require a mill test report when tight limits matter.

| Element | Typical range (wt%) | Role / comment |

|---|---|---|

| Carbon (C) | ≤ 0.15 | Low carbon keeps the steel soft for cutting and bending |

| Manganese (Mn) | 0.85 – 1.15 | Strength and hardenability modifier |

| Silicon (Si) | ~0.15 – 0.40 | Deoxidizer, minor strength influence |

| Sulfur (S) | 0.24 – 0.35 | Improves chip breakage and machinability |

| Phosphorus (P) | 0.04 – 0.10 | Small amounts aid machining stability |

| Lead (Pb) | 0.15 – 0.35 | Primary free-machining element; creates micro pockets |

| Iron (Fe) | Balance | Base metal |

| Trace elements | <0.5 total | Cu, Ni, Cr sometimes present in small amounts |

Sources reporting these typical chemistries include major metal suppliers and material databases.

4. Mechanical and physical properties (typical)

Because 12L14 is supplied in different conditions, mechanical numbers vary by mill, finish, and whether the bar is hot-rolled or cold-drawn. The table below collects commonly quoted typical ranges.

| Property | Typical range (cold-finished unless noted) | Notes |

|---|---|---|

| Density | 0.284 lb/in³ (7.87 g/cm³) | Standard steel density |

| Tensile strength (UTS) | 70 – 90 ksi (≈ 480 – 620 MPa) typical; many sources list ~78 ksi | Varies with finish and cold work. OnlineMetals lists ~78.3 ksi. |

| Yield strength (0.2% offset) | 40 – 65 ksi (≈ 275 – 450 MPa) typical | Lower than many medium carbon steels |

| Elongation (in 2 in) | 10 – 25% | Cold drawing reduces elongation |

| Hardness (HRC / HRB) | Rockwell B 80–100 approximate; HRB 84 referenced | Depends on cold work; can be 60–90 HRB commonly quoted. |

| Modulus of elasticity | ~29,000 ksi (200 GPa) | Typical for carbon steels |

| Thermal conductivity | Typical steel range | Not a distinguishing factor |

Key takeaway: 12L14 delivers moderate strength while prioritizing machinability. Use this when part geometry and tolerances matter more than strength for loaded applications.

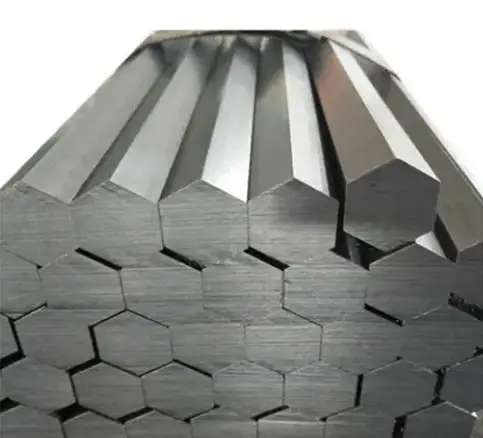

Free Cutting Steel 12L14 Cold Drawn Hex Steel Bar

5. Machinability: what shops need to know

12L14 ranks very high on machinability charts because lead and sulfur create short chips and reduce built-up edge. Shops often cite machinability percentages near 160–170% when benchmarked against a reference standard mild steel. This rating translates into faster spindle speeds, longer tool life, and lower machining cost per part.

Typical cutting data (starting recommendations)

| Operation | Cutting speed (SFM) | Feed | Notes |

|---|---|---|---|

| Turning — finishing | 2000 – 2800 SFM (≡ 635 – 855 m/min) | 0.001 – 0.006 IP/rev for fine finish | High range because of free-cutting chemistry. Use carbide inserts for optimal life. |

| Turning — roughing | 1500 – 2000 SFM | 0.006 – 0.020 IP/rev | Conservative roughing reduces tool shock |

| Milling | 1200 – 1740 SFM (≈ 395 – 530 m/min) | 0.003 – 0.015 IP/tooth | Use rigid fixturing; avoid vibration |

| Drilling | 840 – 1130 SFM (≈ 255 – 345 m/min) | Pecks recommended | Use coolant; short chips desirable |

| Thread whirling / screw machines | High spindle speeds with light cuts | Use sharp tooling and dwell reduction | Free-cutting steels shine in these operations |

Practical shop tips

-

Carbide inserts with positive geometry produce the best balance of finish and tool life.

-

Through-tool coolant or flood cooling reduces built-up edge and clears chips.

-

Because chips are short and granular, automated chip conveyors handle them well.

-

For centerless grinding or finish turning, cold-drawn 12L14 yields very consistent surface finish.

6. Forming, bending, and joining

12L14 bends and forms readily because of its low carbon and ductility, which makes it suitable for parts requiring light stamping, bending, rivets, or knurling after machining. However, the presence of lead and sulfur affects welding behavior.

Welding notes

-

Lead does not alloy into the fusion zone in a beneficial way; it tends to segregate and vaporize, creating fume hazards and weakening weld metal if not addressed. Welding of leaded free-machining steels therefore tends to be discouraged for critical welded structures.

-

If joining is required, consider mechanical fastening, brazing with compatible filler, or using a non-leaded base alloy for welded subassemblies. Prequalification weld trials and metallurgical inspection are necessary when welding cannot be avoided.

7. Heat treatment response and hardening limits

12L14 is a low carbon steel so it does not respond strongly to hardening by conventional quench and temper treatments. Normalizing or annealing will refine grain and relieve residual stresses, but the maximum achievable hardness remains in the low to moderate range because of limited carbon.

Practical notes

-

Normalizing improves machinability consistency for certain supply conditions.

-

Carburizing for case hardening is possible when a harder surface is required; work with heat treaters experienced with leaded steels because cover gas, pack composition, and diffusion controls must avoid lead volatility issues.

-

For components that require substantial core strength or wear resistance, select a higher carbon alloy or design a sacrificial plated layer rather than relying on heat treatment of 12L14.

8. Surface finishing, coatings, plating

12L14 accepts standard finishing operations such as polishing, plating, zinc coating, and passivation treatments used on low carbon steels. Pre-plating cleaning must remove machining oils and surface residues.

Electroplating notes

-

Bright finishes are common because machining gives smooth surfaces when parameters are tuned.

-

Lead in the matrix rarely interferes with plating adhesion but mill test reports should be shared with plating vendors for specific pretreatment recommendations.

-

For corrosion resistance beyond simple zinc plating, consider nickel or chromate systems, observing environmental regulations for plating waste.

9. Corrosion performance and environmental use

12L14 has corrosion behavior typical of low carbon plain steels. In sheltered indoor environments it performs adequately when coated or plated. For outdoor or marine exposure, add protective coatings or choose a corrosion-resistant alloy.

10. Typical applications and industry sectors

The following table lists common parts and industries using 12L14.

| Part type | Reason for choosing 12L14 |

|---|---|

| Fasteners and small threaded parts | High throughput machining, good thread finish |

| Pins, bushings, sleeves | Tight tolerances, good surface finish after turning |

| Fittings, connectors, valve components | Rapid production on automatic lathes |

| Consumer appliance hardware | Economical part cost due to high machining rate |

| Automotive non-structural components | Precision turning without heavy load demands |

| Turned prototypes and low-stiffness shafts | Good for trial components and small shafts |

Case note: machinists often prefer 12L14 when cycle time dominates unit cost and tensile loads remain moderate.

11. Equivalents, standards, and cross references

Common equivalents and identifiers reported in industry references include:

-

UNS G12144

-

AISI 12L14

-

Some EN/JIS equivalents approximate with leaded free-machining grades (check mill cross-reference charts).

When specifying material on drawings, include UNS or AISI designation plus required supply condition (cold drawn, hot rolled) and required mechanical limits or mill test certificate.

12. Health, safety, and regulatory considerations

Because 12L14 contains lead and elevated sulfur, shops should treat processing at elevated temperatures and processes generating fumes, dust, or mist with caution. Key points:

-

Machining with coolant produces short, heavy chips; general particulate generation is low relative to some alloys, but grinding, dry machining, or high-temperature operations that vaporize metal can create airborne lead compounds.

-

Welding or thermal cutting can produce fumes containing lead oxide and other hazardous species; respiratory protection and local fume extraction are required per regulatory guidance.

-

Standard controls include local exhaust ventilation, fume capture at source, appropriate respirators when ventilation is inadequate, frequent hand washing, and housekeeping that avoids dry sweeping of metal dust. Agencies such as OSHA and state health departments publish exposure limits and controls for lead.

Practical compliance steps for shops

-

Obtain the mill SDS/MSDS and include it in the process safety document.

-

Use wet cutting or flood coolant to minimize airborne dust.

-

Install local exhaust hooding near cutting lines and welding stations.

-

Train personnel about lead hazards and provide blood monitoring where required by local law.

13. Quality control, testing, and acceptance criteria

Recommended inspection items for procurement and incoming stock:

-

Certificate of chemical analysis from mill (C, Mn, S, P, Pb).

-

Mechanical test report for tensile strength, yield, and elongation if part function depends on those values.

-

Dimensional inspection for diameter tolerance and surface finish (Ra) after cold drawing or turning.

-

Straightness, concentricity, and roundness checks for shaft stock used in rotating assemblies.

-

Non-destructive testing for critical parts (mag particle or dye penetrant) when cracks or surface discontinuities matter.

MWalloys recommends specifying mill test reports and accepting material only when the report matches the PO specification; for high volume jobs, implement periodic destructive testing to confirm stability of supply.

14. Sourcing and cost: MWalloys positioning

MWalloys supplies 12L14 with factory direct pricing and volume discounts for OEM orders. Common procurement advice:

-

Buy cold-finished bars for tighter diameter tolerances and improved finish.

-

Request certified test reports when parts are safety critical.

-

For long-term contracts, negotiate locked pricing tied to raw material indices or volume breaks.

If procurement favors the lowest unit raw material cost, confirm final per-part machining time since free-machining stock typically reduces total cost even when base price per kilogram may be slightly higher.

15. Practical selection checklist (quick engineering tool)

-

Does the component require high strength under heavy load? If yes, consider higher carbon or alloy steel.

-

Will the part be welded? If yes, avoid leaded stock if weld integrity matters.

-

Is cycle time the dominant cost driver? If yes, 12L14 is a strong candidate.

-

Do surface finish and tight concentricity matter? Cold-drawn 12L14 works well.

-

Are there regulatory considerations for lead in the finished part? Confirm end-use regulations and plating choices.

16. Sample specification snippet for drawing call-out

Material: AISI 12L14 (UNS G12144), cold-drawn, diameter X mm, finish tolerance ±Y mm. Supply: mill certificate required listing chemical analysis, heat number traceability. Surface finish: Ra ≤ 1.6 μm after turning. Qty: N pieces. Note: Welding of base metal prohibited without prequalification.

17. Comparative snapshot: 12L14 vs similar low-carbon grades

| Grade | Key difference vs 12L14 | Typical use case |

|---|---|---|

| 1215 | Similar low carbon free-machining grade; 1215 often has smoother finish and slightly different strength profile | Alternative when marginally higher strength or finish required. |

| 1018 | Lower sulfur/lead content, lower machinability | Choose when welding or higher toughness required |

| 12L15 | Slightly different chemistry that may raise yield strength | Used when strength needs small boost; check supplier datasheet. |

18. Design tips for machinability and part life

-

Increase tool nose radius within tolerance limits to prolong life on finishing passes.

-

Avoid interrupted cuts where possible; where unavoidable use inserts with stronger edge support.

-

Specify minimum draft angles on turned features to aid ejection in automated cells.

-

For threaded parts, consider minor OD undersizing before thread rolling to compensate for leaded material compressive behavior.

19. Supply chain and lead times

Because 12L14 is a common free-machining bar, many mills stock standard sizes in cold-drawn lengths. For custom diameters or small production runs, plan to order standard bar and machine to size. MWalloys maintains factory stocking programs that can reduce lead times for OEM customers.

20. Final recommendations

Use 12L14 when high speed machining, cycle time reduction, and superior finish at scale form the core manufacturing objectives. Avoid for primary load bearing, high temperature service, or welded structural parts without qualification. Require mill certs, and follow safety rules for leaded materials in processing.

Frequently Asked Questions

-

What percentage of lead is in 12L14?

Typical range is 0.15 to 0.35 weight percent lead. This small amount is enough to dramatically improve chip breakage. -

Can 12L14 be welded?

Welding is possible but not recommended for critical welded structures because lead and sulfur can cause fume hazards and may weaken the weld zone. Prequalify weld procedures and ensure fume extraction when welding is unavoidable. -

What machining speeds should I use for turning 12L14?

Finish turning commonly runs in the 2,000 to 2,800 SFM range for carbide tooling; shops often use the higher end because of free-cutting chemistry. Start conservatively then increase speed while monitoring finish and tool wear. -

Is 12L14 stronger than 1215?

No; 1215 tends to exhibit slightly higher strength in many supply conditions. Choose the grade based on the specific mechanical values called out on the mill certificate. -

Will lead content affect plating or finishing?

Generally plating adheres well, but inform the platers about lead content so they can adjust pretreatment steps and wastewater handling. Bright finishes are achievable with proper process control. -

Is 12L14 a good choice for threaded parts?

Yes; short chips and good surface finish make it excellent for turning and threading operations, including thread rolling when dimensions are controlled. -

How does heat treatment change 12L14?

Because of low carbon, hardening is limited by conventional quench and temper. Normalizing or annealing is used to refine grain and reduce residual stresses, not to greatly increase core hardness. -

What safety precautions should shops use?

Implement local exhaust ventilation, personal protective equipment, and housekeeping that avoids creating airborne dust. Refer to MSDS and OSHA guidance for lead exposure control. -

What tolerance and finishes can MWalloys supply?

MWalloys supplies cold-finished bars with industry standard tolerances and can arrange centerless grinding, turn finish, or custom diameters to customer drawing requirements; mill test reports provided on request. -

Is 12L14 recyclable?

Yes; steel scrap streams accept low carbon free-machining steels. Recycling steps must handle any surface coatings or plating residues per local environmental rules.

Selected authoritative sources and references

Key references used to compile this technical brief include metal supplier datasheets, machining data resources, material databases, and occupational safety guidance: OnlineMetals product data, AZoM material review, machining speed charts from machining doctor, supplier pages for free-cutting steels, and authoritative safety publications from OSHA and NIOSH.